close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-29 Origin: Site

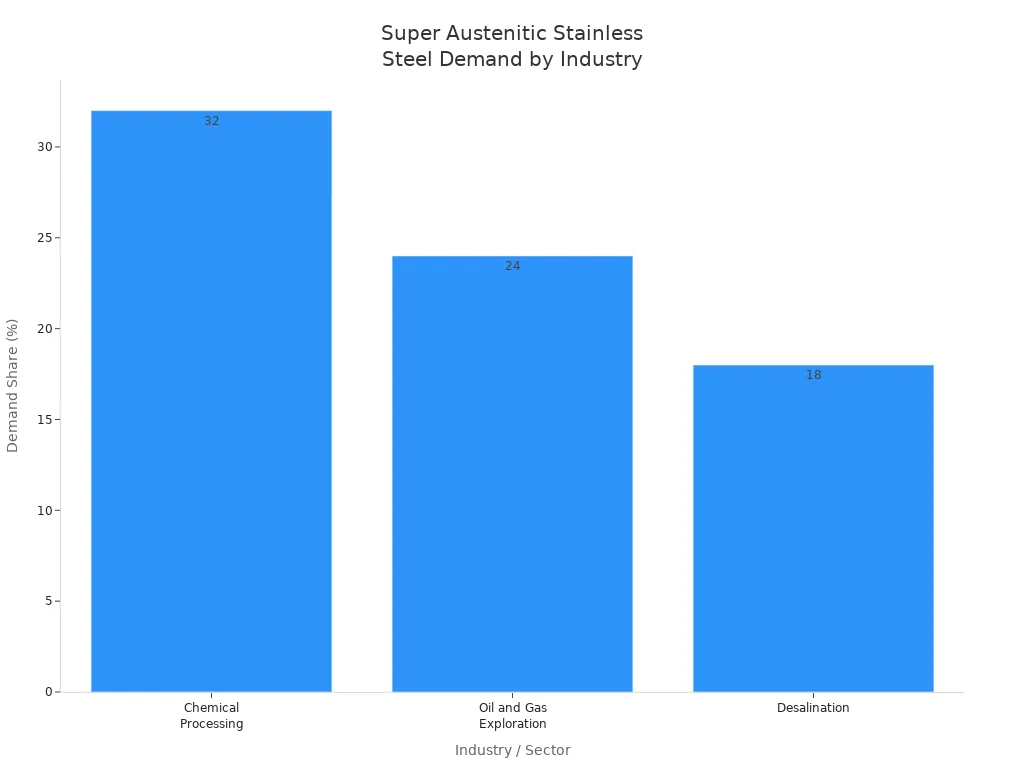

Super austenitic stainless steel stands out in harsh acid environments, delivering unmatched corrosion resistance through advanced alloy design. High levels of nickel and molybdenum increase the critical pitting temperature, making these steels less vulnerable to localized corrosion, even in aggressive chloride or hydrochloric acid conditions. Industries such as chemical processing, oil and gas, and desalination facilities rely on this material for its proven ability to reduce downtime and maintenance costs.

Engineers select super austenitic stainless steel for projects where long-term durability and reliability in corrosive environments are essential.

Super austenitic stainless steel belongs to the austenitic family, one of the five main groups of stainless steel. This family is defined by a face-centered cubic crystal structure, which elements like nickel, manganese, and nitrogen stabilize. International standards such as EN, AISI, UNS, and ASTM recognize super austenitic stainless steels as high-alloy grades with enhanced corrosion resistance. These steels stand out due to their higher levels of chromium, molybdenum, and nitrogen. Alloys such as 254SMO, AL-6XN, and Alloy 20 fall into this category. Their classification as a specialized subgroup comes from their superior resistance to aggressive environments and their high pitting resistance equivalent number (PREN), often above 40.

Super austenitic stainless steel features a unique combination of chemical and mechanical properties. Typical compositions include chromium around 20%, nickel between 18% and 25%, molybdenum near 6%, and nitrogen about 0.20%. This alloy design delivers exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-rich environments like seawater.

