close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-11-07 Origin: Site

Selecting the right austenitic stainless steel bar grade ensures equipment meets demanding industrial requirements. Each austenitic stainless steel bar offers unique properties for specific applications. Key options include 303 for superior machinability, 304 for general use, 316 for enhanced corrosion resistance, 310 for high temperatures, 321 for stability at elevated temperatures, and 200 series for cost-effective strength. Consider corrosion resistance, strength, machinability, temperature limits, and cost when choosing a stainless steel bar.

| Stainless Steel Grade | Common Industrial Uses |

|---|---|

| 303 | Shafts, valve bodies, trim, food industry, chemical resistance. |

| 304 | General food industry, machining parts, welded components. |

| 316 | Marine, pharmaceutical, food, surgical, textile, dyeing equipment. |

| 310 | High-temperature service, heat exchangers, sulfur environments. |

| 321 | High-temperature, titanium-stabilized, improved corrosion resistance. |

| 200 Series | Cost-driven applications, higher yield strength, good weldability. |

Corrosion resistance stands as a primary consideration when selecting an austenitic stainless steel bar for industrial use. Different grades offer varying levels of protection against rust and chemical attack. For example, 304 stainless steel provides exceptional corrosion resistance in most environments, making it a popular choice for food processing, healthcare, and outdoor applications. In marine or chemical processing settings, 316 stainless steel delivers improved corrosion resistance due to its higher molybdenum content. This feature protects equipment from harsh chemicals and saltwater exposure.

The alloying elements in each grade, such as chromium and nickel, play a crucial role in determining how corrosion resistant the material will be. Grades like 321, stabilized with titanium, resist corrosion at high temperatures, making them suitable for welding and heat-intensive processes. In aggressive environments, duplex stainless steel may offer even greater protection, but austenitic grades remain the standard for most industrial needs.

Tip: Always match the corrosion resistance of the stainless steel bar to the specific chemicals and environmental conditions present in your application.

Mechanical strength defines how well a stainless steel bar can withstand applied forces without deforming or breaking. Industrial applications often require materials with high tensile strength and durability. Grades such as 304 and 316 combine good strength with ductility, supporting both structural integrity and flexibility. For heavy-duty uses, some industries may consider martensitic or precipitation-hardening grades, but austenitic stainless steel bars still provide reliable performance for most tasks.

The table below highlights typical strength values for common grades:

| Stainless Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 303 | N/A | ~310 | N/A |

| 304 | Min 515 | Min 205 | Min 40 |

Austenitic stainless steel bars maintain their properties across a wide range of temperatures, making them suitable for both low and high-temperature environments. This versatility ensures consistent performance in demanding industrial settings.

Machinability refers to how easily a material can be cut, shaped, or finished using machine tools. In high-volume manufacturing, machinability directly impacts production efficiency and tool life. Among austenitic stainless steels, 303 stands out for its excellent machinability. The addition of sulfur and manganese in 303 improves chip formation and reduces power consumption during machining. This makes it ideal for producing complex parts quickly and with minimal tool wear.

While 304 stainless steel also offers good machinability, it does not match the efficiency of 303 in demanding manufacturing environments. Selecting the right grade for machinability ensures lower production costs and higher output quality.

Note: Optimizing tooling and machining processes further enhances the machinability of any stainless steel bar, reducing downtime and maintenance needs.

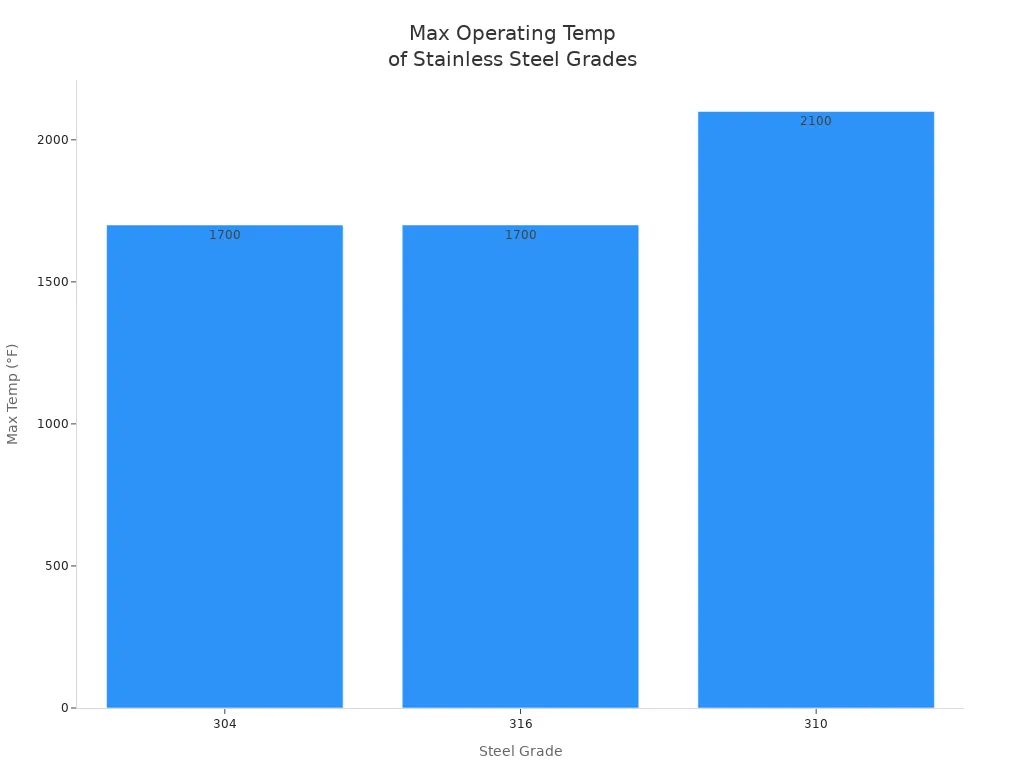

Temperature resistance plays a critical role in selecting an austenitic stainless steel bar for industrial applications. Many industries, such as chemical processing, power generation, and food manufacturing, require materials that maintain their strength and corrosion resistance at elevated temperatures. Each stainless steel grade offers a different threshold for continuous operation in high-heat environments.

