close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-09-12 Origin: Site

You notice a clear difference when you compare super duplex steel to other stainless steels. Its microstructure combines austenite and ferrite, which gives you advanced strength and better resistance to corrosion. This special blend of chromium, molybdenum, and nitrogen protects your equipment in harsh environments. You see super duplex stainless steel in oil and gas platforms, water treatment plants, food processing, power generation, and medical devices because it delivers durability and reliability where you need it most.

When you look at the microstructure of super duplex stainless steel, you see a unique balance between two phases: austenite and ferrite. This dual-phase structure sets it apart from standard stainless steels, which usually contain only one phase. You get a material that combines the best qualities of both.

Super duplex stainless steel has a nearly equal volume fraction of ferrite (α-Fe) and austenite (γ-Fe), typically around 1:1.

This balance gives you enhanced mechanical properties and corrosion resistance compared to standard austenitic or ferritic stainless steels.

Duplex stainless steel often outperforms austenitic grades in tough environments.

You should know that the ferritic phase can become unstable at high temperatures (600–1000°C). This instability may lead to the formation of harmful secondary phases like sigma (σ) and chi (χ), which can reduce the steel’s mechanical strength and corrosion resistance.

Understanding how these phases develop helps you maintain the quality and reliability of super duplex stainless steel.

You can see how the volume fractions compare in different zones:

Phase | Volume Fraction (%) |

|---|---|

Ferrite | 55 |

Austenite | 45 |

Fusion Zone (Hybrid Welding) | 65 (Ferrite) / 35 (Austenite) |

Remelting Area | 68 (Ferrite) / 32 (Austenite) |

Minimum Acceptable Austenite | 25-30 |

Tip: The balanced microstructure in duplex stainless steel makes it ideal for applications like fuel gas desulphurization and desalination, where you need both strength and corrosion resistance.

You get superior performance from super duplex steel because of its advanced alloy composition. The combination of chromium, molybdenum, and nitrogen plays a key role in boosting its properties.

Type of Steel | Chromium Content | Molybdenum Content | Nitrogen Content |

|---|---|---|---|

Super Duplex | 24% - 26% | 4% | 0.05% - 0.5% |

Duplex | 19% - 32% | 3% | N/A |

Austenitic Stainless | N/A | N/A | N/A |

Chromium and molybdenum increase the steel’s resistance to corrosion, especially in environments with acids and chlorides. Nitrogen improves the mechanical strength and helps prevent pitting corrosion. You also benefit from higher yield and tensile strength, better ductility, and reduced risk of harmful phase precipitation.

Here’s how nitrogen addition affects the properties of super duplex stainless steel:

Property | Effect of Nitrogen Addition |

|---|---|

Fatigue Strength | Improved with nitrogen addition |

Corrosion Resistance | Enhanced in duplex steel 2205 with nitrogen |

Yield Strength (YS) | Increased due to nitrogen addition |

Ultimate Tensile Strength (UTS) | Enhanced by nitrogen presence |

Ductility | Improved with nitrogen addition |

Pitting Corrosion Resistance | Increased pitting corrosion potential |

Detrimental Phase Precipitation | Reduced Cr2N precipitation, lowering corrosion risks |

Austenite Phase Content | Increased with nitrogen addition |

You see that super duplex stainless steel stands out because of its carefully balanced microstructure and advanced alloying elements. These features give you a material that delivers reliable performance in the most demanding industrial settings.

When you choose super duplex stainless steel, you get a material built for aggressive environments. This steel stands out because it resists acids, chlorides, and other harsh chemicals that often cause damage in industrial settings. You can rely on its excellent corrosion resistance, which comes from its unique alloy composition and balanced microstructure. These features make it one of the most high-performance stainless steels available today.

You often face pitting and crevice corrosion when you work with metals in salty or acidic conditions. Super duplex stainless steel protects your equipment from these localized attacks better than most other grades. The secret lies in its high levels of chromium, molybdenum, and nitrogen. These elements help form a strong, stable passive layer on the steel’s surface.

You can compare the pitting resistance of different stainless steels using the Pitting Resistance Equivalent Number (PREN). Higher PREN values mean better protection against pitting and crevice corrosion. Look at this table to see how super duplex stainless steel measures up:

Type of Stainless Steel | Typical PREN Range |

|---|---|

Lean Duplex | 22-27 |

Standard Duplex | 28-38 |

Super Duplex | 39-45 |

Hyper Duplex | >45 |

You see that super duplex stainless steel offers exceptional corrosion resistance, especially in environments with high chloride levels. In laboratory tests, duplex stainless steel outperforms standard austenitic grades like 316L. Here’s what you can expect:

Duplex stainless steels have a dual-phase structure that boosts both mechanical properties and corrosion resistance.