Note: The high alloy content not only improves corrosion resistance but also boosts mechanical strength and durability.

A comparison of mechanical properties highlights the advantages:

Stainless Steel Grade | Yield Strength (MPa / ksi) | Tensile Strength (MPa / ksi) |

|---|---|---|

Standard Austenitic (304L, 316L) | ~170 MPa (25 ksi) | ~515 MPa (75 ksi) |

Super Austenitic (S31254, N08367) | ~310 MPa (45 ksi) | ~655 MPa (95 ksi) |

Super austenitic stainless steel also maintains excellent ductility and formability. The low carbon content reduces the risk of carbide precipitation during welding, which helps preserve corrosion resistance. While these alloys are more challenging to machine, their performance in harsh environments justifies the investment.

Industries choose super austenitic stainless steel for its reliability in demanding conditions. The material finds use in sectors where exposure to aggressive chemicals, high temperatures, and chlorides is common.

Oil and Petrochemical: Bellows and equipment in processing plants

Pulp and Paper: Digesters and bleaching systems

Power Generation: Flue gas desulfurization units and internal components

Offshore and Seawater: Condensing pipes and desalination equipment

Salt Industry: Salt production and desalination systems

Heat Exchangers: Units operating in chloride-rich environments

Super austenitic stainless steel also supports the biopharmaceutical and sanitary industries. Manufacturers rely on its corrosion resistance for producing shampoos, sports drinks, and pharmaceutical ingredients. Its ability to withstand harsh cleaning agents and maintain product purity makes it essential in these fields.

Chromium and nickel serve as the backbone of super austenitic stainless steel. Chromium forms a stable, protective oxide layer (Cr₂O₃) on the steel surface. This passive film acts as a barrier, preventing direct contact between the metal and corrosive agents. Nickel stabilizes the austenitic structure, which improves ductility, toughness, and weldability. Together, these elements deliver a unique blend of corrosion resistance characteristics and mechanical strength.

Chromium increases the steel’s electrode potential, making it more resistant to corrosion.

Nickel enhances the stability of the passive film, especially in harsh environments.

Both elements contribute to solid solution strengthening, which increases hardness and durability.

The combination of chromium and nickel optimizes the pitting resistance equivalent, making these alloys reliable in both cryogenic and high-temperature applications.

The synergy between chromium and nickel ensures that super austenitic stainless steels maintain their structure and resist localized corrosion, even in environments rich in chlorides.

Molybdenum plays a critical role in boosting the pitting resistance equivalent of super austenitic stainless steel. This element enhances the protective quality of the passive film, especially in chloride-rich environments. Molybdenum forms stable oxides that inhibit the penetration of aggressive ions like chloride, which often initiate pitting and crevice corrosion.

Molybdenum increases the density and stability of the passive film.

It promotes chromium enrichment at the surface, further strengthening corrosion resistance.

The presence of molybdenum reduces the number and size of pitting sites, which is vital for maintaining a high pitting resistance equivalent.

Molybdenum works synergistically with chromium and nitrogen, creating a more homogeneous and robust barrier against localized corrosion.

In marine and chemical processing industries, the addition of molybdenum ensures that super austenitic stainless steels outperform standard grades in resisting pitting and crevice corrosion.

Nitrogen acts as a powerful austenite stabilizer and solid solution strengthener in super austenitic stainless steel. As an interstitial element, nitrogen introduces elastic distortions in the crystal lattice, which leads to higher yield strength and improved toughness. Nitrogen also allows for partial replacement of nickel, making the alloy more cost-effective without sacrificing performance.

Nitrogen enhances the formation and stability of the passive film, which expands the passive potential range and reduces passive current density. This improvement increases resistance to localized corrosion, such as pitting and intergranular corrosion. High nitrogen content refines grain size and promotes the formation of dense nitride layers on the surface, which further boosts the pitting resistance equivalent.

