close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-15 Origin: Site

The top five stainless steel pipe fitting brands for 2025 are XTD Stainless, Yasco, Stainless Tubular Products, Steel Tubes India, and OmegaOne. Trust and reliability play a crucial role in selecting the right supplier. Industry surveys highlight several key factors:

Supplier reputation and experience, especially with over ten years in stainless steel pipe fitting manufacturing.

High customer ratings and positive testimonials on platforms such as Trustpilot.

Certifications like ISO 9001:2015 and ASTM standards that validate quality.

Consistent product testing and responsive technical support.

These elements help buyers identify brands that deliver dependable performance and long-term value.

Trustworthy stainless steel pipe fitting brands combine quality, certifications, and strong customer support to ensure reliable performance.

Poor quality fittings can cause leaks, corrosion, safety hazards, and costly downtime, so choosing certified products is vital.

Top brands like XTD Stainless, Yasco, Stainless Tubular Products, Steel Tubes India, and OmegaOne each offer unique strengths and product ranges.

Look for certifications such as ISO, ASTM, ASME, and PED to confirm product quality and compliance with industry standards.

Customer support matters; fast, knowledgeable assistance helps avoid installation errors and reduces project delays.

Consider your project’s specific needs, including pressure, temperature, and fluid type, to select the best fitting brand and product.

Evaluate total cost of ownership, not just initial price, to ensure long-term value and fewer maintenance issues.

Request documentation like Mill Test Certificates to verify material quality and build confidence in your purchase.

Brand reputation shapes purchasing decisions in the stainless steel pipe fitting industry. Buyers often evaluate suppliers based on several factors:

Product quality and variety

Delivery time and reliability

Technical support and after-sales service

Price competitiveness and available discounts

Supplier reputation and market presence

Leading brands invest in research, comply with regulations, and build strong distribution networks. These efforts help them meet customer needs and influence preferences. A trusted brand often signals consistent quality and dependable service, which buyers value highly.

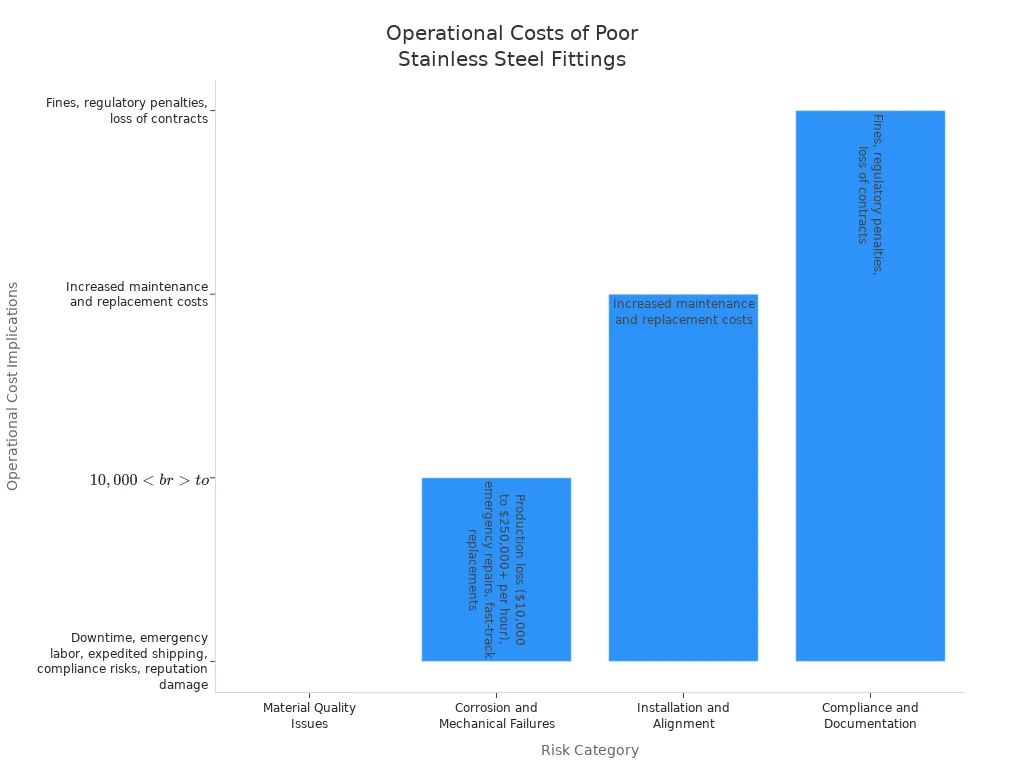

Using unreliable stainless steel pipe fittings can lead to serious consequences. Common risks include:

Galvanic corrosion when mixed with incompatible metals, causing surface pitting and structural weakening

Corrosion-induced leaks that disrupt operations and increase maintenance needs

Shortened system lifespan, leading to frequent replacements and higher costs

Safety hazards from leaks or system breakdowns, which may cause property damage

Improper installation or material selection, reducing pressure and temperature resistance

