close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

The primary distinction between 316 and 316L stainless steel lies in carbon content. Industry standards set the maximum carbon at 0.08% for 316 and 0.03% for 316L. This reduction in carbon gives 316L stainless steel improved resistance to intergranular corrosion and better weldability. As a result, engineers often select 316L for welded structures or environments where corrosion presents a serious concern.

316 stainless steel contains a maximum carbon content of 0.08% by weight. This higher carbon level can lead to the formation of chromium carbides at grain boundaries during welding or heat treatment. When chromium combines with carbon, it forms carbides that deplete the surrounding matrix of chromium. This process reduces the material's ability to resist corrosion, especially intergranular corrosion. Engineers often select 316 stainless steel for applications where welding is minimal or where slightly higher strength is required.

316L stainless steel, the low-carbon version of 316, contains a maximum carbon content of 0.03%. This significant reduction in carbon minimizes the risk of chromium carbide precipitation. As a result, 316L stainless steel maintains more chromium in solid solution, which preserves its corrosion resistance even after welding or exposure to high temperatures. The microstructure of 316L stainless steel typically shows fewer carbide precipitates, which helps prevent intergranular corrosion and weld decay. This property makes 316L stainless steel the preferred choice for welded structures and environments where corrosion resistance is critical.

Note: The lower carbon content in 316L stainless steel not only improves corrosion resistance but also helps prevent the formation of undesirable phases, such as sigma phase, which can degrade mechanical properties and corrosion resistance at elevated temperatures.

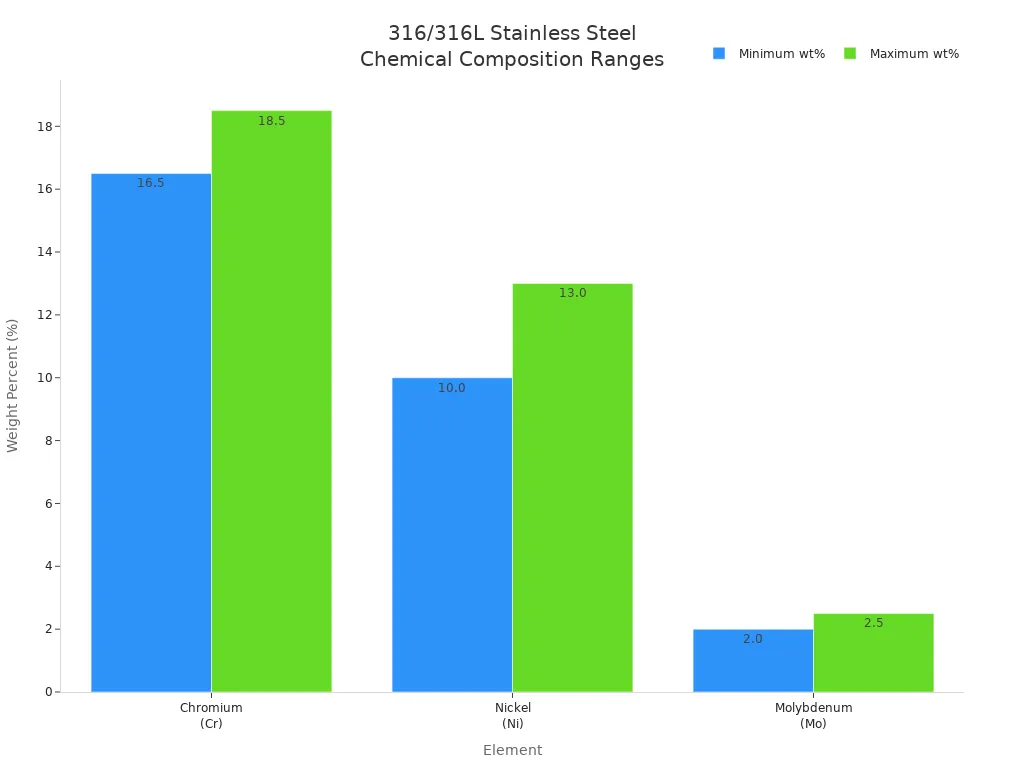

Both 316 and 316L stainless steel share a similar base composition, with chromium, nickel, and molybdenum as their primary alloying elements. These elements provide the well-known corrosion resistance and mechanical strength associated with the 300-series stainless steels. The table below summarizes the typical chemical composition ranges for both grades, as specified by ASTM standards:

| Stainless Steel Type | Carbon (C) wt% | Silicon (Si) wt% | Manganese (Mn) wt% | Phosphorus (P) wt% | Sulfur (S) wt% | Chromium (Cr) wt% | Molybdenum (Mo) wt% | Nickel (Ni) wt% |

|---|---|---|---|---|---|---|---|---|

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0 - 18.0 | 2.0 - 3.0 | 10.0 - 14.0 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0 - 18.0 | 2.0 - 3.0 | 10.0 - 14.0 |

