close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

316 stainless steel contains iron, chromium, nickel, and molybdenum as its main alloying elements. This specific composition gives the alloy excellent corrosion resistance, strong mechanical properties, and a non-magnetic nature. Many industries rely on stainless steel 316 because it performs well in harsh environments. Typical uses include:

Marine equipment, such as boats, ships, and offshore platforms, where saltwater exposure requires high corrosion resistance.

Chemical processing tanks and piping, oil and gas production equipment, and pharmaceutical manufacturing gear, which demand durability and resistance to chemicals.

Food processing machinery and medical devices, which benefit from the alloy’s non-toxicity and stability.

These properties make 316 stainless steel a top choice when compared to other grades.

316 stainless steel is an austenitic alloy recognized for its outstanding corrosion resistance and mechanical strength. International standards such as ASTM, AISI, JIS, and NACE MR0175/ISO 15156 define this material by its specific chemical composition and performance criteria. The typical composition includes about 65-70% iron, 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. Small amounts of carbon, manganese, silicon, phosphorus, and sulfur are also present. These elements work together to create a material that meets strict requirements for use in corrosive environments. Stainless steel 316 stands out because it maintains its properties even when exposed to harsh chemicals or saltwater.

316 stainless steel offers several features that make it a preferred choice in many industries:

Contains 2-3% molybdenum, which is not found in 304 stainless steel. This addition greatly improves resistance to chlorides, pitting, and crevice corrosion.

Has a higher nickel content (10-14%) than 304, which helps stabilize the austenitic structure and increases strength.

Performs well in harsh environments, including marine, chemical processing, pharmaceutical, and healthcare settings.

Provides better weldability and slightly higher heat resistance compared to other austenitic stainless steels.

Often called marine-grade stainless steel due to its excellent performance in saline conditions.

Variants like 316L offer lower carbon content, which improves weldability and resistance to sensitization.

Delivers superior corrosion resistance, especially against chlorides and industrial solvents, and maintains strength at elevated temperatures.

Note: The unique composition of stainless steel 316 makes it suitable for demanding, hygienic, and corrosive applications where other grades may fail.

Several alloy variants of 316 stainless steel exist, each designed to meet specific needs:

316 (standard): Contains up to 0.08% carbon, 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

316L (low carbon): Features reduced carbon content (about 0.03%), which minimizes carbide precipitation during welding. This variant offers improved corrosion resistance in welded structures and is ideal for chemical processing and marine environments.

316H (high carbon): Has increased carbon for better thermal stability and creep resistance, but is more prone to sensitization.

316Ti and 316Cb (stabilized grades): Include titanium or niobium to prevent chromium carbide formation, enhancing resistance to intergranular attack.

316N (high nitrogen): Higher nitrogen content increases hardness and strength.

316LN (low carbon, high nitrogen): Combines the benefits of low carbon and high nitrogen for improved mechanical properties and corrosion resistance.

These variants allow engineers to select the best type of stainless steel 316 for specific applications, balancing factors such as weldability, hardness, and resistance to corrosion.

316 stainless steel contains a blend of major and minor elements. Each element plays a specific role in the alloy’s performance. The chemical composition of this material gives it unique properties that make it valuable in many industries.

The main elements in 316 stainless steel include chromium, nickel, molybdenum, and iron. These elements form the backbone of the alloy.

| Element | Typical Percentage Range (%) |

|---|---|

| Chromium | 16.00 - 18.00 |

| Nickel | 10.00 - 14.00 |

| Molybdenum | 2.00 - 3.00 |

| Iron | Balance |

Chromium provides the primary defense against corrosion. It forms a thin, stable oxide layer on the surface of the steel. This layer protects the metal from rust and chemical attack. Higher chromium content increases resistance to pitting and improves the overall durability of the alloy.

Nickel helps stabilize the austenitic structure of stainless steel 316. It increases toughness and ductility. Nickel also boosts resistance to corrosion, especially in acidic and chloride-rich environments. This element works with chromium to create a strong, non-magnetic alloy.

Molybdenum sets 316 stainless steel apart from other grades. It enhances resistance to pitting and crevice corrosion, especially in saltwater and chemical environments. Molybdenum also improves the alloy’s strength at high temperatures.