The table below highlights documented risks associated with poor quality fittings:

| Risk Category | Specific Failures and Hazards | Safety Risks | Operational Cost Implications |

|---|---|---|---|

| Material Quality Issues | Failure to meet ASTM, EN, ASME standards; inconsistent chemistry; falsified or missing MTRs; poor mechanical properties | Increased likelihood of leaks, cracks, and system failures | Downtime, emergency labor, expedited shipping, compliance risks, reputation damage |

| Corrosion and Mechanical Failures | Pitting corrosion, cracking, wall loss, stress corrosion cracking, embrittlement, fatigue, galling, thread failure, galvanic corrosion | Leaks, seal failures, structural failures, accidents | Production loss ($10,000 to $250,000+ per hour), emergency repairs, fast-track replacements |

| Installation and Alignment | Misalignment, fatigue from inconsistent material strength | Mechanical stress leading to premature failure | Increased maintenance and replacement costs |

| Compliance and Documentation | Lack of heat treatment or pressure rating documentation | Non-compliance with safety standards | Fines, regulatory penalties, loss of contracts |

Regular inspections and compliance with industry standards help prevent these issues. Non-destructive testing methods, such as ultrasonic or radiographic inspection, can detect hidden defects and reduce the risk of failure.

Industry experts identify several criteria that define a trustworthy stainless steel pipe fitting brand:

Certified material quality, such as alloys 304, 316, or 316L, and compliance with ASTM and ASME standards

Manufacturing expertise, including forged fittings and rigorous quality control

Wide range of standard and custom fittings, including sanitary-grade options

Reliable inventory and global shipping to prevent project delays

Strong customer support, technical assistance, and detailed documentation

Brands that meet these criteria deliver fittings that perform safely and reliably in demanding industries like food processing, pharmaceuticals, and chemical manufacturing. Their commitment to quality, service, and compliance builds lasting trust with customers.

XTD Stainless stands out as a leading manufacturer in the stainless steel pipe fitting industry. The company has built a reputation for delivering high-performance products that meet strict industry standards. Their focus on quality and innovation has positioned them as a preferred supplier for many demanding sectors. XTD Stainless invests in advanced manufacturing processes and maintains a strong commitment to product reliability. Their team includes experienced engineers who oversee every stage of production, from material selection to final inspection.

XTD Stainless demonstrates several strengths that set it apart from competitors. The company specializes in duplex stainless steel pipes and fittings, which offer superior corrosion resistance and strength. These products perform well in harsh environments, such as petrochemical plants and marine applications. XTD Stainless also emphasizes rigorous testing and quality control. Every fitting undergoes thorough inspection to ensure it meets or exceeds industry requirements. The company holds certifications like PED, ISO9001, and AD2000, which validate its commitment to quality and safety. Customers benefit from tailored solutions, as XTD Stainless can customize fittings to meet specific project needs. Their technical support team provides guidance on product selection and installation, reducing the risk of costly errors.

Tip: Choosing a supplier with strong certifications and testing standards can help prevent system failures and ensure long-term reliability.

XTD Stainless offers a broad selection of stainless steel pipe fittings and related products. Their range includes austenitic stainless steel pipes, duplex stainless steel pipes, and nickel alloy steel pipes. The company manufactures common fittings such as elbows, reducers, tees, flanges, and valves. These products serve industries like oil and gas, petrochemical, marine, and nuclear power. XTD Stainless designs its fittings to withstand high pressure and extreme temperatures. The company’s duplex stainless steel fittings provide up to double the strength of standard grades, making them ideal for critical applications. XTD Stainless also supports custom orders, allowing clients to specify dimensions, materials, and finishes. Their inventory management system ensures timely delivery, even for large or complex projects.

XTD Stainless enjoys a strong reputation among customers in the stainless steel pipe fitting industry. Many buyers praise the company for its consistent product quality and reliable delivery schedules. Industrial clients often mention that XTD Stainless provides fittings that meet or exceed their expectations for durability and performance. The company’s attention to detail in manufacturing and inspection has earned positive feedback from engineers and procurement managers.

Customers frequently highlight the clear documentation that comes with each order. Mill Test Certificates and inspection reports help buyers verify the material quality and compliance of every fitting. This transparency builds confidence and reduces the risk of installation errors.

Online reviews on industry platforms and forums reflect high satisfaction rates. Users note that XTD Stainless responds quickly to technical inquiries and offers helpful guidance during the selection process. Many customers appreciate the company’s willingness to customize fittings for unique project requirements. This flexibility allows project managers to meet tight deadlines and maintain system integrity.

A significant number of repeat clients come from sectors such as oil and gas, chemical processing, and marine engineering. These industries demand strict adherence to safety and performance standards. XTD Stainless’s ability to deliver certified products on time has helped build long-term relationships with these clients.

The company’s warranty offerings and after-sales support also contribute to its positive reputation. Customers report that XTD Stainless addresses concerns promptly and stands behind its products. This level of service reassures buyers that they are working with a dependable supplier.

Several factors make XTD Stainless a trustworthy choice for stainless steel pipe fittings:

The company complies with recognized industry standards, including ASTM (A182, A403, A312), ASME (B16.5, B16.9, Section IX), and ISO (1127, 2037, 4144). This ensures that every fitting meets strict safety and performance requirements.

XTD Stainless provides Mill Test Certificates and detailed inspection reports with each shipment. These documents verify material quality and confirm compliance with customer specifications.

Quality assurance processes include certified weld inspections, ultrasonic and radiographic testing, and surface finish checks. These steps help detect hidden defects and guarantee product reliability.

