close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

You often encounter austenitic stainless steel grades in your daily life, even if you do not realize it. The most common grades include 301, 302, 303, 304, 304L, 305, 309, 310, 316, 316L, and 321. You see grade 304 in cookware, kitchen sinks, and appliances because it resists corrosion and shapes easily. Grade 316, another popular choice, stands up well to harsh chemicals and saltwater, making it ideal for valves, hose clamps, and equipment in food and chemical processing. These common grades of stainless steels offer reliability and versatility for both professionals and everyday users.

You find austenitic stainless steels unique because of their face-centered cubic (FCC) crystal structure. Nickel stabilizes this structure at room temperature. This makes austenitic stainless steel different from ferritic and martensitic types, which have a body-centered cubic (BCC) structure. The FCC structure gives you better ductility and toughness. You also notice that austenitic stainless steels are generally non-magnetic, while ferritic and martensitic steels are magnetic. The high nickel and chromium content in austenitic stainless steels helps you achieve excellent corrosion resistance in many environments.

Tip: The FCC structure allows austenitic stainless steels to keep their strength and toughness even at very low temperatures.

Here is a quick comparison of stainless steel types:

| Stainless Steel Type | Crystal Structure | Key Alloying Elements | Magnetic Properties | Mechanical & Corrosion Characteristics |

|---|---|---|---|---|

| Austenitic | Face-Centered Cubic (FCC) | Chromium, Nickel | Non-Magnetic | Excellent ductility, excellent corrosion resistance |

| Ferritic | Body-Centered Cubic (BCC) | Chromium, Little to No Nickel | Magnetic | Moderate corrosion resistance, less formable |

| Martensitic | Body-Centered Cubic (BCC) | Chromium, Low Nickel | Magnetic | High strength, lower ductility, lower corrosion resistance |

When you choose austenitic stainless steels, you benefit from several key properties. The FCC structure provides many slip planes, so you can easily form and shape these metals. You get high ductility and toughness, which means the material bends without breaking. Austenitic stainless steels offer excellent corrosion resistance, especially in environments with moisture, chemicals, or salt. Chromium forms a passive layer on the surface, protecting against corrosion. Nickel and sometimes molybdenum further improve this resistance. You also notice that these steels stay non-magnetic and keep their strength at both high and low temperatures. However, they do not harden by heat treatment. You can only increase their strength by cold working, which may reduce ductility.

Key properties you will find:

Excellent corrosion resistance in many environments

High ductility and toughness

Non-magnetic in most conditions

Good formability and weldability

Stable mechanical properties at extreme temperatures

You see austenitic stainless steels in many industries because of their excellent corrosion resistance and mechanical properties. These steels work well in environments where corrosion is a major concern. You find them in food processing, medical equipment, chemical plants, and construction. In the food industry, you use them for kitchen utensils, storage tanks, and dairy equipment. Medical professionals rely on them for surgical instruments and implants. Chemical and petrochemical plants use them for heat exchangers, pressure vessels, and piping systems that handle corrosive fluids. In construction, you see them in building facades, bridges, and handrails. Marine and offshore industries use them for shipbuilding and desalination plants because they resist corrosion from saltwater.

Here are some common applications:

Food processing equipment and storage tanks

Medical devices and surgical instruments

Chemical reactors and piping

Automotive exhaust systems and fuel tanks

Building facades and structural supports

Marine equipment and offshore platforms

You choose austenitic stainless steels when you need excellent corrosion resistance, strength, and durability in demanding environments. Their versatility makes them a top choice for many common applications.

You often see austenitic stainless steel grades in many industries because they offer a balance of corrosion resistance, strength, and workability. The top 10 grades you encounter most often include:

301

302

303

304

304L

305

309

310

316

316L

321

These stainless steel grades appear in everything from kitchenware to chemical processing equipment. You find them in both household and industrial settings. Manufacturers and engineers choose these grades because they meet strict technical standards and deliver reliable performance. You benefit from their versatility, which makes them suitable for a wide range of applications.

Note: You may notice that some grades, like 304 and 316, are especially popular. Their unique mix of corrosion resistance and mechanical properties makes them a top choice for many uses.

When you select austenitic stainless steel grades, you need to consider several important factors. The industry uses specific criteria to decide which grades work best for each application. Here are the main points you should keep in mind:

Corrosion Resistance

You want a grade that resists corrosion in your operating environment. For example, if you work with saltwater or chemicals, you need a grade with high resistance to chlorides and acids.

Mechanical Properties

You look for strength, ductility, and toughness. These properties help the material perform well under stress and deformation.

Form and Process Considerations

You consider how easy it is to machine, weld, or form the material. Some grades handle cold working or heat treatment better than others.

Customer Preferences and Certifications

You may need a specific surface finish or certification, such as ASTM or ASME standards, to meet project requirements.

Cost and Availability

You balance the upfront cost with long-term maintenance and replacement expenses. You also check if the supplier can deliver the grade quickly and offer value-added services like cutting or polishing.

You see that these criteria help you choose the right stainless steel grades for your needs. The most common stainless steel grades, such as 304, 316, and 321, meet these requirements for many industries. You rely on these common grades of stainless steels because they provide a good mix of corrosion resistance, mechanical strength, and processability. You also find that compliance with technical standards and supplier support play a big role in your decision.

Choosing the right grade ensures your project meets safety, durability, and cost goals.

You often choose 301 stainless steel when you need a balance of strength and formability. This grade belongs to the austenitic family, which means you get excellent corrosion resistance in many environments. The chemical composition of 301 includes higher carbon and lower nickel compared to other grades like 304. This combination lets you increase strength through cold working, but you still maintain good ductility.

Here is a table showing the typical chemical composition of 301 stainless steel:

| Element | Range / Max Value |

|---|---|

| Carbon | 0.15 (max) |

| Chromium | 16.0 - 18.0 |

| Nickel | 6.0 - 8.0 |

| Manganese | 2.00 (max) |

| Silicon | 1.00 (max) |

| Nitrogen | 0.10 (max) |

| Phosphorus | 0.045 (max) |

| Sulfur | 0.030 (max) |

You notice that 301 stainless steel stands out for its ability to gain high strength after cold working. When you cold work this material, you increase its yield and tensile strength, but you reduce its elongation. This property makes 301 ideal for parts that need to withstand repeated stress or flexing.