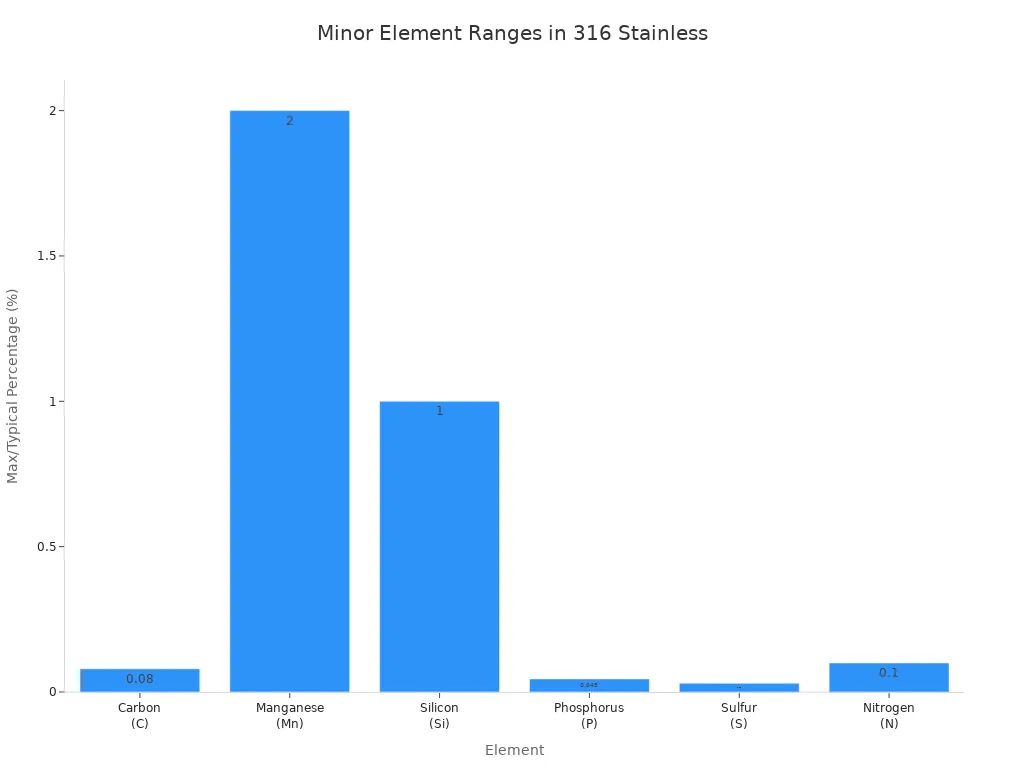

Minor elements in the composition of 316 stainless steel include manganese, silicon, carbon, phosphorus, sulfur, and nitrogen. These elements appear in smaller amounts but still affect the alloy’s properties.

| Element | Standard Percentage Range (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

| Nitrogen (N) | ≈ 0.10 |

Manganese improves hot working properties and increases strength. It also helps remove oxygen and sulfur during steel production.

Silicon acts as a deoxidizer. It helps remove oxygen from the molten steel, which improves the quality of the final product. Silicon also adds to the alloy’s strength.

Carbon: Low carbon content reduces the risk of carbide precipitation during welding. This helps maintain corrosion resistance.

Phosphorus: Small amounts of phosphorus improve machinability but too much can make the steel brittle.

Sulfur: Sulfur also aids machinability but can lower toughness if present in high amounts.

Nitrogen: Nitrogen increases strength and improves resistance to pitting corrosion.

Each element in the chemical composition of 316 stainless steel serves a specific function. The table below summarizes how these elements affect corrosion resistance and mechanical properties.

| Element/Parameter | Effect on Corrosion Resistance | Effect on Mechanical Properties |

|---|---|---|

| Chromium (Cr) | Forms and stabilizes a protective film; increases resistance to pitting and corrosion | Increases strength but may reduce ductility at high levels |

| Nickel (Ni) | Enhances resistance to acids and chlorides | Improves toughness and ductility |

| Molybdenum (Mo) | Boosts resistance to pitting and crevice corrosion | Increases strength at high temperatures |

| Manganese (Mn) | Supports deoxidation and improves corrosion resistance | Adds strength and improves hot workability |

| Silicon (Si) | Helps remove oxygen, improving corrosion resistance | Increases strength |

| Carbon (C) | Low levels maintain corrosion resistance | Too much can cause brittleness |

| Phosphorus (P) | Small amounts improve machinability | High levels reduce toughness |

| Sulfur (S) | Improves machinability | Excess can lower toughness |

| Nitrogen (N) | Increases resistance to pitting | Raises strength and hardness |

Note: The balance of these elements in stainless steel 316 creates a material with excellent corrosion resistance, high strength, and good workability. The unique composition allows the alloy to perform well in demanding environments, such as marine and chemical processing industries.

