close

Choose Your Site

Global

Social Media

Stainless steel plates are very popular in factories because they last a long time and do not rust, even in tough places. Engineers pick stainless steel plates because they are strong and dependable. In a data center cooling system, stainless steel took the place of copper pipes to stop rust and help the system work better for a long time. Tests show that rust can make other steels weak, but stainless steel plates stay strong under pressure. Trusted sellers with good quality checks and certificates help industries like oil and gas, food processing, and building use these plates. Their many uses make them important for lots of factory jobs.

Stainless steel plates do not rust or corrode, so they work well in tough places. Their strength and toughness help machines and buildings last longer. This means you spend less money fixing or replacing them. Stainless steel plates can handle very high heat. They stay strong even in hot factories. The smooth surface makes them easy to clean. This helps keep things clean in food and medical jobs. Stainless steel protects better from rust than carbon steel, aluminum, or plastics. It also lasts longer than those materials. Picking the right stainless steel grade gives the best results for each job. Certified suppliers and careful checks make sure the plates are good quality. Recycling stainless steel plates helps the planet. It saves energy and cuts down on waste.

Stainless steel plates do not rust in tough places. Many factories use them because they stay strong around chemicals, saltwater, or wet air. Chromium in stainless steel makes a thin shield on the plate. This shield keeps water and air out, so rust cannot start. Scientists use special tests to see how chromium helps stop rust. When the chromium shield is thick and steady, stainless steel plates fight rust better than other metals. This is why chemical plants, oil refineries, and ships use these plates. The need for austenitic stainless steel plates is growing. By 2025, the market could be worth $15 billion. This is because many industries want plates that last long and do not rust.

Stainless steel plates do not rust or get ruined by chemicals.

The chromium shield keeps out harsh chemicals and saltwater.

Oil, gas, building, and energy companies use these plates for their rust resistance.

Stainless steel plates last a long time in factories. They do not break down or get weak from rust. Studies show these plates stay strong for many years, even with lots of use. The shield on the plate can fix itself if it gets scratched. This helps the plates last even longer. This self-fixing power makes stainless steel plates better than other materials. Factories pick these plates because they want machines that work for decades. They do not want to fix or replace them often. Stainless steel plates save money and last a long time.

Stainless steel plates are very strong. They can hold heavy things in factories. Tests like pulling and stretching show how strong they are. These tests prove that stainless steel plates do not bend or break easily. They are used in building, cars, and big projects where strength matters. Stainless steel plates help hold up bridges, buildings, and machines.

| Aspect | Description |

|---|---|

| Test Type | Monotone tensile tests at room temperature |

| Materials | Q235B carbon steel substrate and S34553 stainless steel cladding |

| Parameters Measured | Stress-strain curves, Young's modulus, yield strength, ultimate tensile strength, elongation after fracture |

| Findings | Mechanical properties vary with cladding ratio; high strength confirmed |

| Conclusion | Stainless steel plates show predictable, high strength under load |

Stainless steel plates are also hard to scratch or wear out. Factories use them where things rub together a lot. Tests show these plates do not crack or get damaged, even after many uses. They keep their strength when used over and over. This makes them good for conveyor belts, machine parts, and tools that shake or get hit. Stainless steel plates are strong and do not wear out fast. This means less fixing and lower costs.

Stainless steel plates do not get scratched or dented easily.

They stay strong and keep their shape for many years.

Machines and tools last longer with stainless steel plates.

Stainless steel plates work well in hot places. Factories need materials that do not get weak or rusty from heat. Tests show these plates can last over 3,000 hours below 700 °C. Chromium helps the plates stay strong and not rust, even when hot. S31603 stainless steel rusts less and stays stable at high heat compared to other types. This makes stainless steel plates good for furnaces, boilers, and exhaust pipes. Their strength stays the same between 200 °C and 400 °C. This is important for many factory jobs.

| Parameter | S31603 Stainless Steel | SS2562 Stainless Steel |

|---|---|---|

| Temperature Range | 308K to 353K | 308K to 353K |

| Corrosion Rate at 308K | 0.529 mm/year | 0.911 mm/year |

| Corrosion Rate at 353K | 8.701 mm/year | 17.492 mm/year |

| Passivation Behavior at 308K | Unstable passivation | Passivation at 0.09 V before breakdown |

| Microstructural Deterioration | Minimal deterioration | Advanced deterioration at 353K |

Stainless steel plates are needed for hot jobs in power plants, chemical factories, and making things. They do not rust and stay strong in heat, so they are a smart pick for tough factory work.