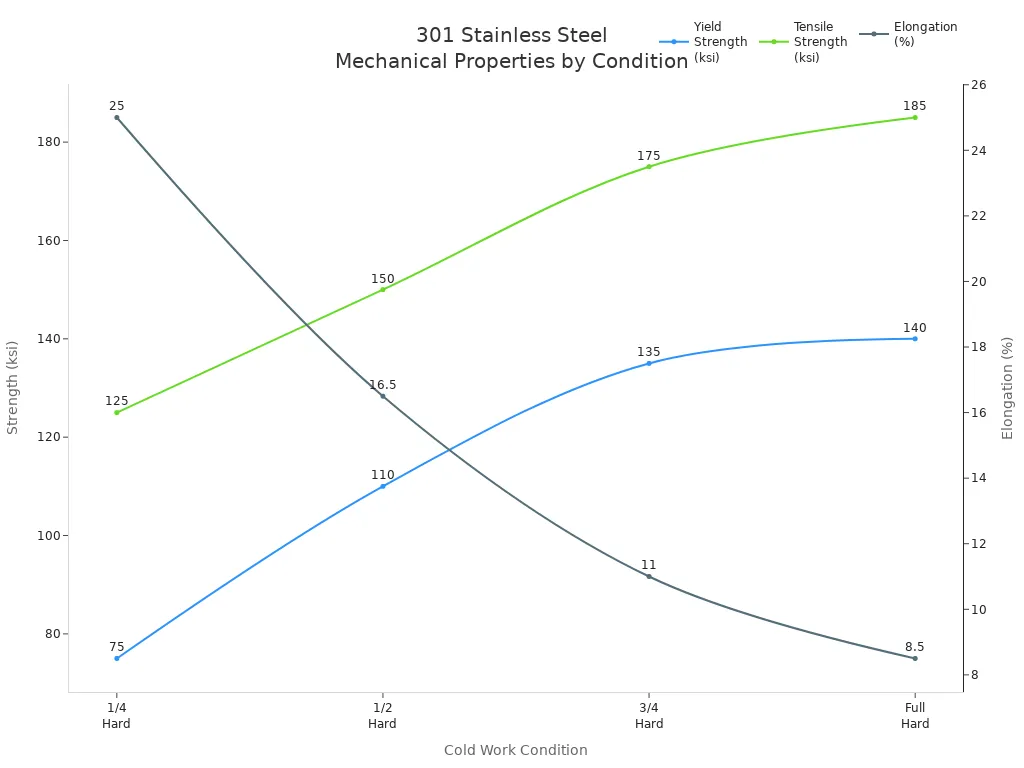

The following chart shows how the mechanical properties change as you increase the hardness of 301 stainless steel:

You also benefit from its good weldability and formability. 301 resists corrosion in mild environments, but you should avoid using it in highly corrosive or marine conditions. The grade performs well at both low and high temperatures, making it versatile for many applications.

Tip: If you need a stainless steel that combines high strength with excellent corrosion resistance, 301 offers a reliable solution, especially when you cold work it.

You find 301 stainless steel in a wide range of applications because of its unique mix of strength, formability, and corrosion resistance. Many industries rely on this grade for both structural and decorative purposes.

Automotive: You see 301 in exhaust systems, trims, battery casings, and electric motor components. Its high strength-to-weight ratio and resistance to corrosion make it a top choice for these parts.

Aerospace: You use 301 for airframes, engine components, and landing gear. The material’s fatigue resistance and high tensile strength help ensure safety and durability.

Construction: You find 301 in exterior cladding, roofing, facades, and structural frameworks. Its corrosion resistance and attractive finish make it popular for architectural features.

Consumer Goods: You encounter 301 in kitchenware, household appliances, and electronic devices. The grade’s formability and surface finish allow for sleek, durable products.

Industrial Equipment: You use 301 for conveyor belts, springs, fasteners, and machinery components. Its durability and high strength support demanding industrial applications.

You also see 301 in mass transit infrastructure, rail systems, and architectural supports. The grade’s versatility and excellent corrosion resistance make it suitable for both industrial and consumer uses.

When you need a stainless steel that can handle repeated bending or flexing, 301 stands out among the most popular grades. Its combination of strength and corrosion resistance ensures long-lasting performance in many environments.

You often choose 302 stainless steel when you need a material with both strength and good corrosion resistance. This grade belongs to the austenitic family, so you get a combination of toughness and formability. The chemical composition includes about 17-19% chromium and 8-10% nickel. These elements help you achieve strong resistance to rust and oxidation, especially in food and sanitary environments.

Here is a table showing the main mechanical properties of 302 stainless steel:

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Ultimate Tensile Strength | 655 MPa | 95,000 psi |

| Yield Strength | 290 MPa | 42,100 psi |

| Elongation at Break | 60% | 60% |

| Hardness (Rockwell B) | 92 | 92 |

| Modulus of Elasticity | 200 GPa | 29,000 ksi |

| Charpy Impact Energy | 200 J | 148 ft-lb |

You can see from these numbers that 302 stainless steel offers high ductility and toughness. The material stretches before it breaks, which helps you in forming and shaping processes. When you cold work 302, you increase its strength but reduce its ductility. This means you can make springs and other parts that need to hold their shape under stress.

