close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-06-16 Origin: Site

Imagine a hospital where doctors rely on surgical tools that must stay strong and clean. Austenitic Stainless Steel makes this possible. It contains high amounts of chromium and nickel, giving it a unique face-centered cubic structure. This structure makes it non-magnetic and very tough. Most kitchen sinks, food processing machines, and even medical implants use this type of steel. In fact, austenitic stainless steels make up about 70% of all stainless steel production. The table below shows typical compositions for medical grades:

Stainless Steel Grade | Carbon max wt% | Chromium wt% | Nickel wt% | Manganese max wt% | Molybdenum wt% | Copper max wt% | Silicon max wt% | Nitrogen max wt% |

|---|---|---|---|---|---|---|---|---|

F138, F139 | ≤ 0.03 | 17–19 | 13.0–15.0 | ≤ 2.0 | 2.25–3.0 | ≤ 0.5 | ≤ 0.75 | ≤ 0.1 |

F745 | ≤ 0.06 | 16.5–19.0 | 11.0–14.5 | ≤ 2.0 | 2.0–3.0 | ≤ 0.5 | ≤ 1.0 | ≤ 0.2 |

Super Austenitic Stainless Steel offers even higher resistance for harsh environments.

Austenitic stainless steel has a unique face-centered cubic structure that makes it strong, tough, and non-magnetic.

Its high chromium and nickel content gives excellent resistance to rust and corrosion, ideal for harsh environments.

This steel is easy to shape and weld, making it popular in food, medical, construction, and automotive industries.

It performs well in extreme temperatures, staying strong in both very cold and very hot conditions.

Different grades of austenitic stainless steel suit various needs, so choosing the right grade ensures the best performance.

Austenitic Stainless Steel stands out because of its unique internal structure. Scientists call this structure "face-centered cubic" or FCC. In this arrangement, atoms sit at each corner and in the center of every face of a cube. This design gives the steel its famous strength and flexibility. The FCC structure also means the steel does not attract magnets, which makes it different from other types of stainless steel.

The FCC structure allows the steel to bend and stretch without breaking. This property helps manufacturers shape the steel into many forms, from thin wires to large sheets. The high number of slip planes in the FCC structure gives the steel excellent formability and toughness. Because of these qualities, austenitic stainless steel works well in both very cold and very hot environments.

Note: The face-centered cubic structure remains stable from extremely low temperatures up to the steel’s melting point. This stability ensures reliable performance in demanding applications.

Austenitic Stainless Steel contains a mix of iron, chromium, and nickel as its main ingredients. Most grades have 15–20% chromium and 8–15% nickel. These elements help the steel resist rust and corrosion. Nickel and manganese keep the FCC structure stable at room temperature. Small amounts of carbon, nitrogen, molybdenum, and other elements may be added to improve specific properties.

For example, chromium protects the steel from rust, while molybdenum increases resistance to acids and salt. Low carbon content helps prevent unwanted reactions during welding. Different grades, such as 304 and 316, use slight changes in these elements to suit different jobs.

Austenitic stainless steel became popular because of its reliable structure and useful composition. Over time, improvements in production made it the most widely used stainless steel family. Today, it accounts for about two-thirds of all stainless steel made worldwide.

Did you know? In 1929, the United States produced over 25,000 tons of stainless steel each year. Now, global production exceeds one million tons annually.

Austenitic Stainless Steel stands out for its excellent resistance to corrosion. The high chromium content forms a thin, invisible layer on the surface. This layer protects the steel from rust and chemical attack. Nickel in the alloy helps keep this protective layer stable, even in harsh environments.

Engineers use accelerated pitting corrosion tests, such as those based on the ASTM G48 standard, to measure how well this steel resists damage. These tests use ferric chloride solutions to mimic aggressive marine conditions. Results show that 304 stainless steel resists pitting and rust, especially when the surface is smooth and exposed to air. Industries like oil and gas rely on these tests to choose materials for equipment that faces seawater and other tough conditions.

Tip: Regular cleaning and a smooth finish can further improve corrosion resistance in real-world applications.

Austenitic Stainless Steel combines strength with toughness. This means it can handle heavy loads and resist breaking or cracking. Mechanical tests, such as tensile strength and yield strength measurements, show that grades like 304, 316, 310, and 321 have tensile strengths around 515-520 MPa. They also stretch up to 40% before breaking, which shows good ductility.

Researchers have found that microstructural features, such as fine grains and special boundaries inside the steel, help stop cracks from spreading. For example, AISI 316Ti keeps its strength and shape better at high temperatures than AISI 303. The J-integral method, used to test fracture toughness, shows that these steels can absorb a lot of energy before breaking. This makes them safe for use in tanks, vehicles, and buildings.