The combined effect of chromium, nickel, molybdenum, and nitrogen results in a super austenitic stainless steel with exceptional corrosion resistance characteristics. The stable passive film formed by these elements protects the alloy from aggressive environments, ensuring long-term durability and reliability.

Boron, though present in small amounts, plays a significant role in the performance of super austenitic stainless steel. Metallurgists add boron to these alloys to enhance their resistance to harmful phase formations and to improve overall corrosion resistance. This microalloying element influences the steel’s microstructure during both solidification and service.

Boron segregates into the residual liquid during the solidification process. This segregation reduces interface energies, which leads to the formation of molybdenum-rich Laves and μ phases instead of the more harmful sigma (σ) phase. The sigma phase, if present, can severely reduce corrosion resistance and mechanical properties. By promoting the formation of less detrimental phases, boron helps maintain the integrity of the alloy in aggressive environments.

Researchers have observed several key effects of boron in super austenitic stainless steel:

Boron does not contribute to sigma phase formation. Instead, it suppresses impurity segregation at grain boundaries and inhibits the precipitation of harmful intermetallic compounds.

When combined with nitrogen, boron accelerates the dissolution of sigma phase during homogenization. This process improves hot workability and service performance.

Microstructural studies show that increasing nitrogen content in boron-microalloyed steels can reduce the area fraction of harmful precipitates by over 50%. This reduction leads to a more refined and corrosion-resistant microstructure.

Boron addition induces the nucleation of Laves phase, which modifies the alloy’s microstructure and further reduces sigma phase precipitation.

The presence of boron at grain boundaries inhibits the formation of brittle intermetallic phases. This effect enhances hot ductility and mechanical performance.

Note: The combination of boron and nitrogen in super austenitic stainless steel not only suppresses the formation of unwanted phases but also improves the alloy’s ability to withstand high-temperature processing and corrosive service conditions.

Boron’s influence extends beyond phase control. By reducing impurity segregation and suppressing the precipitation of brittle phases, boron ensures that the steel retains its toughness and ductility during fabrication. This improvement in hot workability allows manufacturers to produce complex components without sacrificing performance.

Superaustenitic stainless steels deliver exceptional corrosion resistance in some of the world’s most aggressive environments. Their advanced alloy design, featuring high levels of chromium, molybdenum, nickel, and nitrogen, provides a robust defense against both general and localized corrosion. These steels consistently outperform standard grades and even many nickel alloys, especially under harsh acidizing conditions.

Sulfuric acid presents a significant challenge for most metals due to its strong oxidizing and reducing properties. Superaustenitic stainless steels, such as UNS N08029 and SSC-6Mo, show remarkable performance in this environment. Their high molybdenum and chromium content increases the pitting resistance equivalent, allowing them to withstand a wide range of acid concentrations and temperatures.

Laboratory and field tests confirm this advantage. The following table summarizes key findings from iso-corrosion diagrams and industrial data:

Acid Environment | Alloy Type | Test Type | Key Findings |

|---|---|---|---|

Sulfuric Acid | Nickel-chromium-molybdenum alloys (e.g., HASTELLOY® C-276, HYBRID-BC1®, 625, G-35®) | Iso-corrosion diagrams | High resistance across wide concentration and temperature ranges; HYBRID-BC1® alloy tolerates higher temperatures due to higher Mo content. |

Sulfuric Acid | Nickel-copper alloys (e.g., MONEL® 400) | Iso-corrosion diagrams | Moderate resistance; performance affected by cathodic reaction changes at 60-70 wt.% concentration. |

Sulfuric Acid | ULTIMET® alloy | Iso-corrosion diagrams | Similar corrosion resistance to 625 and G-35® alloys; strong temperature dependency; no “moderately safe” regime at some concentrations. |

Sulfuric Acid (Industrial) | Nickel-chromium-molybdenum alloys | Field data and lab data | Used up to ~95°C in highly concentrated sulfuric acid from mining industry; oxidizing species affect corrosion behavior. |

Superaustenitic stainless steels, especially those with high molybdenum content, maintain their corrosion resistance characteristics even as acid concentration and temperature increase. In real-world mining and chemical processing, these alloys operate reliably up to 95°C, where many standard grades fail.