Understanding 316 stainless steel properties helps engineers and manufacturers select the right material for demanding environments. These properties include physical characteristics, mechanical performance, and fabrication behavior. Each aspect plays a vital role in how stainless steel 316 performs in real-world applications.

316 stainless steel has a density nearly identical to other common austenitic stainless steels, such as 304. The addition of molybdenum does not significantly change the density. This similarity allows for easy substitution between grades in design calculations.

| Property/Element | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Density (g/cm³) | ~8.00 | ~8.00 |

| Molybdenum Content (%) | 0 | 2.0 – 2.5 |

| Ultimate Tensile Strength | 73,200 psi | 79,800 psi |

| Corrosion Resistance | Excellent | Even better |

Note: The density of 316 stainless steel remains stable across a wide temperature range, making it reliable for structural and load-bearing uses.

The melting point of 316 stainless steel ranges from 1375°C to 1400°C (2507°F to 2552°F). This range is slightly lower than that of 304 stainless steel due to the presence of molybdenum. Several factors can influence the melting point, including alloy composition, grain size, heat treatment, and manufacturing process.

Alloy composition, especially molybdenum, lowers the melting point.

Trace elements and impurities can shift the melting range.

Finer grain structures tend to reduce the melting temperature.

Heat treatment and pressure also play a role.

Despite the slightly lower melting point, 316 stainless steel properties make it suitable for high-temperature applications.

316 stainless steel typically displays a metallic silver-gray color. The surface finish can vary based on the manufacturing process:

| Finish Type | Surface Appearance Description | Typical Color/Visual Impression |

|---|---|---|

| Mill Finish | Visible machining marks; raw, unrefined surface | Metallic silver-gray, natural metal look |

| Brushed Finish | Uniform grain pattern; satin, matte appearance | Metallic silver-gray with satin texture |

| Polished Finish | Smooth, reflective, mirror-like surface | Bright metallic silver, highly reflective |

| Electropolishing | Smoother and brighter surface; improved corrosion resistance | Bright metallic silver, very smooth |

| Bead Blasting | Uniform, non-reflective matte texture | Matte metallic silver-gray |

Tip: The choice of finish affects both the appearance and corrosion resistance of stainless steel 316, especially in decorative or hygienic applications.

316 stainless steel properties include high strength, excellent toughness, and good ductility. These mechanical properties make it a preferred material for critical components.

316 stainless steel offers higher tensile and yield strength than many other stainless steel grades. The table below shows typical values according to ASTM standards:

| Property | 316 Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Yield Strength (min, ksi) | 30 | 25 |

| Tensile Strength (min, ksi) | 75 | 70 |

| Elongation (min, %) | 40 | 40 |

These values confirm that stainless steel 316 can withstand significant loads before deforming or breaking.

Toughness measures a material’s ability to absorb energy and resist fracture. 316 stainless steel maintains good toughness across a wide temperature range. At room temperature, it shows high impact toughness with ductile fracture behavior. As temperature drops, toughness decreases gradually, but the material does not become brittle. Even at cryogenic temperatures, 316 stainless steel properties ensure it remains ductile, especially after proper heat treatment.

At room temperature, impact toughness is high.

At -193°C, toughness drops but the material still resists brittle fracture.

Heat treatments can improve toughness at both high and low temperatures.

Ductility describes how much a material can stretch before breaking. 316 stainless steel exhibits high ductility, with elongation at break typically around 40%. This means it can undergo significant plastic deformation, which is important for forming and shaping processes. Tensile testing measures ductility in industrial settings. Cold working increases strength but reduces ductility, so manufacturers must balance these properties based on application needs.

316 stainless steel properties include excellent weldability. As an austenitic stainless steel, it can be welded using standard techniques without the need for pre- or post-weld heat treatment. Filler metals that match the base material’s composition are usually recommended. While welding can introduce slight magnetism due to microstructural changes, this effect is minor and reversible with heat treatment. Compared to other stainless steel types, 316 stainless steel welds more easily and reliably.

