close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-29 Origin: Site

In 2025, engineers in medical, automotive, and electronics industries face a critical question: is stainless steel magnetic? The answer depends on the grade and internal structure. Magnetic properties play a decisive role in selecting materials for applications like MRI-compatible surgical tools, solenoid cores, or magnetic detection equipment. For example, austenitic stainless steel magnetic behavior stands out because high nickel and chromium content typically results in nonmagnetic performance, making it ideal where magnetic interference must be minimized.

Stainless steel can be magnetic, but not all types show this property. The magnetic properties of stainless steel depend on its internal structure and chemical composition. Some grades, such as austenitic stainless steels (304 and 316), are generally non-magnetic. Others, like ferritic (430) and martensitic (410, 420, 440) grades, display strong magnetism. Duplex stainless steels fall in between, showing moderate magnetic behavior.

Tip: A simple magnet test can help identify if a stainless steel object is magnetic, but this method does not always reveal the exact grade or processing history.

Here is a quick overview of common stainless steel grades and their magnetic behavior:

Stainless Steel Grade | Magnetic Property | Explanation |

|---|---|---|

304 (Austenitic) | Generally non-magnetic | Non-magnetic in annealed state; slight magnetism possible after cold working |

316 (Austenitic) | Generally non-magnetic | Nickel stabilizes non-magnetic phase; slight magnetism if heavily cold worked |

430 (Ferritic) | Strongly magnetic | Ferritic structure (BCC) causes strong magnetism |

410, 420, 440 (Martensitic) | Strongly magnetic | Martensitic structure (BCT) with carbon content leads to ferromagnetism |

Duplex (e.g., 2205) | Intermediate magnetism | Mixed microstructure causes weak to moderate magnetic response |

The variation in magnetism among stainless steel grades comes from differences in atomic structure and alloy composition. Austenitic stainless steels have a face-centered cubic (FCC) crystal structure, stabilized by nickel, which does not support ferromagnetism. When these steels undergo cold working or welding, small amounts of martensite or ferrite can form, introducing slight magnetism.

Ferritic stainless steels contain a body-centered cubic (BCC) structure. This arrangement allows unpaired electron spins to align, resulting in strong magnetic properties. Martensitic stainless steels transform into a body-centered tetragonal (BCT) structure during heat treatment, which also supports strong magnetism due to the alignment of magnetic domains.

Duplex stainless steels combine both austenitic and ferritic phases. This mixed structure leads to intermediate magnetic properties of stainless steel, making them suitable for applications that require a balance between strength and magnetism.

The scientific explanation for these differences lies in the electronic structure of the atoms and the crystal lattice. Ferromagnetism requires atoms with incomplete inner electron shells and a lattice that supports strong electron exchange. Austenitic grades lack these features, while ferritic and martensitic grades possess the right atomic arrangements and electron densities for magnetic domain formation.

The crystal structure of stainless steel determines its magnetic behavior. Stainless steels can have three main crystal structures: face-centered cubic (FCC), body-centered cubic (BCC), and body-centered tetragonal (BCT).

FCC (Face-Centered Cubic):

Austenitic stainless steels, such as 304 and 316, have an FCC structure. This arrangement makes them paramagnetic, which means they do not show strong attraction to magnets. The FCC structure results from the presence of nickel and other elements. When austenitic stainless steel remains fully austenitic, it exhibits low magnetic permeability. This property benefits industries that require materials with minimal magnetic losses.

BCC (Body-Centered Cubic):

Ferritic stainless steels, like grade 430, have a BCC structure. This structure allows the alignment of magnetic domains, making these steels strongly magnetic. Chromium stabilizes the BCC phase, but it does not eliminate magnetism.

BCT (Body-Centered Tetragonal):

Martensitic stainless steels, such as 410 and 420, form a BCT structure after heat treatment. This structure supports ferromagnetism, so these grades respond strongly to magnets.