Manufacturers value Austenitic Stainless Steel for its easy shaping and joining. The face-centered cubic structure allows the steel to bend, stretch, and form into many shapes without cracking. Workers can roll it into thin sheets, draw it into wires, or press it into complex parts.

Welders find this steel easy to join using common welding methods. The low carbon content in many grades helps prevent problems like carbide precipitation, which can weaken welds. This makes the steel a top choice for building food equipment, medical devices, and architectural features.

Common forming methods:

Rolling

Drawing

Pressing

Spinning

Common welding methods:

TIG (Tungsten Inert Gas)

MIG (Metal Inert Gas)

Spot welding

Austenitic Stainless Steel performs well in both hot and cold environments. At very low temperatures, such as those found in cryogenic storage, the steel becomes even stronger and tougher. Tests show that as the temperature drops, yield and tensile strength increase, although the steel stretches less before breaking. Special microstructures, like ultrafine grains and tiny particles, help the steel stay tough and resist cracking in the cold.

At high temperatures, the steel’s strength decreases as the temperature rises. Flow stress drops, and the steel becomes softer and more likely to deform. For example, 316L stainless steel loses strength at high heat, but still keeps enough toughness for many industrial uses. This balance of properties makes Austenitic Stainless Steel suitable for everything from liquid nitrogen tanks to furnace parts.

Note: The ability to work in extreme temperatures sets this steel apart from many other metals.

Austenitic stainless steel plays a vital role in many industries. Its unique combination of corrosion resistance, strength, and clean appearance makes it a top choice for demanding environments. Below are some of the most important sectors that rely on this material.

The food and beverage industry depends on materials that ensure safety, hygiene, and durability. Austenitic stainless steel meets these needs better than most metals.

Grades such as 304, 316, and 316L are common in brewing vessels, milk tankers, dairy processing equipment, and storage tanks.

The dairy industry uses 316L stainless steel because it resists corrosion in whey protein solutions and other aggressive food environments.

The chromium oxide film on the surface prevents contamination and flavor changes.

Welded zones maintain corrosion resistance, which helps prevent metal ion release and keeps food safe.

Super austenitic grades like 904L handle salty foods and hot brine.

Passivation and electropolishing keep surfaces smooth and easy to clean.

Stainless steel equipment does not add flavors or discoloration to food. Its smooth surface makes cleaning easy, supporting strict hygiene standards.

Hospitals and laboratories require materials that stay clean and resist corrosion. Austenitic stainless steel is the preferred choice for medical and pharmaceutical equipment.

Austenitic stainless steel grades 304L and 316L offer high corrosion and stain resistance. This property is essential for maintaining Good Manufacturing Practice (GMP) compliance. The natural oxide layer on the surface prevents corrosion and reduces contamination risks. Regulatory agencies, including the FDA, require that equipment in direct contact with pharmaceuticals does not corrode, as corrosion can trap residues and microbes. Standards such as ASTM A967–13 and A380/A380M-13 guide the maintenance of surface integrity. Grade 316 stainless steel provides tensile strength similar to mild steel but with better corrosion resistance, making it ideal for medical trays, device components, and pharmaceutical processing equipment. These qualities ensure equipment longevity, safety, and compliance with cleanliness standards.

Austenitic stainless steel shapes modern skylines and infrastructure. Its strength, durability, and appearance make it a favorite for architects and engineers.

Nickel-containing austenitic stainless steel provides high-temperature strength and resists deformation under stress. Iconic buildings like the Chrysler Building and St Paul’s Cathedral have used this material, showing its long-term durability. The material’s recyclability also supports sustainable building practices.

Benefit Category | Description |

|---|---|

Strength-to-Weight | Enables lighter, thinner structures, reducing material use and weight. |

Corrosion Resistance | Lowers maintenance costs and extends building lifespan. |

Sustainability | Recyclable, reducing environmental impact. |

Structural Applications | Used in cladding, street furniture, and reinforcement in concrete. |

Cost Efficiency | Lighter structures reduce transport and energy costs. |

Durability | Proven by long-lasting buildings and monuments. |

Environmental Impact | Supports greener construction practices. |

The automotive and transport industries need materials that withstand harsh conditions and support safety. Austenitic stainless steel meets these demands.

Automotive manufacturers use it for exhaust systems, fuel tanks, and structural panels.

Grades 304 and 316 offer superior corrosion resistance and mechanical strength.