Manufacturers can fabricate 316 stainless steel using a variety of methods:

Cold working (rolling, stamping, drawing)

Machining

Welding

Forming

However, certain challenges arise during fabrication:

The material tends to work harden, making machining more difficult.

Low thermal conductivity causes heat to build up, increasing tool wear.

Using sharp tools, proper cooling, and exclusive equipment for stainless steel helps maintain quality.

Annealing after cold working or welding relieves internal stresses and preserves corrosion resistance.

Note: 316 stainless steel properties also include a high specific heat capacity (480 J/kg·K), allowing it to absorb heat without rapid temperature changes. This feature, combined with its non-magnetic nature in the annealed state, makes it ideal for sensitive and high-temperature environments. Cold working or welding can introduce slight magnetism, but this is usually reversible.

316 stainless steel stands out for its excellent corrosion resistance in chloride-rich settings. Chloride ions, found in saltwater and de-icing salts, can break down the protective oxide layer on many metals. This attack leads to pitting and stress corrosion cracking. The addition of 2-3% molybdenum in 316 stainless steel greatly improves its ability to resist these effects. Higher nickel content, ranging from 10-14%, also helps stabilize the alloy and protect against chloride-induced damage.

The table below compares 316 stainless steel with other common grades:

| Feature / Grade | 18-8 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|---|

| Nickel Content (%) | ~8% | 8.0–10.5% | 10.0–14.0% |

| Chromium Content (%) | ~18% | 17.5–19.5% | 16.0–18.0% |

| Molybdenum Content (%) | 0 | 0 | 2.0–3.0% |

| Corrosion Resistance | Good | Very Good | Excellent (chloride/pitting resistant) |

| Cost | Low | Moderate | Higher |

| Applications | General-purpose, low-exposure | Food equipment, sinks, auto trim | Marine parts, chemical processing |

316 stainless steel is the preferred choice for marine hardware, chemical processing, and environments where salt or harsh cleaners are present. 304 stainless steel does not offer the same level of protection and may fail in these conditions. 316L, a low-carbon variant, is often used in pharmaceutical and marine industries for its excellent corrosion resistance and durability.

Tip: For any application exposed to saltwater or de-icing chemicals, engineers should select 316 stainless steel to ensure long-term performance.

316 stainless steel provides excellent corrosion resistance against many acids and chemicals. The molybdenum content helps the alloy resist pitting from salt exposure and aggressive acids. A thin, stable chromium oxide layer forms on the surface, protecting the metal from acids, bases, and oxidation. This passive layer gives the alloy its high corrosion resistance.

316 stainless steel resists phosphoric acid at most concentrations and sulfuric acid below 10%. It also withstands weak bases, even at high temperatures. However, hydrochloric acid poses a significant risk. Even with its protective layer, 316 stainless steel can corrode when exposed to hydrochloric acid. Strong bases and certain chloride solutions, like sodium hypochlorite, can also cause damage. For most industrial and marine environments, 316 stainless steel offers excellent corrosion resistance, but users should avoid prolonged contact with harsh acids and strong bases.

Stress corrosion cracking (SCC) can affect 316 stainless steel under certain conditions. SCC occurs when tensile stress and a corrosive environment, such as hot chloride solutions, act together. The risk increases above 60°C, especially in the presence of chlorides. Cold working, which introduces residual stresses, makes the alloy more susceptible. Surface defects and manufacturing methods also play a role.

| Factor/Condition | Effect on SCC Susceptibility in 316 Stainless Steel |

|---|---|

| Cold working | Increases susceptibility due to residual stresses |

| Tensile stress | Required for SCC initiation |

| Environment | Hot acidic chloride solutions promote SCC |

| Surface defects | Act as crack initiation sites |

| Carbon content | Low carbon reduces sensitization |

316L stainless steel, with its low carbon content, reduces the risk of intergranular SCC. However, transgranular cracking can still occur if the alloy faces high stress and hot chloride environments. Surface condition matters as well. Machined surfaces with marks perpendicular to the loading direction are more likely to develop cracks. Additive manufacturing methods can introduce porosity, which also increases SCC risk.

