close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-12 Origin: Site

You will find that 2 inch stainless steel pipe follows strict specifications for dimensions, wall thickness, and weight, set by standards like ASME B36.19 and ASTM A312. Understanding these details helps you select the right pipe for your project, ensuring safety and durability. Many industries, from chemical processing to HVAC and plumbing, rely on stainless steel pipes because of their corrosion resistance and strength. As you work with pipes, knowing these standards supports better decision-making and project success.

A 2 inch stainless steel pipe has a fixed outside diameter of 2.375 inches, but wall thickness varies by schedule, affecting strength and weight.

Pipe schedules like 5S, 10S, 40S, and 80S indicate wall thickness; higher schedules mean thicker walls and higher pressure capacity.

Common stainless steel grades include 304, 304L, 316, and 316L, each offering different corrosion resistance and weldability.

Seamless pipes provide higher strength and pressure resistance, ideal for critical systems; welded pipes are cost-effective for general use.

Standards such as ASTM A312, ASME SA312, and ASME B36.19 ensure pipe quality, dimensions, and safety for reliable performance.

Always verify pipe schedule, material grade, length, and finish when specifying or ordering to avoid costly mistakes.

2 inch stainless steel pipes serve many industries like oil and gas, food processing, construction, and pharmaceuticals due to their durability and corrosion resistance.

Following proper standards and testing protects your system from leaks and failures, ensuring safety and long-term reliability.

When you select a 2 inch stainless steel pipe, you need to know the exact dimensions. The standard outside diameter for this pipe size is 2.375 inches (60.32 mm), as defined by ASME B36.19. This outside diameter stays the same, no matter which wall thickness or schedule you choose. You will find both seamless and welded forms available, with common grades including 304, 304L, 316, and 316L. These grades offer excellent corrosion resistance and strength for many applications.

Tip: Always check the outside diameter and wall thickness before ordering. Even a small difference can affect how pipes fit together.

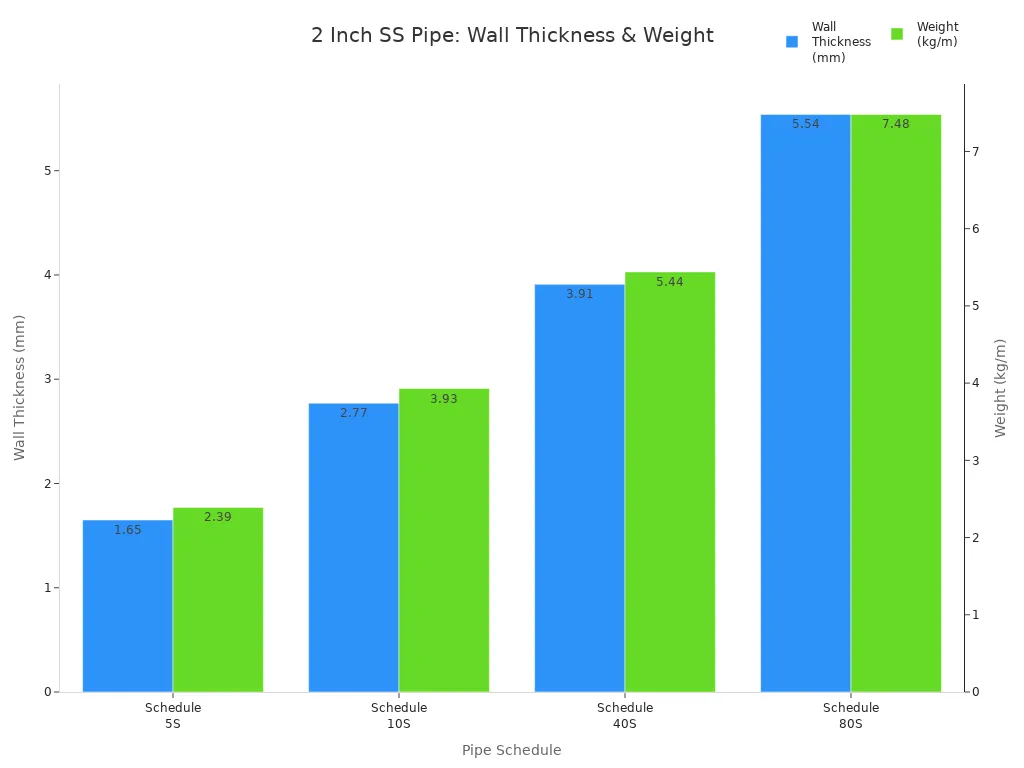

Here is a table showing the standard 2 inch stainless steel pipe dimensions and weights according to ASME B36.19:

Parameter | Value for 2 inch Stainless Steel Pipe (ASME B36.19) |

|---|---|

Outside Diameter (O.D.) | 60.32 mm (2.375 inches) |

Wall Thickness (Schedule 5S) | 1.65 mm (0.065 inches) |

Wall Thickness (Schedule 10S) | 2.77 mm (0.109 inches) |

Wall Thickness (Schedule 40S) | 3.91 mm (0.154 inches) |

Wall Thickness (Schedule 80S) | 5.54 mm (0.218 inches) |

Weight (Schedule 5S) | 2.39 kg/m |

Weight (Schedule 10S) | 3.93 kg/m |

Weight (Schedule 40S) | 5.44 kg/m |

Weight (Schedule 80S) | 7.48 kg/m |

You can see that the outside diameter remains constant, while the wall thickness and weights change with the schedule.

