close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-06-19 Origin: Site

Quality Standards of Common Austenitic Stainless Steel Pipes play a vital role in ensuring safety and reliability. Industries such as food processing, pharmaceuticals, and construction depend on these standards to maintain high product performance.

The global stainless steel pipe market reached USD 32.25 billion in 2024, with projected growth driven by infrastructure and regulatory requirements.

Standards like ASTM, EN, GB/T, and ASME support the use of popular grades such as 304 and 316, which offer excellent corrosion resistance and toughness.

Stringent regulations and advanced manufacturing technologies highlight the need for consistent quality, especially in critical infrastructure.

| Metric/Aspect | Data/Insight |

|---|---|

| Major Application Sectors | Food, pharmaceuticals, chemicals, construction, oil & gas |

| Importance of Quality Standards | Durability, compliance, and safety in demanding environments |

Quality standards like ASTM, ASME, EN, and GB/T ensure stainless steel pipes meet strict requirements for safety, durability, and corrosion resistance.

Grades 304 and 316 are the most common stainless steel pipes, with 316 offering better corrosion resistance due to molybdenum content.

Manufacturing processes such as seamless, welded, and cold working affect pipe strength, surface quality, and performance under harsh conditions.

Regular inspection and testing, including chemical analysis and non-destructive methods, confirm pipe quality and compliance with industry standards.

Following these quality standards helps industries reduce costs, improve product reliability, and support sustainable and safe infrastructure projects.

The Quality Standards of Common Austenitic Stainless Steel Pipes set the foundation for safety and performance in demanding industries. These standards define the requirements for chemical composition, mechanical properties, and manufacturing processes. They help manufacturers and users ensure that pipes meet strict criteria for durability and reliability.

ASTM International and the American Society of Mechanical Engineers (ASME) publish some of the most widely recognized standards for stainless steel pipes. ASTM standards such as A312, A213, and A269 cover different types of austenitic stainless steel pipes. ASTM A312 specifies seamless and welded pipes for high-temperature and general corrosive service. ASTM A213 focuses on seamless tubes for boilers, superheaters, and heat exchangers. ASTM A269 addresses seamless and welded tubes for general service. ASTM A789, A813, and A814 provide additional guidelines for duplex and welded pipes.

ASME B36.19M defines the dimensions and wall thicknesses for stainless steel pipes. This standard ensures compatibility and interchangeability in piping systems. Together, ASTM and ASME standards support industries like chemical processing, oil and gas, and food production.

ASTM and ASME standards help control the quality of stainless steel pipes by specifying material grades, testing methods, and dimensional tolerances.

European and Chinese standards also play a key role in the Quality Standards of Common Austenitic Stainless Steel Pipes. The European Norm (EN) 10216-5 standard covers seamless stainless steel tubes for pressure purposes. It sets requirements for chemical composition, mechanical properties, and testing procedures. EN 10216-5 is widely used in the European Union for applications in power plants, refineries, and the food industry.

China’s GB/T standards, such as GB/T 14975 and GB/T 14976, regulate the quality of stainless steel seamless pipes. These standards focus on chemical composition, mechanical strength, and corrosion resistance. GB/T 13296 applies to seamless pipes for boilers and heat exchangers.

The following table summarizes the scope and application of major standards:

| Standard Type | Specific Standards | Application Scope / Industry Usage |

|---|---|---|

| Domestic (China) | GB/T14975, GB/T14976, GB13296 | Quality control of stainless steel seamless pipes |

| International | ASTM A213, ASTM A269, ASTM A312, ASTM A789, EN10216-5 | Used for stainless steel seamless pipes in chemical, petroleum, power, aerospace, pharmaceutical, and food/beverage industries |

| ASME | B36.19M | Pipe dimensions and wall thickness for stainless steel piping systems |

These standards ensure that pipes meet strict requirements for corrosion resistance, dimensional accuracy, and mechanical strength. They provide a common language for manufacturers and users around the world.

Quality Standards of Common Austenitic Stainless Steel Pipes protect critical infrastructure and support safe operation in harsh environments.