Welding or cold working can change the crystal structure of stainless steel. For example, welding may create ferrite, a magnetic phase, in austenitic stainless steel. Cold working can also increase magnetic properties by forming martensite. Uniform crystal structures, often achieved through CNC machining, result in minimal magnetic permeability.

Researchers have found that phase transformations, such as the change from austenite to martensite, directly affect the magnetic properties of stainless steel. Mechanical treatments, including ultrasonic shot peening, can induce these changes. Grain size and refinement during surface treatments also influence magnetic behavior.

Nickel plays a critical role in the structure and magnetism of stainless steel. When manufacturers add nickel, it transforms the crystal structure from ferritic (BCC) to austenitic (FCC). This change makes the steel non-magnetic. Most austenitic stainless steels contain about 8-10% nickel, which ensures the FCC structure and provides toughness even at very low temperatures. Nickel acts as a key austenite stabilizer, reducing magnetism compared to ferritic structures.

Chromium is another essential alloying element in stainless steel. It forms a passive oxide film that protects against corrosion. Stainless steel must contain at least 10.5% chromium to prevent rusting. However, chromium stabilizes the ferritic phase and does not directly cause non-magnetism. Other elements, such as manganese, carbon, and nitrogen, also influence the crystal structure and magnetic behavior. The magnetic moments of these alloying elements affect both the magnetic and chemical properties of stainless steels.

Alloying Element | Effect on Structure | Effect on Magnetism |

|---|---|---|

Nickel | Stabilizes FCC | Reduces magnetism |

Chromium | Stabilizes BCC | Maintains or increases magnetism |

Manganese | Supports FCC | Slightly reduces magnetism |

Carbon/Nitrogen | Supports FCC | Can influence phase changes |

Austenitic stainless steel magnetic behavior depends on both composition and processing. Grades such as 303, 304, and 316 are widely used in industries that require corrosion resistance and non-magnetic performance. These grades have a face-centered cubic (FCC) structure, which typically results in low magnetic permeability. In their annealed state, these steels do not attract magnets, making them suitable for applications where magnetic interference must be minimized. The presence of nickel and sometimes nitrogen stabilizes the austenitic phase, further reducing the magnetic properties of stainless steel in these grades.

Cold working can significantly alter the austenitic stainless steel magnetic response. During mechanical deformation, such as bending, rolling, or machining, the austenitic phase partially transforms into martensite, which is ferromagnetic. This transformation increases magnetic permeability and causes the steel to attract magnets, especially at sharp corners, sheared edges, or machined surfaces.

Cold working induces partial transformation of the austenitic phase into martensitic phase, which is ferromagnetic.

The degree of magnetic change depends on chemical composition, particularly the content of austenitic stabilizing elements like nickel and nitrogen.

Grades with higher nickel or nitrogen content can tolerate more cold working before magnetic permeability noticeably increases.

The increase in magnetic permeability caused by cold working can be reversed by full solution annealing at approximately 1050 to 1120°C with rapid cooling.

This heat treatment transforms the martensitic phase back to the non-magnetic austenitic phase, which is retained upon cooling.

Therefore, cold working alters the magnetic properties of stainless steel by inducing martensitic transformation and increasing magnetic permeability, but this effect is reversible through appropriate heat treatment.

Nickel content plays a crucial role in austenitic stainless steel magnetic behavior. Experimental studies comparing nickel-free austenitic stainless steel with conventional 316L stainless steel show that both behave like soft magnetic materials. However, the nickel-free steel exhibits lower magnetic saturation than the 316L steel. This result indicates that nickel content enhances magnetic saturation in austenitic stainless steels, while its absence reduces magnetic saturation but does not eliminate soft magnetic behavior. Recent computational studies also reveal that magnetism influences short-range atomic order within these alloys. The magnetic exchange interactions, involving nickel and other elements, significantly affect the alloy's thermodynamic behavior. Nickel's presence contributes to the magnetic exchange interactions that govern these properties.

