close

Choose Your Site

Global

Social Media

When choosing the right pipe for your project, strength is a key consideration. But is a seamless pipe stronger than a welded pipe?

In this article, we will explore the differences between seamless and welded pipes, focusing on their strength, pressure resistance, and suitability for various applications. You’ll learn why seamless pipes often outperform welded pipes in critical environments.

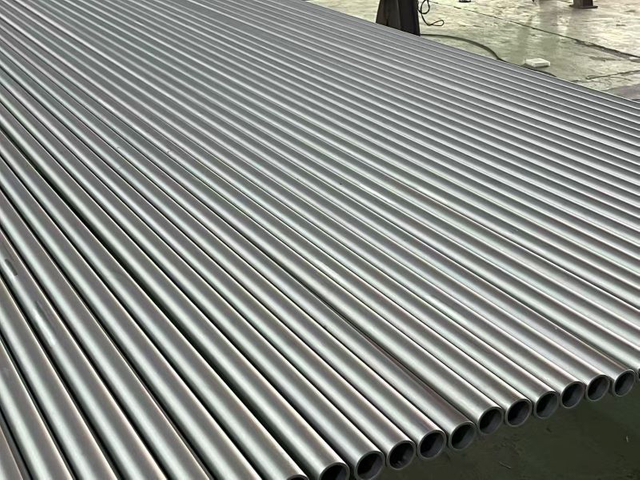

A seamless pipe is a type of pipe made from a single piece of metal. The manufacturing process involves extruding or piercing a solid steel billet to create a hollow tube without any joints or seams. This continuous structure provides enhanced strength and durability compared to pipes that are welded.

The lack of seams in seamless pipes means they have a uniform structure, which contributes to their superior resistance to pressure and mechanical stress. These pipes are ideal for critical applications where reliability and performance are paramount.

In contrast, a welded pipe is made by joining two separate pieces of metal together through a welding process. The welded joint is typically the weakest point in the pipe, as the metal may not fuse as uniformly as the rest of the pipe. This makes welded pipes more prone to failure under extreme pressure or stress, particularly at the seam where the two pieces are joined.

Welded pipes are often more affordable and easier to produce, which is why they are commonly used in non-critical applications where the pipe’s strength is not as critical.

Feature | Seamless Pipe | Welded Pipe |

Manufacturing Process | Made from a single piece of metal | Made by welding two pieces of metal |

Strength | Uniform structure, higher strength | Weaker at the seam |

Pressure Resistance | Better resistance to high pressure | May fail under high pressure at the seam |

Durability | Longer lifespan in harsh conditions | Shorter lifespan due to seam weakness |

Cost | More expensive due to complex production | More affordable and easier to produce |

The strength of a seamless pipe is primarily determined by its manufacturing process. The process begins with a steel billet, which is heated to a high temperature and then extruded through a mold to form a hollow tube. This tube is then elongated using a method called rotary piercing, where the billet is pierced to create a hollow shape. The final product is a continuous pipe without any welds or joints.

The uniformity of this structure contributes to its high tensile strength, making it resistant to pressure and mechanical stress. Since there are no weak points, like welds, the pipe maintains its integrity even under extreme conditions.

On the other hand, welded pipes are made by welding two pieces of metal together. The pipe is formed by rolling a flat metal sheet into a cylindrical shape and then welding the edges. The welding process itself is an area of concern because the metal at the weld joint is more likely to be weaker than the rest of the pipe. This weak spot can lead to failure under stress, especially in high-pressure applications.

Even though welded pipes are generally cheaper and easier to produce, they are not as strong as seamless pipes due to the inherent weakness of the weld. The quality of the weld depends on the technique used, but it is generally not as strong as the solid structure of seamless pipes.

Both seamless and welded pipes undergo heat treatment and sizing, which further impacts their strength. For seamless pipes, the heat treatment process ensures that the pipe has the right balance of strength and flexibility. Heat treatment also helps remove any internal stresses that may have developed during the manufacturing process.

For welded pipes, heat treatment is applied to the weld area to ensure it is properly fused and free from defects. However, the strength of the weld can still be compromised if the welding process is not done correctly, leading to a weaker joint.

Tip: When choosing between seamless and welded pipes, consider the heat treatment process, as it can significantly improve the strength of both types.

