close

Choose Your Site

Global

Social Media

When it comes to plumbing systems, choosing the right materials can make a significant impact on both costs and performance. Two of the most common options you’ll encounter are Stainless Steel Pipe and copper plumbing. The decision isn't always straightforward—both materials have advantages and disadvantages, and the ideal choice depends heavily on your specific project needs, budget constraints, and long-term goals.

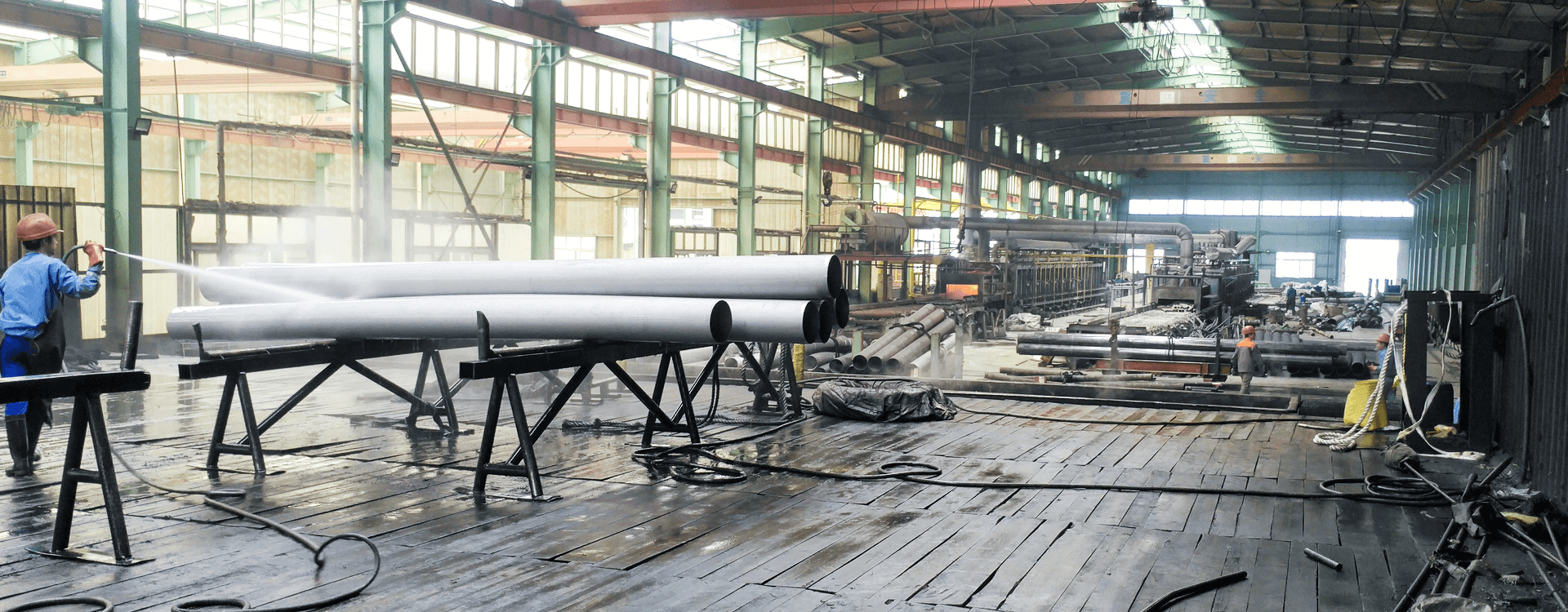

In this detailed comparison, we'll explore the critical aspects of stainless steel pipe vs copper plumbing, focusing primarily on cost efficiency, durability, and suitability for various applications. Additionally, we’ll introduce quality products from Zhejiang Xintongda Special Steel, a reputable stainless steel pipe supplier and stainless steel pipe manufacturer, whose specialized pipes are widely used across industries ranging from petrochemicals to power generation.

Before diving into cost analysis, it's essential to clearly understand these two materials:

Stainless Steel Pipe: Renowned for its strength, corrosion resistance, and durability. Often used in industrial settings and high-pressure applications. Varieties include 253ma seamless stainless steel pipe, 314 seamless stainless steel pipe, and specialized types such as tp347h seamless stainless steel pipe.

Copper Plumbing: Traditional choice in residential plumbing due to ease of installation, antimicrobial properties, and efficient heat conduction. Preferred for household water systems, particularly potable water.

Initial costs are often a critical deciding factor. Let’s break down the installation differences between stainless steel pipes and copper plumbing systems:

| Cost Factor | Stainless Steel Pipe | Copper Plumbing |

|---|---|---|

| Material Costs | Moderate-high initial cost; varies by thickness | High initial cost |

| Installation Difficulty | Requires professional skill | Easier installation (soldering) |

| Labor Costs | Higher due to welding and complexity | Generally lower (quick assembly) |

| Specialized Equipment Needed | Yes (welding, threading machines) | Minimal (basic soldering tools) |

Although copper pipes might seem cheaper initially due to simpler installation, heavy thickness stainless steel pipe and specialized options like Seamless Hyper Duplex Steel pipe offer significant long-term savings, especially in high-pressure or corrosive environments.