The company holds ISO 9001 certification, which demonstrates a formal commitment to quality management and traceability. Batch records allow for easy tracking and accountability.

XTD Stainless emphasizes the importance of sourcing from trusted suppliers who follow rigorous quality controls. This approach ensures that customers receive long-lasting and safe products.

Additional trust factors include the company’s extensive experience, positive customer reviews, warranty coverage, and a balanced approach to price, quality, and service.

By consistently meeting industry standards and prioritizing customer needs, XTD Stainless has established itself as a reliable partner for critical projects. Their dedication to quality and transparency gives buyers the confidence to choose their fittings for demanding applications.

Yasco has earned a reputation as a reliable supplier in the stainless steel pipe fitting market. The company focuses on delivering products that meet strict industry standards. Yasco’s team includes skilled engineers who oversee every stage of production. Their approach combines advanced technology with careful quality control. Many industries trust Yasco for projects that require both durability and precision. The company’s commitment to customer satisfaction sets it apart from many competitors.

Yasco demonstrates several strengths that make it a preferred choice for many buyers. The company invests in precision machining and advanced manufacturing processes. This focus ensures high dimensional accuracy and consistent product quality. Yasco’s fittings show excellent corrosion resistance, making them suitable for harsh environments. The company also offers strong technical support. Their team helps clients select the right fittings for each application. Yasco’s flexible production system allows for quick turnaround times, even on custom orders. Many customers appreciate the company’s ability to deliver both standard and specialized solutions.

Note: Yasco’s technical support team provides guidance on installation and maintenance, helping clients avoid costly mistakes.

Yasco offers a wide selection of stainless steel pipe fittings designed to serve various industries. The company’s product range includes elbows, reducers, stub ends, reducing tees, and end caps. Each product type features unique benefits and serves specific industry needs. The table below highlights the main products, their descriptions, and typical applications:

| Product Type | Description | Applicable Industries | Features |

|---|---|---|---|

| Stainless Steel Elbows | Durable, corrosion-resistant, available in 45°, 90°, 180° angles, polished finish | Plumbing, HVAC, Industrial, Residential, Commercial, Marine | High pressure & heat resistance, easy installation |

| Stainless Steel Reducer | Stable welding process, cost-effective | Construction, Water supply pipelines, Decoration projects | Low cost, flexible size, easy installation |

| Stainless Steel Stub End | Precision machining, high dimensional accuracy, excellent corrosion resistance | Medical equipment, Laboratory equipment, Electronic instruments | High precision, aesthetic, suitable for high-standard applications |

| Stainless Steel Reducing Tee | Smooth transition between pipe sizes, corrosion resistant, strong and accurate | Chemical processing, Petroleum refining, HVAC systems, Food-grade piping | Smooth flow, strong connection, ideal for varying diameters or pressures |

| Stainless Steel End Cap | No weld design, excellent strength and pressure resistance | Oil and gas, Chemical equipment, Nuclear power engineering | High strength, no leakage, corrosion resistance |

Yasco supports customization in size, wall thickness, and material. This flexibility allows the company to meet the needs of complex projects. Clients can request fittings that match unique specifications. Yasco’s products deliver reliable performance in demanding environments. The company’s focus on quality and adaptability ensures that each stainless steel pipe fitting meets or exceeds industry expectations.

Yasco has built a strong reputation among customers in the stainless steel pipe fitting industry. Many clients choose Yasco for its consistent product quality and reliable delivery. The company’s advanced manufacturing facilities in Fujian and Zhejiang provinces allow it to maintain high standards across all production lines. Customers often mention the precision and reliability of Yasco’s fittings, which result from the use of advanced CNC processing equipment and strict quality control procedures.

Buyers from various industries appreciate Yasco’s ability to deliver both seamed and seamless stainless steel pipes. The company’s comprehensive product range includes flanges, fittings, and piping equipment. This variety allows customers to source all necessary components from a single supplier, simplifying procurement and project management.

Many project managers highlight Yasco’s customer-centric approach. The company offers customizable manufacturing, enabling clients to specify size, thickness, and material requirements. This flexibility helps customers meet unique project demands without compromising on quality or delivery time.

Yasco’s professional and experienced team provides one-stop service, guiding clients from product selection to after-sales support. Customers value the technical expertise and responsiveness of Yasco’s staff. The team assists with installation advice and troubleshooting, which reduces the risk of costly errors during project execution.

Yasco’s reputation extends beyond its home market. The company has supplied stainless steel pipe fittings to projects in Vietnam, India, the UAE, South Africa, and Singapore. This global experience demonstrates Yasco’s ability to meet international standards and deliver products that perform reliably in diverse environments.

Clients frequently mention the following strengths in their feedback:

Consistent product quality backed by ISO certification

Timely and reliable delivery schedules

Customizable solutions for complex projects

Clear and detailed documentation with every order

Responsive customer service and technical support

Yasco’s commitment to customer satisfaction has resulted in a high rate of repeat business. Many clients return for future projects, citing the company’s reliability and professionalism. Positive testimonials on industry forums and procurement platforms further reinforce Yasco’s reputation as a trusted supplier.