Grade 304 stainless steel, known for its versatility, can withstand continuous service temperatures up to 1700°F (925°C). Grade 316, which contains molybdenum, also performs well at these temperatures, making it suitable for environments where both heat and corrosion resistance are essential. Grade 310 stands out for its superior high-temperature performance, resisting oxidation and maintaining structural integrity up to 2100°F (1150°C). Grade 321, a titanium-stabilized version of 304, prevents carbide precipitation during prolonged exposure to heat. This stabilization allows it to retain corrosion resistance and mechanical properties at temperatures similar to 304, but with improved reliability during thermal cycling.

The following table summarizes the maximum continuous operating temperatures for common austenitic stainless steel bar grades:

| Grade | Max Continuous Operating Temperature |

|---|---|

| 304 | 1700°F (925°C) |

| 316 | 1700°F (925°C) |

| 310 | 2100°F (1150°C) |

| 321 | ~1700°F (925°C), titanium-stabilized |

Tip: For applications involving frequent temperature changes, consider grades with stabilization elements like titanium. These grades help prevent structural degradation caused by thermal cycling.

Selecting the right grade for temperature resistance ensures equipment longevity and safety in demanding industrial settings.

Cost remains a decisive factor when choosing an austenitic stainless steel bar grade. Material prices can influence project budgets, especially for large-scale or long-term operations. Grade 304 stainless steel offers a balance of performance and affordability. It is the most widely used austenitic grade, providing reliable corrosion resistance and mechanical strength at a lower price point.

Grade 316, which includes molybdenum for enhanced corrosion and heat resistance, typically costs more than 304. This price difference reflects the added alloying elements and the improved properties they provide. Grade 303, a free-machining variant of 304, may have a slightly higher cost due to the sulfur addition, but it offers significant savings in machining time and tool wear. The 200 series grades, designed for cost-sensitive applications, often provide a more economical alternative, though they may not match the corrosion resistance of 304 or 316.

The table below compares the approximate prices and cost characteristics of common grades:

| Stainless Steel Grade | Approximate Price | Scrap Price per Pound | Cost Comparison Summary |

|---|---|---|---|

| 304 | $1.55 per pound (sheet) | $0.56/lb scrap | Lower cost among 304 and 316; commonly used and versatile |

| 316 | N/A (new price not found) | $0.78/lb scrap | Higher cost than 304, due to added molybdenum for corrosion resistance |

Note: Prices fluctuate based on market conditions and supplier contracts. Always consult with manufacturers for the most accurate and current pricing.

Choosing the right grade involves balancing performance requirements with budget constraints. For most general industrial uses, 304 provides an optimal mix of cost and capability. For specialized environments, the higher initial investment in 316 or other premium grades often pays off through reduced maintenance and longer service life.

303 grade stands out among austenitic stainless steel grades for its excellent machinability. Manufacturers add extra sulfur to the alloy, which helps tools cut through the material more easily. This adjustment, however, slightly reduces corrosion resistance compared to type 304 stainless steel. Industries often select 303 for high-speed machining of components such as gears, shafts, screws, and bolts. The grade maintains good strength and toughness, making it suitable for precision parts that require frequent machining.

Key Features of 303 Grade:

Enhanced machinability due to increased sulfur content

Good mechanical strength and toughness

Lower corrosion resistance than 304

Typical Applications:

Machined components (gears, shafts, screws, nuts, bolts)

Valve parts

Fittings in food and beverage equipment

Type 304 stainless steel serves as the baseline for austenitic stainless steel. It contains approximately 18-20% chromium and 8-10.5% nickel, which gives it a balance of corrosion resistance, strength, and formability. This grade resists oxidation and most common chemicals, making it the most widely used stainless steel in the world. Type 304 stainless steel appears in a broad range of industries, including architecture, food processing, medical devices, and automotive manufacturing.

Composition Highlights:

Chromium: 18-20%

Nickel: 8-10.5%

Carbon: up to 0.08%

Common Industrial Applications:

| Application Area | Examples |

|---|---|

| Architecture | Handrails, cladding |

| Food & Beverage | Processing equipment, storage tanks, brewing systems |

| Medical | Surgical instruments, implants |

| Automotive | Exhaust systems, catalytic converters |

Note: Type 304 stainless steel offers a reliable combination of affordability and performance for most general-purpose uses.

Type 316 stainless steel builds on the foundation of 304 by adding 2-3% molybdenum. This addition significantly improves resistance to pitting and crevice corrosion, especially in chloride-rich environments like marine or chemical processing settings. Type 316 stainless steel also maintains high strength and durability, even at elevated temperatures. Industries choose this grade when equipment faces harsh chemicals, saltwater, or sterilization processes.

Key Composition Differences:

Chromium: 16-18%

Nickel: 10-14%

Molybdenum: 2-3%

Carbon: up to 0.08%

Typical Uses:

| Application Area | Examples |

|---|---|

| Marine | Fasteners, pumps, valves, boat fittings |

| Chemical Processing | Reactors, storage vessels, piping |

| Food & Beverage | Processing equipment, kitchen surfaces |

| Pharmaceutical | Surgical tools, cleanroom equipment |

Tip: Type 316 stainless steel provides superior performance in environments where corrosion from chlorides or harsh chemicals is a concern.

These three grades—303, type 304 stainless steel, and type 316 stainless steel—form the backbone of many industrial applications. Each offers a unique balance of machinability, corrosion resistance, and mechanical properties, allowing engineers to match the right material to specific operational demands.