Ferritic stainless steels, such as grade 430, display strong magnetic properties due to their body-centered cubic (BCC) crystal structure. The ferrite phase arrangement of iron atoms is ferromagnetic, causing attraction to magnets. Unlike austenitic stainless steel magnetic grades, 430 is naturally magnetic and not affected by processing. The absence of nickel and predominance of iron and chromium enhance its magnetic properties.

430 stainless steel is significantly magnetic due to its ferritic crystal structure.

The ferrite phase arrangement of iron atoms is ferromagnetic, causing attraction to magnets.

The low or negligible nickel content supports the ferritic structure and magnetic properties.

Unlike austenitic grades, 430 does not undergo phase transformations affecting magnetism.

430 stainless steel has a typical magnetic permeability around 800, making it moderately responsive to magnetic fields and a moderate magnetic flux carrier due to its ferritic structure. This inherent magnetism is stable and not significantly altered by heat treatment or processing.

Martensitic stainless steels, including grades 410 and 420, are magnetic and characterized by high strength and hardness. These steels are commonly used in applications requiring wear resistance and magnetic properties, such as cutlery, surgical instruments, and industrial blades. Martensitic stainless steels generally have stronger magnetic strength than austenitic types and are comparable or stronger than ferritic steels. Grade 410 stainless steel is magnetic in both hardened and annealed states and is known for its high strength and hardness. Grade 420 stainless steel, with higher carbon content, is the hardest stainless steel alloy and remains magnetic in all conditions. The iron content and crystal-like molecular structure ensure that martensitic stainless steels exhibit strong magnetic properties in both annealed and hardened conditions. This magnetism distinguishes them from austenitic stainless steels, which are typically non-magnetic.

Duplex stainless steels combine two different crystal structures: austenitic and ferritic. This unique blend gives duplex grades a balanced set of properties. Engineers often select duplex stainless steels for their high strength, excellent corrosion resistance, and moderate magnetic behavior.

The microstructure of duplex stainless steel contains roughly equal parts of austenite and ferrite. The ferrite phase provides magnetic properties, while the austenite phase reduces overall magnetism. As a result, duplex grades show a magnetic response that falls between fully austenitic and fully ferritic stainless steels.

Property | Duplex Stainless Steel | Austenitic Stainless Steel | Ferritic Stainless Steel |

|---|---|---|---|

Magnetic Response | Moderate | Low to None | High |

Corrosion Resistance | High | High | Moderate |

Strength | High | Moderate | Moderate |

Duplex stainless steels, such as grade 2205, attract magnets but not as strongly as ferritic or martensitic grades. The presence of both phases means that the magnetic properties can vary depending on the exact composition and processing. For example, welding or cold working can increase the amount of ferrite, making the steel more magnetic.

Note: Duplex grades offer a practical solution when engineers need both corrosion resistance and some magnetic response. They often use these steels in chemical processing, oil and gas, and marine environments.

Duplex grades do not match the austenitic stainless steel magnetic performance in applications where minimal magnetism is critical. However, they provide a valuable compromise for many industrial uses.

Precipitation-hardened (PH) stainless steels use a special heat treatment process to achieve high strength and hardness. Manufacturers add elements like copper, aluminum, or niobium to create fine particles, or precipitates, within the steel. These precipitates block dislocation movement, which increases the material's strength.

PH stainless steels, such as 17-4PH (also known as 1.4542 or UNS S17400), display magnetic properties similar to martensitic grades. The crystal structure of these steels is usually martensitic or semi-austenitic after heat treatment. This structure allows the steel to attract magnets.

Key features of precipitation-hardened stainless steels include:

High strength and hardness after aging treatment

Good corrosion resistance, though not as high as austenitic grades

Strong magnetic response, especially in the martensitic condition

Engineers often use PH stainless steels in aerospace, defense, and high-performance mechanical components. The combination of strength and magnetism makes them suitable for gears, shafts, and fasteners that require both durability and magnetic detection.

Tip: The magnetic properties of PH stainless steels can change depending on the heat treatment cycle. Solution annealing followed by aging can alter the balance between austenitic and martensitic phases, affecting magnetism.

