close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

When you compare 304 vs 316 stainless steel, the main difference comes down to molybdenum. Molybdenum enhances corrosion resistance in 316 stainless steel, especially in marine environments. Scientific studies show that about 2% molybdenum in 316 increases pitting resistance and helps the steel heal itself after minor damage. This makes 316 a better choice when you need protection against salt or harsh chemicals. Use this quick table to see how 304 vs 316 stack up:

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Molybdenum | ~0.2% | ~2% |

| Corrosion Resistance | Good | Excellent |

| Cost | Lower | Higher |

| Magnetism | Low | Low |

| Best Use | General | Marine/Chemical |

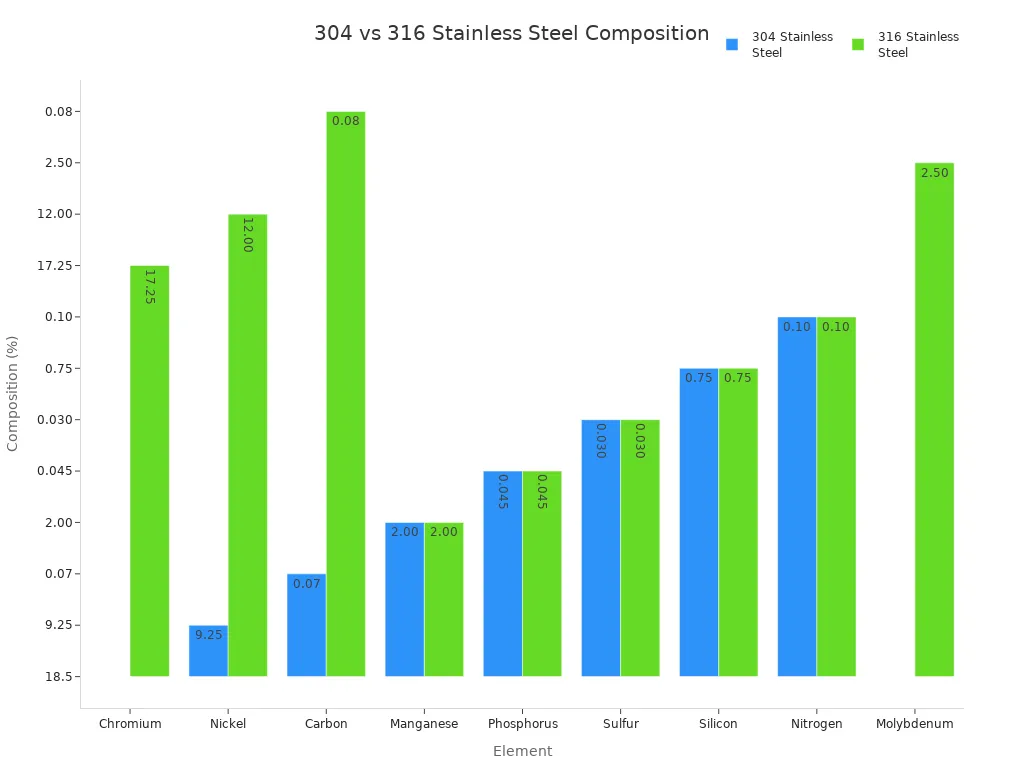

When you compare 304 vs 316 stainless steel, you notice several important differences that affect performance and suitability for specific environments. The most significant distinction lies in their chemical composition. You find that 304 stainless steel contains about 18% chromium and 8-10.5% nickel, with no molybdenum present. In contrast, 316 stainless steel includes a minimum of 2% molybdenum and a higher nickel content. This addition of molybdenum gives 316 a clear advantage in resistance to corrosion, especially in saltwater or environments with harsh chemicals.

The mechanical properties also show subtle differences. Both grades offer similar tensile strength, but 316 stainless steel generally provides a higher yield strength and slightly greater hardness. This makes 316 more durable under stress and less likely to deform. You also see a difference in magnetism. Both 304 and 316 are nonmagnetic in their annealed state, but cold working can induce some magnetism, more so in 304 than in 316.