Stainless steel plates are important in places where safety matters. Food factories and hospitals use them because bacteria cannot grow on them. The surface is smooth and does not have holes. This makes cleaning very easy. Workers can wipe up spills and stains fast. No dirt or germs are left behind. This helps keep food and people safe.

Chromium in the plates makes a thin layer on top. This layer stops rust and fixes itself if scratched. So, stainless steel plates stay clean and do not hold bacteria. Food and medical workers trust these plates for being clean. They meet strict rules for safety and health. Stainless steel plates do not react with food or chemicals. This keeps food and medicine pure. Hospitals use special plates that do not rust and help patients stay healthy.

Stainless steel plates make cleaning quick and easy. Their smooth surface keeps bacteria away and helps keep things clean.

Stainless steel plates are good for the environment. Factories can recycle them many times without losing quality. This makes them a smart pick for companies that care about nature. Studies show stainless steel plates can be better for the earth than other building materials over time. Recycling saves energy and cuts down on waste.

| Sustainability Factor | Stainless Steel Plates | Concrete | Wood |

|---|---|---|---|

| Recyclability | High | Low | Medium |

| Global Warming Potential | Moderate | High | Low |

| Durability | High | Medium | Low |

| End-of-Life Reuse | Yes | No | Sometimes |

How stainless steel plates are made and used affects the earth. Some studies say they use more energy and make more pollution in some cases. But recycling helps lower their total impact. Companies pick stainless steel plates because they last long and can be recycled. They also help stop germs and keep things clean. This makes stainless steel plates a strong and green choice for many jobs.

Many factories use carbon steel because it is strong and cheap. Carbon steel has a lot of carbon, which makes it hard and tough. This is why it is used for bridges, cars, and big machines. But carbon steel does not stop rust well. It needs paint or a special coating to keep rust away, especially in wet or salty places.

Stainless steel plate is different because it has chromium. Chromium makes a thin layer that protects the plate from rust. This is why stainless steel plate is better for food factories, chemical plants, and ships. Carbon steel costs less at first, but it needs more fixing and care later. Stainless steel plate costs more at the start but saves money over time because it lasts longer and needs less work.

Carbon steel is strong and cheap but rusts fast.

Stainless steel plate fights rust and lasts longer, even in tough places.

Factories pick stainless steel plate when they need strength and rust protection.

| Property | Carbon Steel | Stainless Steel Plate |

|---|---|---|

| Corrosion Resistance | Low | High |

| Initial Cost | Low | Higher |

| Maintenance Needs | High | Low |

| Typical Applications | Construction, Cars | Food, Marine, Medical |

Aluminum is light and easy to shape into parts. Many companies use it for things that need to move or be lifted. Airplanes, trains, and some buildings use aluminum because it is lighter than steel. Aluminum does not rust easily, but it is not as good as stainless steel plate in harsh places.

Stainless steel plate is stronger for its weight than aluminum. It can hold more weight without bending or breaking. Stainless steel plate also stays strong in high heat, but aluminum can get weak when it is hot. Factories use stainless steel plate for jobs that need strength and heat resistance.

Aluminum is light and simple to use.

Stainless steel plate is stronger and works better in heat.

For hard jobs, stainless steel plate is often the best pick.

Plastics are used a lot because they are cheap and easy to shape. Many factories use plastics for pipes, tanks, and machine parts. Plastics do not rust, but they can crack, melt, or wear out faster than metals. They also do not do well with high heat or heavy weight.

Stainless steel plate is much stronger and lasts longer than plastics. It does not crack or melt in heat and can last for years. In places where being clean is important, like food factories and hospitals, stainless steel plate is better because it is easy to clean and does not keep germs.

Stainless steel plate gives factories a strong, long-lasting, and clean choice compared to plastics, especially in tough places.

When companies pick materials, they think about more than price. They care about how much it costs over time. This is called lifecycle cost. Stainless steel plates are a good choice because they save money later.

Stainless steel plates last for many years. They do not rust or break easily. Factories do not have to buy new plates often. This means they spend less on repairs and replacements. Many companies like that stainless steel plates help stop shutdowns. When machines work longer, companies save money.