The chemical composition of duplex stainless steel makes it especially effective against pitting and crevice corrosion.

In marine exposure studies, 2507 super duplex stainless steel delayed pitting much longer than 316L and 317L.

After 592 days in a harsh environment, 2507 super duplex stainless steel kept a stable passive zone, showing its superior performance.

You also notice that 2205 duplex stainless steel, with its higher chromium, molybdenum, and nitrogen content, resists pitting and crevice corrosion much better than 316L. The critical pitting temperature of 2205 sits between 316L and super austenitic grades, but super duplex stainless steel takes corrosion resistance even further.

Note: If you need reliable protection in seawater, chemical processing, or desalination, super duplex stainless steel gives you the confidence to operate without frequent maintenance.

Stress corrosion cracking (SCC) can cause sudden failure in stainless steels, especially when you expose them to high temperatures and chloride-rich environments. You want a material that stands up to these threats. Duplex stainless steel, especially super duplex grades, gives you that peace of mind.

Duplex stainless steels show much better resistance to SCC than standard austenitic stainless steels.

Austenitic stainless steel like UNS S31603 becomes very susceptible to SCC as temperatures rise.

Duplex steels maintain strong resistance to SCC across a wide range of test conditions.

You benefit from this resistance because it means fewer unexpected breakdowns and longer service life for your equipment. Super duplex stainless steel combines high strength with outstanding corrosion resistance, making it the top choice for critical applications in oil and gas, marine, and chemical industries.

Tip: When you need a material that can handle both mechanical stress and aggressive chemicals, super duplex stainless steel delivers unmatched performance.

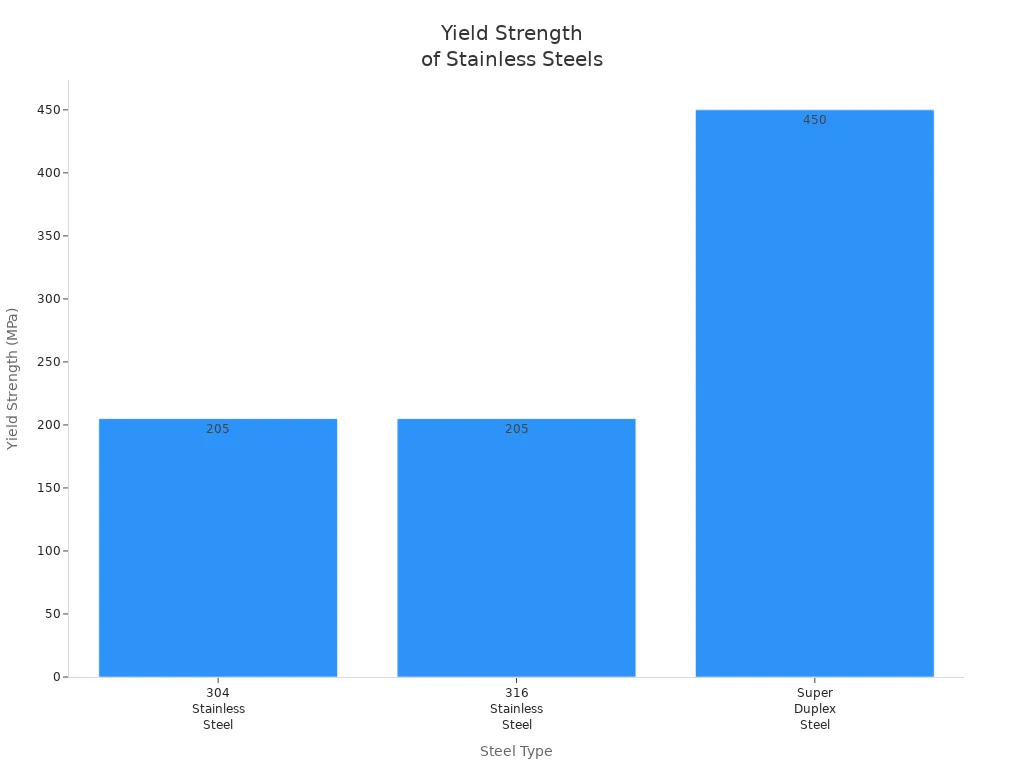

You need materials with high mechanical strength for demanding applications. Super duplex steel gives you a clear advantage over standard stainless steels. When you compare yield strength, you see a big difference. Super duplex stainless steel, especially Duplex 2205, provides a 0.2% yield strength of at least 450 MPa. In contrast, 304 and 316 stainless steels only reach about 205 MPa. This means your equipment can handle heavier loads and higher pressure without deforming.