Precipitation-hardened grades do not provide the same level of corrosion resistance or non-magnetic behavior as austenitic stainless steel magnetic grades. However, they fill a critical role in applications where strength and magnetism are both required.

Heat treatment plays a crucial role in shaping the magnetic properties of stainless steel. Metallurgical research shows that heat treatment changes the microstructure by stabilizing or destabilizing the austenitic phase. This process affects stacking fault energy and can trigger transitions between paramagnetic, antiferromagnetic, and ferromagnetic states. Interstitial elements like carbon and nitrogen, along with alloying elements such as manganese and chromium, influence these transformations. When stainless steel undergoes heat treatment at high temperatures followed by rapid cooling, the microstructure and magnetic behavior shift. For example, applying heat and pressure can transform austenitic stainless steel from a paramagnetic state to a ferromagnetic martensitic phase. This transformation increases both hardness and magnetic response. Press-sintered samples treated under high pressure display greater ferromagnetic properties and mechanical strength. Recent advancements in additive manufacturing have further improved control over these properties. By adjusting laser power, scan speed, and build orientation, engineers can fine-tune the microstructure. Post-processing treatments like annealing and hot isostatic pressing optimize magnetic performance by promoting grain growth and reducing defects.

Cold working alters the internal structure of stainless steel at room temperature. This process includes rolling, drawing, and bending. As the steel deforms, the austenitic phase partially transforms into martensite, which is magnetic. Normally non-magnetic grades, such as 316 stainless steel, can develop a weak magnetic pull after cold working. The degree of transformation depends on the amount of deformation and the composition of the steel. Cold working not only increases strength but also changes the magnetic properties of stainless steel. The transformation from austenite to martensite is especially important in applications where magnetic detection or separation is required.

Cold working deforms the steel, changing its microstructure.

Martensite forms during deformation, increasing magnetism.

Processes like rolling and bending are common methods.

Even small amounts of martensite can make a noticeable difference in magnetic response.