Cost is another factor you need to consider. 316 stainless steel typically costs $1,000 to $1,500 more per ton than 304. This price difference reflects the added nickel and molybdenum, which enhance resistance to corrosion and increase durability in demanding environments.

Tip: If you need stainless steel for marine, chemical, or high-salinity environments, 316 offers superior resistance to corrosion and a longer lifespan, justifying its higher cost.

Below, you can see a detailed comparison of 304 vs 316 stainless steel, covering composition, mechanical properties, corrosion resistance, magnetism, and cost.

| Feature / Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chromium | 17.5 - 19.5% | 16.0 - 18.5% |

| Nickel | 8.0 - 10.5% | 10.0 - 14.0% |

| Molybdenum | None | 2.0 - 3.0% |

| Tensile Strength | 505 - 750 MPa | 500 - 680 MPa |

| Yield Strength | ~215 MPa | ~290 MPa |

| Hardness (Rockwell B) | ~70 | ~79 |

| Corrosion Resistance | Good, but less effective in saltwater | Excellent, especially in saltwater |

| Resistance to Corrosion | Moderate in harsh environments | Superior, especially against chlorides |

| Magnetism | Low (may increase after cold working) | Very low, remains nonmagnetic |

| Cost (per ton) | $2,500 – $3,200 | $3,500 – $4,000 |

| Best Use | General, indoor, mild environments | Marine, chemical, harsh environments |

Both 304 and 316 stainless steels resist corrosion well, but 316 stands out in saltwater and chemical-rich settings.

You will notice that 304 vs 316 stainless steel also differs in magnetism after cold working, with 304 showing more magnetic response.

The price gap between 304 vs 316 reflects the added durability and resistance you get with 316, especially for demanding applications.

Note: Always match your choice of stainless steel to the environment and performance needs. The right grade ensures optimal resistance, longevity, and value.

You will find that 304 stainless steel stands out as the most widely used austenitic stainless steel. Its composition includes approximately 18% chromium and 8% nickel, which is why you often hear it called "18/8 stainless steel." This balance of elements gives 304 stainless steel its excellent corrosion resistance and formability. Small amounts of carbon, manganese, silicon, phosphorus, and sulfur further enhance its performance. When you compare 304 to other grades, you notice that it contains no molybdenum, unlike 316 stainless steel, and no titanium, unlike 321 stainless steel. The table below highlights the main compositional differences among common grades:

| Stainless Steel Grade | Chromium (%) | Nickel (%) | Molybdenum (%) | Other Key Elements | Notes |

|---|---|---|---|---|---|

| 304 | ~18 | ~8 | None | C, Mn, Si, P, S | 18/8 stainless steel; good corrosion resistance and formability |

| 316 | 16-18 | 10-14 | 2-3 | Mn, Si, C | Molybdenum boosts resistance to chlorides |

| 321 | Similar to 304 | Similar to 304 | None | Titanium | Titanium improves weldability and high-temp performance |

| 430 | 16-18 | None | None | Ferritic grade | No nickel; less corrosion resistance, more economical |

You benefit from the corrosion resistance properties of 304 stainless steel in many environments. The high chromium and nickel content create a passive oxide layer on the surface, which protects against oxidation and most acids. This resistance to corrosion makes 304 stainless steel suitable for food processing, kitchenware, and architectural features. However, you should note that its resistance drops in environments with high chloride concentrations, such as coastal areas or swimming pools.

304 stainless steel properties include a strong combination of tensile strength and ductility. You can expect a tensile strength between 505 and 745 MPa and a minimum yield strength of 205 MPa. The material also offers a minimum elongation of 40%, which means you can form, bend, or weld it without cracking. This flexibility allows you to use 304 stainless steel in a wide range of structural and decorative applications.

In its annealed state, 304 stainless steel remains nonmagnetic. If you cold work or deform the material, you may notice a slight increase in magnetism. This characteristic helps you distinguish 304 from other grades, especially when magnetism matters for your project.