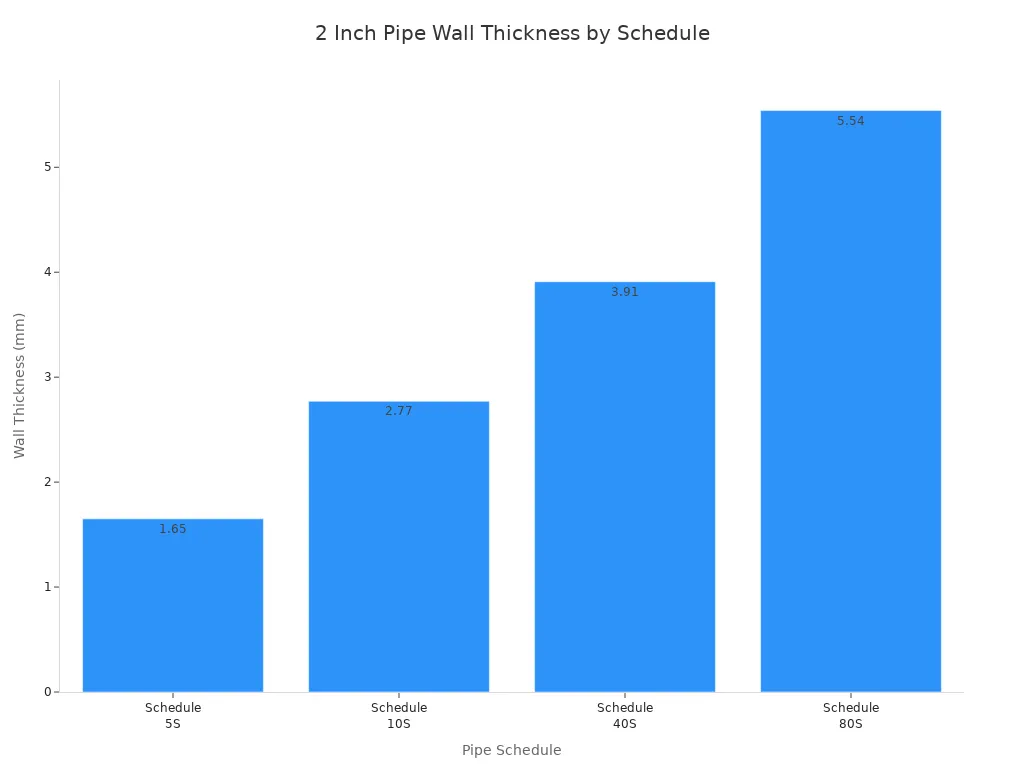

The wall thickness of a 2 inch stainless steel pipe depends on its schedule. The schedule number tells you how thick the pipe wall is. Higher schedule numbers mean thicker walls and higher pressure ratings. For example, Schedule 5S has a wall thickness of 0.065 inches, while Schedule 80S has a wall thickness of 0.218 inches. These differences affect both the strength and the weights of the pipes.

You will often see pipes labeled as Standard (STD), Extra Strong (XS), or Double Extra Strong (XXS). These labels match up with certain schedule numbers. For 2 inch stainless steel pipes, the most common schedules are 5S, 10S, 40S, and 80S. The ASME and ASTM standards make sure these dimensions and weights stay consistent for safety and compatibility.

Note: The schedule you choose should match the pressure and mechanical requirements of your project.

The weights of 2 inch stainless steel pipes change with wall thickness and schedule. For example, a Schedule 40S pipe weighs about 5.44 kg per meter (or 3.66 lbs per foot). The table below shows typical dimensions and weights for a 2 inch stainless steel pipe:

Nominal Size | Outside Diameter (OD) | Wall Thickness (WT) | Inside Diameter (ID) | Weight (lbs per foot) |

|---|---|---|---|---|

2 inches | 2.375 inches | 0.154 inches | 2.067 inches | 3.66 |

You can buy these pipes in standard lengths, such as 10 feet or 20 feet. Some suppliers offer custom lengths to fit your needs. The weights and dimensions help you plan for handling, installation, and support.

Tip: Always confirm the length and weight before placing your order. This ensures the pipe will fit your project and meet safety standards.

When you compare different stainless steel pipe dimensions and weights, you can make better choices for your application. The ASME standards help you find the right pipe for your needs, whether you work in construction, manufacturing, or plumbing.

When you look at a stainless steel pipe size, you might expect the number to match the actual diameter. In reality, the nominal pipe size is a dimensionless label that helps you identify and order pipes, but it does not equal the true outside diameter. For example, a 2 inch nominal pipe size actually has an outside diameter of 2.375 inches. This difference comes from standards like ASME B36.19 and ASME B36.10, which set the rules for how pipes are labeled and measured. The outside diameter is the real measurement from one edge of the pipe to the other, which matters for fitting and installation. The inside diameter changes depending on the wall thickness, but the outside diameter stays the same for each nominal pipe size. Outside North America, you may see pipes labeled with DN (Diametre Nominal), which is also a dimensionless number based on the outside diameter in millimeters.

Note: Always check both the nominal pipe size and the actual outside diameter before you order or install pipes. This helps you avoid costly mistakes.

The schedule of a pipe tells you how thick the wall is. You will see numbers like Schedule 10S, 40S, or 80S. These numbers do not have units. A higher schedule means a thicker wall. The schedule affects the inside diameter, but the outside diameter stays fixed for each nominal pipe size. The wall thickness is important because it changes how much pressure the pipe can handle. For example, a 2 inch Schedule 40S pipe has a thicker wall than a Schedule 10S pipe, so it can hold more pressure. The schedule number comes from a formula that uses the internal pressure and the strength of the pipe material. For stainless steel pipe, the schedule helps you match the pipe to your project's needs for strength and safety.

Schedule | Wall Thickness (inches) | Pressure Rating (approx.) |

|---|---|---|

10S | 0.109 | Lower |

40S | 0.154 | Medium |

80S | 0.218 | Higher |

Tip: Choose the right schedule based on the pressure and mechanical demands of your system.

You will find two main types of pipes: seamless and welded. Each type has its own strengths and best uses.

Seamless pipes have no weld seam. Manufacturers make them by extruding or piercing a solid billet. This gives seamless pipes uniform strength and higher pressure ratings. You should use seamless pipes for high-pressure steam, oil and gas, or chemical processing.

Welded pipes are made by rolling and welding steel strips or plates. They have a weld seam, which can be a weak point, but modern welding methods make them strong and reliable. Welded pipes cost less, come in larger sizes, and work well for water distribution, building supports, and general construction.

Seamless pipes offer better pressure resistance and longer corrosion life. They cost more and take longer to produce. Welded pipes are more affordable and available quickly, but you need to inspect the weld seam for quality.

Choose seamless pipes when you need top performance and safety. Pick welded pipes when you want cost savings and size options.

Alert: For critical systems with high pressure or safety needs, seamless pipes are the best choice. For most building or low-pressure uses, welded pipes offer a good balance of cost and performance.

You will often see ASTM A312 and ASME SA312 listed as the main standards for 2 inch stainless steel pipes. These standards set the requirements for seamless and welded austenitic stainless steel pipes. ASTM A312 comes from ASTM International, while ASME SA312 is part of the ASME Boiler and Pressure Vessel Code. Both standards cover similar material grades, such as 304, 304L, 316, and 316L. These grades offer excellent corrosion resistance and mechanical strength.

ASTM A312 and ASME SA312 require strict testing and quality control. You will find that both standards call for mechanical tests, such as tensile and flattening tests, as well as hydrostatic pressure tests. These tests make sure the pipe can handle high pressure and harsh environments. The standards also specify chemical composition, heat treatment, and dimensional tolerances. For example, the outside diameter tolerance for a 2 inch pipe is ±1/32 inch. Both standards allow for seamless and welded manufacturing methods, including hot rolling, cold drawing, and welding.