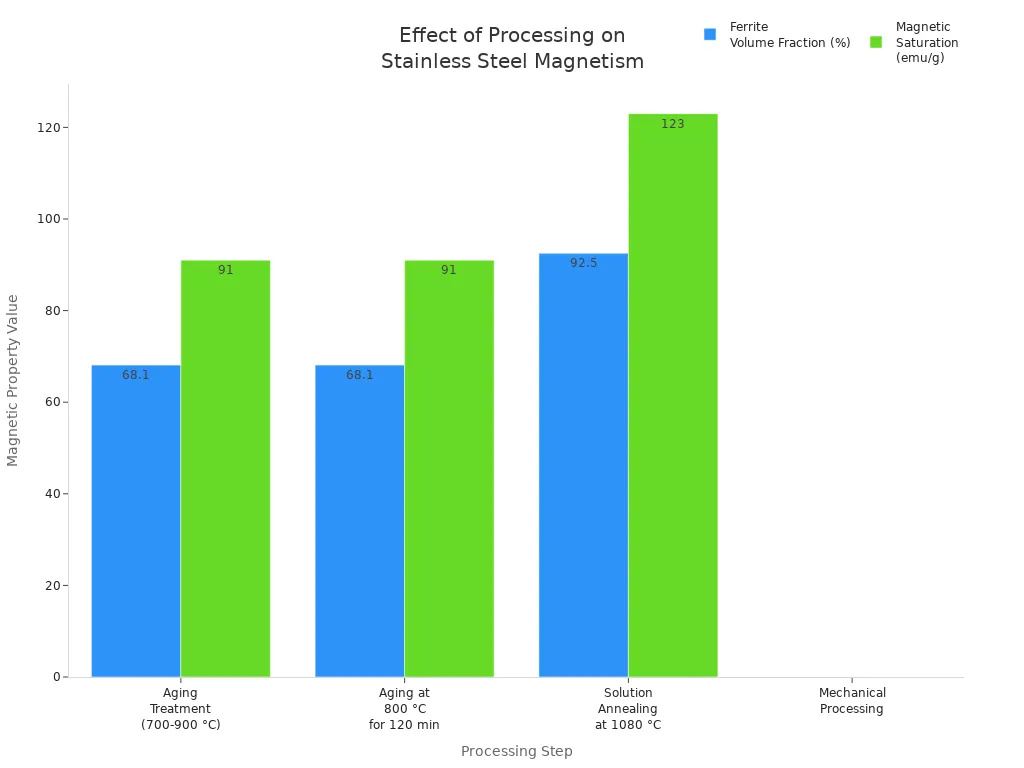

Phase changes during processing directly impact the magnetic properties of stainless steel. Different treatments and mechanical processes alter the balance between magnetic and non-magnetic phases. The table below summarizes how specific processing steps affect phase composition and magnetism:

Phase Change / Processing Step | Description | Effect on Magnetic Properties |

|---|---|---|

Aging Treatment (700-900 °C) | Precipitation of carbides and sigma phase within ferrite matrix | Reduces ferrite content, lowering magnetic saturation |

Aging at 800 °C for 120 min | Maximum precipitation and ferrite reduction | Most significant drop in magnetic properties |

Solution Annealing at 1080 °C | Produces ferrite and austenite without precipitates | Maintains higher magnetic properties due to more ferrite |

Mechanical Processing (cold working, welding) | Induces austenite to martensite transformation | Increases local magnetism |

Mechanical and thermal processing steps, such as welding or casting, can also leave residual martensite or cause phase changes in heat-affected zones. These changes often result in localized or weak magnetic behavior. By understanding and controlling these phase transformations, engineers can tailor the magnetic properties of stainless steel for specific applications.

Automotive engineers rely on stainless steel for its strength, corrosion resistance, and adaptability. In 2025, the magnetic properties of stainless steel play a crucial role in the design of electric vehicles, fuel injection systems, and safety sensors. Ferritic stainless steels, with their strong magnetic response, are often used in solenoids, relays, and fuel injectors. These components benefit from high saturation induction and permeability, which allow for efficient magnetic field generation and rapid actuation. The low coercive force of ferritic grades enables quick demagnetization, essential for fast-acting automotive devices.

Automotive manufacturers also value the high electrical resistivity of ferritic stainless steels. This property reduces eddy current losses, improving the efficiency of electric motors and sensors. Corrosion resistance ensures that these components withstand harsh environments, such as road salt and moisture. Engineers must carefully select grades to balance magnetic performance with durability and cost. In some cases, austenitic stainless steels are chosen for non-magnetic applications, such as body panels or trim, where magnetic interference must be avoided.

Note: The choice of stainless steel grade directly impacts the reliability and efficiency of modern automotive systems.

The medical industry demands materials that ensure patient safety and device reliability. The magnetic properties of surgical steel influence the selection of materials for implants, surgical tools, and diagnostic equipment. Austenitic stainless steels, such as grades 304 and 316, are preferred for MRI-compatible devices because they are generally non-magnetic and highly resistant to corrosion. This prevents interference with imaging and reduces the risk of patient injury.

Ferritic and martensitic stainless steels, which have a body-centered cubic structure, exhibit strong magnetism. These grades are used for tools that require hardness and wear resistance, such as scalpels and dental instruments. However, their magnetic nature can pose risks in environments with strong magnetic fields, like MRI suites. The magnetic properties of surgical steel must be carefully evaluated to avoid complications during imaging or treatment.

Stainless Steel Type | Magnetic Property | Medical Device Use | Notes |

|---|---|---|---|

Austenitic (304, 316) | Non-magnetic (usually) | MRI-compatible implants, surgical tools | Corrosion resistant, safe for imaging |

Martensitic (420, 440C) | Magnetic | Scalpels, dental tools | Hard, may interfere with MRI |

Ferritic | Magnetic | Some medical tools | Lower corrosion resistance |

Testing methods, such as Magnetic Particle Inspection, help ensure that surgical stainless steel meets strict safety and performance standards. Engineers must balance the need for durability, corrosion resistance, and non-magnetic behavior when designing medical devices in 2025.