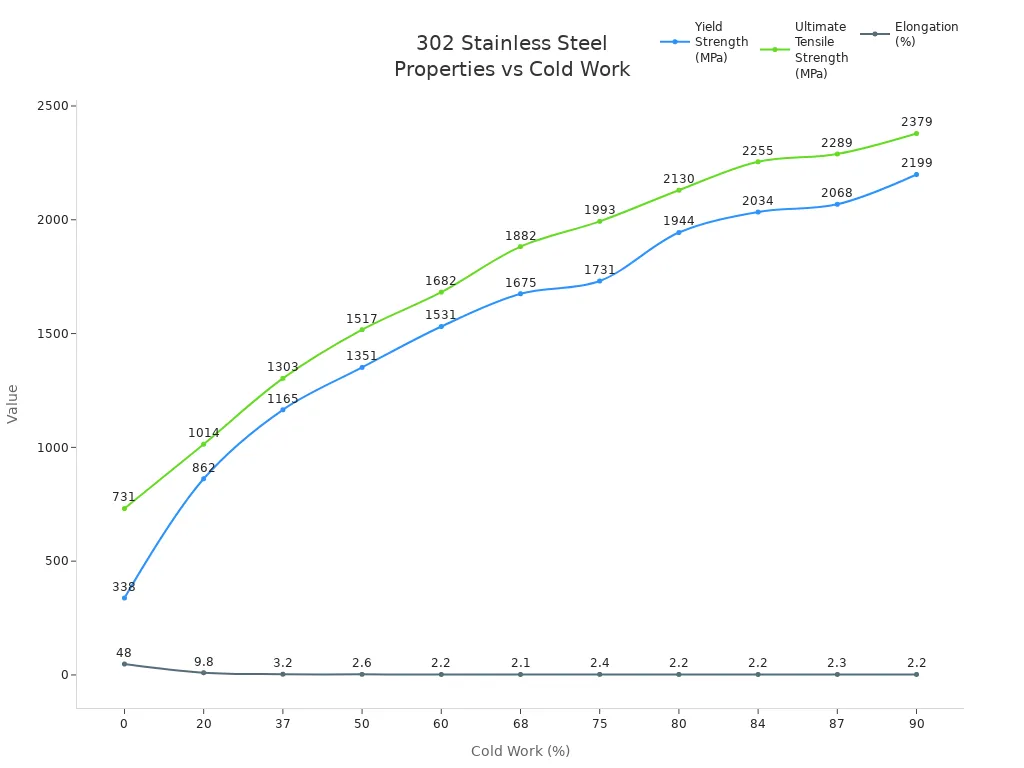

The following chart shows how cold working changes the mechanical properties of 302 stainless steel:

As you increase cold work, yield and tensile strength rise sharply, but elongation drops. This makes 302 a flexible choice for different applications, depending on how you process it.

Tip: You should use 302 stainless steel when you need a balance of strength, corrosion resistance, and formability. It works well in both mild and demanding environments.

You find 302 stainless steel in many industries because of its reliable performance and versatility. This grade appears in products that need to resist corrosion and handle repeated stress. You often see it in medical equipment, such as syringes, needles, and surgical instruments. The food and beverage industry uses 302 for processing equipment, hardware, and sanitary fittings.

Here are some common uses for 302 stainless steel:

Medical equipment: syringes, needles, surgical tools

Food processing equipment and hardware

Aerospace components

Industrial springs and fasteners

Stamping, spinning, and wire forming

Washers, screens, and cables

Pressure vessels and cryogenic tanks

Household products: blenders, dish racks, dishwashers, refrigerators, washing machines

You also find 302 in pressure-containing applications and sanitary systems. Its ability to keep its properties at low temperatures makes it suitable for cryogenic uses. Many manufacturers choose 302 over other grades when they need a material that can handle both forming and high strength.

You can rely on 302 stainless steel for a wide range of applications, from household goods to demanding industrial parts. Its balance of properties makes it one of the most popular austenitic stainless steel grades.

You choose 303 stainless steel when you need a material that machines quickly and easily. This grade stands out among austenitic stainless steels because of its high sulfur content. The sulfur helps you break chips during machining, which reduces tool wear and lets you produce complex parts with speed and accuracy. You often see 303 used in screw machines and CNC machining because it handles cutting and shaping better than most other grades.

Here is a table showing the main chemical elements in 303 stainless steel and how each one affects its properties:

| Element | Approximate % Range | Role / Effect on Properties |

|---|---|---|

| Chromium | 17-19% | Enhances corrosion resistance |

| Nickel | 8-10% | Improves toughness and ductility |

| Sulfur | 0.15-0.35% | Improves machinability by aiding chip breaking |

| Carbon | ~0.15% | Enhances hardness and strength |

| Manganese | Up to 2.0% | Adds strength and workability |

| Phosphorus | <0.20% | Controlled to avoid brittleness |

| Silicon | Up to 1.0% | Improves heat and scaling resistance |

You get excellent machinability from 303, but you trade off some corrosion resistance. The sulfur that helps you machine the steel also makes it less resistant to rust than grades like 304 or 316. You should avoid using 303 in environments with strong chemicals or saltwater. This grade remains nonmagnetic in most conditions, but it can become slightly magnetic after machining.

Tip: Choose 303 when you need to make many small, precise parts quickly, but do not need the highest corrosion resistance.

You find 303 stainless steel in many manufacturing settings where fast, precise machining is important. This grade works best for parts that need tight tolerances and smooth finishes. You often see it in the following applications:

Fasteners such as screws, bolts, and nuts

Gears and shafts that require detailed machining

Aircraft fittings where moderate corrosion resistance is enough

Electrical connectors and terminal fittings

Valve bodies and pump shafts with complex shapes

Automotive bushings and brackets

Precision-machined parts made by Swiss screw machines or CNC equipment

You use 303 when you need to produce large numbers of small, complex parts. The grade’s machinability saves you time and reduces tool costs. You should remember that 303 is not the best choice for food-grade or marine applications because of its lower corrosion resistance.

When you need a stainless steel that machines easily and delivers reliable performance for intricate parts, 303 gives you a practical solution. You benefit from its unique balance of machinability and strength, making it a favorite in many industries.

You often choose 304 stainless steel because it gives you a strong balance of durability, workability, and protection against corrosion. This grade contains at least 18% chromium and 8-10.5% nickel, which help form a passive oxide layer on the surface. This layer shields the metal from rust and many types of corrosion in everyday environments. You can rely on 304 stainless steel for excellent corrosion resistance in most atmospheric conditions and many industrial settings.

You will notice that this grade stands up well to water, acids, and outdoor exposure. However, you should know that warm chloride environments, such as tropical saltwater or areas with high chlorine, can cause pitting or stress corrosion cracking. In these cases, you may want to consider other grades like 316 for better protection.

304 stainless steel is easy to form and weld. You can bend, cut, and shape it without much risk of cracking. Its ductility and toughness make it a favorite for sheet metal work and fabrication. The material keeps its strength after forming, and you do not need much surface preparation before finishing or assembly.

Here is a quick look at the main features:

| Property | Description |

|---|---|

| Corrosion Resistance | Excellent in most environments; avoid warm chlorides |

| Formability | High; easy to bend, cut, and weld |

| Strength | Good tensile strength and durability |

| Surface Finish | Smooth, shiny, and easy to clean |

| Weldability | Excellent; suitable for most joining methods |

Tip: If you need a stainless steel that resists rust and is easy to work with, 304 is one of the most popular grades you can choose.