Stainless Tubular Products has established itself as a key player in the global stainless steel pipe fitting market. The company’s growth reflects both technological innovation and a strong response to industrial demand. Over the years, Stainless Tubular Products has focused on advanced welding, forming, and precision machining. These efforts support industries that require high-quality, durable solutions. The company’s commitment to sustainability stands out, as stainless steel’s recyclability and long service life align with modern environmental goals.

The following table summarizes the company’s historical developments and market presence:

| Aspect | Details |

|---|---|

| Historical Developments | - Technological innovations: advanced welding, forming, precision machining - Industrial growth and urbanization driving demand - Increasing focus on sustainability due to recyclability and durability of stainless steel |

| Market Segmentation | - By Product Type: Seamless pipes and tubes, Welded pipes and tubes - By Application: Oil & Gas, Automotive, Chemical, Construction, Water Treatment, Pharmaceutical, Food Industry, Others - By Geography: Americas, APAC, Europe, Middle East & Africa |

| Key Market Players | Marcegaglia, Fischer Group, Jiuli Group, Sandvik, Tenaris, Nippon Steel Corporation, ThyssenKrupp, Baosteel, ArcelorMittal, Tata Steel, Tubacex, and others |

| Market Dynamics | - Global trade impacts (trade agreements, tariffs, geopolitical events) - Economic growth and industrialization - Urbanization and infrastructure development - Technological advancements |

| Market Forecast | - CAGR of 4.6% from 2024 to 2030 - Projected market size approx. US$47,220 million by 2030 |

This table highlights the mature and competitive nature of the market, as well as the company’s ability to adapt to changing industry needs.

Stainless Tubular Products maintains a competitive edge through several core strengths:

Exceptional corrosion resistance that reduces maintenance and extends product life.

Strong structural integrity, enabling fittings to withstand high pressure and mechanical stress.

Hygienic, easy-to-clean surfaces suitable for food, beverage, and pharmaceutical industries.

Compatibility with a wide range of fluids, temperatures, and pressures.

Metallurgical excellence, combining corrosion resistance and mechanical strength through duplex stainless steel structures.

Superior resistance to pitting, crevice, and stress corrosion cracking, which is critical for harsh environments.

High mechanical strength and durability for demanding industrial applications.

Versatility across industries such as chemical processing, oil and gas, pharmaceuticals, food and beverage, desalination, marine engineering, and structural projects.

Enhanced performance in high-temperature environments, ensuring reliability and safety.

Economic viability through extended lifespan and reduced maintenance costs.

Advanced manufacturing techniques that ensure precision and consistent quality.

Ongoing research and development to meet evolving industry challenges.

Innovation in compression tube fittings, providing secure, leak-proof connections without welding or threading.

Strict adherence to international standards (ASTM, ASME, DIN, JIS) for material quality and dimensional precision.

Comprehensive quality control from raw material sourcing to final inspection.

Reliable logistics, competitive pricing, and strong customer service that foster long-term partnerships.

Stainless Tubular Products’ commitment to quality and innovation ensures that clients receive dependable solutions for even the most challenging environments.

Stainless Tubular Products offers a comprehensive selection of stainless steel pipe fittings and flanges. Their product line includes elbows, tees, reducers, couplings, caps, and flanges made from grades such as 304 and 316L. These fittings provide leak-proof, durable connections for demanding industrial environments, including chemical processing, marine, and food and beverage sectors.

The company’s offerings address a wide range of industry requirements:

Buttweld fittings for permanent welded joints

Pressure fittings designed for high-pressure environments

Weld neck flanges that provide structural integrity under high heat and pressure

Blind flanges used to seal pipe sections

Each product is engineered for superior corrosion resistance, strength, and ease of cleaning. Advanced manufacturing methods, such as forging and machining, ensure precision and high-quality surface finishes. The wide variety of fittings and flanges allows clients to select products based on specific needs, such as pressure, temperature, and fluid type. This adaptability ensures compliance with strict hygienic and mechanical standards across multiple industries.

Stainless Tubular Products enjoys a strong reputation among customers in the stainless steel pipe fitting industry. Many buyers recognize the company for its consistent product quality and dependable service. Industrial clients often mention that the fittings arrive on time and meet strict specifications. This reliability helps project managers avoid costly delays and maintain smooth operations.

Customers from sectors such as oil and gas, food processing, and pharmaceuticals frequently praise the company’s attention to detail. They note that each order includes clear documentation, such as Mill Test Certificates and compliance reports. These documents help engineers verify material quality and ensure regulatory compliance. Procurement teams appreciate the transparency, which reduces the risk of installation errors.

Many engineers highlight the company’s technical support as a key advantage. The support team responds quickly to inquiries and provides practical solutions for complex piping challenges.

Repeat business forms a significant part of the company’s customer base. Clients often return for future projects because they trust the durability and performance of the fittings. Positive word-of-mouth and recommendations on industry forums further strengthen the brand’s reputation.

International customers also express satisfaction with Stainless Tubular Products. The company’s ability to meet global standards and deliver products to diverse markets sets it apart from many competitors. Buyers in Europe, Asia, and the Americas report that shipments arrive on schedule and in excellent condition.

A summary of customer feedback appears below:

| Customer Group | Key Feedback | Notable Benefits |

|---|---|---|

| Industrial Engineers | Reliable quality, precise dimensions | Fewer installation issues |

| Procurement Managers | Transparent documentation, easy traceability | Simplified compliance |

| Project Managers | On-time delivery, responsive support | Reduced project delays |

| International Buyers | Consistent global standards, secure packaging | Confidence in cross-border trade |

Clients also value the company’s willingness to customize fittings for unique applications. This flexibility allows them to address specific project requirements without compromising quality or delivery time.