Cold-worked austenitic stainless steel provides high strength for transit cars, springs, and seatbelt anchors.

The material maintains toughness at very low temperatures, ensuring durability in extreme environments.

The automotive component segment accounts for about 30% of the austenitic stainless steel market.

Ongoing improvements in metallurgy support its use in lightweight, fuel-efficient, and electric vehicles.

The combination of corrosion resistance, strength, and formability makes this steel ideal for vehicles that must last and perform safely.

Austenitic stainless steel finds use in many other sectors due to its versatility.

Major application areas include aerospace, defense, oil and gas, chemical and petrochemical, power generation, marine, shipbuilding, and machinery manufacturing.

The chemical and petrochemical industry holds the largest share of the stainless steel bars market, using the material in reactors, heat exchangers, valves, pumps, and piping systems.

The global stainless steel fabrication market reached about 179.59 billion USD in 2023, with austenitic grades dominating due to their adaptability.

The 300 series is common in aerospace tubing, mining equipment, cutlery, and catalytic converter components.

The 200 series appears in home water tanks, washing machines, dishwashers, cookware, and indoor architecture.

The global casting market for austenitic stainless steel is growing rapidly, especially in Asia-Pacific, Europe, and North America.

Austenitic stainless steel stands out for its ability to perform in extreme temperatures, resist corrosion, and maintain strength, making it the most widely used stainless steel type across industries.

Grade 304 stands as the most widely used austenitic stainless steel. It contains about 18% chromium and 8% nickel. This balance gives it strong corrosion resistance and good mechanical properties. The tensile strength ranges from 520 to 750 MPa, and the proof stress is around 215 MPa. The melting point is close to 1450°C. Grade 304 works well up to 860°C for short periods.

Variants like 304L and 304H adjust the carbon content. 304L has less carbon, which improves weldability and reduces the risk of carbide precipitation. 304H has more carbon, making it stronger at high temperatures. Industry standards such as ASTM and ISO set the requirements for these grades.

Property / Grade | 304 | 304L | 304H |

|---|---|---|---|

Tensile Strength (MPa) | 500 - 750 | 500 - 700 | 500 - 700 |

Proof Stress (MPa) | 190 - 230 | 175 - 220 | 185 |

Elongation (%) | 40 - 45 | 45 | 40 |

Hardness (Brinell) | Up to 215 | Up to 215 | N/A |

304 stainless steel offers excellent corrosion resistance, but it may not perform as well as 316 in environments with high chloride levels.