Note: While 316 stainless steel offers excellent corrosion resistance, users should monitor stress levels and surface quality in chloride-rich, high-temperature environments to prevent SCC.

316 stainless steel shows strong oxidation resistance in many environments. This property means the alloy can withstand exposure to air and heat without forming heavy rust or scale. The chromium in 316 stainless steel forms a thin, stable oxide layer on the surface. This layer protects the metal from further oxidation and helps maintain its appearance and strength.

At high temperatures, oxidation resistance becomes even more important. 316 stainless steel can handle service temperatures up to about 1562°F (850°C). Above this temperature, the protective oxide layer may break down. The molybdenum in 316 stainless steel, while excellent for high corrosion resistance, can actually lower oxidation resistance at very high temperatures. Molybdenum forms a compound called molybdenum trioxide, which does not protect the steel and can lead to faster oxidation in stagnant air.

The table below compares the oxidation resistance of 316 stainless steel with other common grades:

| Stainless Steel Grade | Oxidation Resistance at High Temperatures | Max Service Temp (°F) | Corrosion Resistance | Typical Uses |

|---|---|---|---|---|

| 316 | Good, but limited by molybdenum oxide | ~1562 | Superior, especially in harsh environments | Marine, chemical, medical |

| 304 | Good, similar to 316 but less corrosion resistant | ~1562 | Good | Food, kitchen, general use |

| 309 | Excellent, best for high temperatures | ~1900 | Lower than 316 | Furnace parts, heat exchangers |

316 stainless steel performs well in most industrial and marine settings. It resists oxidation better than many metals, especially when exposed to moisture and chemicals. However, for applications that require exposure to very high temperatures, engineers often choose 309 stainless steel. Grade 309 can withstand temperatures up to 1900°F (1038°C) and offers better oxidation resistance in those conditions.

While 316 stainless steel has a melting point above 2500°F, its practical use for oxidation resistance stops at lower temperatures. Grade 304 stainless steel can also resist oxidation at high temperatures, but it does not match the high corrosion resistance of 316 in aggressive environments. For most uses, 316 stainless steel provides a good balance between corrosion resistance and oxidation resistance.

Tip: When selecting stainless steel for high-temperature use, consider both oxidation resistance and corrosion resistance. For extreme heat, 309 stainless steel is often the better choice, but 316 remains the top pick for environments that demand high corrosion resistance.

The main difference in composition between 316 stainless steel, 304, and 316L lies in the presence of molybdenum and the amount of carbon. 316 stainless steel contains 2-3% molybdenum, which 304 does not have. This addition improves resistance to corrosion, especially in environments with chlorides. Nickel content is also higher in 316, which helps stabilize the structure and increases strength. 316L, a variant of 316, has a lower carbon content (up to 0.03%) compared to standard 316 (up to 0.08%). This lower carbon level in 316L reduces the risk of carbide precipitation during welding, making it better for welded structures.

| Stainless Steel Grade | Carbon Content | Chromium Content | Nickel Content | Molybdenum Content | Notes |

|---|---|---|---|---|---|

| 304 | Up to 0.08% | 18-20% | 8-10.5% | None | No molybdenum, general use |

| 316 | Up to 0.08% | 16-18.5% | 10-14% | 2-3% | Molybdenum for better corrosion resistance |

| 316L | Up to 0.03% | 16-18% | Slightly higher | Slightly higher | Low carbon, best for welding |

The addition of molybdenum and the adjustment of carbon content set 316 stainless steel and 316L apart from 304, giving them unique advantages in harsh environments.

316 stainless steel and 316L both offer better corrosion resistance than 304, especially in chloride-rich settings like marine or chemical industries. The molybdenum in 316 and 316L prevents pitting and crevice corrosion, which can damage 304 in salty or acidic conditions. 316 stainless steel also has higher tensile and yield strength than 304, making it suitable for demanding applications. 316L has slightly lower strength than 316 due to its reduced carbon content, but it excels in weldability and resists corrosion at welds.

| Property | 304 Stainless Steel | 316 Stainless Steel | 316L Stainless Steel |

|---|---|---|---|

| Corrosion Resistance | Good, but less in chlorides | Excellent, especially with chlorides | Excellent, best at welds |

| Pitting Resistance | Lower | High | High |

| Tensile Strength (MPa) | ~505-515 | ~570 | Slightly lower |

| Yield Strength (MPa) | ~205-215 | ~170-290 | Slightly lower |

| Weldability | Good, but risk of corrosion at welds | Good, but needs care | Excellent, low risk at welds |

Tip: For projects that require welding and exposure to harsh chemicals, stainless steel 316L provides the best combination of weldability and corrosion resistance.