Steel Type | 0.2% Yield Strength (MPa) |

|---|---|

304 Stainless Steel | ~205 |

316 Stainless Steel | ~205 |

Duplex 2205 (Super Duplex Steel) | ≥450 |

You also notice the proof strength for duplex stainless steel ranges from 450 to 550 MPa, while 304 stainless steel stays at 280 MPa. This difference shows why you choose duplex stainless steel for tough jobs. The tensile strength of super duplex grades reaches up to 550 MPa, much higher than austenitic types. You can see this comparison in the chart below:

You want your materials to stay strong even when conditions change. Duplex stainless steel offers exceptional mechanical properties, including good ductility and toughness. In impact tests at -46°C, super duplex steel in the solution-annealed condition showed impact toughness values 2.5 to 2.8 times higher than the as-built material. This means your equipment resists cracking and breaking, even in cold environments.

Duplex stainless steel has a microstructure that limits impact toughness because of ferritic phases.

The ductile-to-brittle transition temperature sits around -50°C, so toughness drops at very low temperatures.

Fracture toughness in duplex stainless steel is similar to carbon steel, which can present challenges in freezing conditions.

You benefit from these mechanical properties when you need reliable performance in harsh environments. Super duplex stainless steel stands out for its exceptional mechanical properties, making it the best choice for demanding applications in oil, gas, and chemical industries.

You often see duplex stainless steel in the oil and gas industry because it handles tough environments. When you work on offshore platforms or in subsea equipment, you need materials that resist corrosion and last a long time. Super duplex steel, especially grade 2507 and super duplex 32760, gives you high strength and excellent durability. These super duplex grades protect your equipment from harsh seawater and high-pressure conditions.

Take a look at how service life compares in marine applications:

Material | Service Life in Marine Environments | Corrosion Resistance |

|---|---|---|

Super Duplex Steel | Significantly longer | Exceptional resistance to corrosion in chloride environments |

316L Stainless Steel | Often less than 5 years, sometimes less than 1 year | Severe corrosion in tropical waters, especially due to pitting and crevice corrosion |

You can trust super duplex stainless steel for marine applications like propellers, shafts, and rudders. In oil and gas, you use it for downhole tooling, wellhead equipment, and offshore pipelines. Grade 2507 and super duplex 32760 (also known as UNS S32760) stand out for their corrosion resistant properties and high-performance applications.

Tip: Choosing duplex stainless steel for offshore and marine projects means you spend less time and money on repairs.

You rely on duplex stainless steel for many industrial applications. In chemical process pressure vessels, water treatment plants, and pollution control scrubbers, you need materials that resist acids and last for years. Super duplex 32760 and grade 2507 offer excellent durability and high strength, making them ideal for these uses.

Here are some common applications in chemical and industrial sectors:

Acid handling systems (sulfuric and nitric acid)

Water treatment facilities

Chemical and petrochemical components like pumps, valves, and pipework

Pollution control scrubbers

You select super duplex stainless steel because it lowers maintenance costs over time. Super duplex 2507, for example, may cost more at first, but its long service life and resistance to pitting and crevice corrosion save you money in the long run. You get reliable performance in aggressive environments, which is why you see duplex stainless steel in so many high-performance applications.

Note: Super duplex grades give you the versatility and strength you need for demanding industrial applications.

You see clear advantages when you choose super duplex steel for demanding environments. The table below highlights how it stands out:

Feature | Duplex Stainless Steel | Super Duplex Stainless Steel |

|---|---|---|

Corrosion Resistance | Good | Excellent |

Tensile Strength | High | Higher |

Cost | More affordable | Higher upfront, lower lifecycle cost |

You benefit from exceptional reliability, reduced maintenance, and longer service life. Industry experts recognize super duplex steel as the best choice for critical applications in marine, chemical, and energy sectors. ��

You get a dual-phase microstructure in super duplex steel. This structure combines austenite and ferrite. You benefit from higher strength and better corrosion resistance than regular stainless steel.

You can weld super duplex steel with proper technique. You must control heat input and cooling rates. This helps you avoid harmful phase formation and ensures strong, reliable welds.

You should use super duplex steel in places with high chloride exposure. Oil and gas platforms, desalination plants, and chemical processing equipment need its strength and corrosion resistance.

You get good performance at moderate temperatures. Super duplex steel may lose toughness above 600°C. You should avoid using it in high-temperature applications to maintain reliability.