close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-29 Origin: Site

You likely use 18-8 stainless steel every day, whether you notice it or not. This material, known for its blend of 18% chromium and 8% nickel, makes up about 60% of global stainless steel production. You find 18/8 stainless steel in cookware, kitchen appliances, and even medical equipment because it resists rust and keeps its shine. Manufacturers choose 18-8 stainless steel for products that must stay clean, strong, and reliable. The unique structure of 18 8 austenitic stainless steel brings durability and hygiene to both your home and modern industry.

When you hear about 18-8 stainless steel, you are learning about one of the most popular types of stainless used in the world. This material contains about 18% chromium and 8% nickel. You will find it in the 300 series of austenitic stainless steel. The combination of chromium and nickel gives 18-8 stainless steel its famous resistance to rust and corrosion. Unlike some other types, 18/8 stainless steel does not have molybdenum, so it is less suited for saltwater or harsh chemical environments. However, you benefit from its lower cost and easier machinability. You can also notice that 18-8 stainless steel does not attract magnets, and you can cold work it without making it brittle. Because of these features, you see 18/8 stainless steel in food processing, wastewater treatment, and medical equipment, but not in marine settings where 316 stainless steel works better.

Tip: If you want a material that stays shiny, resists stains, and lasts for years, 18-8 stainless steel is a smart choice for many everyday products.

You might wonder how 18-8 stainless steel became so important. Its invention changed the way industries make products. When manufacturers first used 18/8 stainless steel, they could create rust-resistant parts that lasted longer and needed less maintenance. This breakthrough led to new types of stainless, such as stabilized and ultra-low carbon versions, to solve problems like cracking and corrosion. Over time, industries like chemical, petrochemical, marine, and aerospace adopted 18-8 stainless steel and its improved forms. Advances in production, such as electric arc furnaces, made stainless steel more affordable and higher in quality. Today, you can find international standards for 18-8 stainless steel, which help ensure quality and consistency worldwide.

Standard Organization | Country/Region |

|---|---|

AISI | USA |

AFNOR | France |

DIN | Germany |

UNI | Italy |

JIS | Japan |

GOST | Russia |

UNE | Spain |

SIS | Sweden |

BSI | UK |

EURONORM | European Union |

These standards confirm that 18/8 stainless steel meets strict requirements, no matter where you live.

You can count on 18-8 stainless steel for its strong mechanical and chemical properties. The chemical makeup includes about 17.5-20% chromium and 8-12% nickel, with very low carbon, silicon, and manganese. In its annealed state, 18/8 stainless steel has a yield strength of at least 205 MPa and a tensile strength of at least 515 MPa. It stretches well before breaking, with an elongation of at least 40%. The density is about 7.93 g/cm³, and it melts at temperatures between 1400-1450°C. You also get good thermal and electrical properties, making it useful in many settings. Compared to other stainless steels, 18-8 stainless steel balances corrosion resistance, strength, and workability. You can weld, form, and machine it for a wide range of uses, from kitchen utensils to outdoor structures.

Property Type | Key Properties of 18-8 Stainless Steel (Type 304) |

|---|---|

Chemical Composition (wt%) | Carbon ≤ 0.08%, Silicon ≤ 1.00%, Manganese ≤ 2.00%, Phosphorus ≤ 0.045%, Sulfur ≤ 0.03%, Chromium 17.5-20.0%, Nickel 8.0-12.0%, Nitrogen ≤ 0.10% |

Mechanical Properties (Annealed) | Yield Strength ≥ 205 MPa, Tensile Strength ≥ 515 MPa, Elongation ≥ 40% |

Physical Properties | Density ~7.93 g/cm³, Melting Point 1400-1450°C, Thermal Conductivity 16.2 W/m·K |

With these qualities, you can see why 18/8 stainless steel remains a top choice for both industry and your home.