Electronics manufacturers depend on the precise control of magnetic properties in stainless steel to optimize device performance. Ferritic stainless steels offer high saturation induction and permeability, making them ideal for components like solenoids, relays, and electromagnetic shields. These properties enable the design of smaller, lighter, and more efficient electronic devices.

High electrical resistivity in ferritic grades minimizes energy loss from eddy currents, which is critical for fast-switching components. Low coercive force allows for rapid changes in magnetic state, supporting the development of responsive sensors and actuators. Corrosion resistance ensures long-term reliability, even in challenging environments.

Austenitic stainless steels, typically non-magnetic, are used in sensitive electronic applications where magnetic interference must be minimized. However, cold working can induce magnetism in these grades, so engineers must monitor processing methods to maintain desired properties. Understanding and controlling the magnetic properties of stainless steel remains essential for advancing electronic technology in 2025.

⚡ Engineers who master the magnetic behavior of stainless steel can create more reliable, efficient, and innovative electronic devices.

Food processing facilities demand materials that meet strict hygiene and safety standards. Stainless steel stands out as the material of choice for equipment such as conveyors, mixers, tanks, and cutting tools. The magnetic properties of stainless steel play a key role in both equipment design and food safety.

Engineers select stainless steel grades based on their corrosion resistance, ease of cleaning, and magnetic response. Ferritic and martensitic grades, which are magnetic, often serve in applications where magnetic separation is required. These grades allow for the removal of metal fragments from food products using magnetic traps or separators. This process helps prevent contamination and protects consumers from injury.

Austenitic stainless steels, such as 304 and 316, are widely used in food processing because they resist corrosion and do not react with food acids. These grades are generally non-magnetic, which makes them ideal for surfaces that come into direct contact with food. However, after cold working or welding, even austenitic grades can develop slight magnetism. Engineers must consider this factor when designing equipment for sensitive processes.

Stainless Steel Grade | Magnetic? | Common Use in Food Processing |

|---|---|---|

304 (Austenitic) | No | Tanks, piping, food contact surfaces |

316 (Austenitic) | No | High-acid environments, dairy, sauces |

430 (Ferritic) | Yes | Conveyor belts, magnetic separators |

420 (Martensitic) | Yes | Cutting blades, slicers |

Tip: Magnetic separators in food plants rely on the magnetic properties of surgical steel to capture and remove tiny metal particles from products. This step is critical for meeting food safety regulations.

Surgical stainless steel, known for its purity and resistance to corrosion, is sometimes used in specialized food processing tools. Its non-magnetic nature in the annealed state helps prevent unwanted magnetic attraction of food particles or debris. However, when engineers need to detect or remove metal fragments, they choose magnetic grades for components that interact with magnetic separation systems.

Food safety standards in 2025 require regular testing of equipment for both cleanliness and magnetic response. Technicians use magnet tests to verify that separators and traps function correctly. They also inspect for any changes in magnetic behavior after repairs or modifications. This attention to detail ensures that food products remain safe and free from contamination.

The magnet test remains a popular and practical method for quickly assessing the magnetic properties of stainless steel in industrial environments. Technicians place a handheld magnet on the steel surface. Strong attraction usually indicates a ferritic or martensitic grade, such as 430 or 410. Weak or no attraction suggests an austenitic grade, like 304 or 316. This test provides immediate feedback and helps separate magnetic from non-magnetic types during field inspections or material sorting.

The magnet test is simple and rapid, making it ideal for initial screening.

Cold working can induce slight magnetism in austenitic stainless steel, so results may vary.

This method helps prevent material mix-ups and supports compliance with industry standards.

Stainless Steel Type | Magnetic Property | Common Grades | Notes |

|---|---|---|---|

Austenitic | Generally non-magnetic | 304, 316 | May become weakly magnetic after cold working |

Ferritic | Magnetic | 430 | Strong magnetism, reliable magnet test |

Martensitic | Strongly magnetic | 410, 420 | Strong magnetism, reliable magnet test |

⚠️ The magnet test works well for quick checks but cannot confirm the exact grade or purity. For critical applications, further testing is necessary.