310 grade austenitic stainless steel stands out for its excellent performance in high-temperature environments. This grade contains higher levels of chromium (24-26%) and nickel (19-22%) compared to other austenitic stainless steels. These elements help the material resist oxidation and scaling even when exposed to temperatures up to 2100°F (1150°C). Industries often select 310 grade for furnace parts, heat exchangers, and kilns.

310 grade maintains its strength and toughness at elevated temperatures. It also resists thermal fatigue and cyclical heating, which makes it reliable for equipment that faces frequent temperature changes. The alloy’s high chromium content provides good corrosion resistance, but it performs best in environments where heat is the main concern rather than exposure to aggressive chemicals.

Typical Applications for 310 Grade:

Furnace components

Heat treatment baskets and jigs

Kiln liners

Radiant tubes

Note: 310 grade is not recommended for environments with high concentrations of sulfur gases, as these can cause rapid degradation.

321 grade austenitic stainless steel offers stability during long-term exposure to high temperatures. Manufacturers add titanium to this grade, which prevents carbide precipitation during welding or prolonged heating. This feature helps 321 grade maintain its corrosion resistance and mechanical properties, even after repeated thermal cycles.

The composition of 321 grade closely matches that of 304, but the titanium addition makes it ideal for applications involving continuous or repeated heating between 800°F and 1500°F (427°C to 816°C). Industries use 321 grade in exhaust manifolds, jet engine parts, and chemical processing equipment.

Key Features of 321 Grade:

Titanium-stabilized for improved resistance to intergranular corrosion

Good weldability and formability

Maintains strength at elevated temperatures

Common Uses:

Aircraft exhaust systems

Expansion joints

High-temperature chemical processing

Tip: When welding or fabricating components that will face high heat, 321 grade helps prevent loss of corrosion resistance.

200 series grades provide a cost-effective alternative to traditional 300 series stainless steels. These alloys replace some of the nickel content with manganese and nitrogen, which reduces costs while maintaining good mechanical properties. 200 series grades offer higher yield strength than 304, but their corrosion resistance is generally lower, especially in chloride-rich or acidic environments.

Manufacturers often use 200 series grades for applications where cost savings are important and exposure to harsh chemicals is limited. These grades work well for kitchen utensils, food processing equipment, and some structural components.

| 200 Series Grade | Key Alloying Elements | Typical Uses |

|---|---|---|

| 201, 202 | Manganese, Nitrogen | Cookware, sinks, appliances |

Alert: 200 series grades may not be suitable for marine or highly corrosive environments. Always assess the application’s requirements before selecting these alloys.

Engineers should compare the mechanical and corrosion properties of all available grades to ensure the best fit for each industrial use.

The 'L' suffix in austenitic stainless steel bar grades stands for "low carbon." Grades like 304L and 316L contain less carbon than their standard counterparts. This adjustment in composition brings several important benefits to industrial applications.

Low carbon content improves weldability. When engineers weld stainless steel, high carbon levels can cause carbide precipitation along the weld seam. This process weakens the metal and increases the risk of corrosion, especially in harsh environments. By reducing the carbon content, 'L' grades help prevent this problem. As a result, welded joints stay strong and resist corrosion over time.

Industries often choose 'L' grades for projects that require frequent or critical welding. For example, 316L stainless steel appears in marine equipment and reactor pressure vessels. These applications demand both high corrosion resistance and reliable weld integrity. The lower carbon content in 316L ensures that welded structures perform well, even when exposed to saltwater or aggressive chemicals.

| Grade | Carbon Content (max) | Typical Use Cases | Key Benefit |

|---|---|---|---|

| 304 | 0.08% | General fabrication, non-welded structures | Standard strength |

| 304L | 0.03% | Piping, tanks, welded assemblies | Enhanced weldability |

| 316 | 0.08% | Chemical, food, and marine equipment | Superior corrosion resistance |

| 316L | 0.03% | Marine, pharmaceutical, pressure vessels | Welded corrosion resistance |

Although 'L' grades offer better weldability and corrosion resistance after welding, they have slightly lower mechanical strength than standard grades. This trade-off rarely affects performance in most industrial settings. The improved resistance to corrosion, especially after welding, often outweighs the minor reduction in strength.

Tip: Specify 'L' grades when designing welded structures that will face corrosive environments or require long service life. Dual-certified materials, such as 316/316L, combine the mechanical strength of standard grades with the low carbon benefits of 'L' grades, offering flexibility for demanding projects.

Engineers should consider the application’s welding requirements and exposure conditions before selecting an 'L' grade. In environments where corrosion after welding poses a risk, 'L' grades provide a reliable solution. Their use helps extend equipment lifespan and reduce maintenance costs, making them a smart choice for many industrial applications.