Here is a summary of the key requirements for ASTM A312 and ASME SA312:

Aspect | Details |

|---|---|

Pipe Size Range | 1/8 inch to 30 inches diameter, including 2 inch nominal pipe size (NPS 2) |

Manufacturing | Seamless and welded austenitic stainless steel pipes |

Material Grades | TP304, TP304L, TP316, TP316L |

Mechanical Properties | Tensile strength: 70-80 ksi; Yield strength: 25-35 ksi |

Chemical Composition | Carbon, Silicon, Manganese, Chromium, Nickel, Molybdenum, Sulfur, Phosphorous |

Dimensional Tolerances | OD tolerance for 2 inch pipe: ±1/32 inch |

Wall Thickness | SCH 5S (1.65 mm), SCH 10S (2.77 mm), SCH 40S (3.91 mm), SCH 80S (5.54 mm) |

Heat Treatment | Required post-welding |

Testing | Mechanical, hydrostatic, intergranular corrosion, weld decay, radiographic (optional) |

Note: ASTM A312 is widely used in general industry, while ASME SA312 is essential for pressure vessels and high-temperature piping. Both standards ensure your pipe meets strict safety and reliability requirements.

ASME B36.19 is the main dimension standard for stainless steel pipes. This standard defines the outside diameter and wall thickness for each nominal pipe size, including 2 inch pipes. ASME B36.19 specifies thinner wall thicknesses for stainless steel pipes compared to carbon steel pipes of the same size. This difference means manufacturers must control dimensions very carefully to maintain strength and corrosion resistance.

You will see that ASME B36.19 ensures all pipes have uniform dimensions. This uniformity allows you to use pipes from different manufacturers without worrying about fit or compatibility. The standard also supports the use of pipes in demanding environments, such as chemical plants, food processing, and high-temperature systems.

Here is a table showing the main dimension standards for 2 inch stainless steel pipes under ASME B36.19:

Parameter | Value (2 inch Stainless Steel Pipe) |

|---|---|

Nominal Pipe Size (NPS) | 2 inch |

Outside Diameter (OD) | 60.3 mm (2.375 inches) |

Wall Thickness (Schedule 5S) | 1.65 mm |

Wall Thickness (Schedule 10S) | 2.77 mm |

Wall Thickness (Schedule 40S) | 3.91 mm |

Wall Thickness (Schedule 80S) | 5.54 mm |

Tip: Always check ASME B36.19 when you need to confirm the exact dimensions of your pipe. This standard helps you avoid costly mistakes and ensures your system meets ANSI and American National Standards requirements.

When you need fittings for your 2 inch stainless steel pipe, ASTM A403 is the standard you should follow. This standard covers forged and rolled austenitic stainless steel fittings, such as elbows, tees, reducers, and caps. ASTM A403 applies to both seamless and welded fittings, but not to cast fittings.

Key points of ASTM A403 include:

Covers sizes from 1/2 inch to 48 inch, including 2 inch pipe fittings.

Specifies common grades like WP304/L and WP316/L.

Requires fittings to be seamless or welded, with no harmful defects.

Manufacturing methods include forging, rolling, extrusion, welding, machining, and forming.

All fittings must be heat treated for strength and corrosion resistance.

Chemical composition must match the grade requirements, verified by testing.

Tensile properties must meet ASTM A370 standards.

Surface finish must be free of deep cracks or flaws.

Repairs by welding are limited; major defects must be removed by other methods.

Marking and testing ensure traceability and quality.

Alert: ASTM A403 fittings help you maintain the same high standards as your pipe. Always use fittings that meet this standard to ensure safety, durability, and compliance with ANSI and American National Standards.

When you work with 2 inch stainless steel pipes outside North America, you often encounter EN and other international standards. These standards help you ensure that pipes meet the right quality, safety, and compatibility requirements in different regions. EN standards, such as EN 10216-2 and EN 10217-5, set the rules for both seamless and welded stainless steel pipes. You may also see British Standard BS 3605, German DIN, and Swedish SIS standards used in Europe and other parts of the world.

You will notice that EN and international standards align closely with ASTM and ASME standards. For example, EN standards specify material grades like 304, 316, and 321, which match the grades you find in ASTM A312 and ASME SA312. This alignment makes it easier for you to source pipes and fittings that work across different markets.

Here is a table comparing the main standards for 2 inch stainless steel pipes:

Standard Type | EN/International Standards | ASTM/ASME Standards | Notes |

|---|---|---|---|

Stainless Steel Pipes | BS 3605, EN 10216-2, EN 10217-5, DIN, SIS | ASTM A312 (seamless and welded) | EN and ASTM/ASME standards use similar grades and applications |

Dimensions and Schedules | EN standards specify dimensions | ASME B36.10, ASME B36.19 | ASME standards often harmonize with ASTM and are recognized by ANSI |

Material Specifications | EN grades match ASTM grades | ASTM A312, ASME SA312 | Both cover high-temperature and corrosive service |

Regional Variations | Some regional differences exist | ASTM/ASME widely used in North America | ASME standards are adopted by ANSI and used globally |

You should know that ASME material specifications are developed mainly for pressurized equipment, such as boilers and piping systems. These standards are adopted by law in the US and Canada. ANSI recognizes and supports these standards, making them the legal basis for many projects. ASME often adopts ASTM specifications with only minor changes. For example, ASME SA-312 is almost identical to ASTM A312, with a few technical clarifications. This close relationship ensures that your 2 inch stainless steel pipes meet both safety and legal requirements.

When you select pipes for international projects, always check which standards apply in your region. ANSI standards are common in North America, while EN and other international standards may be required in Europe or Asia. You can often find products that meet both sets of standards, making it easier to ensure compatibility and compliance.

Tip: Always confirm the required standard—EN, ASTM, ASME, or ANSI—before ordering. This step helps you avoid costly mistakes and ensures your piping system meets all local and international requirements.

When you choose a schedule 40 stainless steel pipe, you get a product known for its balance of strength and versatility. The wall thickness for a 2 inch schedule 40 stainless steel pipe is 0.154 inches (3.91 mm). This thickness gives the pipe the ability to handle moderate to high pressure in many systems. The outside diameter stays at 2.375 inches (60.3 mm), which matches the standard schedule 40 stainless steel pipes dimension.

The pressure rating for a 2 inch schedule 40 stainless steel pipe can reach up to 3,177 psi (21,905 kPa). This high rating comes from the combination of wall thickness and the strength of stainless steel. You can see how the wall thickness and pressure rating relate in the table below:

Pipe Size (NPS) | Outside Diameter | Wall Thickness | Schedule 40 Pressure Rating (psi) |

|---|---|---|---|

2 inch | 2.375 inch | 0.154 inch | 3,177 |

Tip: Thicker walls mean higher pressure capacity. If your system needs to handle more pressure, always check the schedule 40 stainless steel pipes dimension and wall thickness before installation.