Considering durability, stainless steel pipes have clear advantages:

Stainless Steel Pipe:

Resistant to corrosion, oxidation, and chemical reactions.

Ideal for harsh environments and industrial applications.

Requires minimal maintenance once installed.

Copper Plumbing:

Good corrosion resistance but susceptible to pinhole leaks and oxidation in highly acidic water.

Requires regular inspection and possible replacements over the years.

For instance, pipes such as 253ma seamless stainless steel pipe and tp347h seamless stainless steel pipe from a reputable stainless steel pipe manufacturer like Xintongda offer unmatched resistance to extreme heat and corrosion, reducing long-term maintenance costs significantly.

The decision between stainless steel pipe vs copper plumbing should depend on your specific project type. Here's a quick look:

Residential Applications:

Copper remains the traditional choice due to ease of installation and good water quality.

Stainless steel is becoming popular due to longer life spans and lower maintenance.

Commercial and Industrial Applications:

Stainless Steel Pipe is favored, especially high pressure stainless steel pipe, as it can withstand demanding operational conditions without frequent replacements or repairs.

Copper is typically avoided for industrial high-pressure or chemical-intensive environments.

Xintongda Special Steel offers specialized products specifically designed for demanding scenarios such as power plants, petrochemical facilities, and oil refineries.

Zhejiang Xintongda Special Steel, as an established stainless steel pipe supplier and stainless steel pipe manufacturer, provides various stainless steel pipe products suitable for diverse applications:

253ma Seamless Stainless Steel Pipe: Known for exceptional heat resistance, ideal for furnace components, heat exchangers, and industrial heaters.

314 Seamless Stainless Steel Pipe: Highly resistant to oxidation at elevated temperatures, perfect for high-temperature industrial applications.

tp347h Seamless Stainless Steel Pipe: Offers superior corrosion resistance, ideal for chemical plants, refineries, and power generation units.

Seamless Hyper Duplex Steel Pipe: Suitable for extremely corrosive environments, combining high strength and excellent corrosion resistance.

Nowadays, sustainability plays an increasingly important role in material selection. When considering stainless steel pipe vs copper plumbing, stainless steel is often considered more sustainable due to:

Longer lifespan, reducing replacements.

Fully recyclable, lowering environmental impact.

Higher resistance to chemicals, reducing leak-related environmental hazards.

Another often overlooked aspect when comparing stainless steel pipe vs copper plumbing is structural stability. Stainless steel pipes often require robust support structures—called stainless steel pipe supports—to manage their weight, especially in heavy thickness stainless steel pipe applications. While copper plumbing usually requires less robust supports, stainless steel's superior strength means fewer support points overall, which can save on overall structural support costs in larger installations.

Here's a simplified guide to help decide which suits your budget:

Choose Stainless Steel Pipe if:

You need long-term cost savings.

You operate under harsh industrial conditions or require very low maintenance.

Your project involves high pressures or corrosive substances.

Choose Copper Plumbing if:

Initial budget constraints are tighter.

Installation speed and ease matter more than long-term durability.

You primarily have a residential or low-demand commercial water supply.

Considering total lifetime costs, stainless steel typically provides greater economic value over copper for industrial, commercial, and even certain residential projects.

Q1: Is stainless steel plumbing more expensive than copper plumbing?

A1: Initially, stainless steel plumbing can be more expensive. However, over time, stainless steel often proves more cost-effective due to its durability and lower maintenance costs.

Q2: Can stainless steel pipes handle high-pressure situations better than copper?

A2: Yes, high pressure stainless steel pipe handles demanding applications far better than copper, especially in industrial environments.

Q3: What type of stainless steel pipe is best for high-temperature environments?

A3: 253ma seamless stainless steel pipe and 314 seamless stainless steel pipe are specifically designed to perform exceptionally well in high-temperature situations.

Q4: Where can I source reliable stainless steel pipes for industrial applications?

A4: Reliable stainless steel pipes can be sourced from certified suppliers like Zhejiang Xintongda Special Steel, a prominent stainless steel pipe manufacturer in China.

Q5: Which type of pipe is better for drinking water systems?

A5: Both stainless steel and copper are safe, but copper is traditionally preferred for potable water due to antimicrobial properties. Stainless steel is increasingly used because of its longevity and corrosion resistance.

In conclusion, choosing between stainless steel pipe vs copper plumbing hinges upon initial budget, project requirements, and long-term objectives. Stainless steel pipes provided by reputable suppliers like Zhejiang Xintongda Special Steel offer excellent durability, low maintenance costs, and superior performance in harsh environments. Copper plumbing still holds value for certain residential applications, primarily due to lower initial costs and ease of installation.

By carefully weighing these factors, you'll ensure the best decision tailored to your specific needs, balancing upfront costs with long-term savings and sustainability.