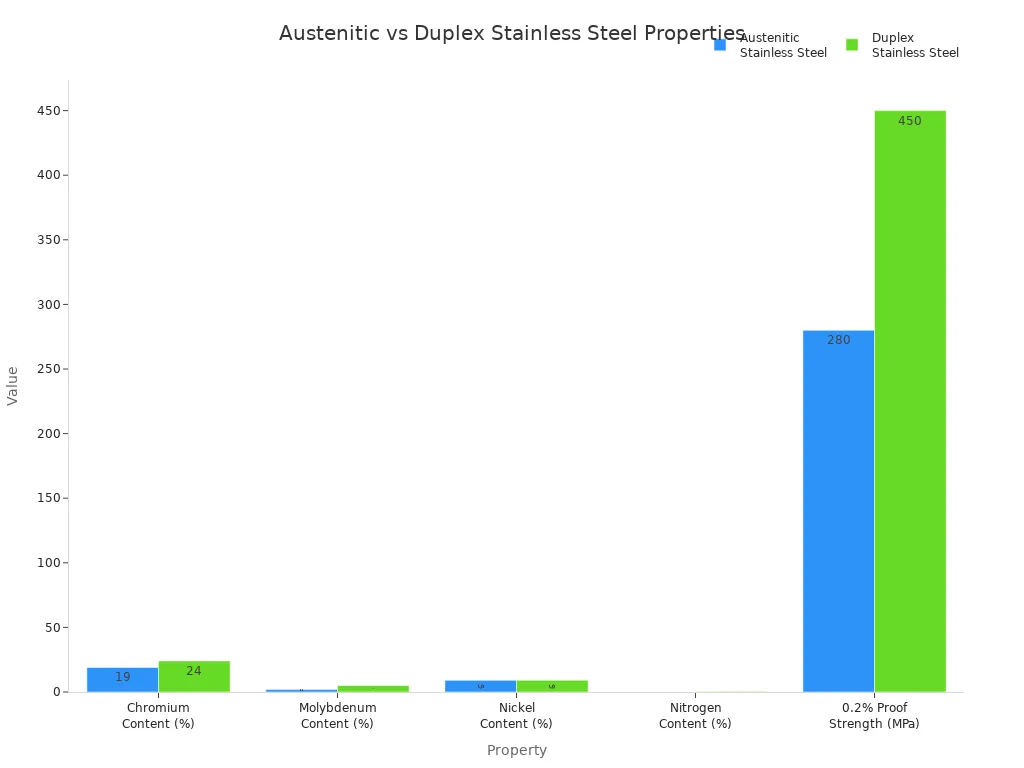

Engineers often compare austenitic and duplex stainless steel bars when selecting materials for demanding environments. Duplex stainless steels combine ferrite and austenite phases, resulting in a unique balance of properties. This biphasic structure gives duplex bars higher strength and superior resistance to stress corrosion cracking, especially in chloride-rich settings. Austenitic bars, such as type 304 stainless steel, offer excellent ductility and toughness but are more susceptible to chloride-induced corrosion.

| Property / Steel Type | Austenitic Stainless Steel (e.g., Type 304) | Duplex Stainless Steel (e.g., 22% Cr Duplex) | Superduplex Stainless Steel |

|---|---|---|---|

| Chromium Content (%) | ~18-20 | 20-28 | Up to 28 |

| Molybdenum Content (%) | Up to ~2 | Up to 5 | Up to 5 |

| Nickel Content (%) | ~8-10 | Up to 9 | Varies |

| Nitrogen Content (%) | Low | 0.05-0.50 | Similar or higher |

| 0.2% Proof Strength (MPa) | ~280 | Minimum ~450 | Minimum ~550 |

| Corrosion Resistance | Good, but susceptible to chloride stress corrosion and pitting | Superior resistance to chloride stress corrosion and pitting | Even higher corrosion resistance |

| Stress Corrosion Cracking | More susceptible | Better resistance | Best resistance |

| Typical Applications | General purpose stainless steel | Offshore oil & gas, chemical processing, marine | Highly demanding environments |

Duplex stainless steel bars excel in offshore, chemical, and marine industries due to their enhanced corrosion resistance and mechanical strength. Austenitic bars remain the standard for general industrial use, offering reliable performance and easier fabrication.

The 300 and 200 series represent two important stainless steel families. The 300 series, including type 304 and type 316 stainless steel, uses higher nickel content, which improves corrosion resistance and ductility. The 200 series replaces some nickel with manganese and nitrogen, making these bars more cost-effective but less resistant to corrosion, especially in harsh environments.

| Aspect | 200 Series Austenitic Stainless Steel | 300 Series Austenitic Stainless Steel |

|---|---|---|

| Chemical Composition | Lower nickel (1-3%), chromium 16-18%, manganese and nitrogen substitute nickel | Higher nickel (8-10%), chromium 16-20%, sometimes molybdenum (e.g., 316) |

| Corrosion Resistance | Lower corrosion resistance, especially in chloride environments | Excellent corrosion resistance, especially in chloride-rich and harsh environments |

| Magnetic Properties | Generally magnetic after cold working | Non-magnetic in annealed condition |

| Tensile Strength | Higher tensile strength | Lower tensile strength but better ductility and toughness |

| Ductility & Weldability | Less ductile, weld cracking possible | Better ductility, excellent weldability |

| Typical Applications | Cost-sensitive, structural parts, appliances | Food processing, medical, chemical, marine, architectural |

| Cost | More cost-effective | More expensive |

The 200 series suits indoor or low-corrosive applications where cost is a priority. The 300 series, especially type 316 stainless steel, remains the preferred choice for environments requiring high corrosion resistance and formability.

Selecting among 303, 304, and type 316 stainless steel bars depends on the balance between machinability and corrosion resistance. Type 303 contains sulfur to improve machinability, making it ideal for heavily machined parts like nuts and bolts. However, this addition slightly reduces its corrosion resistance. Type 304 stainless steel offers excellent corrosion resistance and versatility but is harder to machine due to work hardening. Type 316 stainless steel stands out for its superior corrosion resistance, especially in chloride-rich or marine environments, thanks to added molybdenum.

| Stainless Steel Grade | Corrosion Resistance | Machinability | Key Alloying Elements | Typical Applications |

|---|---|---|---|---|

| 303 | Lowest among the three | Highest | ~18% Cr, 8% Ni, +0.15% S | Heavily machined parts |

| 304 | Moderate; excellent | Lowest | ~18% Cr, 8% Ni | Kitchenware, architecture |

| 316 | Highest, especially against chlorides | Moderate | 16-18% Cr, 10-14% Ni, 2-3% Mo | Chemical, marine |

Tip: Choose 303 for maximum machinability, 304 for general versatility, and 316 for the best corrosion resistance in aggressive environments.