Financial reports show stainless steel plates are a smart buy. For example, Aperam S.A. made EUR 231 million in 2024. ArcelorMittal S.A. had an EBITDA of $7.1 billion that year. These numbers show the stainless steel business is strong. Investors trust it. Companies keep picking stainless steel because it works well and lasts.

Governments also want builders to use stainless steel. The U.S. Bipartisan Infrastructure Law and the European Green Deal support strong materials. Stainless steel plates help make bridges and buildings last for decades.

Stainless steel plates help companies save money. They need less fixing and fewer replacements. Their strength and rust resistance mean less downtime.

Factories that use stainless steel plates help the earth. Stainless steel can be recycled many times. This means less waste and saved resources. Wind turbines and solar panels use stainless steel plates. These projects need materials that last and do not need much care. Stainless steel plates help these systems run with little extra cost.

More companies are making stainless steel plates. They use new machines that save energy. This lowers the cost of making plates and helps the planet.

Here is a simple table to compare lifecycle costs:

| Material | Initial Cost | Maintenance Cost | Replacement Frequency | Recyclability | Total Lifecycle Cost |

|---|---|---|---|---|---|

| Stainless Steel Plate | High | Low | Rare | High | Low |

| Carbon Steel | Low | High | Often | Medium | High |

| Aluminum | Medium | Medium | Sometimes | High | Medium |

| Plastics | Low | High | Often | Low | High |

Stainless steel plates cost more at first but save money later.

They last longer, need less care, and can be recycled.

Companies and governments trust stainless steel for big jobs.

Stainless steel plates are the best value for factories and builders. They help save money and protect the earth. Their long life and low upkeep make them a smart pick for any industry.

The oil and gas industry uses stainless steel plates for many important jobs. Workers put these plates in pipelines, platforms, and refineries. Stainless steel plates do not rust from saltwater or strong chemicals. This helps the oil and gas industry save money on repairs. Pressure vessels made with stainless steel plates hold high pressure and very hot or cold temperatures. These vessels keep oil, gas, and chemicals safe when moving or storing them.

Stainless steel equipment in oil and gas must follow strict rules. Companies pick stainless steel plates because they last longer than other choices. Duplex stainless steel plates are even stronger and fight rust better. These plates work well for deep-sea drilling and places with lots of pressure. The oil and gas industry also uses stainless steel plates in heat exchangers and separators. These machines must stay strong under pressure and lots of use.

Stainless steel plates stop leaks in pipelines.

Pressure vessels made with stainless steel plates keep oil and gas safe.

Stainless steel equipment means less downtime and fewer repairs.

Industry surveys show oil and gas companies use a lot of stainless steel plates. Companies buy stainless steel equipment to make things safer and work better. The oil and gas industry trusts these plates for long-lasting and steady service.

Stainless steel plates are very important in the food and drink business. Factories use stainless steel tools to make, store, and pack food. These plates do not mix with food or drinks. The smooth surface makes cleaning simple. This stops bacteria from growing on the equipment.

Austenitic stainless steel plates, like grades 304 and 316, are used a lot in food factories. These grades do not rust from acids or cleaning liquids. Pressure vessels made with stainless steel plates hold milk, juice, and other drinks. These vessels keep food safe under high pressure and for long times.

Studies show stainless steel plates only let out tiny bits of nickel and chromium when cooking. Quality checks make sure stainless steel tools are safe to use. The food and drink industry trusts stainless steel plates because they last long and are clean.

Stainless steel plates help keep food safe and fresh.

Pressure vessels made with stainless steel plates hold liquids without leaking.

Stainless steel tools are easy to clean and take care of.

The food and drink business is getting bigger. Stainless steel plates help this growth by giving safe and strong equipment.

Chemical plants use stainless steel plates for many kinds of machines. These plates do not get ruined by strong acids, bases, or solvents. Pressure vessels made with stainless steel plates handle high pressure and dangerous chemicals. Stainless steel tools in chemical plants must meet world rules like ASME SA-240 and ASTM A240.

Certifications like ISO 9001 and ISO 14001 show that makers follow strict quality and earth-friendly rules. Stainless steel plates pass tests for not rusting and being strong. ASTM standards help guide these tests to keep chemical plants safe. NADCAP certification also shows stainless steel tools meet high rules for chemical work.

Stainless steel plates protect machines from chemical harm.

Pressure vessels made with stainless steel plates handle high pressure safely.

Stainless steel tools meet tough industry rules.