Hydrochloric acid is notorious for causing rapid corrosion in most stainless steels. Superaustenitic stainless steels, including 904L and 6Mo grades, demonstrate superior localized corrosion resistance in these harsh acidizing conditions. Electrochemical tests at 50°C reveal that 904L forms a protective nickel-fluoride layer in hydrofluoric acid, which also benefits its performance in hydrochloric acid. This layer blocks aggressive ions and supports the formation of a stable passive film, reducing the risk of pitting and crevice corrosion.

Nickel-chromium alloys like 625 and G-35® also show a large “moderately safe” regime in hydrochloric acid, but superaustenitic stainless steels offer a cost-effective alternative with similar or better performance. Field data from chemical plants confirm that these steels resist attack in environments where standard austenitic grades rapidly deteriorate.

Nitric acid, an oxidizing acid, challenges the stability of passive films on stainless steels. Superaustenitic stainless steels, with their optimized alloy composition, maintain a robust passive layer even as acid concentration and temperature rise. Electrochemical impedance spectroscopy and surface film analysis of AISI 304L in nitric acid show that oxidizing species can destabilize the passive film, increasing corrosion rates. However, superaustenitic grades, with higher chromium and molybdenum, retain their protective oxide layer longer, resulting in lower corrosion rates and improved performance.

Tip: When selecting materials for nitric acid service, engineers should consider both the acid concentration and operating temperature. Superaustenitic stainless steels provide a reliable solution for environments where standard grades cannot maintain their passive film.

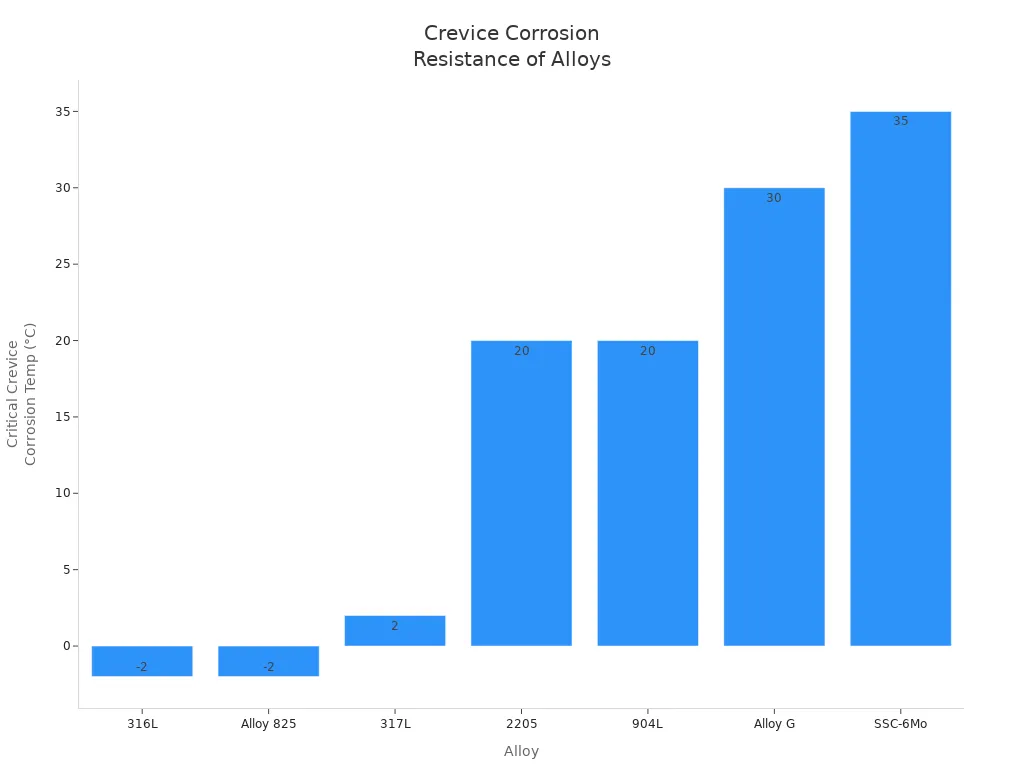

Chloride-induced pitting and crevice corrosion represent major threats in marine and chemical processing applications. Superaustenitic stainless steels excel in these environments due to their high pitting resistance equivalent and optimized alloying. Grades such as 6Mo (UNS N08367) and SSC-6Mo achieve significantly higher PREn values than standard 304L or 316L, translating to better localized corrosion resistance.