You might wonder what makes 18-8 stainless steel so special. The answer lies in its precise mix of chromium and nickel. These two elements give this steel its famous durability and shine. You can see the typical range for each element in the table below:

Element | Typical Range (%) |

|---|---|

Chromium | 18.0 - 20.0 |

Nickel | 8.0 - 11.0 |

Chromium forms the backbone of the alloy, making up 18 to 20 percent of the total. Nickel follows with 8 to 11 percent. This combination creates a strong, stable structure. You get a material that resists rust and keeps its appearance over time. The balance of chromium and nickel is what sets 18-8 stainless steel apart from other types of stainless.

You rely on 18-8 stainless steel for its outstanding corrosion resistance. Chromium in the alloy forms a thin, invisible layer of chromium oxide on the surface. This layer protects the steel from rusting and damage. Even if you scratch the surface, the oxide layer repairs itself when exposed to air. Nickel adds more protection by stabilizing the structure and making the steel tougher against acids and heat.

Chromium creates a self-healing oxide layer that shields the iron base from rust.

Nickel strengthens the structure and helps the steel resist both general and localized corrosion.

The combined effect of chromium and nickel gives you a material that stands up to many environments.

Scientific studies show that 18-8 stainless steel performs well in food processing, medical, and construction settings. You can trust it in kitchens, hospitals, and factories. However, you should know that in places with high chloride levels, such as near the ocean or in chemical plants, this steel may develop pitting or crevice corrosion. For those harsh conditions, you might need a different alloy with added molybdenum.

A study on 304L stainless steel, a type of 18/8 stainless steel, found that it resists most forms of corrosion in normal and moderate environments. When chloride levels rise above 150 mg/L or temperatures increase, the risk of pitting grows. You should keep this in mind if you plan to use 18-8 stainless steel in tough settings.

Note: The corrosion resistance of 18-8 stainless steel comes from both chromium and nickel. Neither element alone can provide the same level of protection.