The formula for pressure rating, known as Barlow’s formula, shows that increasing wall thickness boosts the pipe’s pressure capacity. For example, if you use a thicker wall, the pipe can safely carry more pressure. This is why schedule 40 stainless steel pipe is a popular choice for many demanding applications.

You will find schedule 40 stainless steel pipes in a wide range of industries. Their strength, corrosion resistance, and reliable schedule 40 stainless steel pipes dimension make them a top pick for both industrial and commercial projects. Here are some of the most common uses:

Industry / Application | Usage Details and Characteristics |

|---|---|

Oil and Gas Industry | Used in flow lines and wellhead piping; withstands pressures up to 2,000 psi. |

Construction Industry | Provides structural support and scaffolding; strong enough for bridges and high-rise buildings. |

Automotive Industry | Used in fuel lines and exhaust systems; resists heat and corrosion. |

Plumbing Systems | Common in drainage and main water lines; offers leak-proof joints for homes and businesses. |

Chemical Industry | Handles reactor systems and process piping; thick walls prevent leaks with harsh chemicals. |

Fire Sprinkler Systems | Makes up most main branch lines and risers; heat resistant and strong for safety systems. |

You can also use schedule 40 stainless steel pipe in food, beverage, and pharmaceutical plants. The pipe’s smooth surface and non-contaminating properties make it safe for sensitive products. In residential and commercial plumbing, schedule 40 stainless steel pipes provide long-lasting, leak-free service.

Note: Schedule 40 stainless steel pipes offer a great balance between wall thickness, strength, and cost. You get durability and safety for moderate pressure and temperature systems.

If you need a pipe that can handle tough jobs and last for years, schedule 40 stainless steel pipe is a smart choice. Always check the schedule 40 stainless steel pipes dimension to make sure it fits your project’s needs.

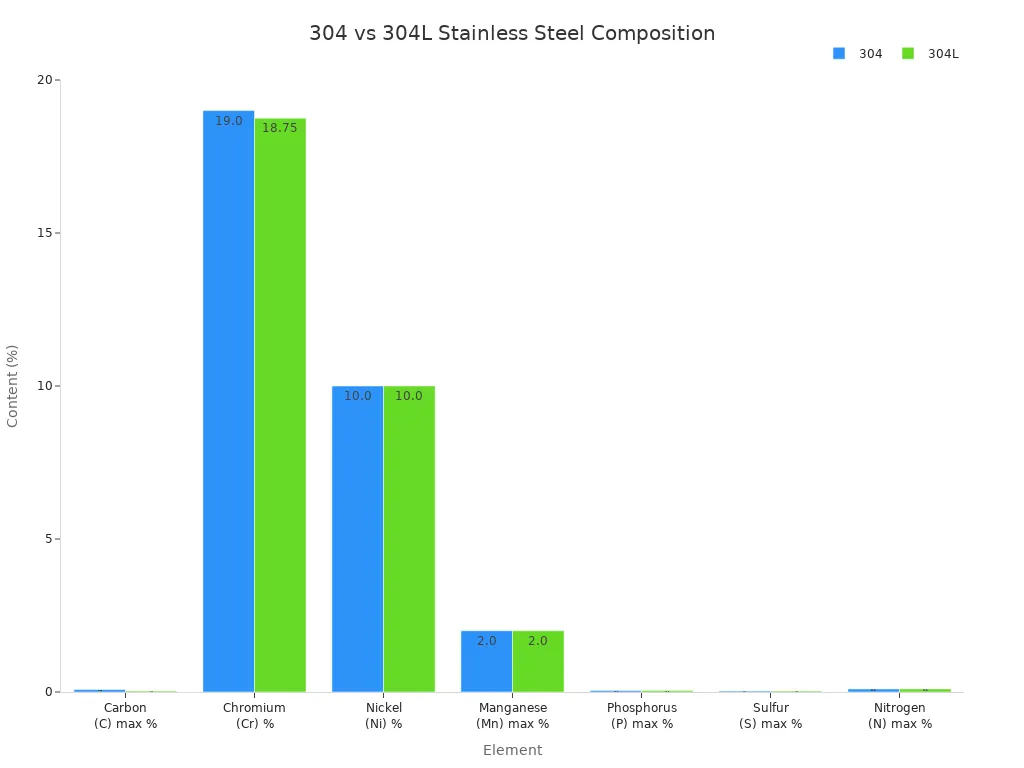

You will often see 304 and 304L grades used for stainless steel pipes. These grades belong to the austenitic family, which means they have high chromium and nickel content. 304 is the most common grade for general-purpose pipes. It offers good corrosion resistance, strength, and weldability. 304L is a low-carbon version of 304. The lower carbon content in 304L reduces the risk of carbide precipitation during welding. This makes 304L a better choice when you need to weld pipes or use them in environments where corrosion from welding could be a problem.

Here is a table that compares the chemical and mechanical properties of 304 and 304L stainless steel:

Property/Element | 304 Stainless Steel | 304L Stainless Steel |

|---|---|---|

Carbon (C) max % | 0.08 | 0.03 |

Chromium (Cr) % | 18.0 - 20.0 | 17.5 - 20.0 |

Nickel (Ni) % | 8.0 - 12.0 | 8.0 - 12.0 |

Tensile Strength (MPa) | ~515 | ~485 |

Yield Strength (MPa) | ~205 | ~170 |

Elongation (%) | 40 - 45 | 35 - 40 |

You can see that 304L has less carbon, which improves weldability and resistance to intergranular corrosion. 304 has slightly higher strength, but 304L is more stable after welding.

If you need pipes for harsh or corrosive environments, you should consider 316 or 316L stainless steel. These grades contain molybdenum, which gives them better resistance to chlorides and pitting corrosion. 316 is often used in marine, chemical, and food processing industries. 316L, like 304L, has a lower carbon content. This makes it even more resistant to corrosion after welding.