304 stainless steel appears in many everyday products. Manufacturers use it for food processing equipment, kitchen sinks, and appliances because it is cost-effective and easy to clean. It also works well in automotive and medical tools. 316 stainless steel, with its molybdenum content, performs better in marine, chemical, and oil and gas industries. It resists corrosion from saltwater and harsh chemicals, making it ideal for boat fittings, chemical tanks, and medical implants. Stainless steel 316L is the top choice for welded structures in corrosive environments, such as pharmaceutical equipment and marine piping, because it prevents corrosion at welds.

| Stainless Steel Grade | Typical Applications | Reasons for Use |

|---|---|---|

| 304 | Food equipment, sinks, appliances, automotive parts | Cost-effective, easy to clean, good corrosion resistance |

| 316 | Marine hardware, chemical tanks, oil and gas equipment, medical implants | Superior corrosion resistance, strength in harsh environments |

| 316L | Welded tanks, pharmaceutical equipment, marine piping | Best corrosion resistance at welds, low carbon |

Note: While stainless steel 316 can replace 304 in most uses, the reverse does not hold true in aggressive environments. Stainless steel 316L stands out when welding and corrosion resistance are both critical.

Industries rely on stainless steel 316 for its strength, durability, and resistance to corrosion. This alloy appears in many industrial products and settings. Manufacturers use it to build equipment that must withstand harsh chemicals, high temperatures, and constant use. Some of the most common industrial products made from 316 stainless steel include:

Food prep tables and sanitary piping in the food and beverage industry

Storage tanks, containment vessels, and processing lines in chemical plants

Welded tanks, pressure vessels, and process piping in fabrication and welding shops

Handrails, architectural trim, and rooftop HVAC systems in construction

Filtration housings and wastewater components in water treatment facilities

Shafting, conveyor components, and high-temperature fixtures in industrial machinery

Engineers choose this alloy because it maintains its properties even after years of exposure to demanding environments. Its ability to resist rust and chemical attack helps reduce maintenance costs and downtime.

Stainless steel 316 is often called a marine grade metal because it performs well in saltwater and coastal environments. Boat builders use it for railings, ladders, fasteners, and underwater supports. Offshore oil rigs and marine exhaust systems also depend on this alloy. Its composition, which includes chromium, nickel, and molybdenum, protects against pitting, crevice corrosion, and chloride-induced stress corrosion cracking.

In chemical processing, stainless steel 316 is the material of choice for tanks, pipes, and vessels that handle aggressive chemicals. It resists acids, chlorides, and high temperatures. This durability means less frequent replacement and lower long-term costs, even though the initial price is higher than other grades. The alloy’s non-magnetic properties and attractive appearance add to its value in both marine and chemical settings.

Tip: Marine grade stainless steel offers exceptional corrosion resistance, high tensile strength, and easy maintenance, making it ideal for harsh marine and chemical environments.

The food and medical industries require materials that are safe, clean, and resistant to corrosion. Stainless steel 316 meets these needs. Food processing plants use it for equipment exposed to saline conditions, such as seafood processing lines. It appears in sanitary piping, tanks, and commercial dishwashers. The alloy’s smooth surface and resistance to frequent cleaning help maintain hygiene.

Medical device manufacturers use stainless steel 316 for surgical trays, orthopedic implants, and cleanroom-grade tubing. Pharmaceutical companies rely on it for manufacturing equipment that must meet strict hygiene standards. Several standards, such as ASTM A240/A240M and NSF/ANSI guidelines, govern its use in these sectors. These standards ensure that the alloy’s chemical composition, mechanical properties, and surface finish meet safety and performance requirements.

Note: The applications of 316 stainless steel in food and medical fields help protect public health by preventing contamination and ensuring long-lasting, reliable equipment.

