close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-09-12 Origin: Site

Super duplex steel stands out because you get a material with a dual-phase microstructure and a high chromium content. The unique mix of austenite and ferrite phases delivers both strength and corrosion resistance. You can see the difference in chromium levels compared to other stainless steels:

Type of Stainless Steel | Chromium Content |

|---|---|

Duplex Stainless Steel | ~22% |

Super Duplex Stainless Steel | ~25% |

You benefit from decades of innovation, starting in the 1950s with alloy experiments and evolving through the 1990s with specialized grades designed for harsh environments.

Super duplex steel continues to advance as a high-performance solution for demanding applications.

You find the most important feature of super duplex steel in its dual-phase microstructure. This means you get both austenite and ferrite phases in one alloy. The combination gives you a balance of toughness and strength. The austenite phase helps prevent cracks from spreading, while the ferrite phase adds rigidity. When you weld duplex stainless steel, the grain size matters. Fine grains increase impact energy, making the steel tougher. If you cool the steel too quickly, you get more ferrite, which can lower plasticity and corrosion resistance.

Fine grain size increases impact energy and toughness.

Ductile austenite phase helps stop crack growth.

Ferrite phase provides strength but can be more brittle.

Proper cooling keeps the right balance for best performance.

The study investigates the corrosion behavior of both ferrite and austenite phases in super duplex stainless steels (SDSSs) using microelectrochemical methods. It highlights the importance of understanding the coupling of these phases to prevent localized corrosion and stress corrosion cracking. The research notes that two distinct anodic dissolution peaks appear in the potentiodynamic polarization curves of SDSSs in acidic chloride solutions, indicating the preferential dissolution of the austenite phase at higher potentials and the ferrite phase at lower potentials.

You see that the dual-phase structure is key to the excellent corrosion resistance and mechanical properties of super duplex.

Super duplex steel stands out because of its high chromium content. You get more chromium than in standard duplex stainless steel or austenitic stainless steel. This extra chromium boosts corrosion resistance and strength, especially in tough environments.

Steel Type | Chromium Content | Additional Notes |

|---|---|---|

Super Duplex Stainless | Higher than standard duplex and austenitic | Enhanced corrosion resistance and strength |

Standard Duplex Stainless | Moderate chromium content | Good corrosion resistance but less strength than super duplex |

Austenitic Stainless | Lower chromium content | Excellent toughness but less corrosion resistance than duplex steels |

You also find other important elements in super duplex, such as molybdenum and nitrogen. These elements work together to improve performance.

Element | Content (%) |

|---|---|

Chromium (Cr) | 24.0-26.0 |

Molybdenum (Mo) | 3.0-5.0 |

Nitrogen (N) | 0.24-0.32 |

Chromium, molybdenum, and nitrogen each play a role in making super duplex steel strong and resistant to corrosion.

Element | Role in Corrosion Resistance |

|---|---|

Chromium | Provides excellent resistance to pitting and crevice corrosion, especially in chloride environments. |

Molybdenum | Enhances pitting resistance. |

Nitrogen | Improves strength and resistance to stress corrosion cracking (SCC). |