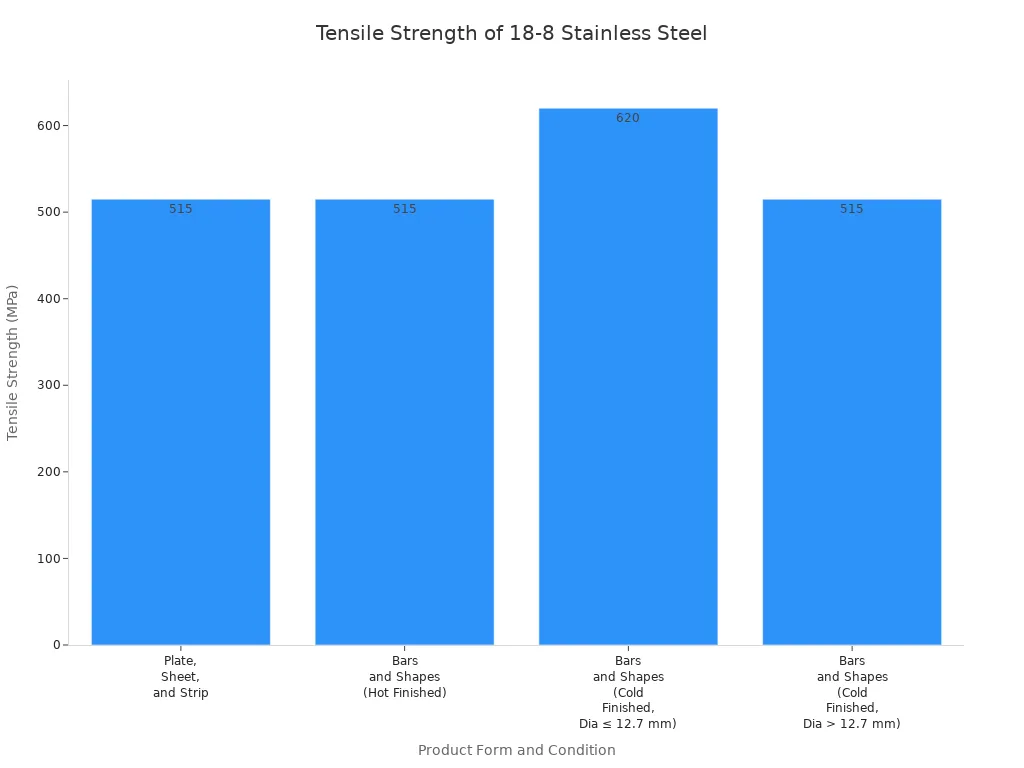

You benefit from the high strength of 18-8 stainless steel. This alloy offers a great balance between toughness and flexibility. Industry standards show that the tensile strength of 18-8 stainless steel ranges from about 515 MPa (75,000 psi) for most forms to 620 MPa (90,000 psi) for cold-finished bars and shapes. You can see the details in the chart below:

Product Form and Condition | Tensile Strength (MPa) | Tensile Strength (psi) |

|---|---|---|

Plate, Sheet, and Strip | ≥ 515 | ~75,000 |

Bars and Shapes (Hot Finished) | ≥ 515 | ~75,000 |

Bars and Shapes (Cold Finished, Dia ≤ 12.7 mm) | ≥ 620 | ~90,000 |

Bars and Shapes (Cold Finished, Dia > 12.7 mm) | ≥ 515 | ~75,000 |

You can use 18-8 stainless steel in products that need to handle stress, bending, or impact. This makes it a top choice for kitchenware, medical tools, and industrial equipment. The combination of corrosion resistance and mechanical strength means you get a material that lasts and performs well in many situations. As a type of austenitic stainless steel, 18-8 stainless steel also stays tough at both high and low temperatures.

You see 18-8 stainless steel everywhere in the food industry. This material stands out for its corrosion resistance, hygienic surface, and ability to withstand frequent cleaning. You find it in equipment that touches food directly or stores ingredients for long periods. Manufacturers choose 18-8 stainless steel because it does not react with food, keeps flavors pure, and resists stains.

Here is a table showing common types of food processing equipment made from 18-8 stainless steel:

Equipment Category | Examples of Equipment Made from 18-8 Stainless Steel |

|---|---|

Dairy and Beverage Processing | Tanks holding dairy, beer kegs, beer processing equipment |

Storage and Transport | Flour silos, syrup tanks, double wall food transport containers |

Food Preparation | Food mixers, peeling machines, food pulverizers, confectionary equipment |

Processing Components | Evaporator tubes, conveyor systems, industrial ovens |

Molds and Containers | Ice cream molds, hollowware, cookware pieces, sinks, containers |

You also find 18-8 stainless steel in many other food applications:

Hollowware such as pitchers, urns, and gravy boats

Cookware pieces including pots and pans

Sinks, stoves, and refrigerators

Pipework, water lines, and ice makers

Food service tables, shelving, and vending machines

You benefit from this material because it is easy to clean, does not rust, and lasts for years. The smooth surface prevents bacteria from sticking, making it ideal for food processing. You can trust 18-8 stainless steel to keep your food safe and your equipment looking new.

You rely on 18-8 stainless steel in chemical and petroleum applications because it offers excellent corrosion resistance. The unique mix of chromium and nickel forms a self-healing oxide layer on the surface. This layer protects the steel from acids and caustic substances found in these industries. You see this material used in storage tanks, pressure piping, and vessels.

18-8 stainless steel stands out for its durability and versatility. You can fabricate it into many shapes and sizes, which makes it perfect for complex machinery and piping systems. While some environments require more specialized alloys, you often find 18-8 stainless steel as the preferred choice for moderately corrosive conditions. It balances cost and performance, so you get reliable protection without overspending.

You should know that in highly corrosive environments, such as those with high chloride levels, other grades like 316 stainless steel may work better. However, for most chemical and petroleum applications, 18-8 stainless steel remains a top pick due to its proven track record and cost-effectiveness.