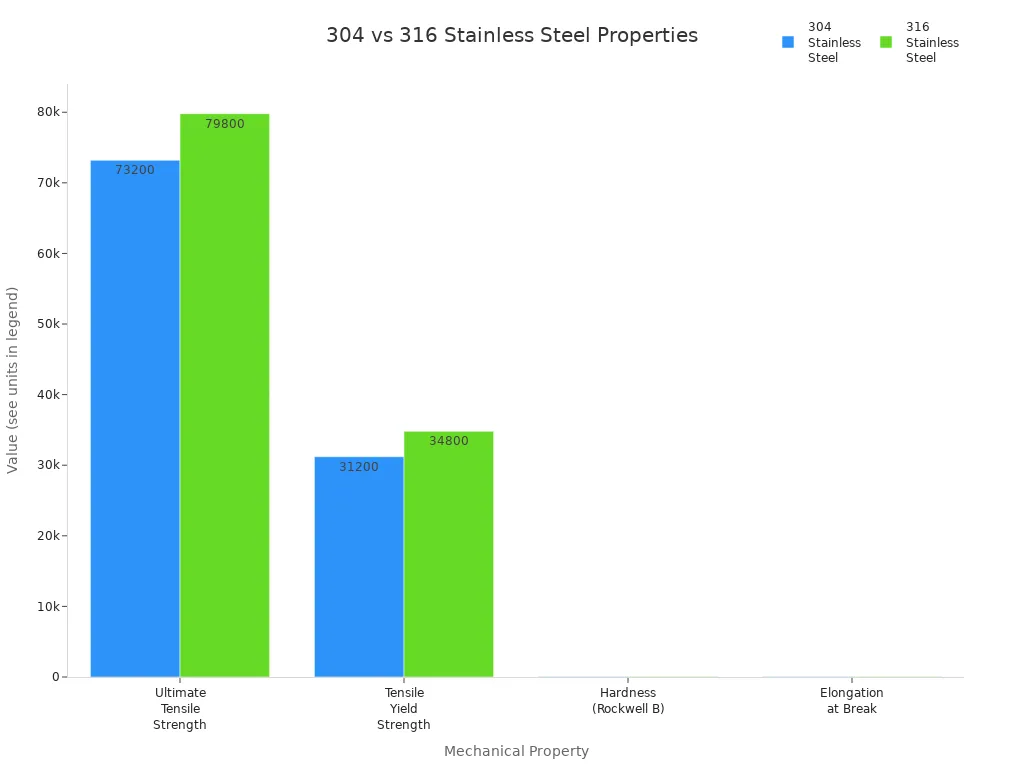

Here is a table comparing 304 and 316 stainless steel:

Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

Ultimate Tensile Strength | ~73,200 psi | ~79,800 psi |

Tensile Yield Strength | ~31,200 psi | ~34,800 psi |

Hardness (Rockwell B) | 70 | 80 |

Elongation at Break | 70% | 60% |

316 and 316L pipes are stronger and more durable in environments with saltwater or chemicals. The addition of molybdenum is the key difference. 316L, with its lower carbon, is ideal for welded pipes in corrosive settings.

Tip: Use 316 or 316L pipes when you need extra protection against corrosion, especially in marine or chemical plants.

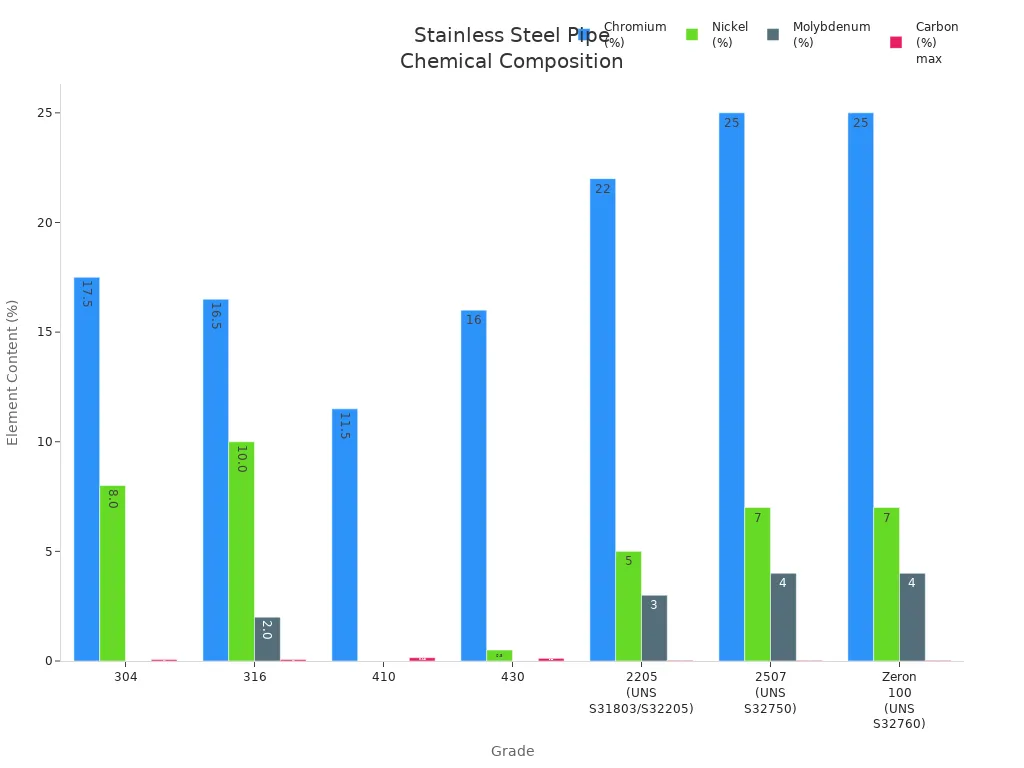

You will find that stainless steel pipes come in many grades, each with its own chemical makeup. The main elements are chromium and nickel. Some grades, like 316, also include molybdenum for added corrosion resistance. Here is a table showing the typical chemical composition for common pipe grades:

Grade | Chromium (%) | Nickel (%) | Molybdenum (%) | Carbon (%) max |

|---|---|---|---|---|

304 | 17.5 - 19.5 | 8.0 - 10.5 | N/A | 0.07 |

316 | 16.5 - 18.5 | 10.0 - 13.0 | 2.0 - 2.5 | 0.07 |

410 | 11.5 - 13.5 | N/A | N/A | 0.15 - 0.30 |

430 | 16 - 18 | 0.5 | N/A | 0.12 |

2205 (UNS S31803/S32205) | 22 - 23 | 5 - 6 | 3 | 0.03 |

2507 (UNS S32750) | 25 | 7 | 4 | 0.03 |

Zeron 100 (UNS S32760) | >25 | >7 | >4 | 0.03 |

You should choose the grade that matches your needs for corrosion resistance, strength, and weldability. The right choice will help your pipes last longer and perform better in your system.

Austenitic stainless steel stands out because of its unique crystal structure. You will find that this structure is called face-centered cubic, or austenite. Nickel and chromium stabilize this structure. Most austenitic stainless steels contain 8% to 12% nickel and 16% to 26% chromium. Manganese and nitrogen also help stabilize the austenite phase. This combination gives you a metal that is non-magnetic in its annealed state. You cannot harden it by heat treatment, but you get high toughness and ductility.