Tip: Choosing a supplier with a proven track record and positive customer reviews can help ensure project success and long-term reliability.

Stainless Tubular Products continues to build trust by listening to customer feedback and adapting its services. The company’s focus on quality, transparency, and support has earned it a loyal following in the global market.

Steel Tubes India stands as a prominent supplier in the global piping industry. The company has built its reputation on delivering high-quality products and maintaining strict compliance with international standards. Steel Tubes India serves a wide range of industries, including oil and gas, petrochemical, power generation, and construction. Their commitment to innovation and customer satisfaction has helped them secure a strong presence in both domestic and international markets. The company’s focus on quality assurance and technical expertise ensures that clients receive reliable solutions for complex projects.

Steel Tubes India demonstrates several strengths that set it apart from competitors. The company invests in advanced manufacturing technologies and rigorous quality control systems. Every product undergoes thorough inspection to meet or exceed industry requirements. Steel Tubes India holds certifications such as ISO 9001, PED, and CE, which validate its dedication to quality and safety. The company’s experienced engineering team provides technical support and guidance throughout the project lifecycle. Clients benefit from fast response times and tailored solutions for unique applications. Steel Tubes India also offers competitive pricing and flexible delivery schedules, making it a preferred partner for large-scale and time-sensitive projects.

Tip: Choosing a supplier with a proven track record and strong certifications can help ensure the long-term reliability of your piping systems.

Steel Tubes India offers one of the most comprehensive product portfolios in the stainless steel pipe fitting industry. Their range includes ASME B16.5 flanges, buttweld fittings, and stainless steel forged fittings. The company manufactures pipes and tubes in various standards, such as IS 1239, DIN 2391 ST52, EN 10219 S235JRH, and EN 10210 S355J2H. Steel Tubes India also supplies specialty alloy pipes, including Hastelloy C276, Monel 400, Duplex 2205, and Super Duplex 2507. Clients can source large diameter steel pipes that comply with EU Directive 97/23/EC, ensuring suitability for high-pressure and critical applications.

In addition to standard fittings, Steel Tubes India provides related products like fasteners and flanges. Their manufacturing capabilities extend to custom solutions for challenging environments. Compared to brands that focus primarily on forged or threaded fittings, Steel Tubes India emphasizes a broad selection of pipes, tubes, and flanges, especially in specialty alloys. This approach allows clients to address diverse project requirements with a single supplier.

The company’s ability to deliver both standard and customized products makes it a versatile choice for industries with demanding specifications. Steel Tubes India’s extensive inventory and global distribution network ensure timely delivery, even for large or complex orders. Their commitment to quality and variety positions them as a leader in the stainless steel pipe fitting market.

Steel Tubes India enjoys a strong reputation among customers in the stainless steel pipe fitting industry. Many buyers recognize the company for its consistent product quality and reliable service. Industrial clients often mention that Steel Tubes India delivers on time and meets strict project specifications. This reliability helps project managers avoid costly delays and maintain smooth operations.

Customers from sectors such as oil and gas, power generation, and construction frequently praise the company’s attention to detail. They note that each order includes clear documentation, such as mill test reports and compliance certificates. These documents help engineers verify material quality and ensure regulatory compliance. Procurement teams appreciate the transparency, which reduces the risk of installation errors.

Many engineers highlight the company’s technical support as a key advantage. The support team responds quickly to inquiries and provides practical solutions for complex piping challenges.

Repeat business forms a significant part of the company’s customer base. Clients often return for future projects because they trust the durability and performance of the fittings. Positive word-of-mouth and recommendations on industry forums further strengthen the brand’s reputation.

International customers also express satisfaction with Steel Tubes India. The company’s ability to meet global standards and deliver products to diverse markets sets it apart from many competitors. Buyers in Europe, Asia, and the Americas report that shipments arrive on schedule and in excellent condition.

A summary of customer feedback appears below:

| Customer Group | Key Feedback | Notable Benefits |

|---|---|---|

| Industrial Engineers | Reliable quality, precise dimensions | Fewer installation issues |

| Procurement Managers | Transparent documentation, easy traceability | Simplified compliance |

| Project Managers | On-time delivery, responsive support | Reduced project delays |

| International Buyers | Consistent global standards, secure packaging | Confidence in cross-border trade |

Clients also value the company’s willingness to customize fittings for unique applications. This flexibility allows them to address specific project requirements without compromising quality or delivery time.

Tip: Choosing a supplier with a proven track record and positive customer reviews can help ensure project success and long-term reliability.

Steel Tubes India continues to build trust by listening to customer feedback and adapting its services. The company’s focus on quality, transparency, and support has earned it a loyal following in the global market.

Steel Tubes India stands out as a trustworthy choice for stainless steel pipe fittings due to several key factors:

The company holds multiple certifications, including ISO 9001:2008, ISO 14001:2004, and OHSAS 18001:2007. These certifications serve as trust seals and demonstrate a commitment to quality, environmental responsibility, and workplace safety.