Laboratory tests using ASTM G48 and G150 methods measure the critical pitting temperature (CPT) and critical crevice corrosion temperature (CCCT). Superaustenitic stainless steels consistently show higher CPT and CCCT values, indicating their ability to resist localized attack at higher temperatures and chloride concentrations. For example, 304L has the lowest CPT, while 6Mo and super duplex 2507 reach the highest values. This performance makes superaustenitic stainless steels the preferred choice for seawater systems, desalination plants, and other chloride-rich environments.

Design also plays a role. Tight joints and proper sealing help prevent crevice corrosion, which can initiate at lower temperatures than pitting. By combining superior alloy design with thoughtful engineering, industries achieve long-term durability in the most demanding settings.

Stress corrosion cracking (SCC) poses a serious risk in environments where tensile stress and corrosive agents act together. Chloride ions, high temperatures, and acidic conditions can trigger SCC in many stainless steels. Superaustenitic stainless steels, however, offer enhanced resistance to this form of attack.

Their high nickel and nitrogen content increases the threshold for SCC initiation. In both laboratory and real-world tests, superaustenitic stainless steels outperform alloys 20 and 825, which often succumb to SCC under similar conditions. The combination of high pitting resistance equivalent, robust passive film, and optimized microstructure ensures that these steels maintain their integrity even in harsh acidizing conditions.

Note: While superaustenitic stainless steels provide excellent resistance to stress corrosion cracking, engineers should still monitor operating conditions and minimize residual stresses during fabrication to maximize service life.

Superaustenitic stainless steels set the standard for corrosion resistance in aggressive acid and chloride environments. Their superior performance, proven in both laboratory and field settings, makes them the material of choice for industries facing the toughest corrosion challenges.

Standard austenitic stainless steels, such as 304 and 316, remain popular choices for many industrial applications. These grades offer good corrosion resistance and mechanical strength. However, their performance in aggressive acid environments often falls short. Scientific studies show that 316 stainless steel outperforms 304 in acidic conditions. The addition of molybdenum in 316 increases its resistance to pitting and crevice corrosion, especially when exposed to chlorides or acids.

Despite these improvements, both 304 and 316 can struggle in environments with high acid concentrations or elevated temperatures. Super austenitic stainless steels, like grade N08029, deliver much better performance under these harsh conditions. Their advanced alloy composition allows them to resist corrosion where standard grades fail. This makes them the preferred option for industries that demand long-term reliability and minimal maintenance in acid-rich settings.

Note: The corrosion resistance trend increases from 304 to 316 to super austenitic stainless steels, with super austenitic grades providing the best protection in acidic environments.

Duplex stainless steels combine austenitic and ferritic structures. This blend gives them higher strength and improved resistance to stress corrosion cracking compared to standard austenitic grades. Duplex steels perform well in many corrosive environments, including those with chlorides. However, their performance in strong acids does not always match that of super austenitic stainless steels.

Duplex grades, such as 2205, offer a balance between cost and corrosion resistance. They work well in moderate acid conditions and provide good mechanical properties. In contrast, super austenitic stainless steels excel in environments with high acid concentrations or where localized corrosion is a concern. Their higher nickel, molybdenum, and nitrogen content gives them an edge in both general and localized corrosion resistance.