316 stainless steel offers several important advantages that make it a top choice for demanding environments. Its unique chemical makeup, which includes molybdenum, gives it better resistance to corrosion than many other stainless steels. This feature helps 316 stainless steel stand up to saltwater, chlorides, and harsh chemicals. Many engineers select 316 for marine, chemical, and medical uses because it resists pitting and crevice corrosion better than 304 stainless steel. It also performs well at high temperatures, keeping its strength and corrosion resistance even when exposed to heat.

The table below compares 316 stainless steel with 304 stainless steel:

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Composition | 18% Chromium, 8% Nickel (No Molybdenum) | 18% Chromium, 10% Nickel, 2-3% Molybdenum |

| Corrosion Resistance | Excellent in mild environments; susceptible to pitting and crevice corrosion, especially with chlorides. | Superior corrosion resistance, including against chlorides and in harsh environments. |

| Strength | Good | Good, slightly higher due to molybdenum |

| High-Temperature Performance | Good for many applications, but can be susceptible to corrosion at very high temperatures. | Excellent high-temperature strength and corrosion resistance. |

| Weldability | Excellent | Excellent |

| Cost | More cost-effective | More expensive |

| Typical Applications | Food processing equipment, kitchen appliances, sinks, architectural trim, pump and valve components. | Marine environments, chemical processing, pharmaceutical manufacturing, medical devices, heat exchangers. |

| Magnetic | Slightly Magnetic | Slightly Magnetic |

316 stainless steel also has a non-toxic surface and resists bacterial growth. This makes it a safe choice for food processing and medical equipment. Its smooth finish options help keep surfaces clean and attractive. Many industries use 316 stainless steel for products that need to look good and stay hygienic.

However, 316 stainless steel does have some limitations. The alloy costs more than 304 stainless steel because of its higher nickel and molybdenum content. It is also harder to machine and form, which can make manufacturing more difficult. Its thermal conductivity is lower than some other metals, so it does not transfer heat as quickly.

Key advantages of 316 stainless steel:

Superior corrosion resistance, especially in salty or acidic environments

High strength and durability under heavy loads

Excellent performance at high temperatures

Non-toxic and easy to clean, ideal for food and medical uses

Attractive surface finishes for decorative or hygienic products

Main limitations of 316 stainless steel:

Higher cost compared to other stainless steels

Lower machinability and formability, making it harder to shape

Lower thermal conductivity, which affects heat transfer

Tip: When choosing a stainless steel grade, consider both the environment and the specific needs of the application. 316 stainless steel works best in harsh, corrosive, or high-temperature settings where long-term durability matters most.

316 stainless steel stands out for its unique chemical makeup and strong properties. It resists corrosion in harsh environments, handles high temperatures, and offers good formability and weldability. Many industries value stainless steel 316 for its durability and attractive appearance. Users should note some limitations, such as higher cost, lower impact strength than carbon steel, and possible stress corrosion cracking.

Excellent corrosion resistance in marine and chemical settings

Withstands extreme temperatures and pressures

Easy to form and weld

Higher cost and lower impact strength than some alternatives

Susceptible to stress corrosion cracking in certain conditions

316 stainless steel contains molybdenum, which improves resistance to corrosion, especially from saltwater and chemicals. 304 stainless steel does not have molybdenum. This difference makes 316 better for harsh environments.

316 stainless steel resists rust very well. However, it can still rust if exposed to harsh chemicals or if the protective oxide layer gets damaged. Regular cleaning helps maintain its corrosion resistance.

316 stainless steel is generally non-magnetic in its annealed state. Cold working or welding can introduce slight magnetism, but it remains much less magnetic than ferritic or martensitic stainless steels.

Engineers use 316 stainless steel in marine equipment, chemical processing plants, food processing machinery, and medical devices. Its corrosion resistance and strength make it ideal for these demanding applications.

Clean 316 stainless steel with mild soap and water. Avoid using harsh chemicals or steel wool, which can scratch the surface. Rinse and dry thoroughly to prevent water spots and maintain its appearance.

316 stainless steel can withstand temperatures up to about 850°C (1562°F) for continuous service. For short periods, it can handle even higher temperatures. Prolonged exposure above this range may reduce its oxidation resistance.

Standard welding methods work well with 316 stainless steel. Using low-carbon variants like 316L helps prevent corrosion at welds. Proper cleaning after welding ensures the best corrosion resistance.

Yes, 316 stainless steel is safe for food and medical applications. Its non-toxic surface resists bacteria and corrosion, making it a preferred material for sanitary environments.