Tip: When you need a material that resists corrosion and stays durable in chemical settings, 18-8 stainless steel is a smart option.

You find 18-8 stainless steel in many metallurgical and aerospace applications. In metallurgical machinery, you see it used for steel sheets, plates, tubes, bars, rods, and wires. These intermediate products become parts for larger machines and structures. The strength and corrosion resistance of 18-8 stainless steel make it suitable for demanding environments.

In aerospace, you notice this material in fasteners, such as those on aircraft cowlings and inspection hole covers. While entire aircraft rarely use stainless steel, some historical planes like the Budd Oonestoga and Fleetwings Seabird featured stainless steel airframes. These examples show how 18-8 stainless steel can handle stress, vibration, and exposure to the elements.

Here is a table with examples of metallurgical and aerospace components made from 18-8 stainless steel:

Application Area | Examples of Components and Products Made from 18-8 Stainless Steel |

|---|---|

Metallurgical Machinery | Steel sheet & plate, steel tube & pipe, steel bar & flat, rod & wire |

Aerospace Industry | Stainless steel fasteners for aircraft cowlings, inspection hole covers, and other parts |

General Machinery | Machinery and parts manufactured from intermediate products |

You choose 18-8 stainless steel for these applications because it stays strong, resists corrosion, and performs well under pressure. The material’s versatility allows you to use it in everything from industrial machines to critical aerospace parts.

You see 18-8 stainless steel in many medical device applications. Hospitals and clinics rely on this material for its unique combination of properties. When you look at surgical trays, instrument handles, and diagnostic equipment, you often find 18-8 stainless steel at work. Here’s why manufacturers choose it for these important applications:

You get good corrosion resistance, which helps devices last longer and stay safe for patients.

The material works well for hospital equipment and less critical instruments, such as trays, forceps, and scissors.

You benefit from its formability, making it easy to shape into complex parts.

While it does not resist chloride-induced pitting as well as some other alloys, it still performs well in moderate environments.

Its cost-effectiveness and wide acceptance make it a practical choice for many device components.

You can trust 18-8 stainless steel to deliver reliable performance in a range of medical settings. Its smooth surface makes cleaning easy, which helps prevent the spread of germs. You also see it in dental tools, wheelchairs, and IV stands. The combination of hygiene, durability, and affordability keeps it popular in medical device applications.

You depend on 18-8 stainless steel for high-pressure pipes and vessels in many industries. This alloy stands out for its ability to handle stress and pressure without breaking or deforming. The high tensile strength, ranging from about 500 to 750 MPa, means you can use it in demanding applications like chemical processing, water treatment, and food production. The chromium content forms a protective oxide layer, which shields the steel from rust and chemical attack. You also benefit from its weldability and formability, which allow you to create complex piping systems and pressure vessels.

The non-porous surface of 18-8 stainless steel makes cleaning easy and supports hygienic safety in sensitive environments. You find this material in food and chemical processing equipment, automotive parts, marine equipment, and water treatment systems. These applications require both safety and long-term durability under pressure. The alloy’s resistance to acids and cleaning chemicals adds to its lifespan, making it a cost-effective choice for high-pressure applications.

Tip: When you need a material that combines strength, corrosion resistance, and easy maintenance, 18-8 stainless steel is a smart solution for high-pressure pipes and vessels.

You interact with 18-8 stainless steel every day in your kitchen. This material appears in mixing bowls, sinks, dish racks, and even the trim on your refrigerator. Manufacturers choose 18 8 austenitic stainless steel for these products because it resists rust and stains. You get a surface that stays shiny and looks new, even after years of use. The smooth finish makes it easy to clean, so you can wipe away spills and food particles without effort.

You also benefit from the strength of this steel. It holds up under heavy pots, sharp utensils, and frequent washing. You do not need to worry about cracks or dents in your kitchen appliances. The non-porous surface keeps bacteria from hiding, which helps you maintain a hygienic kitchen. When you see a sparkling sink or a sturdy mixing bowl, you are likely looking at 18-8 stainless steel at work.