A simple comparison:

Property | Standard Austenitic | Duplex Steels | Super Austenitic |

|---|---|---|---|

Strength | Moderate | High | Moderate-High |

Acid Resistance | Moderate | Moderate | Excellent |

Chloride Resistance | Good (316) | Very Good | Excellent |

Cost | Lower | Moderate | Higher |

Nickel alloys, such as Alloy 625 and Alloy 825, set the benchmark for corrosion resistance in the most extreme environments. These materials contain high levels of nickel, chromium, and molybdenum. Their performance in strong acids and high-chloride conditions is outstanding. However, the cost of nickel alloys often limits their use to only the most demanding applications.

Super austenitic stainless steels bridge the gap between standard stainless steels and nickel alloys. They offer similar corrosion resistance and mechanical properties in many acid environments, but at a lower cost. This makes them an attractive choice for projects that require high-performance stainless steels without the premium price tag of full nickel alloys.

Tip: When selecting materials for acid service, engineers should weigh both performance and cost. Super austenitic stainless steels provide a practical solution for many applications that would otherwise require expensive nickel alloys.

Selecting the right material for corrosive environments often comes down to balancing performance with cost. Super austenitic stainless steels and nickel-based alloys both offer excellent corrosion resistance, but their price points differ significantly. This difference shapes decisions in industries where budget and long-term reliability matter.

Nickel-based alloys, such as Alloy 625 and Alloy 825, command a premium price. The high cost of nickel and other alloying elements drives up the price of these materials. Manufacturers often reserve nickel alloys for applications where only the highest corrosion resistance and durability will suffice. Aerospace, chemical processing, and certain marine environments rely on these alloys when failure is not an option. The initial investment in nickel alloys can be substantial, but their unmatched performance in extreme conditions justifies the expense for critical systems.

Super austenitic stainless steels, including grades like 254SMO and AL-6XN, achieve high corrosion resistance by increasing the content of chromium, molybdenum, and nickel. This alloying strategy improves their ability to withstand acids and chlorides, but it also raises their cost compared to standard stainless steels. However, super austenitic stainless steels remain less expensive than nickel-based alloys. This price advantage makes them attractive for projects that demand high corrosion resistance but cannot support the budget for full nickel alloys.

Tip: When evaluating material options, engineers should consider not only the purchase price but also the total cost of ownership. Super austenitic stainless steels often reduce maintenance, replacement, and downtime costs over the lifespan of equipment.

The following table summarizes the typical cost and performance characteristics:

Material Type | Relative Cost | Corrosion Resistance | Typical Applications |

|---|---|---|---|

Standard Austenitic (304, 316) | Low | Moderate | General industry, food processing |

Duplex Stainless Steel | Moderate | Good | Oil & gas, marine, chemical plants |

Super Austenitic | High | Excellent | Chemical processing, desalination |

Nickel-Based Alloy | Very High | Outstanding | Aerospace, extreme chemical service |

Material selection often involves trade-offs. Super austenitic stainless steels fill the gap between standard stainless and nickel alloys. They provide a cost-effective solution for many aggressive environments. When budgets are tight but corrosion resistance cannot be compromised, engineers frequently choose super austenitic grades. Nickel-based alloys remain the top choice for the harshest conditions, but their use is limited by cost.

Engineers and researchers have gathered extensive field data on superaustenitic stainless steels in challenging environments. These materials have proven their value in marine and chemical processing applications where corrosion and mechanical stress threaten equipment longevity.

Marine environments show that high nitrogen superaustenitic stainless steels, such as 304NH and 316NH, perform exceptionally well under continuous seawater exposure and tensile stresses.

Applications include heater tubes, shipbuilding, offshore power generation, subsea oil recovery hydraulic control systems, and chemical injection tubing on offshore platforms.

Experimental results reveal that these steels exhibit lower corrosion rates, increased pitting resistance, and excellent resistance to stress corrosion cracking compared to conventional 304 and 316L grades.

Microstructural studies confirm that increasing nitrogen content reduces the severity of stress corrosion cracking, with 304NH and 316NH showing only slight effects while standard 304 suffers severe damage.

Mechanical properties, including yield and tensile strength, improve in high nitrogen variants, supporting their durability in demanding marine operations.

