close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-12 Origin: Site

To choose the best stainless steel pipes and fittings for your project, you must first know what your project needs. Look at the type of fluid, the grade of materials, and the pressure rating. Check if the products meet industry standards. Trust suppliers with a strong record for quality. When you balance cost, performance, and compliance, your system will last longer and work better.

First, know what your project needs. Check the fluid type, pressure, temperature, and environment. Do this before you pick pipes and fittings.

Choose the right stainless steel grade. Use SS304 for most jobs. Use SS316 for tough places with salt or chemicals. This helps keep things safe and strong.

Use pipes, fittings, and adapters made from the same material. This stops leaks and rust. It keeps your system working well.

Pick the right pipe size, wall thickness, and connection type. This helps stop leaks. It also lets your system handle pressure and heat.

Always buy from trusted suppliers. They should follow industry rules and give quality certificates. This helps you get safe and long-lasting products.

Knowing what your project needs is very important. Every industrial project is different. You need to think about the fluid type, pressure, temperature, and where the pipes will be used. These things help you make a safe and strong system for moving fluids.

The kind of fluid in your pipes matters a lot. If you move water, oil, or mild chemicals, stainless steel stops rust well. For strong acids or seawater, you may need extra protection like special linings. Stainless steel has a layer that keeps it from rusting. This makes it a good choice for many uses. You should pick the right fittings, such as elbows, tees, reducers, and flanges, for your job.

You need to know the pressure and temperature your pipes will face. Stainless steel pipes can handle high pressure and hot or cold temperatures. The table below shows the best temperature ranges for common grades:

Stainless Steel Grade | Recommended Temperature Range |

|---|---|

304 | -196°C to 800°C |

316 | -196°C to 1000°C |

Stainless steel is strong and does not change much with heat. This makes it good for tough jobs. Always pick a grade that fits your pressure and temperature needs.

Where you use the pipes affects how fast they rust. Things like wet air, heat, soil, and pollution can make rust happen faster. In places near the ocean or with chemicals, rust can be worse. You should use stainless steel grades that fight rust in tough places. Using coatings and other ways to stop rust helps pipes last longer. Stainless steel is strong and can be recycled, which is good for the environment.

Tip: Always check what your project needs before picking pipe materials. This helps your system work well and stay safe for a long time.

Picking the right stainless steel pipe grade is important. Each grade has special features for different jobs. You need to know how grades work in different places. This helps your system work well.

Austenitic stainless steel pipe is used a lot in industry. It is strong and does not rust easily. You can use it in many projects. This pipe is not magnetic. It keeps its shape in hot or cold places. You can weld and bend it into many shapes. This helps you build different systems.

Here is a table that shows why people like austenitic stainless steel pipes:

Property | Description | Industrial Relevance |

|---|---|---|

Corrosion Resistance | Protective layer stops acids, alkalis, and harsh chemicals | Needed for chemical, food, and pharmaceutical industries |

Heat Resistance | Handles temperatures up to 1150°C | Used in power plants and chemical processing |

Mechanical Strength | High strength for pressure and heavy use | Good for pipelines and boilers |

Weldability & Fabrication | Easy to weld and shape | Helps in building and fixing pipe systems |

Hygienic Surface | Smooth and non-reactive | Important for food and medicine sectors |

Non-Magnetic Nature | Non-magnetic when annealed | Useful for electronics and sensitive equipment |

Thermal Fatigue Resistance | Resists cracking from temperature changes | Lasts longer in power plants and reactors |

You can use these pipes in many places. They work well in chemical plants, marine jobs, and water treatment. They are strong and do not rust, so they are safe for tough jobs.

You often have to pick between SS304 and SS 316 pipe fittings. Both are austenitic stainless steel grades. They are different in some ways.

SS304 is good for most jobs. It is strong and easy to weld. It costs less. You can use it for water, food, and general piping.

SS 316 pipe fittings have molybdenum. This helps them fight rust from saltwater or chemicals. SS 316 pipe fittings stay strong in hot or cold places. They do not break in the cold.