Industrial settings often require more precise evaluation of magnetic properties. Professionals use advanced techniques to measure magnetic permeability and analyze the steel’s behavior under different conditions.

Advanced Technique | Description and Application |

|---|---|

Barkhausen Magnetic Noise Method | Detects ferromagnetic phases and plastic strain, useful for monitoring martensitic changes. |

Hall Sensors | Characterize fatigue damage in austenitic stainless steels. |

Magnetoresistive Sensors | Measure local residual magnetic fields, especially in weld joints. |

Finite Element Analysis (FEA) | Simulates stress, strain, and magnetic field distributions during testing. |

Jiles Magnetic–Mechanical Model | Describes magnetic-elastic effects under mechanical stress. |

Technicians also use ASTM Standard Method A342 for standardized permeability measurements. These advanced methods provide accurate data for quality control, research, and safety-critical applications. Permeability measurements and magnetic saturation analysis help distinguish between stainless steel types and ensure the right material is used in demanding environments.

Magnetic property testing helps confirm the general category of stainless steel. Ferritic and martensitic grades, such as 430 and 410, show strong magnetism. Austenitic grades, including 304 and 316, are usually non-magnetic unless cold worked. This distinction allows engineers to separate 300-series austenitic from 400-series ferritic stainless steels.

Stainless Steel Type | Grade Examples | Magnetic Property |

|---|---|---|

Austenitic | 302, 304 | Non-magnetic (except when cold worked) |

Ferritic | 430 | Magnetic |

Martensitic | 410 | Magnetic |

However, magnetic testing alone cannot identify the exact grade or detect impurities. Some mild steels may also show similar magnetic responses. For precise identification, professionals combine magnetic tests with chemical analysis or spectral methods. This approach ensures accurate material selection and prevents costly errors in manufacturing or construction.

Selecting stainless steel for modern applications demands a clear grasp of how grade, processing, and structure shape magnetic properties. Engineers who understand these factors can match material performance to project needs, whether for corrosion resistance, machinability, or magnetic response.

Austenitic grades like 304 and 316 are generally non-magnetic but may become slightly magnetic after cold working.

Ferritic and martensitic types offer strong magnetism, while duplex grades provide a balance of strength and moderate magnetism.

For detailed guidance, engineers can consult technical resources such as the Hobart Brothers Stainless Steel Technical Guide or review grade comparison tables:

Grade | Type | Magnetic? | Common Use |

|---|---|---|---|

304 | Austenitic | No (unless cold worked) | Food processing, appliances |

316 | Austenitic | No (unless cold worked) | Marine, chemical processing |

410 | Martensitic | Yes | Construction, tools |

430 | Ferritic | Yes | Automotive, decorative |

2205 | Duplex | Weak | Oil, gas, chemical environments |

Careful selection ensures optimal performance and long-term value in 2025 and beyond.

No, not all stainless steel is magnetic. Ferritic and martensitic grades show strong magnetism. Austenitic grades, such as 304 and 316, remain mostly non-magnetic unless cold worked.

Yes. Cold working, such as bending or rolling, can transform some austenitic stainless steels into a partially magnetic state by forming martensite.

Magnetism affects device compatibility with MRI machines. Non-magnetic stainless steel, like 316, prevents interference and ensures patient safety during imaging procedures.

A simple magnet test works. Place a magnet on the steel. Strong attraction means the steel is likely ferritic or martensitic. Weak or no attraction suggests an austenitic grade.

304 and 316 austenitic stainless steels work best for food processing. They resist corrosion and remain mostly non-magnetic, making them safe for direct food contact.

Yes. Heat treatment can alter the microstructure. For example, solution annealing can restore non-magnetic properties in austenitic grades after cold working.

Magnetic response helps separate austenitic from ferritic or martensitic grades. However, it cannot confirm the exact grade. Chemical analysis provides more precise identification.