You see 304 stainless steel in many everyday products and industrial settings. Its excellent corrosion resistance and easy cleaning make it a top choice for both home and commercial use. You will find this grade in kitchenware, such as pots, pans, sinks, and cooking appliances. Food processing equipment and storage tanks also use 304 stainless steel because it meets hygiene standards and stands up to repeated washing.

In construction, you rely on 304 for architectural trim, railings, and exterior features. The material keeps its appearance and strength even when exposed to rain or pollution. Plumbing and water handling systems use 304 stainless steel for pipes, valves, and fasteners. These parts last longer in wet environments and require less maintenance.

You also find 304 stainless steel in automotive trim, wheel covers, and hose clamps. It handles heat, chemicals, and moisture, making it suitable for demanding conditions. Medical devices and laboratory equipment use this grade because it resists corrosion and is easy to sterilize.

Here are some common applications:

Kitchenware and cooking appliances

Food processing and storage equipment

Medical devices and laboratory tools

Architectural components and building trim

Plumbing fixtures, piping, and water tanks

Automotive parts and fasteners

You can count on 304 stainless steel for a wide range of applications. Its combination of excellent corrosion resistance, durability, and easy fabrication makes it one of the most trusted grades in both household and industrial products.

You often choose 304L stainless steel when you need a material that combines excellent corrosion resistance with easy fabrication. The "L" in 304L stands for "low carbon." This means the carbon content stays below 0.03%. Because of this, you avoid problems that can happen during welding, such as the formation of chromium carbides. These carbides can cause intergranular corrosion, which weakens the steel at the welds. With 304L, you do not have to worry about this issue.

When you weld 304L, you keep its corrosion resistance strong. You do not need to perform post-weld heat treatment, which saves you time and money. The steel keeps its strength and resists oxidation, even in high-temperature weld zones. You get a material that works well for welded structures in harsh or corrosive environments.

Here is a quick look at the main features of 304L:

| Property | Description |

|---|---|

| Carbon Content | ≤ 0.03% (low) |

| Corrosion Resistance | Excellent, especially after welding |

| Weldability | Outstanding; no post-weld heat treatment needed |

| Strength | Slightly lower than standard 304, but still very good |

| Sensitization Risk | Very low, even in heat-affected zones |

Tip: If you plan to weld stainless steel and want to avoid extra steps, 304L gives you a reliable solution.

You see 304L used in many industries because it handles welding and corrosion so well. This grade stands out when you need to build tanks, pipes, or equipment that must hold up under tough conditions. You often find 304L in chemical containers, pressure vessels, and heat exchangers. These applications require strong welds and resistance to rust or chemical attack.

Many companies in the chemical processing, food processing, and marine industries prefer 304L. You might see it in breweries, sugar refineries, and water filtration systems. Medical equipment makers also use 304L because it resists corrosion and does not become magnetic easily. This helps in sensitive environments where cleanliness and non-magnetic properties matter.

Here are some common applications for 304L stainless steel:

Chemical containers and processing equipment

Pressure vessels and heat exchangers

Piping systems for water, chemicals, or food products

Marine hardware and boat fittings

Medical devices and surgical tools

Food processing equipment, including brewing and sugar refining machinery

Architectural details and building facades

Water filtration screens and components

You also find 304L in aerospace and automotive structures, especially where welded joints need to last. If you work with welded components in harsh environments, you will likely choose 304L over other grades. Its low carbon content makes it the best option for welded assemblies that must resist corrosion for a long time.

When you need a stainless steel that can handle welding without losing its protective qualities, 304L is one of the most trusted grades available.

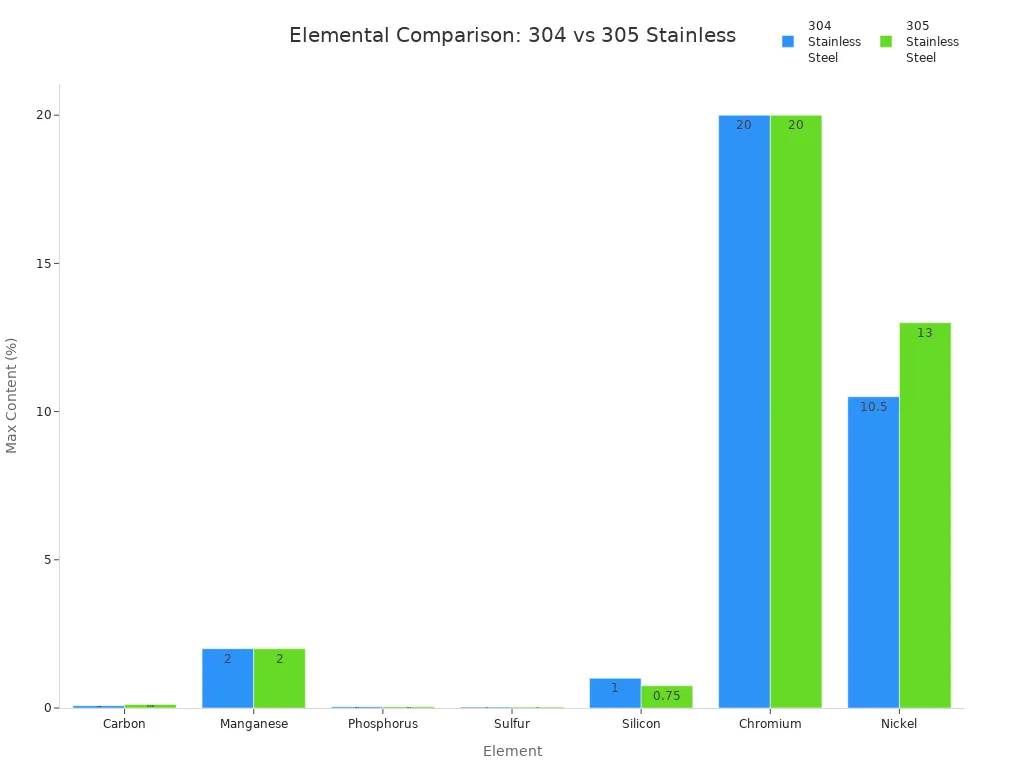

You choose 305 stainless steel when you need a material that resists corrosion and forms easily into deep shapes. This grade stands out because it contains more nickel than 304 stainless steel. The higher nickel content (10.5–13%) gives you better resistance to corrosion and helps the steel stay soft during forming. You can see the difference in composition between 304 and 305 in the table below:

