close

Choose Your Site

Global

Social Media

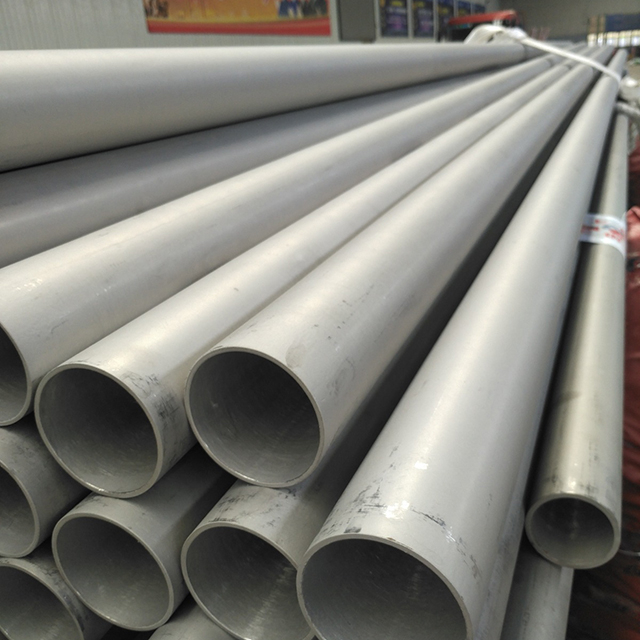

Austenitic stainless steel is a crucial material used in many industries today. But what exactly makes it stand out from other steels? Understanding its properties and uses can help you make informed decisions.

In this post, we’ll discuss what austenitic stainless steel is, why it’s so important, and where it’s commonly used. By the end, you’ll know the basics of this versatile material.

Austenitic stainless steel is one of the most widely used types of stainless steel, renowned for its durability and resistance to corrosion. It is primarily made of iron, with significant amounts of chromium, nickel, manganese, and carbon. The proportions of these elements in the alloy determine its characteristics and performance.

Iron (Fe): The base metal that forms the majority of the alloy.

Chromium (Cr): Ranges from 16% to 26% in most austenitic grades. Chromium helps in forming a thin, invisible layer of chromium oxide on the surface, which protects the steel from rust and corrosion.

Nickel (Ni): Generally makes up about 6% to 22%. Nickel enhances the material's corrosion resistance and increases the steel’s flexibility. It also stabilizes the face-centered cubic (FCC) structure of austenitic steel, which makes it non-magnetic.

Manganese (Mn): Typically added in small amounts (up to 6%) to improve the steel’s strength and resistance to corrosion.

Carbon (C): Low levels of carbon are maintained to prevent the formation of carbide, which could weaken the structure of the steel.

This combination of elements gives austenitic stainless steel its corrosion resistance, ductility, and ability to withstand high temperatures, making it one of the most popular choices for various industrial applications.

Austenitic stainless steel is prized for several key features that set it apart from other materials. These properties make it particularly useful in industries such as food processing, medicine, construction, and automotive engineering.

One of the most distinctive characteristics of austenitic stainless steel is its non-magnetic property. This is due to its unique face-centered cubic (FCC) structure. Unlike ferritic and martensitic stainless steels, which have a body-centered cubic (BCC) structure and are magnetic, austenitic stainless steel does not exhibit any magnetic properties. This makes it ideal for applications where magnetic interference is not acceptable, such as in medical devices and high-tech machinery.

Austenitic stainless steel’s high resistance to corrosion is a result of its high chromium content. The chromium reacts with oxygen in the environment to form a thin, passive oxide layer on the surface, which acts as a barrier against rust and other forms of corrosion. This passive layer is self-healing, meaning that even if the surface is scratched, it can regenerate itself in the presence of oxygen. This makes austenitic stainless steel suitable for environments with high levels of humidity, chlorides, and acids, such as in marine or food processing environments.

Austenitic stainless steel is extremely formable. Its ductility allows it to be easily shaped, bent, or molded without breaking or cracking. This property is especially valuable in manufacturing and fabrication processes where complex shapes are required, such as in the construction of equipment, pipes, and kitchenware. The ability to form intricate designs without compromising strength makes it a versatile material in a variety of applications.