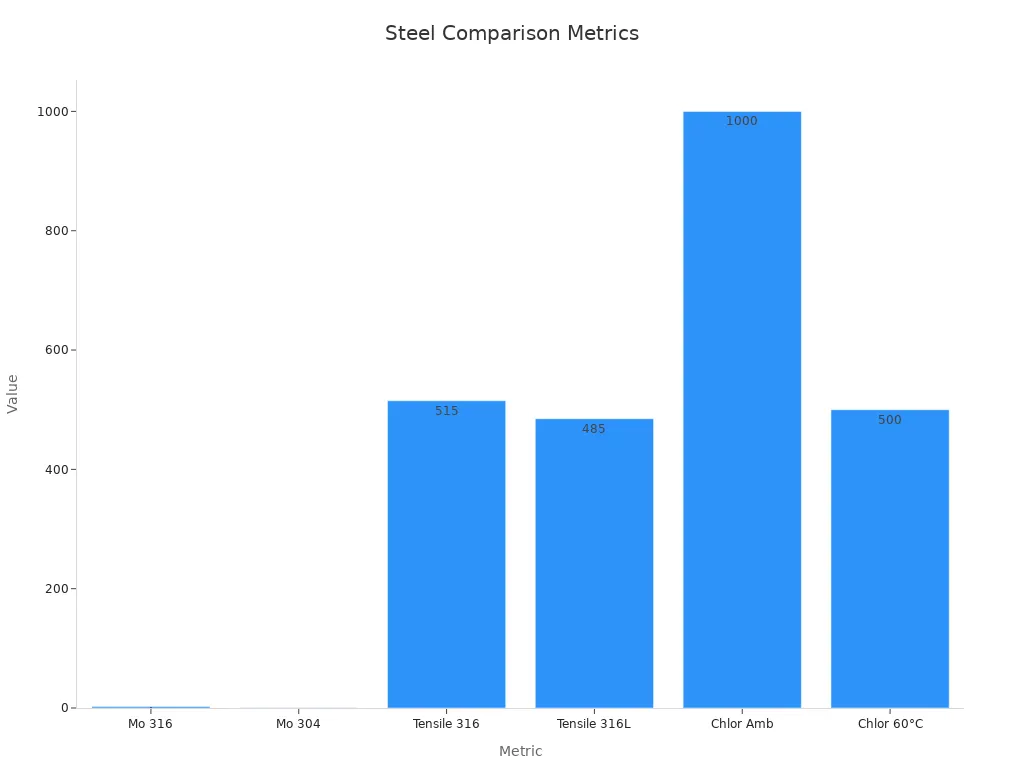

Grade 316 improves on 304 by adding molybdenum, usually around 2.1%. This addition boosts resistance to corrosion, especially from chlorides and acids. The tensile strength for 316 is at least 515 MPa, and for 316L, it is 485 MPa. The lower carbon content in 316L reduces the risk of sensitization during welding.

Property | 316 | 316L |

|---|---|---|

Molybdenum (%) | 2.0 - 3.0 | 2.0 - 3.0 |

Tensile Strength (MPa) | 515 min | 485 min |

Carbon (%) | 0.02 | 0.02 |

Chloride Limit (mg/L, ambient) | 1000 | 1000 |

Chloride Limit (mg/L, 60°C) | 500 | 500 |

316 stainless steel is the preferred choice for marine, chemical, and pharmaceutical equipment. Its durability and corrosion resistance make it suitable for harsh environments.

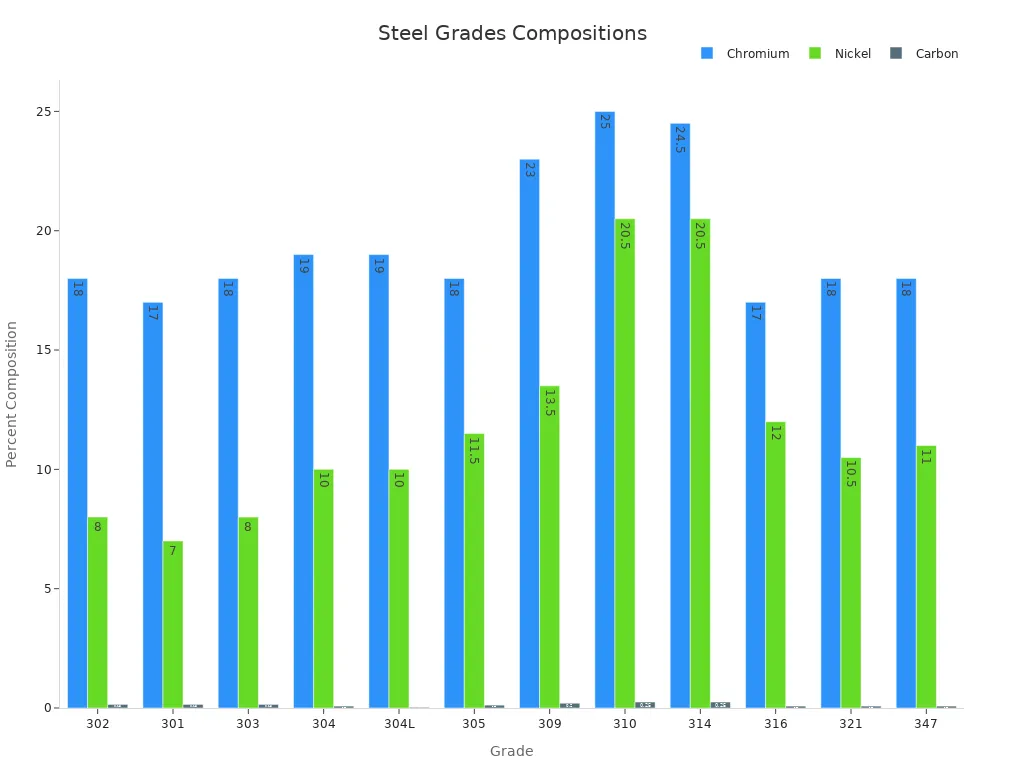

Many other austenitic stainless steel grades exist, each designed for specific needs. Grade 310 contains high chromium and nickel, giving it excellent strength and oxidation resistance at high temperatures. Grade 904L has even more chromium, nickel, and molybdenum, making it ideal for use in acidic or salty environments. Grade 321 adds titanium to prevent intergranular corrosion, while grade 347 uses niobium and tantalum for similar reasons.