You rely on 18-8 stainless steel for many types of cookware and cutlery. This material gives you a balance of durability, safety, and affordability. Here are some reasons why manufacturers use 18-8 stainless steel in these applications:

Chromium in the steel bonds with oxygen to prevent rust and corrosion.

Nickel increases durability, so your knives and forks last longer.

The steel is stronger than many other metals and keeps its shape over time.

18-8 stainless steel costs less than 18-10 stainless steel but still offers good corrosion resistance.

You find it in mixing bowls, cookware, and sinks because it is stable and easy to machine.

Both 18-8 and 18-10 stainless steels meet strict food safety standards, making them safe for food-contact products.

The choice of 18-8 stainless steel balances quality and affordability, which is important for everyday kitchen utensils.

You notice this steel in your spoons, forks, knives, and even in the handles of pots and pans. It does not react with acidic foods, so you can cook tomato sauce or lemon-based dishes without worry. The material keeps its shine and resists scratches, which means your cutlery looks good for years. You also find that it is easy to clean, so you spend less time scrubbing and more time enjoying your meals.

You trust 18-8 stainless steel when you drink from a reusable water bottle or use a travel mug. The chromium in this steel forms a protective layer that stops rust and keeps harmful substances out of your drink. This feature ensures your bottle stays safe and free from contamination. The smooth, non-porous surface resists bacterial growth, which makes it a hygienic choice for storing liquids.

You also benefit from the durability of 18 8 austenitic stainless steel. Your water bottle can handle drops, bumps, and daily use without breaking or leaking. The material meets FDA standards for food contact, so you know it will not affect the taste or purity of your water. You can wash your bottle easily, and it will not hold onto odors or stains.

When you use stainless utensils, you get the same advantages. The steel resists corrosion and keeps its appearance, even after many washes. You can trust that your utensils are safe, easy to clean, and built to last.

Tip: Choose 18-8 stainless steel water bottles and utensils for a safe, durable, and hygienic option that supports your health and the environment.

You see 18 8 austenitic stainless steel in many household fixtures around your home. This material appears in places where you need both strength and a clean look. You often find it in areas that get wet or need frequent cleaning. The smooth, non-porous surface helps prevent bacteria from growing and makes cleaning easy.

Here are some common household fixtures made from 18 8 austenitic stainless steel:

Sinks and countertops in kitchens and bathrooms

Faucets and handles on doors or cabinets

Bathroom accessories like towel racks, soap dishes, and shower caddies

Window frames and sliding door tracks

Decorative parts such as trim, kick plates, and light switch covers

You benefit from these fixtures because they resist rust and stains. The material keeps its shine even after years of use. You can wipe away fingerprints and water spots with little effort. This makes your home look modern and well-kept. When you choose 18 8 austenitic stainless steel for your fixtures, you get both style and long-lasting performance.

Tip: If you want fixtures that stay clean and look new, choose stainless steel. You will spend less time cleaning and more time enjoying your home.

You notice 18 8 austenitic stainless steel in many architectural elements, both inside and outside buildings. Architects and builders use this material because it combines beauty with strength. The excellent corrosion resistance means your window frames and decorative parts will not rust, even in humid or rainy climates. The high strength-to-weight ratio allows for slim, modern designs that do not sacrifice durability.

You see this material in window frames, stair railings, and cladding on building exteriors. Its non-porous surface helps it last longer and makes maintenance simple. You can also find it in handrails, elevator doors, and wall panels. The ability to shape 18 8 austenitic stainless steel into complex forms gives designers more freedom to create unique looks.

In construction, you benefit from using this material as part of your building’s structure or decoration. It stands up to weather, pollution, and daily wear. As a result, your building keeps its appearance and value over time. When you select construction materials, 18 8 austenitic stainless steel offers a smart balance of function and style.

Note: Many modern buildings use stainless steel for both structural and decorative purposes. You get a sleek look and reliable performance in one package.