Grades 304 and 316 stand out as the most widely used austenitic stainless steels for pipe manufacturing. Atlas Steels datasheets provide detailed information about these grades, including their chemical composition, mechanical strength, and performance in different environments. Grade 304 contains about 18% chromium and 8% nickel. Grade 316 includes approximately 16% chromium, 10% nickel, and 2-3% molybdenum. The addition of molybdenum in 316 improves its resistance to corrosion, especially in environments with high chloride levels, such as marine and chemical processing plants.

Low-carbon versions, 304L and 316L, offer better weldability and reduce the risk of carbide precipitation during fabrication. Industry data confirms that 304 is suitable for general corrosion resistance and mechanical strength, while 316 performs better in aggressive settings that demand higher durability. Experimental studies show that 316L resists corrosion more effectively than 304L, especially at high temperatures. Tests also reveal differences in oxide layer formation and mechanical properties, such as ductility and strain hardening, between these two grades.

Engineers and manufacturers rely on these documented specifications to select the right material for each application, ensuring safety and long service life.

Manufacturers produce austenitic stainless steel pipes in a range of standard sizes and shapes. The ASTM A312 specification defines the main manufacturing processes and dimensional tolerances for seamless, welded, and heavily cold-worked pipes.

| Process Type | Description |

|---|---|

| Seamless (SML) | Pipe formed without any welding. |

| Welded (WLD) | Pipe made by automatic welding, usually without filler metal. |

| Heavily Cold-Worked | Welded pipe cold worked with at least 35% thickness reduction. |

Standard pipe dimensions include outer diameters from 6 mm to over 600 mm, wall thicknesses from 0.5 mm to 30 mm, and lengths up to 12 meters. The ERW (Electric Resistance Welded) process shapes steel strips into pipes and welds the seam using high-frequency induction. This method produces pipes with uniform thickness and tight tolerances. Manufacturers use heat treatment to maintain mechanical properties and corrosion resistance. Cold working improves surface finish and strength, while hot working increases flexibility.

Hot working creates strong, flexible pipes.

Cold working enhances corrosion resistance and surface quality.

Heat treatment ensures pipes perform well under extreme conditions.

Standardized dimensions and processes help ensure that pipes meet strict industry requirements for quality, safety, and performance.