You will see 304 stainless steel in countless applications across industries. In the food and beverage sector, you find it in kitchen sinks, cookware, processing equipment, and storage tanks because of its hygienic surface and resistance to corrosion. The medical and pharmaceutical industries rely on 304 for surgical instruments, sterilization equipment, and pharmaceutical processing. In architecture and construction, you see it used for building facades, roofing, railings, and structural components. The automotive industry uses 304 stainless steel for exhaust systems and trim, while chemical processing plants use it for tanks, pipes, and reaction vessels. You also encounter 304 in household appliances like refrigerators, washing machines, and dishwashers, as well as in industrial equipment such as pumps and valves.

Tip: Choose 304 stainless steel when you need a cost-effective, versatile material with reliable resistance to corrosion and excellent formability for general-purpose applications.

When you consider 304 stainless steel for your projects, you gain access to a material that balances performance, durability, and cost. Understanding the advantages and disadvantages helps you make informed decisions, especially when you need reliable results in demanding environments.

You benefit from excellent corrosion resistance in most indoor and outdoor settings. The high chromium and nickel content protect surfaces from rust and staining.

You find that 304 stainless steel offers outstanding formability. You can bend, weld, or shape it into complex designs without losing strength.

The smooth, non-porous surface makes cleaning and sanitizing easy. This feature is especially important in food processing, medical, and kitchen applications.

You can trust 304 stainless steel to remain non-reactive with food ingredients. It does not alter flavors or introduce contaminants, which ensures food safety.

You enjoy long-term durability. The material resists mechanical wear and tear, so you spend less time and money on repairs or replacements.

You often choose 304 stainless steel because it is widely available and cost-effective compared to higher-alloyed grades.

You may encounter limitations in highly corrosive environments. 304 stainless steel does not perform well when exposed to high concentrations of chlorides, acids, or alkalis.

You notice that it costs more than alternatives like aluminum or carbon steel. If your project does not require high corrosion resistance, you might consider other options.

The thermal conductivity of 304 stainless steel is lower than that of copper. This can be a drawback if you need rapid heating or cooling in your application.

You might observe a slight increase in magnetism after cold working, which could affect certain uses.

Note: Always match the material to your environment. If you expect exposure to saltwater or harsh chemicals, you should consider upgrading to a more resistant grade.

You often see 304 stainless steel in food processing because it meets strict hygiene and safety standards. The table below summarizes the main pros and cons in this context:

| Advantages of 304 Stainless Steel in Food Processing Equipment | Disadvantages of 304 Stainless Steel in Food Processing Equipment |

|---|---|

| Excellent corrosion resistance to common food acids and moist environments | Not suitable for highly acidic or alkaline environments; may corrode under extreme conditions |

| Smooth, non-porous surface allows easy cleaning and sanitization | More expensive than alternatives like aluminum or carbon steel |

| Non-reactive with food ingredients, ensuring food safety | Limited thermal conductivity compared to metals like copper, which can be a drawback for rapid temperature changes |

| Durable against mechanical wear and tear, reducing repair frequency | N/A |

When you weigh the pros and cons, you see why 304 stainless steel remains a top choice for general-purpose applications. You get a strong balance of performance, safety, and value, especially when you need a material that stands up to daily use and frequent cleaning.

You will notice that 316 stainless steel stands out because of its unique chemical makeup. This grade contains 16-18% chromium and 10-14% nickel, but what truly sets it apart is the addition of 2-3% molybdenum. The molybdenum content gives 316 stainless steel its excellent corrosion resistance, especially in environments exposed to chlorides and aggressive chemicals. You also find small amounts of manganese, silicon, and carbon, which help balance the alloy and improve its workability. This composition makes 316 stainless steel a top choice when you need superior resistance to corrosion and durability in harsh settings.