You will notice that austenitic stainless steel resists corrosion very well. It also has excellent weldability, which means you can join pipes easily without losing strength. The most common grades belong to the 300 series. Type 304, for example, contains about 18% chromium and 8% nickel. Type 316 adds molybdenum, which improves resistance to harsh chemicals and saltwater. More than half of all stainless steel pipes produced worldwide use type 304. This fact shows that austenitic grades make up the majority of stainless steel pipe production.

Tip: If you need a pipe that can handle tough environments and last for years, austenitic stainless steel is often your best choice.

You will see austenitic stainless steel pipes in many industries. These grades offer several advantages that make them the top pick for 2 inch pipe applications:

High chromium and nickel content gives you strong resistance to corrosion and oxidation.

You can use these pipes in oil and gas, chemical, power, food and beverage, marine, and pharmaceutical industries.

They provide strength and durability, so your pipes can handle high pressures and corrosive substances.

The material is non-toxic and easy to clean, which is important for hygienic uses.

Their versatility and ability to resist harsh environments make them ideal for many sectors.

Here is a table that highlights the key characteristics of popular austenitic stainless steel grades for 2 inch pipes:

Stainless Steel Grade | Key Characteristics Relevant to 2 inch Pipe Applications |

|---|---|

304 | Excellent corrosion resistance, ductility, mechanical strength; suitable for general use but less resistant to chlorides. |

316 | Enhanced corrosion resistance due to molybdenum; ideal for chloride-rich and harsh chemical environments. |

321 | Titanium-stabilized for high-temperature stability and resistance to intergranular corrosion, useful in elevated temperature piping. |

304L / 316L | Low carbon variants reduce sensitization during welding, improving durability in welded pipe assemblies. |

316LVM | Variant used in pharmaceutical and hygienic applications for high purity and corrosion resistance. |

You benefit from several important properties when you choose austenitic stainless steel pipes:

Property / Application Aspect | Explanation / Relevance to Austenitic Stainless Steel Pipes (e.g., 304, 316) |

|---|---|

Corrosion Resistance | High chromium and nickel content provide superior resistance to oxidation, chemical exposure, and chloride-induced corrosion, essential for durability in various environments. |

Mechanical Strength and Ductility | Maintains strength and flexibility across temperature ranges, suitable for pressure piping including 2 inch pipes. |

Weldability | Good weldability supports fabrication and installation in piping systems. |

Hygienic Surface Finish | Smooth finish prevents bacterial growth, ideal for food, beverage, and pharmaceutical industries requiring sanitary conditions. |

Chemical Resistance | Effective against acidic and chloride-rich media, ensuring safety and longevity in harsh chemical environments. |

Industry Standards Compliance | Properties ensure pipes meet durability, safety, and regulatory requirements for industrial applications. |

Note: You can rely on austenitic stainless steel pipes for both performance and safety. Their widespread use in 2 inch pipe applications comes from their unmatched combination of strength, corrosion resistance, and versatility.

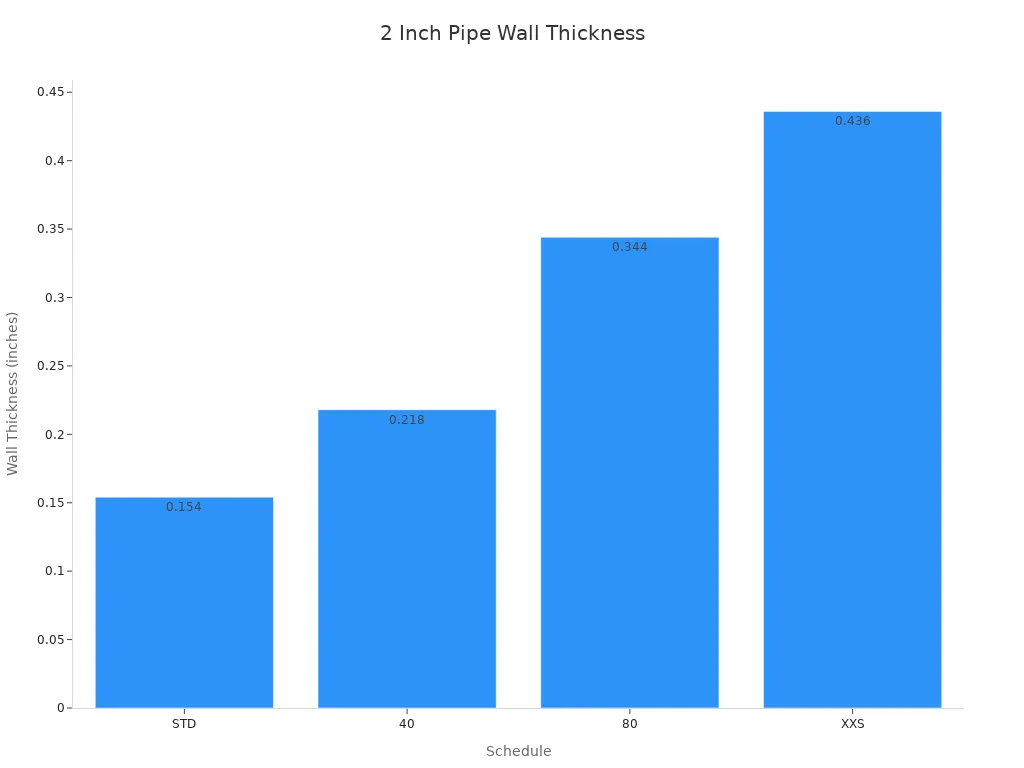

When you select a 2 inch stainless steel pipe, you need to understand the exact stainless steel pipe dimensions and weights. These values help you plan your project, estimate support needs, and ensure safety. You can find these numbers in a stainless steel pipe dimension chart, which shows the standard outside diameter, wall thickness, and weights for each schedule.

The outside diameter for a 2 inch pipe always measures 2.375 inches. The wall thickness changes with the schedule. As the wall gets thicker, the pipe becomes heavier and can handle more pressure. You will see these values in the table below, which follows ASME B36.19 standards and matches what you find in Engineering ToolBox data tables.

Schedule | Wall Thickness (inches) | Weight (lbs/ft) | Weight (kg/m) |

|---|---|---|---|

STD | 0.154 | 3.66 | 5.44 |

40 | 0.218 | 5.02 | 7.47 |

80 | 0.344 | 7.28 | 10.84 |

XXS | 0.436 | 8.97 | 13.36 |

Tip: Use this stainless steel pipe dimension chart to compare different schedules. You can quickly see how the wall thickness and weights change as you move from STD to XXS.