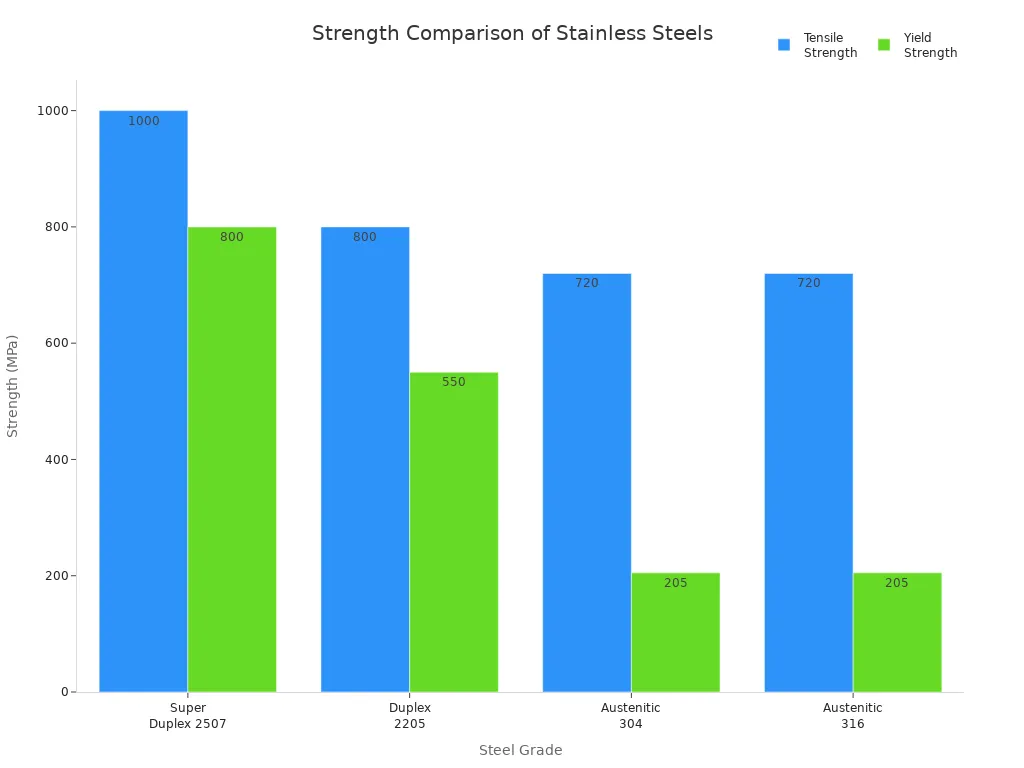

You benefit from the impressive strength of super duplex steel. It has much higher tensile and yield strength than duplex stainless steel or austenitic grades. This makes it ideal for high-pressure and high-stress applications.

Steel Grade | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

Super Duplex 2507 | Up to 1000 | Around 800 |

Duplex 2205 | 700 - 800 | Exceeding 550 |

Austenitic 304 | 520 - 720 | Around 205 |

Austenitic 316 | 520 - 720 | Around 205 |

You also see that super duplex stainless steel has a very high PREN (Pitting Resistance Equivalent Number), which means it resists pitting corrosion better than other stainless steels.

Type of Stainless Steel | Typical PREN Range |

|---|---|

Lean Duplex | 22-27 |

Standard Duplex | 28-38 |

Super Duplex | 39-45 |

Hyper Duplex | >45 |

Super duplex stainless steel has a PREN value exceeding 40, showing superior resistance to pitting corrosion.

The high PREN comes from the increased chromium content, which is about 27% in super duplex compared to 22% in duplex stainless steel.

Super duplex performs better in environments with high chloride levels.

You can rely on super duplex for both strength and corrosion resistance, making it a top choice for demanding industries.

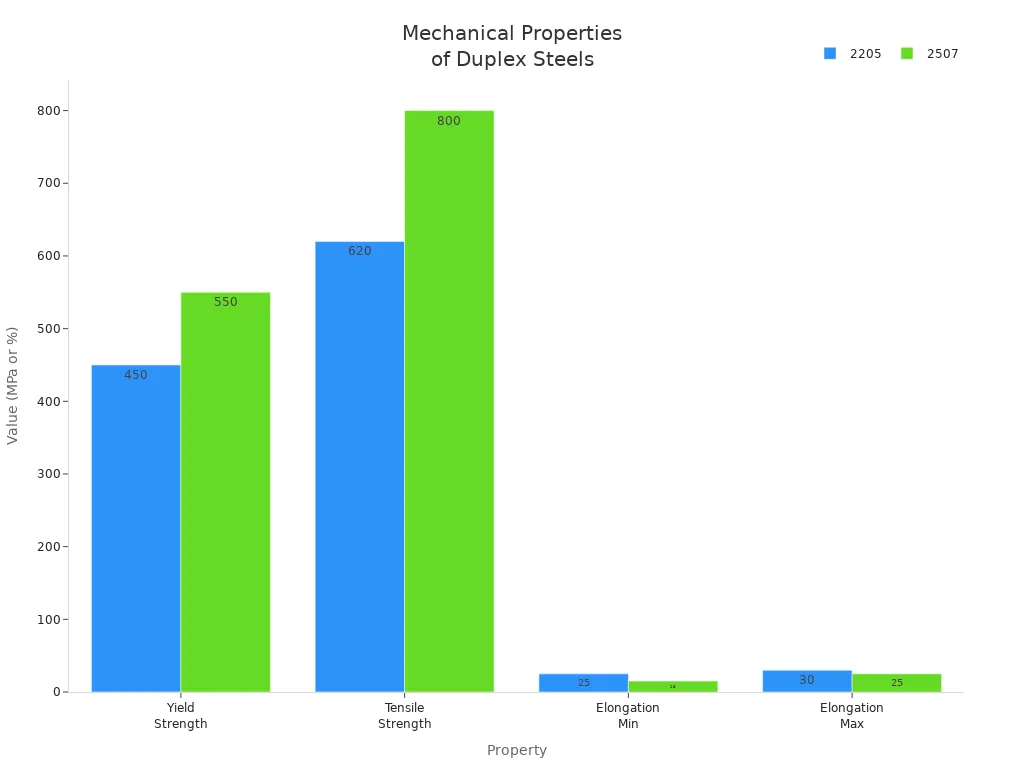

You notice clear differences between standard duplex and super duplex. Both types have a dual-phase structure, but super duplex offers higher strength and better corrosion resistance. You see this in the mechanical properties:

Property | Duplex 2205 | Super Duplex 2507 |

|---|---|---|

Yield Strength | ~550 MPa | ≥550 MPa |

Tensile Strength | ~800 MPa | 800–900 MPa |

Elongation | ~15% | ≥25% |

Super duplex provides greater elongation, which means you get more ductility. You also benefit from improved resistance to pitting and stress corrosion cracking. This makes super duplex a better choice for harsh environments.