You benefit from the excellent corrosion resistance of 316 stainless steel in demanding environments. The molybdenum in the alloy increases its resistance to pitting and crevice corrosion resistance, which is critical in marine and chemical processing settings. You can rely on this grade to withstand saltwater, acidic compounds, and many industrial chemicals. This level of resistance to corrosion ensures long-lasting performance, even when exposed to harsh or unpredictable conditions.

316 stainless steel properties include impressive mechanical strength and hardness. You can see the typical values in the table below:

| Property | Typical Values (Metric) | Typical Values (Imperial) | Notes |

|---|---|---|---|

| Ultimate Tensile Strength | 620 - 795 MPa | 90 - 115 ksi | Annealed, cold drawn condition |

| Yield Tensile Strength | 206 MPa | 30,000 psi | Annealed condition |

| Hardness (Brinell) | 146 | 146 | Annealed condition |

| Hardness (Rockwell B) | 79 | 79 | Converted from Brinell |

| Elongation at Break | 30% | 30% | Annealed condition |

| Modulus of Elasticity | 164 GPa | 24,000 ksi | Annealed condition |

You will find that 316 stainless steel maintains its strength at high temperatures and resists deformation under stress. This makes it ideal for structural components and equipment that must handle both mechanical loads and exposure to corrosive fluids.

In its annealed state, 316 stainless steel remains nonmagnetic. If you cold work or deform the material, you may notice a slight increase in magnetism, but it stays lower than 304 stainless steel. This property can help you select the right material for applications where magnetism could interfere with sensitive equipment.

You will see 316 stainless steel used in a wide range of applications where excellent corrosion resistance is essential. In marine environments, you find it in boat railings, underwater hardware, offshore platforms, and saltwater filtration systems. The chemical and petrochemical industries rely on 316 stainless steel for tanks, reactors, piping systems, heat exchangers, pumps, and valves that handle corrosive fluids. You also encounter this grade in coastal construction, desalination plants, and fasteners exposed to harsh chemicals. The combination of pitting and crevice corrosion resistance, strength, and durability makes 316 stainless steel the preferred choice for challenging environments.

Tip: Choose 316 stainless steel when you need unmatched resistance to corrosion, especially in marine or chemical processing settings. Its performance justifies the higher cost in these demanding applications.

When you consider 316 stainless steel for your project, you gain access to a material that excels in harsh and demanding environments. You will find that its unique properties offer several advantages, but you should also weigh the potential drawbacks before making your final choice.

You benefit from exceptional corrosion resistance. The addition of molybdenum in 316 stainless steel helps prevent pitting and crevice corrosion, especially in environments with chlorides, saltwater, or aggressive chemicals.

You can rely on 316 stainless steel to maintain its strength and resist scaling at high temperatures. This makes it suitable for equipment exposed to heat or thermal cycling.

You will appreciate its biocompatibility. 316 stainless steel does not react with most chemicals or biological materials, so you often see it in medical devices and pharmaceutical manufacturing.

You can weld 316 stainless steel with excellent results. When you use proper welding techniques and post-weld treatments like pickling and passivation, you create a dense protective film that further improves corrosion resistance.

You find that polished 316 stainless steel surfaces are smooth and easy to clean. This reduces the risk of contamination in sensitive applications.

You will notice that 316 stainless steel costs more than 304 stainless steel. The higher price comes from the added molybdenum and nickel, which improve performance but increase material expenses.

You may find machining 316 stainless steel more challenging. Its hardness and tendency to work-harden require sharp tools and slower speeds, which can slow down production and raise costs.

You must pay close attention to welding procedures. Improper welding can lead to sensitization, which reduces corrosion resistance. Always use recommended techniques and post-weld treatments.

You might encounter issues with galling and gouging under pressure. Careful design and proper lubrication help prevent surface damage during assembly or operation.

You need to control metal particle generation in pharmaceutical and food processing equipment. High-speed contact or abrasion can introduce contaminants, so you must design and finish surfaces carefully.