| Element | 304 Stainless Steel (%) | 305 Stainless Steel (%) |

|---|---|---|

| Carbon | max 0.08 | max 0.12 |

| Manganese | max 2 | max 2 |

| Phosphorus | max 0.045 | max 0.045 |

| Sulfur | max 0.03 | max 0.03 |

| Silicon | max 1 | max 0.75 |

| Chromium | 18-20 | 18-20 |

| Nickel | 8-10.5 | 10.5-13 |

The extra nickel in 305 stainless steel lowers its work hardening rate. You can shape it into deep or complex forms without cracking. This property makes 305 a top choice for deep drawing and spinning processes. The corrosion resistance matches or slightly exceeds that of 304, so you can use it in many environments where rust is a concern. You also get good weldability and a smooth, attractive surface finish.

Tip: If you need a stainless steel that forms into deep shapes without becoming too hard, 305 gives you the flexibility you want.

You find 305 stainless steel in many consumer and industrial products. Its low work hardening rate and excellent formability make it ideal for deep drawn parts. You often see this grade in kitchen products, utensils, and appliances. Manufacturers use it for tank covers, mixing bowls, and other items that require deep drawing.

Here are some common applications for 305 stainless steel:

Appliances and kitchen products

Utensils, cups, pans, and mixing bowls

Tank covers and deep drawn consumer goods

Pens, eyelets, rivets, and tubes

Electrical parts such as eyelets and spun parts

You also see 305 used in the food processing, chemical, and textile industries. Its corrosion resistance and easy maintenance make it a favorite for kitchen utensils and appliances. Medical device makers use 305 for surgical tools like catheters because it resists corrosion and forms into precise shapes. In aerospace and automotive fields, you find 305 in wires, ropes, cables, and structural supports.

Food processing equipment

Medical surgical tools (such as catheters)

Aerospace and automotive components (wires, cables, supports)

You benefit from 305 stainless steel when you need to make deep drawn parts that must keep their shape and resist corrosion. This grade gives you reliable performance in both household and industrial applications.

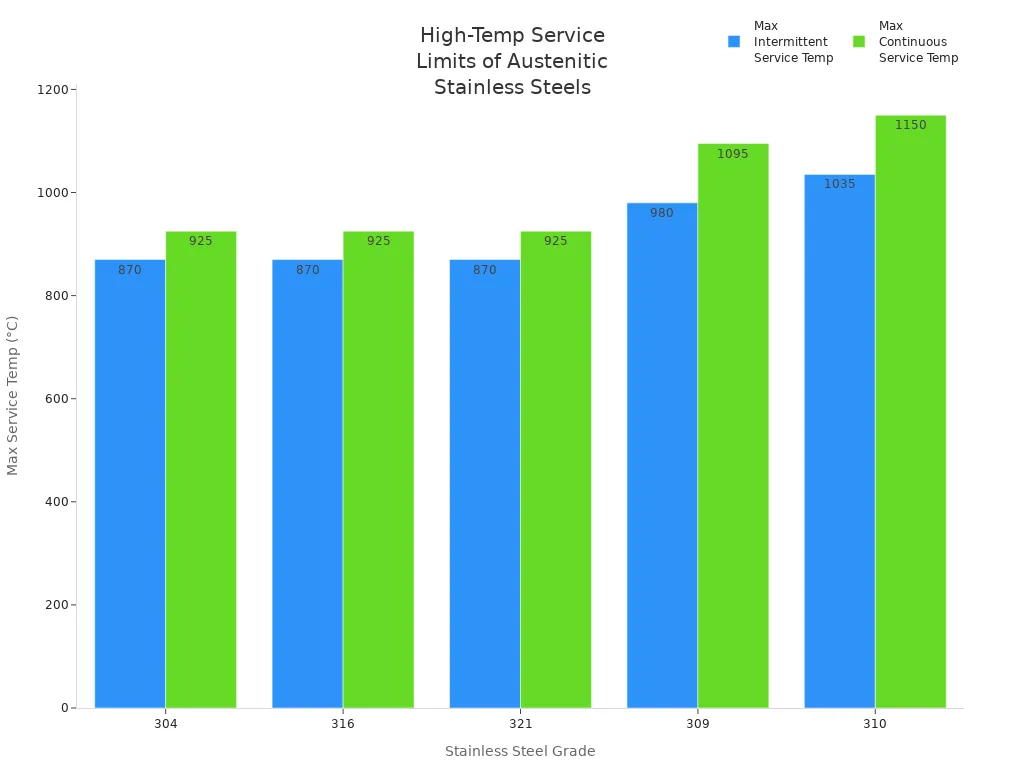

You choose 309 stainless steel when you need a material that stands up to high heat and resists oxidation. This grade contains more chromium and nickel than many other austenitic grades. The higher chromium (about 22%) and nickel (about 12%) content gives you better protection against rust and scaling, even at very high temperatures. You can see how 309 compares to other grades in the table below:

| Stainless Steel Grade | Chromium Content (%) | Nickel Content (%) | Max Intermittent Service Temperature (°C) | Max Continuous Service Temperature (°C) |

|---|---|---|---|---|

| 304 | 18 | 8 | 870 | 925 |

| 316 | 17 | 11 | 870 | 925 |

| 321 | 18 | 9 | 870 | 925 |

| 309 | 22 | 12 | 980 | 1095 |

| 310 | 25 | 20 | 1035 | 1150 |

You notice that 309 stainless steel can handle continuous service up to 1095°C (about 2000°F) and intermittent service up to 980°C. This makes it a strong choice for environments where other grades might fail. The alloy keeps its strength and resists warping or breaking, even after repeated heating and cooling cycles. You also benefit from its good resistance to corrosion in many industrial settings. The balance of chromium and nickel helps you avoid problems with scaling and oxidation, which can damage other metals at high temperatures.

Tip: If you need a stainless steel that performs well in both oxidizing and slightly reducing atmospheres, 309 gives you reliable results.