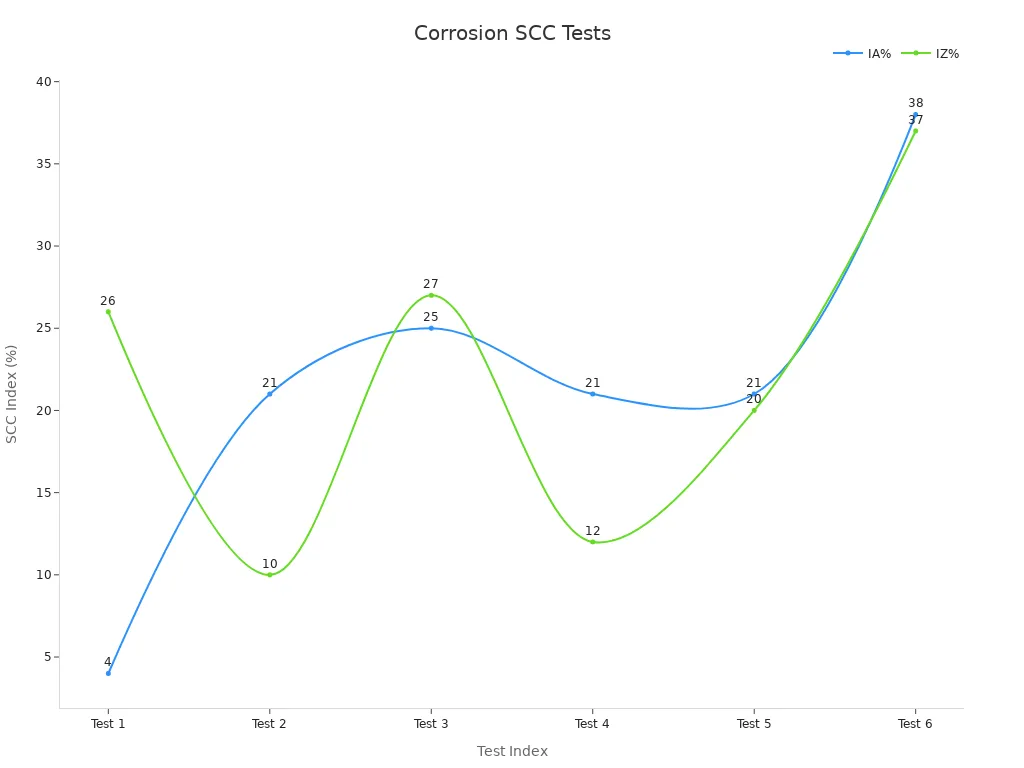

Corrosion resistance stands as a critical requirement for austenitic stainless steel pipes. The ability of these pipes to withstand harsh environments depends on their chemical composition and the formation of a stable chromium-rich oxide film. Studies show that AISI 316L and 304L pipes resist stress corrosion cracking (SCC) even in high-chloride and high-temperature conditions. The following table presents results from slow strain rate tests, which measure embrittlement indexes (IA% and IZ%) for these materials:

| Material | Strain Rate (s⁻⊃1;) | Environment Phase | Waiting Time (h) | IA% (Elongation-based) | IZ% (Area Reduction-based) |

|---|---|---|---|---|---|

| AISI 316L | 10⁻⁵ | Liquid phase | 0 | 4 | 26 |

| AISI 316L | 10⁻⁵ | Liquid phase | 55 | 21 | 10 |

| AISI 316L | 10⁻⁵ | Gas phase | 0 | 25 | 27 |

| AISI 316L | 10⁻⁶ | Liquid phase | 0 | 21 | 12 |

| AISI 316L | 10⁻⁶ | Gas phase | 0 | 21 | 20 |

| AISI 304L | 10⁻⁵ | Liquid phase | 0 | 38 | 37 |

Researchers highlight that factors such as oxygen, pH, temperature, and chloride concentration affect corrosion mechanisms. The addition of molybdenum in 316L improves resistance to pitting and cracking, making it suitable for aggressive environments.

Mechanical properties ensure that stainless steel pipes perform reliably under pressure, tension, and temperature changes. Tests on pipes under combined internal pressure and axial tension show that corrosion defects can reduce pipe strength. Engineers use numerical models to predict how corrosion depth affects burst and failure pressures.

Comparative tests before and after reel-laying reveal that tensile, compression, bending, and torsion resistance can increase by up to 45% due to plastic deformation.

Experimental and theoretical studies confirm that the reel-laying process enhances pipe strength and durability.

Measurements of pipe length, diameter, and axial stiffness at different pressures help verify balanced performance.

These findings support the development of safe and reliable pipes that meet the Quality Standards of Common Austenitic Stainless Steel Pipes.

Inspection and testing methods verify that pipes meet industry standards and perform as expected. Technicians use Positive Material Identification (PMI) to confirm alloy composition. Hardness testing checks heat treatment results. Destructive tests, such as tensile and bend tests, measure strength and ductility. Non-destructive testing (NDT) methods, including ultrasonic and radiographic tests, detect internal and surface defects.

| Inspection/Testing Method | Description/Analytical Report Type | Certification/Standard Reference |

|---|---|---|

| Visual Inspection | Checks for surface defects, alignment, shape | ASME, API |

| Dimensional Inspection | Measures diameter, wall thickness, length | ASME, API |

| Non-Destructive Testing (NDT) | Radiographic, Ultrasonic, Magnetic Particle, Dye Penetrant | ASME, API, ASTM |

| Mechanical Testing | Tensile, Charpy Impact, Hardness tests | ASME, API, ASTM |

| Metallurgical Testing | Microstructure and chemical composition analysis | Mill Test Certificate (MTC) per EN 10204 |

| Hydrostatic Testing | Pressure test to ensure pipe integrity | ASME, API |

| Certification Documentation | Mill Test Certificate (MTC) level 3.2 with third-party validation | EN 10204, Lloyd’s, SGS, Cotecna |

Qualified personnel with certifications from organizations such as ASME and API conduct these tests. Third-party validation and certification documents, like Mill Test Certificates, provide assurance of compliance and quality.