Despite being flexible and easy to work with, austenitic stainless steel retains excellent tensile strength. This means it can withstand considerable force or stress without stretching or breaking. This makes it ideal for use in structural components that are exposed to high mechanical stress, such as in automotive parts, aircraft components, and marine hardware.

In addition to its tensile strength, austenitic stainless steel is highly ductile, which means it can be stretched and deformed without breaking. This characteristic is crucial in applications where the material needs to be shaped into complex geometries or thin sheets, such as in electrical components and kitchen appliances. Austenitic steels can absorb substantial energy before fracturing, making them highly resilient under extreme conditions.

Ferritic Stainless Steels: Ferritic steels have lower levels of carbon and are magnetic. They tend to have lower corrosion resistance compared to austenitic steels but are used in applications where magnetic properties are needed, such as in automotive exhaust systems.

Martensitic Stainless Steels: This type of steel has higher carbon content, which makes it harder and more durable. However, martensitic steels are more prone to rusting than austenitic steels and are less resistant to corrosion. They are often used in cutlery, tools, and surgical instruments because of their hardness and ability to hold an edge.

Duplex stainless steels are a blend of austenitic and ferritic structures. While they offer higher strength and improved resistance to stress corrosion cracking compared to austenitic steels, they do not offer the same level of corrosion resistance in acidic or chloride-rich environments. Austenitic steels remain the preferred choice when corrosion resistance is the primary concern.

Austenitic stainless steel is favored for applications where corrosion resistance, formability, and strength are critical. Its non-magnetic property, high ductility, and ability to withstand extreme temperatures make it the best choice for industries such as food processing, chemical manufacturing, medical equipment, and construction.

Compared to ferritic and martensitic steels, austenitic stainless steel provides superior resistance to oxidation, rust, and corrosion, making it more suitable for harsh environments such as marine or chemical settings.

The most commonly used grade, 304 stainless steel is known for its excellent corrosion resistance, easy fabrication, and good formability. It is used in kitchen appliances, food processing equipment, and water systems.

316 stainless steel contains molybdenum, which enhances its resistance to pitting corrosion in chloride-rich environments. This makes it ideal for applications in chemical processing, marine environments, and pharmaceutical industries.

321 stainless steel is stabilized with titanium to improve its resistance to high-temperature oxidation. It is often used in high-temperature environments such as in furnaces and gas turbines.

This grade is specifically designed for machinability. It is often used in screws, bolts, and other precision machining applications. However, it has a slightly lower resistance to corrosion compared to 304 and 316 grades.

The “L” in stainless steel grades stands for low carbon. For example, 304L and 316L have reduced levels of carbon, which minimizes the risk of chromium carbide formation during welding. This enhances their weldability and corrosion resistance, making them suitable for high-temperature applications where welding is necessary.

Super austenitic stainless steels, such as 904L, are high-performance alloys with increased levels of molybdenum, nickel, and chromium. These alloys provide superior corrosion resistance in aggressive environments, such as those involving sulfuric acid or seawater. 904L is commonly used in chemical processing and offshore applications.

Austenitic stainless steel is known for its versatility, durability, and cost-effectiveness. It excels in resisting corrosion, high temperatures, and mechanical stress, making it a top choice across many industries. Whether you're working on construction, food processing, or medical devices, austenitic stainless steel is a reliable material for your needs. Consider using it for your next project to benefit from its long-lasting performance and strength.

A: The main advantage of austenitic stainless steel is its corrosion resistance, combined with high strength. This makes it suitable for applications exposed to harsh environments, like marine and chemical processing.

A: Consider corrosion resistance, temperature tolerance, and mechanical properties. Choose a grade based on the specific environment and requirements, such as 316 for marine use or 304 for general applications.

A: Austenitic stainless steel is generally more expensive than other types due to its high nickel and chromium content. However, its longevity and performance in harsh environments provide excellent value.

A: Yes, certain grades like 316 and 321 are designed for high-temperature environments, maintaining strength and durability even at elevated temperatures.

A: Yes, austenitic stainless steel is weldable. Low-carbon grades like 304L and 316L improve weldability by minimizing chromium carbide formation, which helps prevent corrosion at weld sites.