Note: If your project has salt, chemicals, or high stress, use SS 316 pipe fittings. They last longer and need fewer repairs.

Here is a quick comparison:

SS304: Good for less harsh places. It costs less but is not as strong against salt or chemicals.

SS 316 pipe fittings: Best for marine, chemical, or high-pressure jobs. They cost more but last longer and save money over time.

You must match the pipe grade to your project’s needs. Think about what will go through the pipe. Check the temperature and if there is salt or chemicals. SS 316 pipe fittings are best for tough places like near the sea or in chemical plants. SS304 works well for water or food pipes where rust is not a big problem.

When you pick a grade, look at the cost too. SS 316 pipe fittings cost more than SS304. But they save money on repairs and downtime. You should also check if you need seamless or welded pipe. Seamless pipe is stronger and good for high pressure. Welded pipe is good for lower pressure and costs less.

Here is a table of common stainless steel grades and where you use them:

Stainless Steel Grade Type | Common Grades | Key Characteristics | Typical Industrial Applications |

|---|---|---|---|

Austenitic | 304, 316 | Great corrosion resistance, strength, easy to shape; 316 has molybdenum for extra protection | Chemical plants, marine, food, medical |

Duplex | S31803, S32205 | High strength, very good corrosion resistance, weldable | Harsh environments, salty water |

Super Duplex | S32750, S32760 | Top corrosion resistance, high strength | Offshore, desalination, chemical plants |

Martensitic | 410, 420, 431, 440C | High strength, hard, wear-resistant | Valves, pumps, tools |

Ferritic | 408, 409, 416, 430 | Magnetic, moderate corrosion resistance | Car exhausts, water heaters |

Tip: Always check the rules for your project. Make sure your stainless steel pipe and ss 316 pipe fittings meet codes like ASTM A-312. This keeps your system safe and legal.

You can save money by picking the right grade for each part. Use ss 316 pipe fittings where there is lots of salt or chemicals. Use SS304 in places that are not as harsh. This gives you the best value and makes your system last longer.

When you pick stainless steel pipes and fittings, you need to think about a few things. You want your system to last a long time. It should be safe and work well. Here is what you should know.

You need to use the same material for pipes, fittings, and adapters. If you mix metals, you can get rust or leaks. For example, using stainless steel pipes and fittings with copper or plastic can cause problems. These problems can hurt your system or make it stop working. SS 316 pipe fittings are best for places with strong chemicals. They do not rust as fast as other grades. Always check if your fittings and adapters are the same grade as your pipes. This helps stop leaks or thread damage.

Tip: Using the right materials keeps your system safe and strong. It also helps you save money on repairs and stops downtime.

Stainless steel piping can handle high pressure and heat. But you still need to stop rust. If you use the wrong mix, like steel fittings with plastic pipes, you can break the threads and cause leaks. Always pick fittings and adapters that match your pipe’s material and grade. This keeps your system safe and working well.