Industrial environments often demand materials that can withstand extreme heat without losing strength or corroding. Austenitic stainless steel bars, especially grades 310 and 321, excel in these high-temperature settings. Their unique alloy compositions help them maintain structural integrity and resist oxidation when exposed to elevated temperatures.

| Grade | Key Characteristics | Temperature Suitability | Notes |

|---|---|---|---|

| 321 | Titanium stabilized austenitic stainless steel | Up to 1652˚F (900˚C) | High strength, scaling resistance, phase stability, prevents carbide precipitation during welding |

| 310 | High chromium and nickel content | High-temperature resistance (above 900˚C) | Excellent oxidation resistance and strength at elevated temperatures |

| Austenitic Stainless Steel Family | High weldability, high ductility, high-temperature resistance | Suitable for high-temp industrial use | General properties making them ideal for such applications |

Grade 310 stands out for its ability to perform in environments above 900˚C. Its high chromium and nickel content provide excellent resistance to oxidation and scaling. This makes grade 310 a top choice for furnace parts, heat exchangers, and other equipment exposed to continuous heat. The alloy maintains both strength and toughness, even during rapid temperature changes.

Grade 321 offers another solution for high-temperature applications. Engineers often select this grade for its titanium stabilization. The addition of titanium prevents carbide precipitation during welding or prolonged heating. This feature helps grade 321 retain its corrosion resistance and mechanical properties up to 1652˚F (900˚C). Industries use 321 stainless steel in exhaust manifolds, jet engine parts, and chemical processing equipment where phase stability and scaling resistance are critical.

Tip: For welded structures exposed to high heat, grade 321 provides extra protection against intergranular corrosion.

Austenitic stainless steels, as a family, bring several advantages to high-temperature industrial use. They offer high weldability and ductility, which simplifies fabrication and installation. Their resistance to thermal fatigue ensures long service life, even in demanding conditions.

When comparing high-temperature grades, engineers should consider the specific operating temperature, the need for welding, and the risk of oxidation. Grade 310 suits applications with extreme heat and oxidation risks. Grade 321 works best where welding and phase stability matter most.

Selecting the right high-temperature stainless steel bar grade ensures equipment reliability, reduces maintenance, and extends service life in harsh industrial environments.

Chemical processing environments demand materials that can withstand aggressive chemicals, high temperatures, and frequent cleaning. Selecting the right austenitic stainless steel bar grade ensures equipment durability and safety. Engineers often choose grades based on corrosion resistance, weldability, and stability at elevated temperatures.

The following table summarizes the most suitable grades for chemical processing:

| Grade | Key Alloying Elements | Corrosion Resistance Features | Application Reasoning |

|---|---|---|---|

| 316 | 16% Chromium, 10% Nickel, 2% Molybdenum | Enhanced resistance to chlorides due to molybdenum | Ideal for devices exposed to chlorides and harsh chemicals. |

| 316L | Low carbon variant of 316 | Reduced carbide precipitation during welding | Preferred for welded equipment in chemical and pharmaceutical industries. |

| 321 | Titanium stabilized | Resists intergranular corrosion and high-temperature exposure | Used in high-temperature reactors and piping. |

| 347 | Niobium and tantalum stabilized | Resistant to sensitization and intergranular corrosion at high temperatures | Applied in heat exchangers and furnace components. |

| 304 | ~18% Chromium, 8% Nickel | Good resistance for milder chemicals | Used for tanks and piping with less aggressive substances. |

Note: Type 316 stainless steel stands out for its superior resistance to pitting and crevice corrosion, especially in chloride-rich environments.

Regulatory compliance is essential in chemical processing. Standards such as ASTM A312/A312M and ASTM A240/A240M specify chemical composition and mechanical properties for stainless steel bars and plates. Industry-specific standards, including those for petroleum and chemical industries, ensure safety and performance. Quality control measures, such as regular inspection for wear and corrosion, help maintain equipment integrity and prevent contamination.

Routine maintenance practices include:

Inspecting for pitting and crevice corrosion

Ensuring seals and gaskets remain intact

Cleaning spills immediately to reduce contamination risks

Scheduling shutdowns for thorough cleaning and inspection

These steps help extend the service life of austenitic stainless steel bar products in chemical processing applications.

The food and beverage industry relies on stainless steel for its hygiene, corrosion resistance, and ease of cleaning. Equipment must withstand frequent washdowns, exposure to acids, and contact with a variety of food products. Grades 304 and 316 are the most common choices for these applications.

Grade 304 contains 18% chromium and 8% nickel. It offers excellent corrosion resistance to oxidizing acids and cleaning agents. Manufacturers use it for sinks, storage tanks, fermentation vats, and dishwashers.

Grade 316 includes higher levels of chromium, nickel, and molybdenum. This composition provides superior resistance to chlorides and acids. It is ideal for meat processing plants, environments with high salt content, and equipment that requires frequent cleaning.

Austenitic stainless steels used in food and beverage processing must meet strict hygiene requirements. Surfaces must be smooth and non-porous to prevent bacterial growth and allow easy sanitization. Regulatory standards such as FDA, NSF, and EHEDG set guidelines for material safety and cleanliness. Surface finishes like #4 brushed or electropolished further enhance cleanability and corrosion resistance.

| Requirement Category | Details |

|---|---|

| Corrosion Resistance | Must resist acids, chlorides, and cleaning chemicals. |

| Surface Finish | Smooth, non-porous, roughness below 32 Ra for easy cleaning. |

| Regulatory Compliance | Must meet FDA, NSF, EHEDG standards. |

| Stainless Steel Grades | 304/304L for general use; 316/316L for more corrosive or saline environments. |

| Manufacturing Standards | ISO 9001:2015, TUV approval, PED certification, and documentation for quality assurance. |

| Surface Finishing Options | #4 brushed, mirror, electropolished, and passivated finishes for hygiene and corrosion resistance. |

Tip: Grade 316 is the preferred choice for equipment exposed to salty or acidic foods and aggressive cleaning routines.

Construction projects often require materials that can endure outdoor exposure, structural loads, and variable weather conditions. Austenitic stainless steel bar grades provide the necessary strength and corrosion resistance for these demanding environments.