Chemical plants need stainless steel plates for safe and good work. These plates help companies follow safety rules and spend less on fixing machines.

Stainless steel plates are important in today’s building work. Builders use them to make buildings strong and also to look nice. These plates are used for bridges, floors, walls, and roofs because they are tough and last a long time. Many architects like to use stainless steel sheets that are 4-5 mm thick. These sheets help support heavy things in buildings.

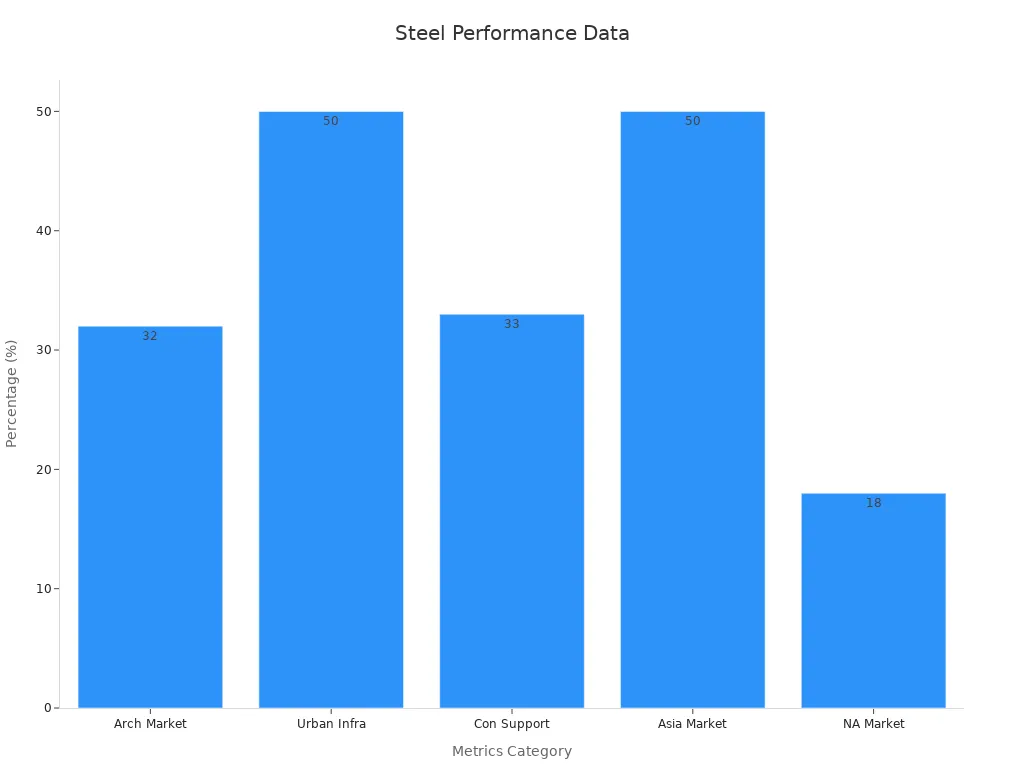

A new report says architects use more than 32% of all stainless steel plates. More than half of city building projects now use stainless steel. This is happening more in Asia-Pacific, where over half of the world’s stainless steel construction takes place. In North America, about one out of four public and home buildings use stainless steel.

| Aspect | Details |

|---|---|

| Thickness Preference | 4-5 mm stainless steel sheets are picked for strength and lasting power |

| Market Share by Application | Architecture uses over 32% of the market; more than half of city projects use stainless steel for looks and long life |

| Usage in Construction | About 33% of building supports use 4-5 mm sheets for holding up weight |

| Regional Market Share | Asia-Pacific leads with over 50% of the world’s share; North America has about 18% with 25% use in public and home buildings |

| Key Material Advantages | Long-lasting, fights rust, looks good, and holds up heavy things |

Stainless steel checkered plates are used for floors, stairs, and walls. Their bumpy surface helps stop people from slipping in busy places. These plates do not rust or get ruined by rain or sun, so they last a long time and need little care. Builders also like stainless steel because it looks clean and fits many styles.

Stainless steel can be recycled, which helps the planet. Many builders now want green materials, and stainless steel is a good choice.

The market for stainless steel checkered plates is growing quickly. Experts think it will reach $4.10 billion by 2033, growing 6% each year. More people living in cities and new building projects make this happen. Stainless steel plates help cities build places that are strong, safe, and nice to look at.