Steel Tubes India offers a lifetime replacement warranty on stainless steel tube fittings. This warranty assures customers of long-term product reliability.

Full traceability is provided for all original tube fittings. Customers can verify the origin and quality of every fitting, which enhances transparency and trust.

Customization options are available. The company can mark fittings with customer part numbers and thread types, such as NPT, BSPT, or BSPP, to meet specific project needs.

Steel Tubes India maintains a large stock of over 85,000 fittings and valve parts. This inventory enables the fastest delivery in the industry, reducing project lead times.

Production uses automated CNC machines built to German standards. Stringent quality control has resulted in a 0% rejection rate in exports over the past decade.

Each unit is individually tested before dispatch. This practice ensures that only high-quality products reach the customer.

Packaging includes branded boxes with barcode lot identification and plastic cap protection. This attention to detail prevents damage during transit and supports easy inventory management.

The company has extensive export experience, serving clients in more than 53 countries. This global reach demonstrates the ability to meet diverse regulatory and performance requirements.

Additional value additions include high-pressure sustainability, impeccable surface finish, mill test reports (EN10204 NACE 3.1, 3.2), third-party inspections, and competitive pricing.

Customer service is a priority. Steel Tubes India provides same-day shipping, consultancy for alternate sizes or materials, and a world-class buying experience.

Customers can trust Steel Tubes India for their commitment to quality, transparency, and customer satisfaction. These strengths make the company a reliable partner for critical piping projects worldwide.

OmegaOne stands as a recognized leader in the stainless steel pipe fitting industry. Founded in 1987 and headquartered in Willoughby, Ohio, the company has built a strong reputation for quality and innovation. OmegaOne operates two ISO-certified manufacturing facilities in Ohio, which allows for domestic production and inventory management close to customers. Over the years, OmegaOne has expanded its manufacturing capabilities, product offerings, and quality programs. The company forms part of a unified business platform with SHF and AMFM, supplying a broad range of stainless-steel adapters, fluid power fittings, braid bands, instrumentation fittings, and valves. OmegaOne serves diverse markets, including marine, industrial, chemical, and oil and gas sectors. The company’s acquisition by SHF, a Harbour Group company, has further enhanced its market reach and operational resources. This integration strengthens OmegaOne’s position as a trusted supplier to hose and industrial distributors across North America.

OmegaOne’s achievements include sustained growth since 1987, continuous expansion of manufacturing and product lines, ISO certifications, and integration into a larger platform that boosts its market presence and service capabilities.

OmegaOne has earned its reputation through a focus on precision and reliability, especially in hydraulic hose fittings. The company specializes in high-quality fittings designed for demanding applications. As a US-based manufacturer since 1995, OmegaOne prioritizes quality over volume. This approach ensures strong quality control, shorter lead times, and accessible technical support. OmegaOne manufactures domestically, which provides full control over product quality and allows for tailored inventory to meet specific customer needs.

The company offers unmatched customer service. Clients benefit from expert guidance, problem-solving, and exceptional delivery options, including same-day shipping and personal package delivery. Many customers praise OmegaOne for quick responses, high-quality products, and excellent service. These strengths make OmegaOne a preferred choice for critical hydraulic connections in industries such as manufacturing, construction, and agriculture.

Tip: Choosing a supplier with domestic manufacturing and strong customer support can help ensure reliable supply and fast problem resolution.

OmegaOne provides a comprehensive selection of stainless steel pipe fittings and related products. The company’s product line includes:

Hydraulic hose fittings and adapters

Metal hose braid bands

Instrumentation fittings

Fluid power fittings

Stainless steel valves

These products serve a wide range of industries, from marine and chemical processing to oil and gas. OmegaOne’s fittings are engineered for high precision and durability, making them suitable for both standard and custom applications. The company’s inventory includes both domestic and imported fittings, which allows for flexible sourcing and quick delivery. OmegaOne’s integration with SHF and AMFM expands its product offerings and ensures customers have access to a broad inventory across North America.

A summary table of OmegaOne’s main product categories and their applications appears below:

| Product Category | Typical Applications | Key Features |

|---|---|---|

| Hydraulic Hose Fittings | Manufacturing, Construction, Ag | High precision, reliable sealing |

| Metal Hose Braid Bands | Marine, Industrial, Chemical | Corrosion resistance, flexibility |

| Instrumentation Fittings | Oil & Gas, Chemical, Food Processing | Leak-proof, easy installation |

| Fluid Power Fittings | Power Generation, Automation | High strength, pressure rated |

| Stainless Steel Valves | Industrial, Marine, Chemical | Durable, corrosion resistant |

OmegaOne’s commitment to quality, broad product range, and responsive service make it a top choice for stainless steel pipe fitting solutions in North America.

OmegaOne has built a strong reputation among customers in the stainless steel pipe fitting industry. Many buyers praise the company for its consistent product quality and fast delivery. Industrial clients often mention that OmegaOne provides fittings that meet strict specifications and perform reliably in demanding environments. The company’s domestic manufacturing gives customers confidence in the origin and quality of each product.

Customers highlight several key strengths in their feedback:

Responsive Service: OmegaOne’s customer service team responds quickly to inquiries and provides clear technical guidance. Clients appreciate the ability to speak directly with knowledgeable staff who understand their project requirements.