These findings demonstrate that superaustenitic stainless steels deliver reliable performance and long-term durability where standard grades may fail.

Real-world case studies highlight the superior performance of superaustenitic stainless steels in aggressive acid service. The following table compares the critical crevice corrosion temperature of several alloys, illustrating the advantage of high-performance stainless steels:

Alloy | Critical Crevice Corrosion Temperature (°C) | Notes on Performance |

|---|---|---|

316L | -2 | Standard austenitic, lower resistance |

Alloy 825 | -2 | Similar to 316L |

317L | 2 | Slightly better than 316L |

2205 | 20 | Duplex, improved resistance |

904L | 20 | High alloy austenitic, better resistance |

Alloy G | 30 | Nickel-based, enhanced resistance |

SSC-6Mo | 35 | Superaustenitic, highest resistance due to Mo, Ni, Cr, and N |

Laboratory testing and decades of plant experience confirm that superaustenitic stainless steels, such as SSC-6Mo and NAG 18/10, outperform alternative alloys in nitric acid and other aggressive environments. These materials resist pitting, crevice corrosion, and intergranular attack, ensuring the integrity of process vessels and piping over many years.

Many industries rely on superaustenitic stainless steels for their unmatched performance. Chemical processing plants use these alloys for piping, heat exchangers, and reactor vessels exposed to strong acids. Offshore platforms and marine facilities specify superaustenitic grades for critical components that face continuous seawater immersion and high operational stresses. The salt and desalination industries benefit from the high resistance to localized corrosion, which reduces maintenance and extends equipment life.

A recent study on modified superaustenitic stainless steel produced by induction melting demonstrated corrosion resistance comparable to commercial 254SMO. The research emphasized the importance of alloying elements and proper heat treatment in maintaining performance, even when using cost-effective production methods. This evidence supports the long-term durability and mechanical reliability of superaustenitic stainless steels in the harshest environments.

Super austenitic stainless steels deliver excellent corrosion resistance in many environments, but their performance can decline at elevated acid temperatures. Researchers have found that the protective chromium-rich oxide layer, which normally shields the steel, becomes less stable when exposed to temperatures between 240°C and 300°C, especially in high-chloride conditions. As temperature rises, the passive film can degrade, allowing chloride ions to penetrate more easily. This process increases the risk of localized corrosion, such as pitting and crevice attack.

Experimental studies show that alloys like S31603 and SS2562 experience higher corrosion rates as temperatures increase from 308K to 353K in acidic chloride-sulfate solutions. SS2562, for example, loses its passivation entirely above 308K, while S31603 shows unstable protection. Microscopic analysis reveals more severe micro-pitting and grain boundary damage at higher temperatures. These findings highlight the importance of considering both acid concentration and operating temperature when selecting materials for aggressive environments.

Note: Super austenitic stainless steels may not provide reliable protection in hot, highly acidic, and chloride-rich environments. Engineers should monitor service conditions closely to prevent unexpected failures.

Manufacturers face several challenges when fabricating and welding super austenitic stainless steels. The high alloy content increases toughness and work hardening, making machining more difficult. Specialized cutting tools and slower speeds are often required to achieve precise results. During forming, surface contamination must be avoided to maintain corrosion resistance.

Welding presents additional complexities. The presence of elements like nickel, manganese, molybdenum, and chromium can lead to the formation of intermetallic phases in the heat-affected zone. These phases can weaken the microstructure and reduce mechanical properties. To address these issues, fabricators use advanced welding techniques such as gas metal arc welding (GMAW), tungsten inert gas (TIG) welding, and laser welding. Careful control of welding parameters, filler material selection, and post-weld treatments help preserve the alloy’s superior properties.

Specialized welding methods improve weld quality and maintain corrosion resistance.

Laser welding with different shielding gases can produce defect-free joints with high strength.

Pulsed current TIG welding enhances penetration and reduces defects.

Despite the higher complexity and cost, these fabrication steps ensure that super austenitic stainless steels meet the demands of critical industries.