Grade 304 is widely used in construction for its balance of strength, formability, and corrosion resistance. It performs well in most outdoor settings but may not withstand saltwater exposure.

Grade 316 contains molybdenum, which enhances resistance to saline and coastal environments. This grade is especially suitable for structures near the ocean or in areas with de-icing salts.

Grade 321, stabilized with titanium, prevents carbide precipitation during welding. It is used in high-temperature applications and outdoor structures that require temperature stability.

The 300 series austenitic stainless steels, with at least 16% chromium and 6% nickel, offer excellent durability and formability. These properties make them the preferred choice for building facades, handrails, bridges, and architectural features exposed to the elements.

Alert: For coastal or salt-exposed construction, always specify grade 316 to prevent pitting and extend service life.

Marine environments present some of the harshest conditions for stainless steel bars. High chloride levels in seawater, combined with fluctuating temperatures, create a strong risk for corrosion, especially crevice and pitting corrosion. Selecting the right austenitic stainless steel grade ensures long-term durability and safety for marine equipment, fasteners, and structural components.

Austenitic stainless steels remain the preferred choice for most marine applications due to their excellent corrosion resistance and mechanical properties. However, not all grades perform equally well in these challenging settings. The following points highlight key considerations for grade selection in marine environments:

UNS S31266 stands out for its superior resistance to crevice corrosion in chlorinated seawater. This grade shows no crevice corrosion initiation below 35°C, even at chlorine levels up to 15 ppm. It performs reliably in heat exchangers, seawater piping, and other submerged components.

Grade 316 and 316L offer strong resistance to pitting and general corrosion in saltwater. The addition of molybdenum improves their ability to withstand chloride attack, making them a standard choice for boat fittings, marine fasteners, and offshore structures.

Lower alloyed duplex grades, such as UNS S32205, do not provide adequate protection in chlorinated seawater. These grades may fail under severe crevice conditions or at elevated temperatures.

Temperature and chlorine levels play a critical role in corrosion risk. As temperature rises above 40°C, even highly alloyed stainless steels can experience crevice corrosion at low chlorine concentrations. Engineers must consider both environmental temperature and residual chlorine when specifying materials.

| Stainless Steel Grade | Marine Suitability | Key Features | Typical Applications |

|---|---|---|---|

| UNS S31266 | Excellent | Superior crevice corrosion resistance | Heat exchangers, seawater piping |

| 316/316L | Very Good | Molybdenum for chloride resistance | Boat fittings, fasteners, pumps |

| 304/304L | Moderate | General corrosion resistance, less for chlorides | Deck hardware, interior components |

| S32205 (Duplex) | Poor | Not suitable for chlorinated seawater | Not recommended |

Tip: For marine environments with high chlorine or elevated temperatures, always verify the grade’s performance limits. Regular inspection and maintenance help extend service life in aggressive coastal or offshore conditions.

Special regulations may apply to marine equipment, especially for vessels or offshore platforms. Compliance with standards such as ASTM A276 and ASTM A479 ensures material quality and traceability. Proper grade selection, combined with routine cleaning and inspection, helps prevent costly failures and ensures safety in marine operations.

Selecting the right austenitic stainless steel bar for industrial use requires a systematic approach. The following checklist helps engineers and procurement teams make informed decisions:

Identify Application Requirements

Determine the primary needs of the project, such as corrosion resistance, strength, and temperature limits.

Assess the Operating Environment

Evaluate exposure to chemicals, moisture, salt, or extreme temperatures. Grades like 304 and 316 perform well in a wide range of environments.

Review Mechanical Properties

Check the required strength, ductility, and toughness. Higher nickel content, as found in grade 316, increases toughness.

Consider Fabrication Needs

Decide if the bar will need machining, welding, or forming. Free-machining grades like 303 reduce tool wear, while low-carbon grades such as 304L or 316L improve weldability.

Understand Grade Designations

Familiarize yourself with common systems like AISI, SAE, and UNS. This knowledge ensures the selected stainless steel matches the application.

Evaluate Cost and Availability

Balance initial material costs with long-term maintenance and replacement expenses.

Check Compliance and Certification

Confirm that the chosen grade meets industry standards and customer requirements.

Tip: Always document each step to ensure traceability and compliance with project specifications.

Before purchasing, ask suppliers targeted questions to confirm the suitability of the stainless steel bar:

What level of corrosion resistance does this grade provide for my environment?

Is the grade suitable for welding or does it require special procedures?

How does the grade perform during machining or forming?

What are the mechanical strength and toughness values?

Does the grade meet relevant industry standards and certifications?

What are the upfront and long-term costs, including maintenance?

Is the material available in the required sizes and finishes?

These questions help match the stainless steel to the specific industrial process and ensure reliable performance.

Many users make avoidable errors when selecting an austenitic stainless steel bar:

Choosing a grade without considering its forming characteristics, which can lead to excessive springback or work hardening.

Ignoring the rapid work hardening of austenitic grades, resulting in tool wear or cracking.

Overlooking the need to adapt tooling and forming techniques to the selected grade’s properties.

Failing to consult fabricators about welding or machining requirements, which can cause defects or inefficiencies.

Alert: Understanding the mechanical behavior and fabrication needs of each grade prevents costly mistakes and ensures a successful project outcome.

Selecting the right austenitic stainless steel bar grade often involves complex decisions. Many industrial projects present unique challenges that standard guidelines cannot address. In these situations, consulting a materials expert or metallurgist becomes essential.

Key Scenarios for Expert Consultation:

Unusual Corrosive Environments:

Some applications involve exposure to aggressive chemicals, high salinity, or fluctuating pH levels. Experts can analyze the environment and recommend grades with the best resistance. They may also suggest protective coatings or alternative alloys.