Engineers and manufacturers often compare standards from the United States, Europe, and China when selecting stainless steel pipes. Each region uses its own system for grade designations and specifications. The table below shows how grade names differ between the US and several European countries. This comparison helps users identify equivalent materials across regions.

| Standard Region | Designation Examples |

|---|---|

| US (AISI) | 304, 304L, 310, 316, 316L, 317L, 321, 347 |

| UK (BSI) | 304S15/304S16, 304S11, 310S24, 316S31, 316S11, 317S12, 321S31, 347S31 |

| Germany (Werkstoff Nr.) | 1.4301/1.4303, 1.4306, 1.4845, 1.4401, 1.4404, 1.4438, 1.4541/1.4878, 1.4550 |

| Germany (DIN 17006) | X 5 CrNi 18 10 / X 5 CrNi 18 12, X 2 CrNi 18 11, X 12 CrNi 25 21, X 5 CrNiMo 17 12 2, X 2 CrNiMo 17 13 2, X 2 CrNiMo 18 16 4, X 6 CrNiTi 18 10 / X 12 CrNiTi 18 9, X 6 CrNiNb 18 10 |

| Sweden (SIS) | 23 32, 23 52, N/A, 23 47, 23 48, 23 67, 23 37, 23 38 |

Note: The table highlights the equivalence and differences in grade designations between US and European standards. Chinese standards use a different system, but direct statistical comparisons are not available in the referenced data.

Selecting the best standard for a project requires careful evaluation. Engineers use several tools and models to guide their decisions. They consider the following factors:

Life cycle assessment (LCA) helps estimate the environmental impact of each pipe grade.

Life cycle cost (LCC) analysis calculates the total cost of ownership, including maintenance and replacement.

Corrosion prediction models use data such as corrosion rates and chloride content to estimate service life.

User-friendly tools combine LCA, LCC, and corrosion models, allowing users to select grades based on site-specific needs like water pressure and chloride concentration.

Experimental and statistical analyses, including AI models, provide insights into machinability and surface quality.

Case studies from wastewater treatment plants show that duplex grades can lower costs and reduce environmental impact in high-chloride settings.

These frameworks help users match the Quality Standards of Common Austenitic Stainless Steel Pipes to their project’s technical, economic, and environmental requirements.

Adhering to the Quality Standards of Common Austenitic Stainless Steel Pipes supports safety, reliability, and long-term performance. These standards define technical tests, manufacturing steps, and certification needs. Companies that follow them see better product durability, lower maintenance costs, and higher market demand.

| Aspect | Benefit of Quality Standards |

|---|---|

| Product Quality | Improved durability and corrosion resistance |

| Financial Performance | Reduced costs and better market acceptance |

| Sustainability | Greener production and custom solutions |

For best results, engineers should consult current standards and work with certified suppliers. Further research or expert advice can help select the right pipe for each project.

Grade 316 contains molybdenum, which increases corrosion resistance. Grade 304 does not have molybdenum. Engineers choose 316 for harsh environments, such as marine or chemical plants. Grade 304 works well in general applications.

Seamless pipes have no welded joints. This design reduces weak points and improves strength. Industries use seamless pipes in high-pressure or high-temperature systems to ensure safety and reliability.

ASTM A312 sets requirements for chemical composition, mechanical properties, and testing. Manufacturers follow these rules to produce pipes that meet industry expectations. This standard helps guarantee consistent quality and performance.

Technicians use salt spray tests, pitting resistance tests, and slow strain rate tests. These methods measure how well pipes resist corrosion in different environments. Results help engineers select the right grade for each application.

Yes. Certified inspectors check pipes using standards like EN 10204 or ASME. They issue Mill Test Certificates (MTC) to confirm compliance. Certification ensures that pipes meet safety and quality requirements.