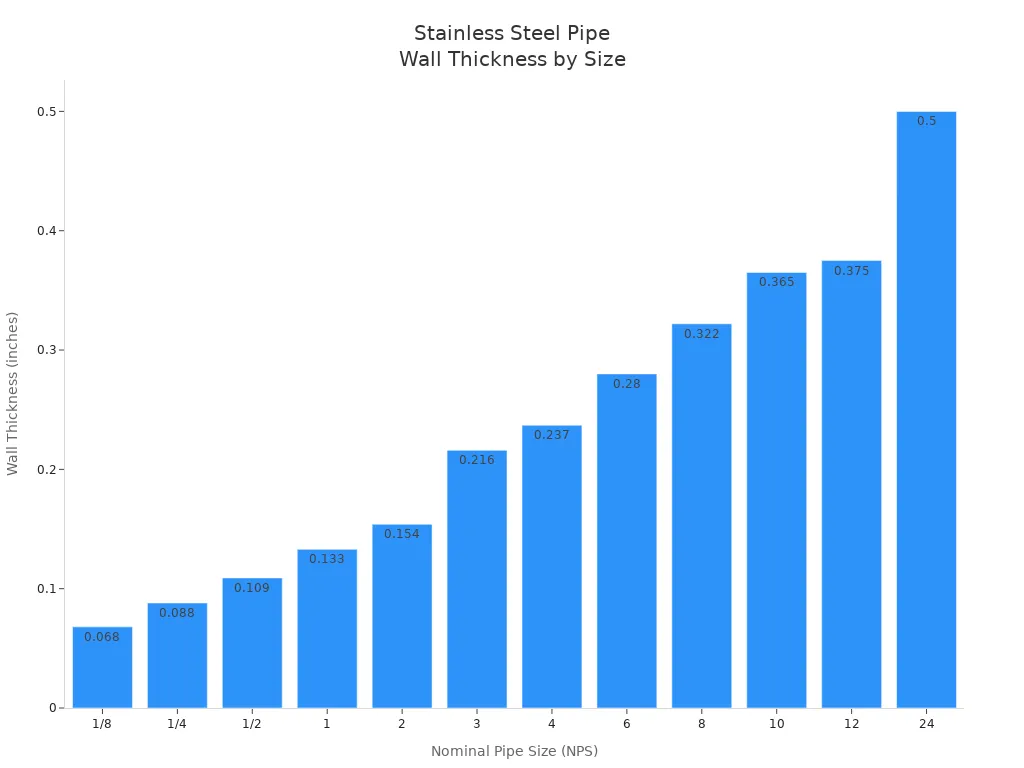

Getting the right size and thickness is very important. It helps stop leaks and keeps the flow good. Stainless steel pipes and fittings use the Nominal Pipe Size (NPS) system. This system tells you the outside diameter. The schedule number shows how thick the wall is. For example, Schedule 40 and Schedule 80 are common. Schedule 80 pipes have thicker walls than Schedule 40. Thicker pipes can handle more pressure.

Here is a table with some common sizes:

Nominal Pipe Size (NPS) | Outside Diameter (inches) | Schedule | Wall Thickness (inches) | Inside Diameter (inches) |

|---|---|---|---|---|

1/2 | 0.840 | 40 | 0.109 | 0.622 |

1 | 1.315 | 40 | 0.133 | 1.049 |

2 | 2.375 | 40 | 0.154 | 2.067 |

4 | 4.500 | 40 | 0.237 | 4.026 |

6 | 6.625 | 40 | 0.280 | 6.065 |

You can see how wall thickness changes in this chart:

If you pick the wrong size or thickness, your pipes might leak or break. Always check the pressure and heat your system will have. Use thicker pipes for higher pressure. SS 316 pipe fittings and adapters are good for hard jobs. They can handle stress and rust. Seamless piping is stronger and has fewer weak spots. Welded piping is good for lower pressure and costs less.

Note: Always follow rules like ASTM or ASME. These rules make sure your stainless steel pipes and fittings are safe and good quality.

There are different ways to connect stainless steel pipes and fittings. Each way has its own good points and best uses.

Threaded Connections:

These are easy to put together and do not need special tools. You use them for small pipes and low pressure. They cost less but can leak if not sealed well. Always match thread standards to stop leaks.

Welded Connections:

Welded pipes give you strong, leak-proof joints. You need skilled workers and special tools. This type is best for high pressure and heat. Welded fittings and adapters are used in important jobs. But welding can cause problems if not done right.

Flanged Connections:

Flanged fittings and adapters are strong and easy to take apart. They are good for big pipes and high pressure. Flanged connections cost more and need more space.

Here is a table that compares threaded and welded fittings:

Feature | Threaded Fittings | Welded Fittings |

|---|---|---|

Installation | Easy and fast; no special tools | Needs skilled labor and special equipment |

Cost | Lower labor and material costs | Higher labor and equipment costs |

Pressure & Temperature | Good for low to medium pressure and temperature | Best for high pressure and temperature |

Maintenance | Easy to replace and disassemble | Must cut pipe to replace |

Leak Resistance | Moderate; can loosen and leak over time | Excellent; strong, leak-proof joints |

Application Suitability | Small, light-duty, low-pressure systems | High-stress, high-pressure, critical systems |

Tip: Pick the connection type that fits your system’s pressure, heat, and repair needs.