High-Temperature or Cryogenic Conditions:

When equipment operates at extreme temperatures, material performance can change. Experts understand how different grades behave under thermal stress. They help select bars that maintain strength and resist oxidation or embrittlement.

Critical Welded Structures:

Projects that require extensive welding, especially in pressure vessels or pipelines, benefit from expert advice. Specialists can recommend low-carbon or stabilized grades to prevent weld decay and ensure long-term reliability.

Regulatory or Certification Requirements:

Some industries, such as food processing or pharmaceuticals, must meet strict standards. Experts know the latest regulations and can guide material selection to ensure compliance with FDA, ASTM, or ISO requirements.

Custom Fabrication or Unusual Dimensions:

When a project needs non-standard bar sizes, shapes, or finishes, experts can coordinate with suppliers. They help ensure the material meets both mechanical and aesthetic specifications.

Failure Analysis or Problem Solving:

If previous equipment has failed due to corrosion, cracking, or wear, an expert can investigate the root cause. They provide recommendations to prevent future issues and improve system performance.

Tip: Early consultation with a stainless steel specialist can prevent costly mistakes and project delays. Experts bring valuable insights that go beyond standard datasheets.

Questions an Expert Can Help Answer:

| Situation | Expert Contribution |

|---|---|

| New process or environment | Material compatibility assessment |

| Unclear grade performance | In-depth analysis and testing recommendations |

| Multiple grades seem suitable | Comparative evaluation based on real-world data |

| Need for lifecycle cost analysis | Guidance on total cost of ownership and maintenance |

Engineers and procurement teams should not hesitate to reach out when uncertainty arises. An expert’s input ensures the selected stainless steel bar grade aligns with both technical and business goals. This proactive approach supports safety, compliance, and long-term value for any industrial application.

Proper cleaning and upkeep play a vital role in preserving the performance and appearance of austenitic stainless steel bars. Regular preventive cleaning, at least once or twice a year, removes contaminants that can lead to corrosion. Warm water and mild detergent work well for most dirt and dust. For stubborn stains, mild abrasives or cleaners containing phosphoric or citric acid may be used, followed by thorough rinsing and drying. Operators should avoid carbon steel brushes or steel wool, as these tools can embed rust-causing particles into the surface.

Special care is needed after exposure to de-icing salts or marine environments. Inks and adhesives respond best to solvents like xylene or alcohol, while water scale can be removed with vinegar and warm water. Passivation, which involves immersing the steel in a citric acid solution, restores the protective chromium oxide layer and extends corrosion resistance. Before passivation, the surface must be clean, and the process should use the correct acid concentration, temperature, and immersion time. Mechanical agitation and elevated temperatures can improve cleaning results. During installation, workers should prevent contamination from grinding or welding nearby iron-based metals, as this can cause rust spots.

Tip: Schedule regular inspections using visual and non-destructive testing methods, such as ultrasonic testing, to detect early signs of degradation and maintain structural integrity.

The service life of austenitic stainless steel bars depends on the selected grade and the operating environment. Grades like 316 and 347 offer enhanced resistance to sensitization and localized corrosion, making them suitable for harsh chemical or marine settings. Alloying elements such as molybdenum, titanium, and niobium improve corrosion resistance and prevent carbide precipitation, which can lead to sensitization and intergranular attack.

Low-carbon or stabilized grades, including 304L and 347L, are recommended for welded structures. These grades limit the risk of sensitization during welding, especially in temperature ranges from –40° to 315°C. In offshore and chloride-rich environments, grade 316 is often the only austenitic stainless steel used for pressure-containing parts due to its superior resistance to pitting and chloride stress corrosion cracking. Routine maintenance, including corrosion monitoring and mitigation strategies like cathodic protection, helps optimize asset longevity.

| Grade | Typical Service Life (Years) | Best Use Cases |

|---|---|---|

| 304/304L | 10–20+ | General industrial, indoor use |

| 316/316L | 20–30+ | Marine, chemical, offshore |

| 321/347 | 15–25+ | High-temperature, welded structures |

When replacing austenitic stainless steel bars in critical applications, a systematic approach ensures continued safety and performance. Engineers should begin by identifying key regions, such as weld locations and areas of metallurgical interest. Careful sectioning prevents the introduction of defects. Proper mounting and grinding with controlled cooling protect against thermal damage. Polishing removes deformation and work-hardened layers, while thorough cleaning eliminates contaminants.

After preparation, etching reveals the microstructure without causing intergranular corrosion artifacts. Microscopic analysis confirms the absence of sensitization or defects. Selecting the right grade is essential. Grades like SS316 and SS347, with added molybdenum, titanium, or niobium, resist sensitization and localized corrosion. For welded joints, low-carbon or stabilized grades prevent intergranular attack. Welding best practices include using appropriate filler metals and removing heat tint by brushing or pickling.

Plan replacement by mapping welds and sample orientation.

Section and mount bars carefully.

Grind and polish surfaces with controlled cooling.

Clean and etch samples for microstructural analysis.

Use low-carbon or stabilized grades for welding.

Remove heat tint after welding to prevent corrosion sites.

Alert: In offshore or chloride-rich environments, grade 316 remains the preferred choice for pressure-containing parts due to its resistance to pitting and stress corrosion cracking.

A large chemical processing facility faced frequent equipment failures due to aggressive acids and high chloride concentrations. The engineering team needed a solution that would extend the lifespan of reactor vessels and piping. They selected type 316 stainless steel bars for their superior resistance to pitting and crevice corrosion. The molybdenum content in 316 provided a strong defense against the harsh chemicals present in the plant.

The team also chose 316L for welded joints. The low carbon content reduced the risk of sensitization and intergranular corrosion after welding. This decision improved the reliability of the plant’s piping network. The maintenance team reported a significant drop in unplanned shutdowns.

Tip: In chemical plants, always match the stainless steel grade to the specific chemicals and cleaning agents in use.