You find 309 stainless steel in many heat-resistant applications. This grade works well in industries that need materials to survive extreme temperatures and harsh conditions. You often see it in furnace parts, such as burners, doors, fans, and piping. Power plants use 309 for boiler tubes and pulverized coal burners because it keeps its strength and resists oxidation. Chemical processing plants rely on 309 for heat exchangers and storage tanks, where both heat and corrosion are concerns.

Here are some common applications for 309 stainless steel:

Furnace components: burners, doors, fans, piping, recuperators

Fluidized bed furnaces: grids, piping, wind boxes

Power generation: boiler tubes, tube hangers, pulverized coal burners

Chemical processing: heat exchangers, catalytic recovery systems, storage tanks

Food processing: ovens, grills, and equipment that must stay clean and resist rust

Waste treatment: incinerators, rotary kilns, calciners

Thermal processing: annealing covers, boxes, muffles, retorts, walking beams

You also find 309 in paper mill equipment and petroleum refining systems. The alloy performs well in environments with sulfur, nitriding, or thermal cycling. However, you should avoid using it in highly carburizing atmospheres, as it may not resist those conditions as well as some other grades.

You can count on 309 stainless steel when you need a material that lasts in high-heat, high-stress environments. Its unique combination of strength, oxidation resistance, and durability makes it a top choice for demanding industrial applications.

You choose 310 stainless steel when you need a material that can handle extreme heat and resist oxidation. This grade stands out because it contains high levels of chromium and nickel. These elements help you fight rust and scaling, even at temperatures up to 2000°F. You get a material that keeps its strength and shape when exposed to both high heat and rapid temperature changes.

Here is a table showing the main chemical and mechanical properties of 310 stainless steel:

| Property | Value/Range |

|---|---|

| Carbon | Up to 0.25% |

| Chromium | 24.0–26.0% |

| Nickel | 19.0–22.0% |

| Manganese | Up to 2.00% |

| Silicon | Up to 1.50% |

| Phosphorus | Up to 0.045% |

| Sulfur | Up to 0.030% |

| Ultimate Tensile Strength | 75–80 ksi |

| Yield Strength | 30–35 ksi |

| Elongation | 40–52% |

| Hardness (Rockwell B) | Max 95 |

| Density | 0.285–0.290 lb/in⊃3; |

| Modulus of Elasticity | 28.5–29.0 million psi |

| Thermal Conductivity | 8.0 Btu/ft·hr·°F |

| Electrical Resistivity | 30.7 microohm-in |

You notice that 310 stainless steel keeps moderate strength at high temperatures. The material does not become brittle or lose its shape easily. You also benefit from its good ductility, which means you can form and weld it for many different shapes. This grade does not harden by heat treatment, but you can strengthen it by cold working.

Tip: If you need a stainless steel that resists both heat and corrosion, 310 gives you a reliable choice for demanding environments.

You find 310 stainless steel in many high-temperature applications. This grade works well in industries where equipment faces both heat and harsh chemicals. You often see it used for furnace parts, heat exchangers, and boiler components. The food processing industry uses 310 for equipment that must stay clean and resist food acids, even at high heat.

Here are some common applications for 310 stainless steel:

Chemical processing equipment that handles hot, corrosive fluids

Boiler systems, including superheater tubes, burner nozzles, and furnace conveyor belts

Heat exchangers in chemical and petroleum plants

Food processing machinery for pasteurization and retort cooking

Power generation equipment such as steam turbines and heat exchanger tubes

Aerospace parts that need strength and oxidation resistance at high temperatures

Industrial kilns, annealing furnaces, and incinerators

You can also see how different industries use 310 stainless steel in the table below:

| Industry | Application Details |

|---|---|

| Petrochemical | Tanks, valves, pipes, flanges, pressure vessels, pumps, condensers, and heat exchangers |

| Food and Beverage | Food processing equipment, pasteurization, retort cooking, high-heat and corrosion-resistant machinery |

| Aerospace | Parts needing strength and oxidation resistance up to 1000°C, complex shapes |

| Power Generation | Boilers, steam turbines, heat exchangers, and flexible high-temperature components |

You benefit from 310 stainless steel when you need a material that can handle both heat and corrosion. This grade gives you flexibility for many demanding applications, especially where other grades might fail.

You choose 316 stainless steel when you need a material that stands up to tough environments. This alloy contains chromium, nickel, and molybdenum. The addition of molybdenum makes a big difference. It helps the steel resist corrosion from saltwater, acids, and harsh chemicals. You see this grade form a protective oxide layer on its surface. This layer repairs itself when scratched, so the metal keeps resisting rust and stains.

Compared to other grades, 316 gives you better protection against pitting and crevice corrosion. You notice this especially in places with chlorides, like seawater or cleaning agents. The steel stays strong even at high temperatures, up to about 1700°F. You get a tensile strength between 75,000 and 90,000 psi and a yield strength from 30,000 to 45,000 psi. The material also stretches well, with elongation between 40% and 60%. You cannot harden it by heat treatment, but you can make it stronger by cold working.

316 stainless steel stays non-magnetic in its annealed form. You find it easy to weld and form into many shapes. Its resistance to corrosion and high strength make it a top choice for demanding jobs.

Tip: If you work in a place with salt, chemicals, or frequent cleaning, 316 stainless steel gives you the best protection against corrosion.

You find 316 stainless steel in many places where other grades might fail. Its main strength lies in its ability to resist corrosion from salt and chemicals. In marine environments, you use it for boat fittings, dock hardware, and underwater equipment. The steel does not rust easily, even when exposed to seawater every day.

In chemical processing plants, you rely on 316 for tanks, pipes, and reactors. These parts must handle acids, caustic solutions, and high temperatures. The molybdenum in the alloy helps prevent corrosion from these harsh substances. You also see 316 in desalination plants, offshore oil rigs, and coastal bridges. These structures face constant exposure to salt and moisture.

Here are some common applications for 316 stainless steel:

Boat fittings: cleats, railings, propellers

Dock and underwater hardware

Offshore oil platforms and desalination plants

Chemical tanks, reactors, and piping systems

Heat exchangers in chemical and food industries

Coastal construction: bridges, piers, and supports

You also find this grade in food and beverage machinery. The steel resists corrosion from food acids and frequent washing. Medical device makers use 316 for surgical tools and implants because it stays clean and does not react with body fluids.