Reliable Delivery: Many buyers note that OmegaOne delivers orders on time, even for urgent or custom requests. The company’s same-day shipping option helps project managers avoid costly delays.

Consistent Quality: Users report that OmegaOne’s fittings arrive with precise dimensions and excellent surface finishes. The company’s ISO-certified processes ensure that each product meets industry standards.

Transparent Documentation: Each shipment includes detailed documentation, such as Mill Test Certificates and compliance reports. This transparency helps engineers verify material quality and regulatory compliance.

Problem-Solving Approach: Customers value OmegaOne’s willingness to address challenges and provide solutions for unique applications. The company often works with clients to develop custom fittings or adapt inventory to specific needs.

“OmegaOne’s team always goes the extra mile. They helped us solve a critical fitting issue on short notice and delivered exactly what we needed.”

— Project Manager, Industrial Contractor

A summary table of customer feedback appears below:

| Customer Type | Key Feedback | Main Benefit |

|---|---|---|

| Industrial Buyers | Fast, reliable delivery | Reduced project downtime |

| Engineers | High-quality, precise fittings | Fewer installation issues |

| Distributors | Responsive support, clear paperwork | Easier inventory management |

| Project Managers | Custom solutions, flexible service | On-time project completion |

Repeat business forms a large part of OmegaOne’s customer base. Many clients return for future projects because they trust the company’s commitment to quality and service. Positive reviews on industry forums and procurement platforms further reinforce OmegaOne’s reputation as a dependable supplier.

Selecting the right stainless steel pipe fitting brand depends on several factors. Each brand brings unique strengths to the table. XTD Stainless focuses on advanced engineering and custom solutions. Yasco stands out for its precision machining and flexible manufacturing. Stainless Tubular Products leads with a broad product range and strong global presence. Steel Tubes India offers unmatched inventory and rapid delivery. OmegaOne excels in domestic manufacturing and responsive customer service.

Buyers should consider the following when comparing these brands:

Certifications and Compliance: Some brands hold more international certifications, which ensures higher quality and safety standards.

Product Range: Certain companies provide a wider selection of fittings, including specialty alloys and custom options.

Technical Support: Brands differ in the level of technical guidance and after-sales support.

Delivery Speed: Inventory size and logistics capabilities affect how quickly products reach the customer.

Customization: Some suppliers offer more flexibility for custom orders and project-specific requirements.

Tip: Evaluate your project’s needs before choosing a supplier. Consider factors such as delivery time, technical support, and available certifications.

The table below highlights the unique strengths of each top brand. Use this comparison to identify which supplier best matches your requirements.

| Brand | Unique Strengths | Certifications | Product Range | Customer Support | Delivery Speed |

|---|---|---|---|---|---|

| XTD Stainless | Advanced engineering, duplex alloys, custom solutions | ISO, PED, AD2000 | Wide, custom fittings | Strong technical team | Reliable, global |

| Yasco | Precision machining, flexible manufacturing | ISO | Standard & custom fittings | Installation guidance | Fast, flexible |

| Stainless Tubular Products | Broad range, global presence, hygienic solutions | ASTM, ASME, DIN, JIS | Extensive, industry-specific | Responsive, global | Consistent, global |

| Steel Tubes India | Large inventory, specialty alloys, rapid delivery | ISO, PED, CE | Pipes, tubes, flanges, alloys | Fast, tailored support | Fastest in industry |

| OmegaOne | Domestic manufacturing, hydraulic focus, quick ship | ISO | Hydraulic, instrumentation | Exceptional, US-based | Same-day available |

This comparison helps buyers quickly assess which stainless steel pipe fitting brand aligns with their project goals. Each company offers distinct advantages, so matching these strengths to your needs ensures the best results.

Every industry has unique requirements when it comes to pipe fittings. Project managers in the oil and gas sector often prioritize high-pressure resistance and corrosion protection. Food and beverage manufacturers look for hygienic designs and easy-to-clean surfaces. Chemical processing plants demand fittings that can withstand aggressive substances and extreme temperatures.

Selecting the right stainless steel pipe fitting brand starts with understanding these specific needs. Engineers should review the operating environment, including temperature, pressure, and exposure to chemicals. They should also consider the type of fluid or gas that will pass through the system. Some brands offer specialized products for marine, pharmaceutical, or high-purity applications.

Tip: Create a checklist of your project’s technical requirements before comparing brands. This approach helps narrow down the options and ensures the chosen fittings will perform reliably.

Budget plays a significant role in the selection process. Companies must balance cost with quality and long-term value. While some brands offer premium fittings with advanced features, others provide more cost-effective solutions for standard applications.

Procurement teams should compare not only the initial purchase price but also the total cost of ownership. Lower-priced fittings may seem attractive, but they can lead to higher maintenance costs or early replacement if quality is lacking. Investing in a reputable brand often results in fewer failures and less downtime.

A simple table can help teams evaluate options:

| Brand | Initial Cost | Maintenance Cost | Expected Lifespan | Value for Money |

|---|---|---|---|---|

| Brand A | High | Low | Long | Excellent |

| Brand B | Medium | Medium | Medium | Good |

| Brand C | Low | High | Short | Fair |

Note: Always factor in warranty coverage and after-sales support when assessing value.