The following chart visually compares the minimum and maximum weight percentages of the key alloying elements in 316 and 316L stainless steel:

Chromium, present at 16–18%, forms a passive oxide layer that protects the steel from oxidation and corrosion. Nickel, ranging from 10–14%, stabilizes the austenitic structure, enhancing ductility and toughness. Molybdenum, at 2–3%, increases resistance to pitting and crevice corrosion, especially in chloride-rich environments.

Some variants of 316L stainless steel may include added nitrogen. Nitrogen, even in small amounts, strengthens the austenitic matrix and improves both yield strength and resistance to localized corrosion. Nitrogen atoms interact with dislocations in the crystal lattice, making it harder for the structure to deform. This addition also refines grain size and helps maintain corrosion resistance by forming stable nitrides, which protect against pitting and intergranular attack.

Tip: When selecting between 316 and 316L stainless steel, consider not only the carbon content but also the presence of nitrogen and other alloying elements. These factors can significantly influence performance in demanding environments.

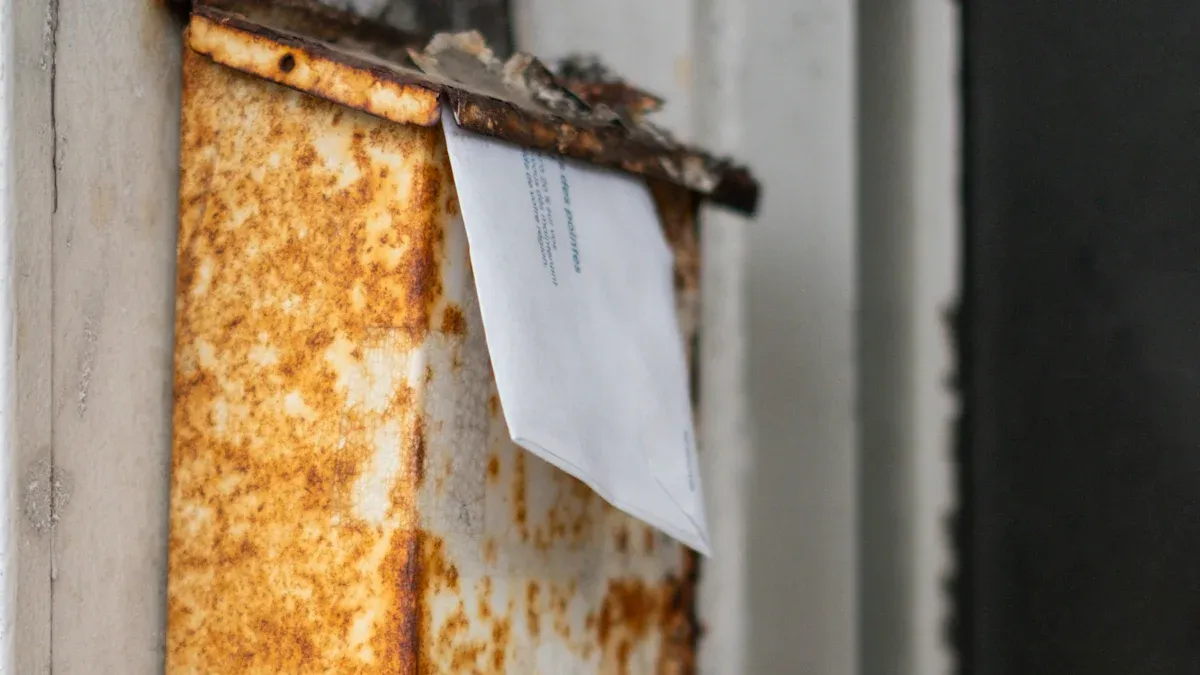

316L stainless steel demonstrates excellent corrosion resistance in a wide range of environments. Its low carbon content prevents chromium carbide precipitation at grain boundaries, which helps maintain a continuous and stable passive oxide film. This feature gives 316L stainless steel superior corrosion resistance, especially in welded structures and components exposed to aggressive conditions. In marine environments, 316L stainless steel resists pitting and crevice corrosion caused by chloride ions. Field tests show that, under seawater immersion at atmospheric conditions, 316L stainless steel exhibits a low corrosion rate of 0.0019 mm/year over 10 days. When exposed to high temperature and pressure in seawater, the corrosion rate increases to 0.0045 mm/year, indicating that elevated conditions accelerate degradation but the material still performs reliably.