When you need a stainless steel that can handle salt, chemicals, and high heat, 316 stands out among all grades. Its unique mix of strength and corrosion resistance makes it a favorite for the toughest applications.

You choose 316L stainless steel when you need a material that combines excellent corrosion resistance with strong weldability. The "L" in 316L stands for "low carbon." This lower carbon content helps you avoid problems that can happen during welding, such as intergranular corrosion. When you weld 316L, you do not have to worry about chromium carbides forming at the grain boundaries. This means you keep the steel’s corrosion resistance, even in thick sections or after welding. You can also perform stress-relieving heat treatments without losing corrosion protection.

The table below shows how the reduced carbon content in 316L affects its performance:

| Aspect | Impact of Reduced Carbon Content in 316L Stainless Steel |

|---|---|

| Weldability | Improved, with less risk of weld decay and intergranular corrosion |

| Corrosion Resistance | Enhanced, especially in chloride-rich or harsh environments |

| Mechanical Strength | Slightly lower than standard 316, but still strong enough for most uses |

| Long-term Reliability | Better durability in tough environments, with less risk of pitting or crevice corrosion |

You notice that 316L offers superior immunity to weld decay, which makes it ideal for complex welding jobs. The steel keeps its strength and shape, even after repeated heating and cooling. However, you may see a small drop in mechanical strength compared to other grades because of the lower carbon. In some sliding or frictional uses, you might notice increased galling, so you should consider this if wear resistance is important.

Tip: Choose 316L when you need a stainless steel that resists corrosion after welding and stands up to harsh chemicals or saltwater.

You find 316L stainless steel in many industries that demand high corrosion resistance and clean surfaces. Pharmaceutical and biotech companies use it for processing equipment, storage tanks, and sanitary fittings. You see it in food and dairy plants, where cleanability and hygiene matter. Breweries and beverage makers rely on 316L for tanks, valves, and tubing that must handle both acids and cleaning chemicals.

Chemical processing plants use 316L for digesters, pressure vessels, and piping systems. The textile industry trusts this grade for equipment that faces dyes and harsh chemicals. Aerospace and oil and gas companies use 316L for parts exposed to seawater or corrosive fluids. You also find this steel in marine applications, such as shipping vessels and underwater hardware, because it resists pitting from saltwater.

Here are some common applications for 316L stainless steel:

Pharmaceutical and biotech processing equipment

Food, dairy, and brewing tanks, valves, and sanitary fittings

Chemical and textile processing machinery

Pressure vessels and storage tanks

Tubing and piping for corrosive fluids

Aerospace and oil and gas components

You choose 316L when you need a material that combines easy welding, strong corrosion resistance, and long-term reliability. This grade stands out among stainless steels for its ability to handle tough environments and demanding applications.

You choose 321 stainless steel when you need a material that stands up to heat and resists corrosion after welding. This grade contains titanium, which plays a special role. Titanium binds with carbon, forming titanium carbides. This process stops chromium carbides from forming at the grain boundaries. You avoid intergranular corrosion, which can weaken welded joints. You get a material that keeps its strength and corrosion resistance, even after exposure to high temperatures.

Here are some key features you notice with 321 stainless steel:

Titanium stabilization prevents chromium carbide formation.

You see improved resistance to intergranular corrosion, especially in welded structures.

Corrosion resistance matches what you find in 304 and 304L grades when annealed.

The alloy performs well at high temperatures, with a maximum operating temperature around 1650°F.

You benefit from strong creep and stress rupture resistance, making it reliable for demanding applications.

The physical and mechanical properties stay stable during continuous service up to about 1500°F (815°C).

Note: You often select 321 stainless steel for pressure vessels, boilers, and other equipment that faces both heat and stress. The titanium stabilization gives you peace of mind when you need long-term durability.

You find 321 stainless steel in many high-temperature and high-stress environments. This grade works well in aerospace, chemical, and automotive industries. You see it used for aircraft exhaust systems and engine parts. These components face extreme heat and need to keep their strength and shape. The oxidation resistance and ability to handle thermal cycling make 321 a top choice for these applications.

In chemical processing, you rely on 321 for heat exchangers, pressure vessels, and storage tanks. The alloy resists both heat and corrosion, so your equipment lasts longer. You also see 321 in boilers, furnace parts, and other thermal equipment. The material stands up to repeated heating and cooling without losing its properties.

Automotive exhaust systems use 321 stainless steel to handle hot exhaust gases. The grade extends the life of pipes and mufflers. You also find 321 in petroleum refining, where piping and heat exchangers must survive both high temperatures and corrosive chemicals. Expansion joints benefit from the flexibility and heat resistance of 321, allowing them to absorb movement without cracking.

Here is a table showing common applications for 321 stainless steel:

| Industry | Typical Applications |

|---|---|

| Aerospace | Aircraft exhausts, engine parts |

| Chemical | Heat exchangers, pressure vessels, storage tanks |

| Automotive | Exhaust systems, mufflers, pipes |

| Thermal Equipment | Boilers, furnace parts, expansion joints |

| Petroleum | Refining equipment, piping, heat exchangers |

You choose 321 stainless steel when you need a grade that combines heat resistance, corrosion protection, and long-term reliability. This alloy gives you confidence in the most demanding applications.

You often see many stainless steel grades in daily life and industry. Each grade has unique features that make it suitable for specific applications. The table below compares the top 10 austenitic stainless steel grades. You can use this table to quickly understand the main differences and choose the right material for your needs.

| Grade | Corrosion Resistance | Strength (Tensile) | Weldability | Key Alloying Elements / Notes | Typical Applications |

|---|---|---|---|---|---|

| 301 | Excellent | High, improves with cold work | Good | Chromium, nickel; high ductility | Springs, automotive trim, rail cars |

| 302 | Similar to 304 | Higher due to more carbon | Good | Like 304 but more carbon | Medical devices, fasteners, wire forms |

| 303 | Slightly lower than 304 | Not hardenable, easy to machine | Good, but less corrosion resistant | Added sulfur for machinability | Screws, bolts, gears, precision parts |

| 304 | Excellent | ~621 MPa | Very good | Most common, balanced properties | Sinks, cookware, food equipment |

| 304L | Excellent, especially after welding | Slightly lower than 304 | Outstanding | Low carbon for better welds | Tanks, piping, welded structures |

| 305 | Excellent | Lower work hardening rate | Good | Higher nickel for deep drawing | Deep drawn parts, kitchen utensils |

| 309 | High | Higher than 304 | Good | More chromium and nickel, high temp resistant | Furnace parts, heat exchangers |

| 310 | Superior oxidation/corrosion | Better than 304 | Good | High nickel and chromium for heat resistance | Kilns, boilers, chemical processing |

| 316 | Superior in chlorides/pitting | ~579 MPa | Very good | Molybdenum for marine/chemical use | Marine, chemical, food processing |

| 316L | Superior, especially after welding | Slightly lower than 316 | Excellent | Low carbon, best for welded marine/chemical | Pharma, biotech, marine, food plants |

| 321 | Improved at high temp/welded | Retains strength at high temp | Good | Titanium stabilized for weld durability | Aircraft, exhausts, heat exchangers |

Use this table to compare the most important properties and typical applications for each grade. You can quickly see which stainless steel grades fit your project.