You find austenitic stainless steel in many industries, but super duplex stands out for its strength and corrosion resistance. The composition sets them apart:

Type of Steel | Composition Characteristics | Applications |

|---|---|---|

Austenitic Stainless Steel | Contains chromium-nickel (300 series) and manganese-chromium-nickel-nitrogen (200 series). Non-magnetic, highly formable, and ductile. | Used in chemical plants, power plants, food processing, and dairy equipment. |

Duplex Stainless Steel | Composed of both austenite and ferrite microstructures, offering higher strength and resistance to stress corrosion cracking. | Suitable for aggressive environments like Oil & Gas, chemical process industries, and marine applications. |

You get better resistance to stress corrosion cracking with super duplex stainless steel. In chloride-rich environments, super duplex resists corrosion much better than austenitic grades:

Steel Type | Susceptibility to SCC | Chloride Concentration Resistance | Temperature Resistance |

|---|---|---|---|

Austenitic Stainless Steel (e.g., 316L) | High | Low | Above 55°C |

Duplex Stainless Steel | Low | High | Higher than Austenitic |

Super duplex gives you a strong advantage in environments with high chloride levels.

You see a big difference when you compare carbon steel to super duplex. Carbon steel needs coatings or galvanization to fight corrosion. Super duplex steel has built-in corrosion resistance, so you do not need extra protection. You get much higher strength and durability with super duplex stainless steel. In tough industrial settings, super duplex resists intergranular corrosion and stress corrosion cracking, while carbon steel often fails without protective layers.

Super duplex offers long-term reliability and lower maintenance costs in demanding applications.

You often face environments that challenge most metals. Super duplex materials give you the edge in places with high-temperature chloride, sour gas, and aggressive chemicals. You see these conditions in oil and gas pipelines, chemical reactors, and marine structures. Super duplex grades resist corrosion and cracking, even when exposed to seawater or acidic solutions. This means you can trust super duplex to last longer and perform better where other alloys fail.

Tip: Super duplex stainless steel keeps its strength and corrosion resistance even in extreme conditions, making it a top choice for harsh settings.

You find super duplex materials in many industries that demand both strength and corrosion resistance. Here is a table showing where you might use super duplex and what equipment benefits from it:

Industry | Specific Applications |

|---|---|

Oil & Gas | Downhole tooling, wellhead and subsea equipment, pumps and valves |

Pollution Control | Scrubbers, precipitators, fans, and pumps |

Marine | Propellers, shafts, rudders, and seals |

Chemical Process Industry | Equipment for handling sulfuric, nitric, and phosphoric acids |

Vegetable Processing | Mixers and centrifuges for grains and vegetables |

Water Treatment | Sewage treatment, desalination, and swimming pools |

Paper and Pulp | Components throughout pulp and paper production processes |

You see super duplex in offshore oil platforms, desalination plants, and marine engineering. These industries rely on super duplex stainless steel for its durability and resistance to harsh chemicals and saltwater.

You might notice that super duplex has a higher initial cost than some other alloys. However, you save money over time because super duplex materials need less maintenance and last longer. Super duplex steel offers lower lifecycle costs compared to standard duplex stainless steel and austenitic grades. Its high strength allows for thinner walls, which makes inspection and maintenance easier. You also reduce downtime and replacement costs, which adds up to big savings for your operation.

Note: When you choose super duplex, you invest in long-term reliability and lower total costs, especially in demanding environments.

You see super duplex steel deliver outstanding performance because of its unique alloy composition and dual-phase microstructure. The table below highlights the elements that give you high strength and corrosion resistance:

Element | Contribution to Properties |

|---|---|

Chromium | Forms a protective oxide layer for corrosion resistance |

Nickel | Improves ductility and toughness |

Molybdenum | Increases resistance to pitting corrosion |

Nitrogen | Enhances strength and pitting resistance |

You benefit from super duplex steel in industries facing harsh conditions, such as oil and gas or marine construction. Looking ahead, you can expect new alloy innovations, sustainable production, and advanced manufacturing methods to keep super duplex steel relevant and in demand.

You get higher strength and better corrosion resistance with super duplex steel. The dual-phase structure and extra chromium content set it apart from regular stainless steel.

You can weld super duplex steel, but you need to control heat input and cooling rates. This helps you maintain the right balance of austenite and ferrite for top performance.

Tip: Use qualified welding procedures to avoid cracking and ensure durability.

You find super duplex steel in oil and gas, chemical processing, and marine industries. It works best in places with high chloride levels and harsh environments.

You pay more upfront for super duplex steel. However, you save money over time because it lasts longer and needs less maintenance.

Alloy Type | Initial Cost | Maintenance Cost | Lifespan |

|---|---|---|---|

Super Duplex Steel | High | Low | Long |

Carbon Steel | Low | High | Short |