Grade | Chromium (%) | Nickel (%) | Molybdenum (%) | Carbon max (%) | Other Elements | Main Property |

|---|---|---|---|---|---|---|

310 | 25 | 20.5 | — | 0.25 | — | High-temp strength |

904L | 19–23 | 23–28 | 4–5 | 0.02 | — | Acid resistance |

321 | 18 | 10.5 | — | 0.08 | Titanium | Prevents corrosion |

347 | 18 | 11 | — | 0.08 | Nb, Ta | High-temp stability |

Austenitic Stainless Steel grades differ in composition and properties. This variety allows engineers to select the right material for each application, from kitchen equipment to chemical plants.

Ferritic stainless steels contain more chromium and little or no nickel. They have a body-centered cubic (BCC) structure. This structure makes ferritic steels magnetic and less ductile than austenitic types. Ferritic grades, such as 430, resist corrosion but do not match the toughness or formability of austenitic grades. Ferritic steels work well for indoor applications and cost less. They do not perform as well in very cold or very hot environments.

Austenitic grades, on the other hand, have a face-centered cubic (FCC) structure. They resist corrosion better and stay tough at both high and low temperatures. Their non-magnetic nature and easy formability make them popular for cookware, food equipment, and medical tools.

Property | Ferritic (e.g., 430) | Austenitic (e.g., 304, 316) |

|---|---|---|

Structure | BCC | FCC |

Magnetic | Yes | No |

Ductility | Moderate | High |

Corrosion Resistance | Good | Excellent |

Cost | Lower | Higher |

Martensitic stainless steels contain more carbon and less nickel. They can be hardened by heat treatment. This property gives them high strength and wear resistance. Martensitic grades, such as 410 and 440C, are magnetic and often used for knives, tools, and turbine blades. However, they do not resist corrosion as well as austenitic grades.

Austenitic grades do not harden with heat treatment but keep their strength and ductility. They resist corrosion better and work well in chemical, food, and medical industries. Martensitic steels suit jobs that need sharp edges or high strength, while austenitic steels fit uses that need cleanliness and corrosion resistance.

Choosing the right stainless steel depends on several factors:

Welding suitability: Grades 304L and 316L work best for welding because their low carbon content reduces corrosion at welds. Grade 347 suits chemical plants for stress corrosion resistance.

Heat treatment needs: Hardenable grades like 440C and 17-4PH provide high hardness and wear resistance. Non-hardenable grades like 304 and 316 keep their strength without heat treatment.

Strength requirements: High-strength martensitic and precipitation-hardening steels fit aerospace and automotive uses. Moderate strength grades like 304 and 316 work for structural uses. Duplex grades such as 2205 combine strength and corrosion resistance.

Corrosion resistance: Marine and chloride-rich environments favor 316, 316L, and 904L. Duplex 2205 works well for industrial corrosion. Heat-resistant grades like 310 suit high-temperature jobs.

Formability: Grades 304, 316, and 430 are easy to form for cookware and architecture. Grades 2205 and 3CR12 balance formability and corrosion resistance.

Machinability: Grades 303 and 416 are easy to machine. Grade 3CR12 balances machinability and wear resistance.

Cost considerations: Grades 316 and 2205 cost more but last longer in harsh environments. Grades 430 and 3CR12 offer savings for indoor uses.

Pitting engineering diagrams help engineers choose materials for water systems. These diagrams use chloride levels, temperature, and oxidation to show where pitting may occur. Surface finish, welds, and contaminants can affect these results. For fatigue-critical parts, engineers use advanced models to predict how long a steel will last under repeated stress. These models help match the right grade to the job.

Tip: Always match the steel grade to the environment and performance needs for the best results.

Austenitic stainless steels have become essential in modern life. Their strength, ductility, and corrosion resistance support industries from construction to healthcare. Over time, these steels have proven their value in iconic buildings and critical equipment.

The market is projected to grow steadily, driven by urbanization, sustainability, and new technologies.

Asia-Pacific leads in industrial development, while North America and Europe focus on innovation and green practices.

Anyone seeking durable, reliable materials should consider these steels.

Questions or comments? Share your thoughts below!

Austenitic stainless steel has a face-centered cubic (FCC) structure. This atomic arrangement prevents magnetism. Even after shaping or welding, the steel stays non-magnetic in most cases.

Stainless steel resists rust, but it can still corrode in harsh conditions. High salt, acids, or poor cleaning may damage the protective layer. Regular care helps keep the surface shiny and rust-free.

Yes, austenitic stainless steel is safe for food. The smooth surface does not react with food or drinks. It prevents bacteria from sticking, making it ideal for kitchens and food factories.

Austenitic stainless steel stays strong in both hot and cold environments. It does not crack in freezing temperatures. It also keeps its shape and strength when exposed to high heat, making it useful in many industries.