In acidic environments, 316L stainless steel maintains acceptable corrosion resistance at moderate temperatures. Laboratory and plant data indicate that both 316 and 316L stainless steels have corrosion rates below 5 mils per year in phosphoric acid at temperatures under 100°C. Additively manufactured 316L stainless steel outperforms conventional wrought 316L in highly acidic solutions (pH ≤ 3), due to its refined microstructure and more stable passive film. This improvement results in a corrosion current density two orders of magnitude lower than conventional 316L, making it a strong choice for demanding chemical processing applications.

316 stainless steel also provides strong corrosion resistance, particularly in chloride-rich and acidic environments. The presence of molybdenum enhances its ability to withstand pitting and crevice corrosion. Laboratory tests in molten NaCl-KCl salt at 500°C show a corrosion rate of 17.12 μm/year for 316 stainless steel, which increases with temperature. At 700°C, the corrosion rate reaches 205.36 μm/year, demonstrating that high temperatures can significantly impact performance. Compared to 304 stainless steel, 316 stainless steel consistently shows lower corrosion rates, highlighting its suitability for harsh environments.

In phosphoric acid, 316 stainless steel tolerates temperatures above 115°C in laboratory settings, but plant data recommend use below 100°C for both 316 and 316L. The corrosion resistance of 316 stainless steel remains reliable in many industrial applications, but it does not offer the same level of protection against intergranular corrosion as 316L, especially after welding.

Intergranular corrosion occurs when chromium carbides form at grain boundaries, depleting the surrounding regions of chromium and reducing corrosion resistance. 316L stainless steel, with its lower carbon content, minimizes the risk of carbide precipitation. This property gives 316L natural immunity to weld decay, a common form of intergranular corrosion that affects welded joints. Unlike 316 stainless steel, which may require post-weld annealing to restore corrosion resistance, 316L maintains its protective properties without additional heat treatment.

316L stainless steel reduces the risk of chromium carbide precipitation at grain boundaries.

The low carbon content provides natural immunity against weld decay, while 316 stainless steel needs annealing for similar protection.

316L performs better in heavy welding applications, offering excellent intergranular corrosion resistance.

Molybdenum contributes to overall corrosion resistance, but the key factor for intergranular corrosion resistance is the reduced carbon content.

Research confirms that higher carbon content in stainless steels like 316H leads to sensitization and increased susceptibility to intergranular corrosion. In contrast, 316L stainless steel avoids this issue, maintaining superior corrosion resistance in welded and high-temperature environments.

Note: For applications involving welding or exposure to aggressive environments, 316L stainless steel provides the best balance of corrosion resistance and durability. Its superior corrosion resistance makes it the preferred choice for marine, chemical processing, and pharmaceutical industries.

316L stainless steel offers excellent weldability, making it the preferred choice for heavy gauge fabrication and critical welded structures. Its low carbon content minimizes the risk of chromium carbide precipitation during welding. This property helps maintain corrosion resistance in the heat-affected zone (HAZ) and prevents weld decay. Metallurgical studies confirm that 316L stainless steel welds show fewer carbide precipitates at grain boundaries, resulting in reduced sensitization and a lower risk of intergranular corrosion compared to standard 316 stainless steel.

To achieve optimal weldability and minimize weld decay, fabricators follow several best practices:

Control heat input and cooling rates to prevent the formation of harmful phases such as sigma and chi.

Use TIG welding for superior heat control and reduced hazardous emissions.

Select appropriate filler materials, such as ER316L, to match the base metal properties.

Maintain a clean work environment and use dedicated stainless steel tools to avoid contamination.

Apply post-weld heat treatment (PWHT) to decrease corrosion rates in the weld and HAZ.

Perform post-weld cleaning and passivation with mild acid solutions to restore the protective chromium oxide layer.

Thermo-kinetic treatments at controlled temperatures further improve microstructural uniformity and reduce weld decay. Cooling methods, such as quenching in water or salt solutions, also influence surface characteristics and corrosion potential. Experienced welders play a crucial role in managing heat concentration and thermal expansion, which can otherwise cause warping or distortion.