Tensile strength is a measure of how much force a material can withstand without breaking. Seamless pipes typically have higher tensile strength compared to welded pipes. Since seamless pipes are made from a single piece of metal, they have a uniform structure, allowing them to distribute the load more evenly across the entire pipe.

In contrast, welded pipes are more prone to weak spots at the welded seam, which can cause the pipe to break or deform under tensile stress. While welded pipes can perform well under normal conditions, they are not suited for applications that require high tensile strength, such as oil and gas pipelines.

Tip: For applications that demand high tensile strength, choose seamless pipes for their superior performance and reliability.

Seamless pipes are significantly stronger when it comes to pressure resistance. The absence of welds means seamless pipes can withstand much higher internal pressures without failing. This is particularly important in industries like oil and gas, where pipes are exposed to high-pressure environments over long periods.

Welded pipes, while suitable for lower-pressure applications, may experience failures at the seam when exposed to extreme pressure. The welded joint can be a weak point, leading to cracks or leaks, especially if the weld is not properly executed or if the pipe is subjected to pressure fluctuations.

Seamless pipes are also more resistant to corrosion than welded pipes. The uniform structure of seamless pipes means there are fewer areas where corrosion can start. The welded seam in welded pipes is particularly vulnerable to corrosion, especially in environments where pipes are exposed to moisture, chemicals, or other corrosive elements.

In applications where pipes are exposed to harsh chemicals or high moisture, seamless pipes are the better choice. Their resistance to corrosion ensures a longer lifespan, reducing the need for frequent maintenance or replacements.

Industry/Use Case | Benefit of Seamless Pipe | Application Example |

Oil and Gas | High pressure resistance, corrosion resistance | Deep-sea drilling, oil pipelines |

Automotive and Aerospace | High strength and precision for critical components | Exhaust systems, fuel lines |

Construction | Structural integrity for heavy-duty use | Support beams, heavy machinery |

Chemical Processing | Resistance to corrosive chemicals | Piping in chemical plants |

The oil and gas industry relies heavily on seamless pipes due to their ability to withstand high pressures and extreme environmental conditions. These pipes are used in deep-sea drilling, offshore rigs, and pipelines that transport oil and gas over long distances. Seamless pipes ensure that the integrity of these critical systems is maintained, even under harsh conditions.

In the automotive and aerospace industries, seamless pipes are used to manufacture high-strength components that require precision and durability. For example, seamless pipes are used in exhaust systems, fuel lines, and hydraulic systems where the pipes must endure high pressure and temperature fluctuations.

Seamless pipes are also commonly used in the construction and heavy machinery industries. They provide the structural integrity required for large-scale construction projects, such as bridges and high-rise buildings. The strength of seamless pipes makes them ideal for supporting heavy loads and withstanding harsh weather conditions.

The production of seamless pipes is more complex than welded pipes, leading to higher costs. The manufacturing process for seamless pipes requires more advanced technology and equipment, making them more expensive to produce. This can be a limitation for companies that need to balance cost and quality.

Another challenge with seamless pipes is their availability in various sizes. While welded pipes can be produced in virtually any size by simply welding together two pieces of metal, seamless pipes are more limited in their range of sizes due to the extrusion and elongation processes. For applications requiring custom sizes or large quantities, welded pipes may be a more cost-effective option.

Seamless pipes are stronger than welded pipes due to their uniform structure and lack of seams. This makes them more suitable for high-pressure, high-stress applications, offering superior strength, durability, and corrosion resistance. Zhejiang Xintongda Special Steel Manufacturing Co., Ltd. provides high-quality seamless pipes, ensuring long-term reliability and performance for critical industries.

A: A seamless pipe is stronger because it is made from a single piece of metal without seams, making it more resistant to high pressure and mechanical stress than welded pipes.

A: Seamless pipes are more durable due to their uniform structure and absence of welds, which can be weak points in welded pipes, especially under extreme conditions.

A: The extrusion and rotary piercing processes used in seamless pipe manufacturing create a solid, uniform pipe with no weak points, giving it greater strength compared to welded pipes.

A: Yes, seamless pipes tend to be more expensive due to the complex manufacturing process, but their superior strength and durability often justify the higher cost for critical applications.

A: While welded pipes can handle some pressure, seamless pipes are preferred in high-pressure systems due to their superior strength and lack of weld-related weaknesses.