Certifications serve as proof of quality and compliance. Leading brands display certifications such as ISO 9001, PED, ASTM, and ASME. These credentials indicate that the manufacturer follows strict quality management systems and meets international standards.

Project managers should verify that the selected stainless steel pipe fitting brand holds the necessary certifications for their industry. Some projects, especially in pharmaceuticals or food processing, require fittings with additional sanitary or safety approvals.

A certified product reduces the risk of system failure and regulatory issues. It also provides peace of mind to engineers and end users.

Always request documentation for certifications and test reports before finalizing a purchase. This step ensures transparency and helps avoid costly mistakes.

Customer support plays a vital role in the selection of a stainless steel pipe fitting brand. Reliable support ensures that buyers receive assistance before, during, and after the purchase. Strong customer service can prevent costly mistakes and reduce downtime. Many industries require technical guidance for installation, troubleshooting, or compliance documentation. Brands that offer responsive support help clients solve problems quickly.

Key aspects of excellent customer support include:

Availability: Support teams should respond promptly to inquiries. Fast answers help project managers keep schedules on track.

Technical Expertise: Staff with deep product knowledge can guide buyers through complex specifications. They can recommend the right fittings for unique applications.

After-Sales Service: Good brands provide help after the sale. This includes warranty claims, replacement parts, and installation advice.

Clear Communication: Support teams should explain solutions in simple terms. They should provide clear documentation and instructions.

Multiple Channels: Leading brands offer support through phone, email, chat, and online resources.

Tip: Always test a supplier’s customer support before placing a large order. Send a technical question or request documentation. Evaluate how quickly and clearly the team responds.

The table below summarizes what to look for in customer support:

| Support Feature | Why It Matters | Example Benefit |

|---|---|---|

| Fast Response | Keeps projects on schedule | Quick resolution of issues |

| Technical Guidance | Ensures correct product selection | Fewer installation errors |

| After-Sales Service | Reduces downtime and costs | Easy warranty claims |

| Clear Documentation | Simplifies compliance and installation | Accurate records |

| Multiple Channels | Increases accessibility | Convenient communication |

Strong customer support builds trust and long-term relationships. Buyers should prioritize brands that invest in their support teams.

Selecting the right stainless steel pipe fitting brand requires careful evaluation. Buyers should match their project needs with the strengths of each supplier. Start by reviewing technical requirements, such as pressure ratings, material grades, and certifications. Consider the total cost, including maintenance and warranty coverage.

A step-by-step approach helps simplify the decision process:

List Project Requirements: Identify the key technical and regulatory needs.

Compare Brands: Use comparison tables to evaluate strengths, certifications, and support.

Check Customer Feedback: Read reviews and testimonials from similar industries.

Test Support: Contact the supplier with questions to assess responsiveness.

Request Documentation: Ask for sample certificates and test reports.

Review Delivery Options: Confirm lead times and inventory availability.

Assess Value: Balance price, quality, and service for the best long-term outcome.

Note: The best brand is not always the cheapest. Long-term reliability and strong support often save money over time.

Decision-makers should involve engineers, procurement teams, and end users in the selection process. This teamwork ensures that the chosen brand meets all technical, budget, and operational goals. By following a structured approach, buyers can select a stainless steel pipe fitting brand that delivers safety, performance, and peace of mind.

The top five brands—XTD Stainless, Yasco, Stainless Tubular Products, Steel Tubes India, and OmegaOne—each deliver unique strengths in the stainless steel pipe fitting market. Their proven quality, certifications, and customer support make them the most trustworthy choices for 2025. Readers should review the comparison tables and selection tips before making a decision.

Share your experience with these brands or ask for advice in the comments below.

Buyers should check for ISO 9001, ASTM, ASME, and PED certifications. These standards confirm that the manufacturer follows strict quality and safety guidelines. Certified products help ensure reliable performance in demanding environments.

Grade 304 resists corrosion in most environments. Grade 316 contains molybdenum, which increases resistance to chemicals and saltwater. Engineers often select 316 for marine or chemical applications.

Most leading brands offer custom manufacturing. Buyers can specify dimensions, wall thickness, and material grades. Customization helps meet unique project requirements and ensures a proper fit.

Mill Test Certificates verify the chemical composition and mechanical properties of each fitting. These documents help engineers confirm compliance with project specifications and industry standards.

Buyers should purchase directly from authorized distributors or the manufacturer. They should request certifications and test reports. Trusted brands provide clear documentation and traceability for every order.

Industries such as oil and gas, chemical processing, food and beverage, pharmaceuticals, and marine engineering rely on stainless steel pipe fittings. These sectors require high durability and corrosion resistance.

Delivery times vary by brand and order size. Some suppliers offer same-day shipping for in-stock items. Large or custom orders may require additional lead time. Buyers should confirm delivery schedules before placing an order.

Buyers should contact the supplier’s customer support team immediately. Most reputable brands offer warranties and will replace defective products. Clear documentation and photos help speed up the resolution process.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Stainless Steel Tube Dimensions Chart Explained for Industrial And Residential Uses

Top 10 Applications for Stainless Steel Tube Schedule 10 in 2025

Top 10 Stainless Steel Tube Fittings for Marine And Industrial Applications

Comparing Stainless Steel Tube Suppliers for Your Next Project

A Comprehensive Guide To Stainless Steel Tube Schedule 40 Dimensions And Charts