316 stainless steel provides good weldability but presents more challenges than 316L stainless steel. The higher carbon content increases the risk of carbide precipitation during welding. This process can lead to sensitization, making the material more susceptible to intergranular corrosion in the HAZ. Post-weld annealing may be necessary to restore corrosion resistance, especially in applications where the welded area will face aggressive environments.

Fabricators must carefully control welding parameters to avoid weld defects. Issues such as fusion and penetration problems can arise, particularly when joining pipes to flanges or when there are differences in material thickness. Even skilled welders may encounter increased failure rates if material quality or argon purging is inadequate. Proper surface preparation and the use of suitable filler materials remain essential for maintaining weld strength and corrosion resistance.

Weld decay refers to the localized loss of corrosion resistance in the HAZ due to chromium carbide precipitation. This phenomenon occurs more frequently in stainless steels with higher carbon content. 316L stainless steel, with its reduced carbon level, demonstrates a much lower tendency for weld decay. Microstructural analyses consistently show fewer chromium carbide precipitates in 316L welds, which translates to better long-term performance in corrosive environments.

Tip: For projects requiring extensive welding or exposure to harsh chemicals, selecting 316L stainless steel ensures superior weldability and long-term durability. Its resistance to weld decay makes it the industry standard for critical applications.

316 stainless steel generally provides higher strength than 316L. The difference comes from the higher carbon content in 316, which increases hardness and tensile strength. Material datasheets show that 316 stainless steel has a minimum tensile strength of 75 ksi and a yield strength of 30 ksi. In comparison, 316L stainless steel offers a minimum tensile strength of 70 ksi and a yield strength of 25 ksi. The following table summarizes these values:

| Property | 316 Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Minimum Tensile Strength | 75 ksi | 70 ksi |

| Yield Strength (0.2%) | 30 ksi | 25 ksi |

Both grades deliver reliable performance in demanding environments. However, engineers often select 316 when higher strength is a priority. After welding, both materials may experience a reduction in strength, but proper post-weld heat treatment can restore or even improve certain mechanical properties.

316L stainless steel stands out for its superior ductility and workability. The lower carbon content allows for easier forming, bending, and deep drawing without cracking. This makes 316L a preferred choice for complex shapes and heavy fabrication. During welding, 316L maintains its ductility better than 316, which can become more brittle due to carbide precipitation. Post-weld heat treatment at moderate temperatures, such as 450°C to 650°C, helps reduce residual stresses and enhances both toughness and ductility. However, excessive heat treatment can introduce brittle phases, so careful control of temperature and duration remains essential.

316L stainless steel’s excellent ductility supports its use in applications that require frequent forming or repeated stress cycles. This property also contributes to its popularity in industries where flexibility and durability are critical.

Both 316 and 316L stainless steel perform well at elevated temperatures, but their maximum recommended operating temperatures differ. 316 stainless steel has a melting range between 2,500 °F and 2,550 °F. However, it is less suitable for very high-temperature applications compared to 304 stainless steel. In most industrial settings, 316 and 316L are used at temperatures up to 800°F–1,500°F. Experimental studies show that 316L stainless steel maintains a stable austenite phase and microstructure at temperatures up to 800°C (about 1,472°F). This stability ensures reliable mechanical properties and corrosion resistance during prolonged exposure to heat.

The mechanical properties of both grades can change after welding or heat treatment. For example, post-weld heat treatment at 750°C for 24 hours increases microhardness in 316L due to carbide precipitation. Proper heat treatment enhances the synergy between strength and ductility, but excessive temperatures can cause the formation of brittle phases and reduce overall performance.

For applications involving high temperatures, engineers should consider the specific operating range and the need for post-weld treatments to maintain optimal mechanical properties.

316 stainless steel serves as a versatile material across many industries. Its combination of high mechanical strength, excellent corrosion resistance, and reliable heat tolerance makes it suitable for demanding environments. Manufacturers often select this alloy for construction, heavy machinery, and automotive components. The material’s ability to withstand high loads and stresses supports its use in building facades, bridges, and structural supports. In the aerospace sector, engineers rely on its heat resistance for jet engine parts and exhaust systems. The food processing industry values its hygienic properties and ease of cleaning, which help maintain sanitary conditions. Medical device manufacturers use it for surgical instruments and equipment, benefiting from its non-reactive surface and fabricability.