Key Results:

Equipment lifespan increased by over 30%

Maintenance costs dropped by 20%

Compliance with industry safety standards improved

A commercial bakery required new mixing tanks and conveyor systems. The equipment needed to withstand daily washdowns and exposure to acidic ingredients. The project manager specified 304 stainless steel bars for most components. This grade offered excellent corrosion resistance and met all food safety regulations.

For parts exposed to brine and acidic fruit fillings, the team upgraded to 316 stainless steel. The added molybdenum protected against pitting from salt and acids. All surfaces received a smooth, polished finish to prevent bacterial growth and simplify cleaning.

| Equipment Part | Grade Used | Reason for Selection |

|---|---|---|

| Mixing tanks | 304 | General corrosion resistance |

| Conveyor frames | 304 | Easy fabrication, food safe |

| Brine-exposed parts | 316 | Enhanced resistance to chlorides |

Note: Food equipment must meet strict hygiene standards. Smooth finishes and proper grade selection help prevent contamination.

A shipyard needed fasteners for a fleet of coastal vessels. The fasteners would face constant exposure to saltwater and fluctuating temperatures. The design team selected 316 stainless steel bars for bolts, nuts, and washers. The molybdenum in 316 provided strong resistance to pitting and crevice corrosion, which are common in marine environments.

The team avoided 304 stainless steel for these parts. 304 can corrode quickly in saltwater, leading to equipment failure. After installation, the fasteners showed no signs of rust or degradation, even after several years of service.

Marine Fastener Selection Checklist:

Choose 316 or higher grades for saltwater exposure

Inspect fasteners regularly for signs of corrosion

Use passivated finishes to enhance corrosion resistance

Alert: In marine applications, improper grade selection can lead to rapid failure and costly repairs.

Custom fabrication projects often present unique challenges that standard stainless steel grades cannot always address. Engineers and fabricators must select materials that meet specific design, performance, and aesthetic requirements. Austenitic stainless steel bars offer the versatility needed for custom solutions in industries such as architecture, medical devices, and specialized machinery.

A fabrication shop recently received a request to build a set of custom architectural railings for a coastal resort. The client required a sleek, modern appearance and long-term resistance to salt spray. The engineering team evaluated several grades and chose 316L stainless steel bars. This grade provided excellent corrosion resistance and weldability, which ensured the railings would maintain their appearance and structural integrity over time.

In another example, a medical device manufacturer needed precision-machined components for surgical instruments. The design called for tight tolerances and a flawless surface finish. The team selected 303 stainless steel bars for their superior machinability. This choice reduced tool wear and allowed for efficient production of complex parts. The finished instruments met strict hygiene standards and passed all quality inspections.

Custom fabrication projects often require collaboration between engineers, fabricators, and material suppliers. The following checklist helps teams achieve successful outcomes:

Define the application’s mechanical, chemical, and aesthetic requirements.

Consult with suppliers about available grades and finishes.

Evaluate the need for special properties, such as enhanced machinability or weldability.

Request material certifications and traceability documents.

Plan for post-fabrication treatments, such as passivation or polishing.

Tip: Early involvement of material experts can prevent costly redesigns and ensure the final product meets all specifications.

| Project Type | Recommended Grade | Key Benefit |

|---|---|---|

| Coastal architecture | 316/316L | Superior corrosion resistance |

| Medical instruments | 303 | Excellent machinability |

| Food processing equipment | 304/304L | Hygiene and general corrosion resistance |

| High-temperature fixtures | 321 | Stability during thermal cycling |

Custom fabrication demands flexibility and attention to detail. By selecting the right austenitic stainless steel bar grade, teams can deliver products that perform reliably in demanding environments. This approach also helps control costs and reduce maintenance over the product’s lifecycle.

Selecting the right stainless steel bar grade ensures equipment meets both mechanical and environmental demands. Key considerations include matching strength, corrosion resistance, and temperature stability to the application.

Grades like 304 and 316 offer moderate strength, excellent ductility, and high melting points, making them ideal for food, chemical, and marine industries.

Grade 316’s molybdenum content enhances performance in aggressive environments.

Always specify clear requirements, choose reputable suppliers, and request certifications.

For complex projects, consulting a materials expert helps guarantee optimal stainless steel performance.

Type 304 stands as the most widely used austenitic stainless steel bar grade. It offers a strong balance of corrosion resistance, strength, and affordability. Many industries choose 304 for its versatility in both indoor and outdoor environments.

Engineers select 316 stainless steel bars when equipment faces exposure to chlorides, saltwater, or harsh chemicals. The added molybdenum in 316 improves resistance to pitting and crevice corrosion, making it ideal for marine and chemical processing applications.

'L' grades contain lower carbon content. This feature helps prevent carbide precipitation during welding. Projects that involve frequent or critical welding often specify 304L or 316L to maintain corrosion resistance and ensure strong, reliable welds.

Grade 303 offers superior machinability due to added sulfur. This adjustment allows for easier cutting and shaping. Grade 304 provides better corrosion resistance but proves harder to machine, which can increase tool wear and production time.

Service life depends on grade selection, operating environment, and maintenance practices. Grades like 316 last longer in corrosive settings. Regular cleaning and inspection help prevent early failure and extend the lifespan of stainless steel bars.

Yes, certain grades like 310 and 321 perform well at elevated temperatures. Grade 310 resists oxidation up to 2100°F (1150°C). Grade 321, stabilized with titanium, maintains strength and corrosion resistance during thermal cycling and welding.

Users should clean stainless steel bars with warm water and mild detergent. For tougher stains, use non-abrasive cleaners. Avoid steel wool or carbon steel brushes. Regular cleaning and inspection help maintain appearance and prevent corrosion.

Buyers should request certifications such as ASTM, ISO, or EN standards. These documents confirm the material’s composition, mechanical properties, and traceability. Certifications help ensure the stainless steel bar meets project and regulatory requirements.