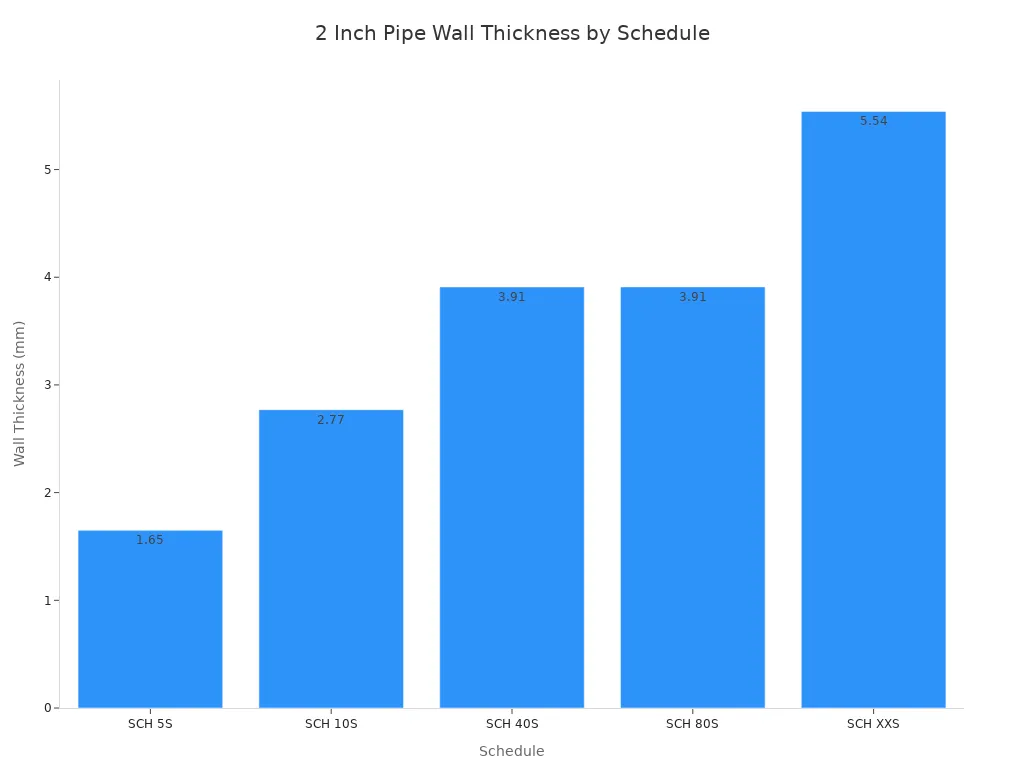

You can also visualize the differences in wall thickness using the chart below. This bar chart shows how each schedule increases the wall thickness for a 2 inch pipe.

You should always check both the dimensions and weights before you order or install pipes. The right choice depends on your system’s pressure, flow, and support requirements. If you need a pipe that can handle higher pressure, pick a schedule with a thicker wall and higher weights. If your project needs lighter pipes, choose a lower schedule.

A stainless steel pipe dimension chart gives you a quick way to compare options. You can use these tables to plan for shipping, installation, and long-term maintenance. Many engineers and buyers rely on these charts to avoid mistakes and ensure their systems meet safety codes.

️ Note: Always use the latest stainless steel pipe dimension chart from trusted sources. This step helps you avoid costly errors and keeps your project on track.

When you specify a 2 inch stainless steel pipe, you need to understand how standards and schedules work together. The nominal pipe size, or NPS, tells you the general size, but the schedule number shows the wall thickness. For stainless steel pipes, you will see schedules like 5S, 10S, 40S, and 80S. The "S" means the schedule is for stainless steel, which often has different wall thicknesses than carbon steel pipes.

You should always check the schedule because it affects the pipe’s strength, pressure rating, and internal diameter. For example, a Schedule 40S pipe has a wall thickness of about 3.91 mm, while Schedule 80S is thicker at 5.54 mm. The outside diameter stays the same, but the inside diameter gets smaller as the wall gets thicker. This change increases the pipe’s weight and pressure resistance.

You also need to look at the standards that define these sizes and schedules. ASME B36.19M is the main standard for stainless steel pipes. It lists the nominal sizes, outside diameters, and wall thicknesses. When you read a specification, you will see the schedule and the standard together. This combination helps you pick a pipe that meets your needs for pressure, temperature, and corrosion resistance.

Tip: Always consider the operating pressure, temperature, and environment before choosing a schedule. Thicker walls mean higher pressure capacity, but also more weight and cost.

You should also pay attention to pipe lengths. Pipes come in Single Random Length (SRL), Double Random Length (DRL), or Cut-to-Length (CTL). These options affect how many joints you need and how much material you use.

When you write or read technical documents, you will see a standard format for specifying stainless steel pipes. This format helps everyone understand exactly what pipe you need. You should include the following details:

Nominal pipe size (NPS)

Schedule number (with "S" for stainless steel)

Material grade (such as 304, 304L, 316, or 316L)

Applicable standard (like ASTM A312 or ASME SA312)

Surface finish (if needed, such as 2B or 1D)

Pipe length (SRL, DRL, or CTL)

Here are some common ways to specify a 2 inch stainless steel pipe:

2" NPS, Schedule 40S, ASTM A312, TP304, SRL

2" NPS, Schedule 10S, ASME SA312, TP316L, DRL, 2B finish

You may also see specifications written in a table for clarity:

Parameter | Example Value |

|---|---|

Nominal Size | 2 inch NPS |

Schedule | 40S |

Standard | ASTM A312 |

TP304 | |

Length | Single Random Length |

Surface Finish | 2B |

️ Note: Always double-check each part of your specification. Clear and complete details help avoid mistakes during ordering and installation.

By following these steps, you make sure your 2 inch stainless steel pipe meets all project and safety requirements.