You notice that corrosion resistance is a key factor when you select stainless steel grades. Grades like 304, 304L, and 316 offer excellent protection in most environments. If you need even more resistance, especially in marine or chemical settings, you should look at 316 or 316L. These grades contain molybdenum, which helps fight pitting and crevice corrosion.

Strength also matters. You get the highest strength from 301, especially after cold working. Grades like 302 and 309 also provide strong performance. If you need a grade that forms easily, 305 is a good choice because it does not harden quickly during shaping.

Weldability is important for many applications. Most austenitic stainless steel grades weld well. You get the best welds with low-carbon grades like 304L and 316L. These grades resist weld decay and keep their corrosion resistance after joining.

Remember: The right grade depends on your environment, the strength you need, and how you plan to fabricate your parts.

You find these stainless steel grades in many applications. For example, you use 304 for kitchen sinks, cookware, and food processing equipment. If you work in marine or chemical industries, you often choose 316 or 316L because they resist corrosion from salt and chemicals. When you need parts that must bend or flex, 301 is a strong option. For deep drawn shapes, 305 works best. If you need to machine many small parts, 303 saves you time and effort.

In high-temperature environments, you rely on 309, 310, or 321. These grades keep their strength and resist oxidation even when exposed to heat. You see them in furnaces, boilers, and exhaust systems.

You can match each grade to its best use by checking the table above. This helps you pick the right stainless steel for your next project.

When you select austenitic stainless steel grades, you need to look at several important factors. Each project has unique requirements, so you should match the grade to your specific needs. Here are the main points you should consider:

Corrosion Resistance

Think about the environment where you will use the material. If your application faces saltwater or harsh chemicals, you need a grade like 316 or 316L. For general use, 304 often works well. If you expect high temperatures, 310 or 309 may be better choices.

Mechanical Properties

Check the strength, toughness, and durability you need. Some applications require high strength or resistance to impact and fatigue. Grades like 301 provide extra strength after cold working.

Formability

If you need to shape the material into complex forms, choose grades with good formability. Grades such as 304 and 316 let you create deep or intricate shapes without cracking.

Machinability

For projects that involve a lot of machining, select grades designed for easy cutting. Grade 303 contains sulfur, which makes it easier to machine into precise parts.

Weldability

If you plan to weld the material, low-carbon grades like 304L and 316L help you avoid corrosion at the welds. These grades keep their corrosion resistance even after welding.

Heat Treatment

Some applications need specific mechanical properties. If you need to adjust hardness or strength, check if the grade allows for heat treatment or cold working.

Cost and Availability

Always balance performance with cost. Some stainless steel grades cost more because they contain extra alloying elements. Make sure the grade you choose is available from your supplier.

Tip: Always match the grade to the environment and the demands of your application. This helps you avoid costly repairs or replacements later.

You can make the selection process easier by following a few simple tips:

Start by listing the main challenges your application will face, such as exposure to chemicals, salt, or high heat.

Use the comparison table to narrow down your options based on corrosion resistance, strength, and fabrication needs.

Talk to your supplier or a materials expert if you have special requirements. They can help you find the best fit among the many stainless steel grades.

Consider the total cost, not just the price per pound. A more corrosion-resistant grade may save you money over time by reducing maintenance and downtime.

Test a small sample if you are unsure. This lets you see how the material performs before you commit to a large order.

Remember: The right stainless steel grade ensures your equipment lasts longer and performs better in its intended environment. Careful selection leads to safer, more reliable applications.

Understanding the differences between austenitic stainless steel grades helps you make better choices for your projects. The right grade boosts performance and extends the life of your equipment. Always match the grade to your environment and needs. Use the comparison table to guide your decision. If you feel unsure, talk to a materials expert.

Remember: Smart selection leads to safer, longer-lasting results. ️

You get austenitic stainless steel with a face-centered cubic structure. This structure gives you high ductility, toughness, and non-magnetic properties. You also see better corrosion resistance compared to ferritic or martensitic stainless steels.

You can weld most austenitic grades with standard techniques. Grades with low carbon, like 304L and 316L, resist weld decay. You avoid extra steps after welding when you choose these grades.

You should use 316 or 316L stainless steel for marine settings. These grades contain molybdenum, which helps you resist saltwater corrosion and pitting. You get longer-lasting performance near the ocean.

You should pick 304 or 316 stainless steel for food processing. Both grades resist corrosion and meet hygiene standards. 316 works better if you handle salty or acidic foods.

You find austenitic stainless steel non-magnetic in most cases. Cold working or welding can make it slightly magnetic, but it stays less magnetic than other types.

You should select 309, 310, or 321 stainless steel for high heat. These grades keep their strength and resist oxidation at elevated temperatures. You see them in furnaces and exhaust systems.

You get the best machinability with 303 stainless steel. The added sulfur helps you cut and shape parts faster. Other grades, like 304, need slower speeds and sharper tools.

You avoid intergranular corrosion with low-carbon grades like 304L and 316L. These grades keep their corrosion resistance after welding. You do not need extra heat treatment.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Exploring the Magnetism of Stainless Steel for Modern Applications

Super austenitic stainless steel outperforms in real-world acid tests

Emerging Manufacturing Techniques for Austenitic Stainless Steel Bars

Exploring The Role of 18-8 Austenitic Stainless Steel in Modern Manufacturing And Homes

Top 10 Austenitic Stainless Steel Grades and Their Everyday Uses