316 stainless steel contains molybdenum, which enhances its resistance to chlorides and aggressive chemicals. This property makes it a preferred choice for marine-grade steels and chemical processing equipment exposed to harsh substances.

The table below summarizes common uses and the properties that make 316 stainless steel suitable:

| Industry/Application | Common Uses | Key Properties |

|---|---|---|

| Marine | Ship hardware, coastal infrastructure | Chloride resistance, durability |

| Chemical Processing | Storage tanks, piping, heat exchangers | Acid/alkali resistance, strength |

| Food Processing | Conveyors, storage tanks, prep surfaces | Hygiene, corrosion resistance |

| Medical Devices | Surgical tools, implants | Cleanability, biocompatibility |

| Construction | Bridges, supports, facades | Mechanical strength, longevity |

316L stainless steel stands out in applications where weldability and post-weld corrosion resistance are critical. Its low carbon content prevents sensitization during welding, making it ideal for fabricating tanks, pressure vessels, and piping systems. The chemical industry uses this alloy for reactors, pumps, and valves that handle strong acids and alkalis. In the food and beverage sector, manufacturers choose it for mixers, sanitary piping, and storage containers that require frequent cleaning and exposure to acidic or salty ingredients. The pharmaceutical industry relies on 316L for sterile prep tables, cleanroom tubing, and drug manufacturing equipment, where hygiene and regulatory compliance are essential. Marine and coastal applications benefit from its ability to resist chloride-induced corrosion, supporting the longevity of boat railings and submerged supports.

316L stainless steel meets FDA and sanitary standards, ensuring cleanability and long-term durability in environments where hygiene cannot be compromised.

Marine application demands materials that withstand saltwater and harsh weather. Both 316 and 316L stainless steels appear in ship fittings, railings, propeller shafts, and underwater enclosures. Their molybdenum content provides exceptional resistance to pitting and crevice corrosion, making them reliable marine-grade steels.

Food processing facilities use these alloys for conveyor systems, mixers, and storage tanks. The smooth, non-reactive surfaces prevent bacterial buildup and withstand repeated cleaning with caustic agents. 316L’s superior weldability ensures that welded joints remain resistant to corrosion, supporting sanitary operations.

Pharmaceutical manufacturing requires strict hygiene and corrosion resistance. Cleanroom equipment, sterile fluid delivery systems, and storage containers often use 316L stainless steel. Its low carbon content allows use in the as-welded condition, maintaining integrity and compliance with regulatory standards.

Chemical processing plants rely on both grades for storage tanks, piping, and processing equipment. The alloys’ resistance to acids, alkalis, and chlorides ensures safe handling of corrosive substances. 316L’s enhanced weldability and corrosion resistance make it the preferred choice for welded structures and aggressive chemical environments.

Selecting between 316 and 316L stainless steel starts with understanding the operating environment. Both grades contain molybdenum, which improves resistance to pitting and crevice corrosion in chloride-rich settings. However, 316L’s lower carbon content provides natural immunity against weld decay, even without post-weld heat treatment. This makes 316L the preferred choice in environments where corrosion is a major concern, especially after welding.

316L resists intergranular corrosion caused by chromium carbide precipitation, making it reliable in marine, chemical, and pharmaceutical industries.

In process industries like paper and pulp factories, 316L is widely used for its ability to withstand harsh corrosive media and maintain performance after welding.

316 is more susceptible to intergranular corrosion, particularly in the 427°C to 816°C range, especially after welding.

For applications involving prolonged chloride exposure or aggressive chemicals, 316L offers greater long-term reliability.

Welding requirements play a critical role in grade selection. 316L stainless steel’s low carbon content reduces the risk of carbide precipitation during welding. This property minimizes the need for solution annealing after welding or repairs, saving time and cost.

316L is preferred when weld repairs are likely or when post-weld heat treatment cannot be performed.

Industry specifications often require 316L for machined parts in corrosive services where welding or repairs may occur.

The corrosion resistance of fully annealed 316 and 316L is similar, but 316L maintains this resistance in the as-welded condition.

Choosing 316L can help avoid the complexity and expense of post-weld heat treatment, especially in large or intricate assemblies.