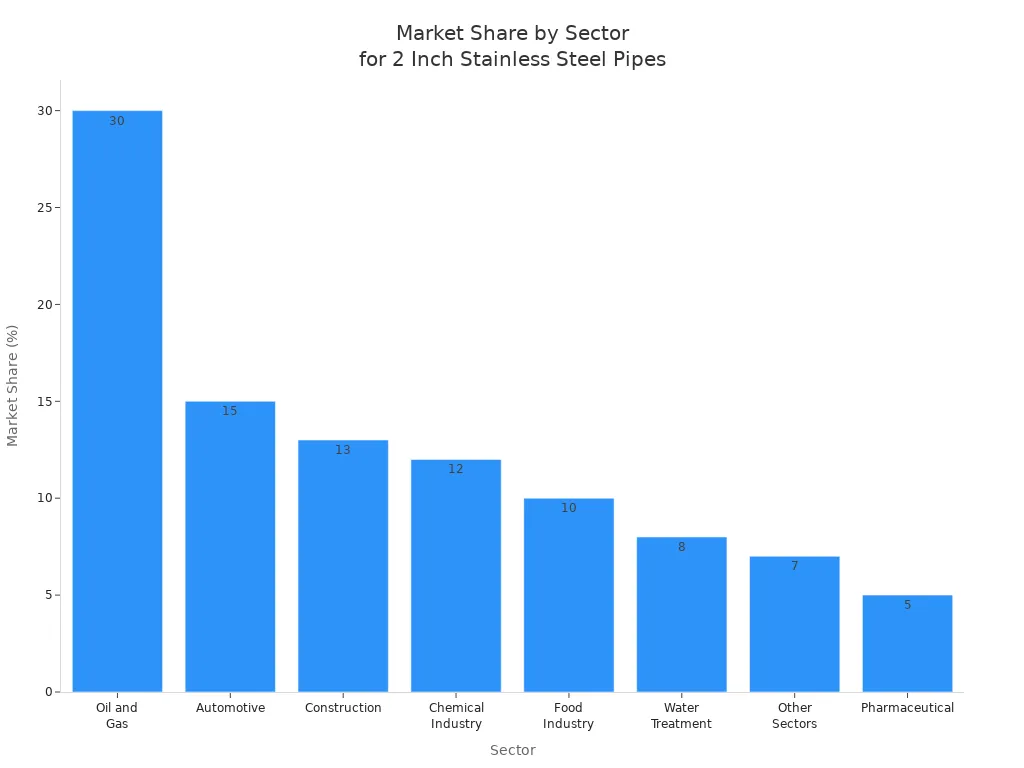

You will see 2 inch pipes used in many industries because they offer strength, corrosion resistance, and long service life. These pipes play a key role in oil and gas, construction, automotive, food processing, and water treatment. In the oil and gas sector, you use pipes to move oil, gas, and chemicals under high pressure. Their resistance to rust and corrosion makes them ideal for pipelines, refineries, and offshore platforms.

In the food industry, you rely on pipes for hygienic transport of liquids like milk and juice. These pipes do not react with food, so they keep products safe and pure. Automotive companies use pipes for exhaust systems, fuel lines, and structural parts. The high strength and heat resistance help vehicles run safely and efficiently.

Construction projects use pipes for plumbing, heating, air conditioning, and structural support. The durability and corrosion resistance mean buildings last longer and need less maintenance. Water treatment plants use pipes to carry water and chemicals, even in harsh conditions. Pharmaceutical companies choose these pipes for sterile environments, where purity and cleanliness matter most.

Here is a table that shows how different sectors use 2 inch pipes:

Sector | Market Share (%) | Key Uses and Characteristics |

|---|---|---|

Oil and Gas | ~30% | Transporting oil, gas, fluids under high pressure; corrosion resistance; used in pipelines, refineries, offshore platforms |

Food Industry | ~10% | Non-reactive pipes for hygienic transport of liquids (milk, juices); used in pasteurizers and heat exchangers |

Automotive | ~15% | Exhaust systems, fuel lines, structural components; high strength and heat resistance |

Chemical Industry | ~12% | Transporting chemicals and corrosive fluids; resistance to chemical attack and high temperatures |

Construction | ~13% | Plumbing, heating, air conditioning, structural reinforcement; durability and corrosion resistance |

Water Treatment | ~8% | Piping in water treatment, desalination, wastewater plants; corrosion and scaling resistance |

Pharmaceutical | ~5% | Pipes for sterile environments and pharmaceutical liquids; non-reactive for purity |

Other Sectors | ~7% | Electronics, aerospace, energy; specialized applications requiring strength and corrosion resistance |

The global market for stainless steel pipes reached $41.3 billion in 2020. Experts expect it to grow to $49.7 billion by 2025 and $71.3 billion by 2035. This growth comes from new infrastructure, urbanization, and the need for strong, long-lasting materials. Asia-Pacific leads the way, with rapid growth in China and India. North America and Europe remain strong markets, especially in oil, gas, and construction. You also benefit from advances in manufacturing, which improve quality and lower costs. The recyclability of stainless steel pipes supports sustainability goals in many industries.

You need to follow strict standards when you select and use pipes in any project. These standards, such as ANSI/ASME B36.19 and ASTM A312, set the rules for pipe dimensions, wall thickness, material grades, and pressure ratings. By following these rules, you make sure your pipes can handle the pressures and temperatures in your system.

Pipe schedules, like Schedule 10, 40, or 80, tell you the wall thickness. Thicker walls mean the pipe can handle more pressure and last longer.

Material standards, such as ASTM grades 304 and 316, ensure the right chemical makeup and strength for each pipe.

Pressure and temperature ratings help you avoid pipe failure during operation.

Quality control steps, like Mill Test Certificates and hydrostatic testing, prove that your pipes meet safety and performance requirements.

Industry certifications address special needs in food, pharmaceutical, and oil and gas sectors.

You protect your system and the people who use it by choosing pipes that meet these standards. Testing and certification reduce risks and help you avoid costly failures. When you follow the right standards, you build safer, more reliable systems for every application.

️ Tip: Always check that your pipes meet the latest standards before you buy or install them. This step keeps your project safe and up to code.

Choosing the right specifications and standards for 2 inch stainless steel pipes protects your system from leaks, failures, and costly downtime. You ensure safety, performance, and compliance by following recognized standards, using proper testing, and selecting the correct pipe schedule and material.

Regular inspections and testing confirm that pipes meet dimensional and material requirements.

Consulting organizations like ANSI and ASTM helps you stay current with best practices.

Always match pipes to your project’s needs for pressure, corrosion resistance, and compatibility.

Rely on accurate data and trusted standards to make informed decisions about pipes in every application.

You see "2 inch" as the nominal pipe size. This label does not match the actual outside diameter. For a 2 inch pipe, the outside diameter measures 2.375 inches.

You select the schedule based on your system’s pressure and strength needs. Higher schedules mean thicker walls and higher pressure ratings. Always check your project’s requirements before you decide.

304 stainless steel works well for most uses. 316 contains molybdenum, which gives you better resistance to chemicals and saltwater. Choose 316 for harsh or marine environments.

Yes, you can weld these pipes. Grades like 304L and 316L have low carbon content. This feature helps prevent corrosion after welding and keeps your joints strong.

Seamless pipes offer higher pressure resistance and uniform strength. Welded pipes cost less and work well for many uses. You should pick seamless pipes for critical or high-pressure systems.

You should look for ASTM A312 or ASME SA312 for pipe material. Check ASME B36.19 for dimensions. For fittings, use ASTM A403. These standards ensure quality and safety.

Most suppliers offer standard lengths of 20 feet (about 6 meters). Some also provide 10-foot lengths or custom cuts. Always confirm the length before you order.

Yes, you can use it for drinking water. Stainless steel resists corrosion and does not leach harmful substances. Make sure the pipe meets local health and safety codes.

content is empty!