You benefit from 18-8 stainless steel in many ways. This material stands out for its excellent corrosion resistance, thanks to its 18% chromium and 8% nickel content. Chromium forms a protective oxide layer that prevents rust, while nickel adds toughness and durability. You see this steel in a wide range of applications, from kitchen sinks to surgical instruments. Its strength allows you to use it for heavy loads and mechanical stresses. You also enjoy its hygienic properties, which make it ideal for food, medical, and dental applications. The bright silvery finish adds aesthetic appeal to household and industrial products.

You find 18-8 stainless steel in domestic, architectural, transport, medical, food, and pharmaceutical industries. It works well for general-purpose applications, such as refrigerators, dishwashers, and food processing equipment. Manufacturers choose this steel because it is easy to weld and machine. You can recycle it, which supports environmental sustainability. The long-lasting nature of 18-8 stainless steel means you replace products less often, saving money and resources.

Excellent corrosion resistance

Strong and durable for demanding applications

Hygienic and easy to clean

Attractive appearance

Versatile in manufacturing processes

100% recyclable

Tip: When you want a material that combines strength, hygiene, and beauty, 18-8 stainless steel is a smart choice for many uses and applications.

You should also consider some limitations of 18-8 stainless steel. This material does not resist chlorides well. Saltwater and de-icing salts can cause rapid corrosion, especially in coastal environments. If you live near the ocean or use products outdoors, you may notice rust spots over time. The lack of standardization for "18/8" means nickel content can vary between suppliers, which affects performance in some applications.

Prolonged exposure to high temperatures above 425°C weakens the alloy. You may see reduced strength and corrosion resistance in these conditions. After fabrication, 18-8 stainless steel can become slightly magnetic. This property may interfere with sensitive electronics in certain applications.

Poor resistance to chlorides and saltwater

Variable nickel content between suppliers

Limited high-temperature performance

Slight magnetism after fabrication

Note: For harsh environments or high-heat applications, you may need to choose a different stainless steel grade.

You help the environment when you choose 18-8 stainless steel. This material is 100% recyclable without losing quality. Unlike other materials that degrade after recycling, stainless steel can go through an infinite recycling loop. Recycling saves energy—about 60% less than producing new steel—and reduces CO2 emissions by 58%. Companies like Klean Kanteen use up to 90% post-consumer recycled 18/8 stainless steel, cutting greenhouse gas emissions by half and reducing energy demand by 30%.

Producing new stainless steel from raw materials uses a lot of energy and emits more CO2. When you recycle, you save the energy equal to 1.8 barrels of oil per ton of steel. If all stainless steel came from scrap, energy use would drop by 67% and CO2 emissions by 70%. You also reduce landfill waste and avoid toxic chemicals. Some manufacturers use hydro-power energy, making the process even cleaner.

♻️ Choosing products made from recycled 18-8 stainless steel supports a healthier planet and reduces your carbon footprint.

You may wonder if 18-8 stainless steel and 304 stainless steel are the same. Both types have almost identical compositions, with about 18% chromium and 8% nickel. However, 18-8 is a general term for this mix, while 304 is a specific grade with tighter controls on its makeup. When you choose 304 stainless steel, you get a material with more consistent quality and sometimes a slightly higher nickel content. This gives 304 stainless steel a small edge in corrosion resistance and strength, especially in harsh environments or at high temperatures. Both types resist rust, stay non-magnetic, and work well for forming and machining. You often see 18-8 stainless steel in food equipment and kitchenware, but grade 304 is preferred for demanding jobs that need higher performance.

Tip: If you need reliable performance in tough conditions, 304 stainless steel offers a bit more protection and strength than general 18-8 stainless steel.

You might also compare 18-8 stainless steel to 316 stainless steel. The main difference comes from the addition of molybdenum in 316, which makes it much better at resisting corrosion, especially in salty or chemical-rich environments. While 18-8 stainless steel works well for most kitchen and food uses, it can rust in places with lots of chlorides, like near the ocean. 316 stainless steel handles these conditions better, so you see it in marine hardware, chemical plants, and surgical tools. It is also stronger and more durable, but it costs more and is harder to machine.