While super austenitic stainless steels offer outstanding performance, they are not always the best choice for every application. Cost remains a significant factor. Ferritic stainless steels, such as AISI 444 and AISI 445, provide reasonable corrosion resistance at a lower price. These grades have proven effective in architectural projects and benefit from alloying advances that improve sustainability and production efficiency.

In some cases, engineers select less expensive alloys to meet budget constraints, accepting higher maintenance costs over time. For applications where only surface protection is needed, weld overlay cladding on carbon steel can reduce equipment costs by up to 50%. Dissimilar welding, which combines super austenitic stainless steels with super-duplex or nickel alloys, is common in marine and petrochemical industries to balance performance and cost.

Failure Mode | Typical Cause/Environment | Appearance/Effect | Key Mitigation Strategies |

|---|---|---|---|

Pitting Corrosion | Chloride ions, stagnant conditions | Small, deep pits | Use higher PREN alloys, maintain smooth surfaces |

Crevice Corrosion | Tight gaps, deposits, chlorides | Localized attack in shielded areas | Avoid crevices, regular cleaning, proper gaskets |

Stress Corrosion Cracking | Tensile stress + chlorides >60°C | Fine, branching cracks | Use SCC-resistant alloys, stress relief, control environment |

Intergranular Corrosion | Sensitization, carbide precipitation | Attack along grain boundaries | Use low carbon or stabilized grades |

General Corrosion | Strong acids or alkalis | Uniform thinning | Select highly resistant alloys, consider coatings |

⚠️ Tip: Alternative materials or hybrid solutions may be preferable when cost, fabrication complexity, or specific environmental factors outweigh the benefits of super austenitic stainless steels.

Superaustenitic stainless steels stand out in corrosive and acidic environments for several reasons:

Their PREN exceeds 48, offering superior pitting and crevice corrosion resistance.

A stable MoO₃ passive film protects against aggressive acids and chlorides.

Corrosion tests show better performance and economic value than many nickel alloys.

Proper welding preserves molybdenum, maintaining corrosion resistance.

Superaustenitic stainless steels balance long-term durability and cost, making them ideal for critical industrial projects. Materials experts recommend consulting metallurgists to select the right grade and fabrication method for each application.

Super austenitic stainless steel contains higher levels of chromium, nickel, molybdenum, and nitrogen. These elements give it superior corrosion resistance and mechanical strength compared to standard grades like 304 or 316.

Yes. Super austenitic stainless steel resists pitting and crevice corrosion in seawater. Engineers often use it for desalination plants, offshore platforms, and marine piping because of its durability in chloride-rich environments.

Welding super austenitic stainless steel requires special techniques. The high alloy content can form unwanted phases if not controlled. Skilled welders use proper filler materials and post-weld treatments to maintain corrosion resistance.

Super austenitic stainless steel outperforms most other stainless steels in acids like sulfuric, hydrochloric, and nitric acid. Its alloy composition protects against both general and localized corrosion, even at higher temperatures.

Industries such as chemical processing, oil and gas, pulp and paper, and desalination benefit most. These sectors need materials that withstand aggressive chemicals and minimize maintenance.

Super austenitic stainless steel costs more than standard grades. However, it remains less expensive than nickel-based alloys. Its long service life and reduced maintenance often offset the higher initial cost.

Not always. While super austenitic stainless steel offers similar corrosion resistance in many environments, some extreme conditions still require full nickel alloys. Material selection depends on specific chemical and temperature requirements.

High temperatures and fabrication complexity present challenges. The protective oxide layer can break down above certain temperatures. Specialized welding and machining techniques are necessary to preserve its properties.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Exploring the Magnetism of Stainless Steel for Modern Applications

Super austenitic stainless steel outperforms in real-world acid tests

Emerging Manufacturing Techniques for Austenitic Stainless Steel Bars

Exploring The Role of 18-8 Austenitic Stainless Steel in Modern Manufacturing And Homes

Top 10 Austenitic Stainless Steel Grades and Their Everyday Uses