Good quality is very important in building. Builders trust companies that have strong checks and real certificates. Companies like Xintongda follow strict rules and give real proof. Their plates pass outside tests and come in safe boxes. This helps builders know the plates will work well in every job, from tall buildings to bridges.

Stainless steel plates are also used in other jobs, like oil and gas, because they work well. In building, they do not rust, hold up heavy things, and stay looking clean. This makes them a smart choice for the future.

Austenitic stainless steel is the most used type in factories and buildings. It has a lot of chromium and nickel. These help it fight rust and stay strong in many places. Studies show it forms a solid mix that gives it strength and stops rust. Factories like it because it does not crack when welded. New austenitic stainless steel has less carbon. This helps stop rust after welding. It works well in food, chemical, and medicine factories. It can handle very hot or cold places. Many engineers pick it because it lasts long, is easy to clean, and welds well.

Austenitic stainless steel keeps its shape and strength for years. Its smooth surface makes cleaning easy, which is important in food factories and hospitals.

Factories use grades 304, 316, and 904L for different jobs. Each grade has special things that make it good for certain work. The table below shows some main properties:

| Property | 304 | 316L | 904L |

|---|---|---|---|

| Chromium (%) | 18-20 | 16-18 | 19-23 |

| Nickel (%) | 8-10.5 | 10-14 | 23-28 |

| Molybdenum (%) | — | 2-3 | 4-5 |

| Tensile Strength (MPa) | 515-620 | 485-620 | 490-690 |

| Yield Strength (MPa) | 205-275 | 170-310 | 220-450 |

| Corrosion Resistance | Good | Better | Best |

| Typical Use | Food, Home | Marine, Pharma | Chemical, Offshore |

Grade 304 is the most common stainless steel. It is used for kitchen tools, tanks, and pipes. Grade 316 has more nickel and molybdenum. This helps it fight rust in salty or chemical places. Factories use 316 for boat parts and medical tools. Grade 904L has even more nickel and molybdenum. It stands up to strong acids and harsh chemicals. Companies use 904L in chemical plants and oil rigs. This grade costs more but lasts longer in hard jobs.

Picking the right stainless steel grade depends on many things. Engineers check how well it fights rust first. For example, grade 316 is better in salty or chemical places. They also look at strength, bending, and toughness. Some jobs need steel that bends, others need it strong. How easy it is to weld and shape matters too. Low carbon grades help stop cracks when welding. Cost and how long it will last are also important. Many companies use ASTM rules to make sure the steel is good.

Rust resistance for the place it will be used

Strength and toughness

Needs for shaping and welding

Cost and how long it will last

Certification and what the customer wants

Tip: Always pick the stainless steel grade that fits the job. This helps machines last longer and work better.

Alloying elements are very important for how stainless steel fights rust. Different elements change how the metal acts in tough places. Some elements make the metal stronger, but others can make it weaker.

Carbon and nickel help stop rust in annealed austenitic stainless steels.

Nickel and silicon help cold-worked steels fight rust better.

Nitrogen makes annealed steels less able to stop rust.

Phosphorus and molybdenum make cold-worked steels weaker against rust.

Manganese, copper, chromium, sulfur, and aluminum do not change rust resistance much.

A new steel with 18% chromium, 18% nickel, 2% silicon, and 0.06% carbon, plus low phosphorus and molybdenum, fights rust better than old alloys.

Chromium and molybdenum are very important for stopping rust. Chromium makes a thin, strong layer called Cr2O3 on the steel’s surface. This layer keeps the metal safe from rust and helps stop bacteria from sticking. Molybdenum adds more safety, especially in places with acid or sulfides. Stainless steel with more chromium and molybdenum, like SS 316, rusts less even when bacteria are around. The mix of these elements makes the protective film stronger, which helps stop rust.

Thin film stainless steels made by ion beam sputtering fight rust even better. These films have a special structure with fewer weak spots. The alloying elements in these films change the protective layer and make the metal’s structure better. This helps the steel stop damage from harsh chemicals.

Tip: The right mix of alloying elements helps stainless steel fight rust, so it is great for hard jobs.

The place around stainless steel changes how well it stops rust. Things like acid, heat, and salt can change how the metal works. In factories, sensors watch how fast stainless steel plates rust in different places. For example, in hydrometallurgical plants, lots of sulfuric acid and heat up to 90 °C make rust happen faster. Stainless steel grade 316L rusts faster than grade 2507 in these tough places. The inside structure and what the steel is made of matter a lot.