Mechanical strength requirements also influence the decision. 316 stainless steel, with its higher carbon content, delivers greater tensile and yield strength. This makes it suitable for applications that demand higher mechanical strength and resistance to stress corrosion cracking, especially at elevated temperatures.

| Property | 316 Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Carbon Content | Up to 0.08% | Up to 0.03% |

| Tensile Strength | Higher (approx. 515-1180 MPa) | Slightly lower (approx. 485-1160 MPa) |

| Yield Strength | Higher (~205 MPa) | Lower (~170 MPa) |

| Ductility | Less ductile | More ductile |

| Formability | Less formable | More formable |

| Weldability | Risk of carbide precipitation | Better, less prone to cracking |

| High Temp Performance | Retains strength above 700°C | Loses strength faster at high temps |

Projects that require maximum strength and heat resistance favor 316 stainless steel. In contrast, 316L is better for applications involving extensive welding, bending, or shaping, where ductility and resistance to intergranular corrosion after welding are more important.

When selecting between 316 and 316L stainless steel, cost often becomes a deciding factor for many projects. Both grades belong to the premium end of the stainless steel market, but their prices do not always match exactly. Manufacturers and buyers should understand the cost implications before making a final choice.

316L stainless steel usually costs about 5% to 10% more per kilogram than standard 316 stainless steel. This price difference results from the stricter control of alloy composition and the enhanced corrosion resistance required for 316L. Producers must use more precise manufacturing processes to achieve the lower carbon content and, in some cases, add nitrogen to meet performance standards. These steps increase production costs, which suppliers pass on to buyers.

The following table summarizes the typical price range for both grades:

| Stainless Steel Grade | Typical Price Range (USD/kg) | Relative Cost Difference |

|---|---|---|

| 316 | $2.50 – $4.50 | Baseline |

| 316L | $2.75 – $5.00 | 5–10% higher |

Note: Prices can vary by region, supplier, and order volume. Always request updated quotes for large projects.

For small-scale applications, the cost difference may seem minor. However, in large-scale projects—such as constructing chemical processing plants, marine structures, or food production facilities—the extra cost for 316L can become significant. For example, a 100-ton order could result in thousands of dollars in additional material expenses.

Despite the higher price, many industries choose 316L for its superior weldability and corrosion resistance. The long-term savings from reduced maintenance, fewer repairs, and longer service life often outweigh the initial investment. Engineers and procurement teams should weigh the upfront cost against the potential for lower lifecycle expenses.

Key points to consider when evaluating cost:

316L offers better performance in welded or highly corrosive environments.

The price premium for 316L reflects its enhanced properties and stricter quality controls.

For projects where welding is minimal and corrosion risk is low, 316 may provide a more cost-effective solution.

Tip: Always balance material cost with performance requirements and expected service conditions. The right choice can lead to better value over the lifespan of the equipment or structure.

The primary difference between 316 and 316L stainless steel lies in carbon content, which directly affects corrosion resistance, weldability, and mechanical strength. The table below highlights these distinctions:

| Aspect | 316 Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Carbon Content | Up to 0.08% | Up to 0.03% |

| Corrosion Resistance | Good, risk after welding | Superior, especially at welds |

| Weldability | Needs post-weld treatment | Excellent, less risk of decay |

| Strength | Slightly higher | Better ductility, toughness |

For welded or highly corrosive environments, 316L offers lower maintenance and longer service life. For high-strength needs, 316 may be preferred. Complex projects benefit from expert consultation.

The main difference is carbon content. 316 contains up to 0.08% carbon, while 316L has a maximum of 0.03%. This lower carbon level in 316L improves weldability and resistance to intergranular corrosion.

Yes, both grades can be welded. However, 316L is preferred for welding because it resists carbide precipitation, which helps prevent weld decay and maintains corrosion resistance at the joints.

316L stainless steel performs better in marine environments. Its low carbon content protects against pitting and crevice corrosion caused by saltwater, making it ideal for ship fittings and coastal structures.

316L usually costs about 5–10% more than 316. The higher price reflects stricter quality controls and improved corrosion resistance, especially after welding or in aggressive environments.

Engineers sometimes use these grades interchangeably, but not always. 316L is best for welded structures or corrosive environments. 316 works well where higher strength is needed and welding is minimal.

Nitrogen strengthens 316L stainless steel and improves its resistance to localized corrosion. Some manufacturers add nitrogen to enhance mechanical properties and maintain corrosion resistance, especially in demanding applications.

Industries such as marine, food processing, pharmaceuticals, and chemical processing use both grades. 316L is common in welded equipment, while 316 is chosen for parts needing higher strength.

Both grades resist rust very well. However, exposure to harsh chemicals or saltwater over time can cause surface discoloration or minor corrosion. Regular cleaning helps maintain their appearance and performance.