You can also use fittings and adapters like tees, crosses, reducer nipples, double nipples, sockets, and end caps. Each one has its own pressure rating and job. Always check that your fittings and adapters match your pipe size and pressure needs.

If you want your system to last, use the right stainless steel pipes and fittings. Pick the correct size, thickness, and connection type. This keeps your pipes safe, leak-free, and easy to fix.

You need to make sure your stainless steel pipes and fittings follow the right rules. These rules help keep your system safe and strong. Some important codes are ASTM, ASME, and ISO. ASTM has rules like A182, A403, and A312 for pipes and fittings. ASME B16.5 and B16.9 are for flanges and buttwelding fittings. ISO and EN rules are used for projects around the world. Here is a table with some main standards:

Standard Organization | Standard Number(s) | Scope / Description |

|---|---|---|

ASTM | A182, A403, A312 | Forged fittings, seamless and welded pipes, corrosion service |

ASME | B16.5, B16.9, Section IX | Flanges, buttwelding fittings, welding procedures |

ISO | 1127, 2037, 4144 | Tubes and fittings for food and other industries |

If you follow these codes, your fittings will work well under pressure and heat. This helps stop leaks or breaks. Always ask your supplier for certificates and test reports.

Tip: Following codes like ASME B31.3 and ASTM makes sure your fittings are strong, resist rust, and do not leak.

You want your fittings to work well and last a long time. Good suppliers check their products carefully. They test for strength, leaks, and smooth surfaces. They use special tests like ultrasonic or radiographic checks to find hidden problems. Always ask for Mill Test Certificates and inspection reports. These papers show the fittings meet the right rules.

A good supplier will have certifications like ISO 9001. They keep records for every batch they make. This helps you find out where a problem started. You can trust suppliers who have a good name and clear quality checks.

Look for:

Weld inspections that are certified

Checks to make sure the material is right

Surface finish checks

All the right paperwork

Note: Good quality fittings help your system run longer and stay safe.

Do not pick fittings just because they are cheap. Cheap fittings can break early and cause leaks or stops. High-quality fittings, like ones made from 316 stainless steel, cost more at first. They work better and last longer. This saves money on repairs and keeps your system working.

When you look at suppliers, check their experience, customer reviews, and warranty. A good supplier gives fair prices, good help, and quick delivery. They help you get the best mix of price, quality, and long life.

Think about:

The grade of material and how smooth it is

Testing and certificates

How good the supplier is and their support

Tip: The best value comes from fittings that match your needs for price, quality, and how well they work.

You can pick the best stainless steel pipes and fittings by using simple steps. First, make sure the fittings match your project’s pressure, temperature, and material needs. Use a checklist to help you remember all the important things:

Key Factors for Pipe Fitting Selection | Description |

|---|---|

Pressure and Temperature Ratings | Check if fittings can handle your system’s needs. |

Material Compatibility | Use fittings that are the same as your pipe material. |

Flow Requirements | Pick fittings that let fluid move easily. |

Installation Methods | Choose fittings that work with your tools. |

Cost | Think about both price and how long fittings last. |

Regulatory Compliance | Make sure fittings follow industry rules. |

Environmental Considerations | Pick fittings that are good for the environment. |

Future Expansion Plans | Use fittings that let your system grow later. |

Talking to trusted suppliers helps you get fittings that last a long time, even in hard places. When you pick the right fittings, your system stays safe, works well, and saves money for many years.

Seamless pipes have no welds. They handle higher pressure and stress. Welded pipes have a seam. They cost less and work well for low or medium pressure. You should choose based on your project’s needs.

You need to check what fluid goes through the pipe and where you use it. SS304 works for water and food. SS316 resists salt and chemicals. Always match the grade to your environment and fluid.

Mixing metals can cause rust or leaks. You should use the same grade for pipes and fittings. This keeps your system safe and helps it last longer.

You should inspect pipes and fittings at least once a year. Look for rust, leaks, or damage. Early checks help you fix problems before they get worse.