Here is a table to help you see the differences:

Feature | 18-8 Stainless Steel (304) | 316 Stainless Steel |

|---|---|---|

Chromium Content | ~18% | 16-18% |

Nickel Content | ~8% | 10-14% |

Molybdenum Content | None | 2-3% |

Corrosion Resistance | Good, but not for saltwater | Excellent, even in saltwater |

Typical Applications | Kitchenware, food processing | Marine, chemical, medical |

Cost | Moderate | Higher |

��️ Choose 316 stainless steel for the toughest environments, but stick with 18-8 for most everyday uses.

You gain several unique benefits when you use 18-8 stainless steel. This material stands out for its excellent corrosion resistance in most chemical and atmospheric settings. You can easily form and weld it, which makes it a favorite for manufacturers. The bright, shiny finish looks attractive in kitchens and on appliances. You also get a material that is easy to clean, making it perfect for food and medical uses. Unlike some other grades, 18-8 stainless steel balances cost, strength, and workability. It is non-magnetic and keeps its shape well under stress.

Feature | 18-8 Stainless Steel (Type 304) Advantages |

|---|---|

Corrosion Resistance | Excellent in most environments |

Strength and Durability | Good tensile strength, holds up at high temperatures |

Formability and Weldability | Easy to shape and join |

Hygienic Suitability | Great for food and medical uses |

Appearance and Finish | Bright, attractive surface |

Cost | More affordable than higher-alloy grades |

Note: 18-8 stainless steel may not be the best choice for very harsh or high-temperature settings, but it offers a strong mix of value and performance for most applications.

You see 18-8 stainless steel everywhere, from kitchen tools to industrial machines. Its corrosion resistance, strength, and easy shaping make it vital for both manufacturing and daily products.

The self-healing oxide layer keeps your items rust-free and durable.

Its hygienic surface supports safe food and medical use.

You help the planet by choosing recyclable stainless steel.

Material science continues to improve 18-8 stainless steel, so you can expect even better performance and sustainability in the future.

You see "18-8" to describe stainless steel with about 18% chromium and 8% nickel. This mix gives the steel its corrosion resistance and shiny finish. You find it in many household and industrial products.

You can use 18-8 stainless steel outdoors in most environments. It resists rust and weathering. In areas with saltwater or high chloride, you may see some corrosion over time. For harsh outdoor settings, you may want a different grade.

Yes, you can safely use 18-8 stainless steel for food contact. It does not react with most foods. You see it in cookware, utensils, and kitchen appliances. The smooth surface helps prevent bacteria from sticking.

You clean 18-8 stainless steel with mild soap and water. Use a soft cloth or sponge. For tough stains, you can use a baking soda paste. Avoid harsh chemicals or steel wool, which can scratch the surface.

You may notice slight magnetism after cold working or forming. The steel starts as non-magnetic, but shaping or bending can change its structure. This does not affect its corrosion resistance or strength.

You can weld 18-8 stainless steel with standard welding methods. It forms strong joints and keeps its corrosion resistance. Use proper filler materials for best results. Clean the welded area to prevent discoloration.

You find 18-8 stainless steel in sinks, cookware, cutlery, water bottles, and building fixtures. Its strength, corrosion resistance, and easy cleaning make it popular in homes and industries.

Tip: Always check the product label to confirm the stainless steel grade before buying.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Exploring the Magnetism of Stainless Steel for Modern Applications

Super austenitic stainless steel outperforms in real-world acid tests

Emerging Manufacturing Techniques for Austenitic Stainless Steel Bars

Exploring The Role of 18-8 Austenitic Stainless Steel in Modern Manufacturing And Homes

Top 10 Austenitic Stainless Steel Grades and Their Everyday Uses