Long tests outside show that wind, rain, wet air, and salt all change how well steel fights rust. At first, wind and rain matter most because they wash away the protective layer. Later, wet air and salt become more important. Salt can build up and cause more rust. Pollution like SO2 and NO2 does not matter much unless there is a lot.

| Environmental Factor | Effect on Corrosion Resistance |

|---|---|

| Acidic Media | Makes rust happen faster |

| High Temperature | Makes rust happen quicker |

| Chloride Ions | Causes rust and small holes |

| Rainfall | Washes away the protective layer |

| Humidity | Helps salt stick and cause rust |

| Pollution | Not much effect unless there is a lot |

Watching these things helps factories know how rust happens. By knowing the place, engineers can pick the best stainless steel for each job.

Note: The environment can change fast, so checking often helps stainless steel plates last longer.

Getting stainless steel plates from trusted suppliers is very important. Companies want suppliers with good certifications. These show the supplier follows high rules for quality. The Norsok M-650 certificate is needed in oil and gas jobs. It proves the supplier can give plates that work in hard places. NADCAP is another big certification. It checks if suppliers follow strict rules for making metal parts. Suppliers with NADCAP often have better products and fewer mistakes. Many companies pick certified suppliers because they trust the products.

Good suppliers help projects finish on time.

Certifications mean workers are skilled and systems are strong.

Certified suppliers can fill big orders and deliver fast.

Quality checks start before making the plates. Suppliers look at raw materials to make sure they are right. They check for damage or dirt when materials come in. Tools like calipers and micrometers get checked often to keep them correct. Workers check equipment every day to find problems early. Special tests look inside welds to find hidden issues. Leak and pressure tests make sure plates work in real life. Size checks make sure plates fit the design. First Article Inspection reports show the first batch is good. Third-party inspectors help check everything is right.

Metallurgical tests check what metals are in the plate.

Hardness and tension tests show how strong the plates are.

Certificates of Conformance prove the plates meet standards.

Third-party checks help find problems before shipping.

Xintongda does full quality checks and lets third parties inspect. This helps customers feel sure about their order.

Good packaging keeps plates safe when shipped. Companies use strong boxes and straps to stop plates from moving. Some use wooden boxes or bags for extra safety. Tracking systems watch the plates as they travel. This helps customers know their order is safe. Regular checks and clear rules help keep packaging good. Special tests, like ultrasound or vacuum checks, make sure the packaging is sealed tight. These steps help stop damage or dirt.

Strong packaging keeps plates safe from bumps and weather.

Worker training helps stop packing mistakes.

Real-time tracking lets customers see their shipment.

Xintongda uses careful packing to send plates safely everywhere. This focus on safety and quality helps customers trust their orders will arrive in great shape.

Stainless steel plates are special for factories because they are very strong and do not rust. They last a long time, even in hard jobs. Engineers use these plates when they need something tough. Picking the right grade and a trusted supplier helps get the best results.

Stainless steel plates are dependable and worth the money.

Certified suppliers like Xintongda make sure you get good quality.

Think about using high-quality, certified stainless steel plates for your next project. This will help your machines work well for a long time and help you worry less.

Stainless steel plates do not rust or corrode. Chromium makes a shield on the plates. This shield keeps them strong in wet or salty places. It also works in places with chemicals. Many companies use stainless steel because it lasts a long time.

Stainless steel plates have smooth surfaces. Workers can clean them fast. Bacteria and dirt cannot stick to the plates. Food factories use these plates to keep food safe. They help meet health rules.

Yes, they can. Stainless steel plates stay strong in heat. They do not bend or break when hot. Power plants and factories use them in boilers and furnaces.

Engineers like stainless steel because it lasts longer. It does not rust like carbon steel does. Stainless steel needs less fixing. This helps save money over time.

Factories can recycle stainless steel plates many times. Recycling uses less energy and makes less waste. This is good for companies that care about the earth.

Buyers should look for certificates like Norsok M-650 or ISO 9001. These show the supplier follows strict quality rules. Certified plates work well in hard jobs.

The pharmaceutical industry uses stainless steel plates in clean rooms. They also use them in equipment. These plates help keep medicine pure. Their smooth surface stops germs and makes cleaning easy.

Suppliers pack plates in strong boxes or bags. This stops scratches and dents. Tracking systems let customers see where their order is until it arrives.