Tip: Always match the grade of stainless steel to your environment and application. 316 stainless steel offers superior performance in marine, chemical, and pharmaceutical settings, but you should consider the higher cost and fabrication requirements.

| Feature | 316 Stainless Steel Pros | 316 Stainless Steel Cons |

|---|---|---|

| Corrosion Resistance | Superior resistance to chlorides and harsh environments due to molybdenum addition | Higher cost compared to 304 |

| High-Temperature Strength | Maintains strength and corrosion resistance at elevated temperatures | None specifically noted for temperature |

| Biocompatibility | Non-reactive, suitable for medical and pharmaceutical applications | None specifically noted |

| Weldability | Excellent weldability | Requires careful welding to avoid sensitization |

| Machinability | N/A | More difficult to machine due to hardness |

| Application Suitability | Ideal for pharmaceutical manufacturing, chemical processing, and medical devices | N/A |

You should always balance the pros and cons of 316 stainless steel based on your specific needs. When you require maximum corrosion resistance, durability, and cleanliness, this alloy stands out as a top performer.

You encounter both 304 stainless steel and 316 stainless steel in a wide range of everyday and industrial settings. Each grade has strengths that make it the right choice for specific applications. You often see 304 stainless steel in household items and commercial kitchen surfaces. Its balance of corrosion resistance, affordability, and easy fabrication makes it a favorite for food preparation areas, sinks, and appliances. You also find it in architectural features, automotive parts, and medical equipment.

316 stainless steel stands out in environments where you need extra protection from corrosion. You use it for outdoor fixtures, marine hardware, and heavy-duty equipment. Its superior resistance to chlorides and acids makes it ideal for chemical processing equipment, pharmaceutical equipment, and medical implants.

The table below highlights common applications for both grades in household and commercial settings:

| Stainless Steel Grade | Common Uses in Household Settings | Common Uses in Commercial Settings |

|---|---|---|

| 304 stainless steel | - Kitchen equipment (sinks, prep tables) - Household appliances (refrigerators, ovens, dishwashers) - Faucets, door handles - Architectural elements (handrails, decorative panels) - Automotive parts (exhaust systems, trims) - Medical instruments (surgical tools, lab tables) | - Food & beverage industry (food processing, brewing tanks) - Commercial kitchens - Office building railings - Automotive components - Medical and laboratory equipment |

| 316 stainless steel | - Outdoor heavy-duty equipment exposed to harsh environments - Marine hardware (boat fittings, dock hardware) - Medical implants and surgical tools | - Marine and coastal environments (saltwater resistant fittings) - Chemical and pharmaceutical industries (chemical tanks, pipelines) - Industrial high-temperature applications (heat exchangers, pressure vessels) - Outdoor structures (bridges, oil rigs) - Heavy-duty industrial machinery |

Tip: Choose 304 stainless steel for most indoor and moderate outdoor uses where cost and ease of fabrication matter. Select 316 stainless steel when you need extra durability in aggressive or corrosive environments.

You need to pay close attention to the environment when selecting stainless steel applications. In marine applications, 316 stainless steel is the clear winner. Its molybdenum content gives it superior resistance to chloride-induced corrosion, which is common in saltwater and coastal environments. Field studies show that 316 stainless steel maintains a smooth surface and resists pitting and crevice corrosion, even after a year of deep-sea exposure. You can trust it for boat fittings, dock hardware, and offshore platforms.

304 stainless steel performs well in less harsh environments, but it cannot match the durability of 316 stainless steel in marine or chemical-rich settings. If you use 304 stainless steel in these conditions, you may see rust, pitting, or surface damage over time. For marine applications, you should always choose 316 stainless steel to ensure a longer lifespan and reduced maintenance.

316 stainless steel is recommended for marine accessories exposed to saltwater due to its superior corrosion resistance.

304 stainless steel is better suited for indoor or less harsh environments.

Field reports confirm 316 stainless steel exhibits less corrosion and maintains integrity longer in high-saline environments.

Users report 316 stainless steel fittings resist corrosion better and last longer than 304 in marine conditions.

Despite higher cost, 316 stainless steel offers longer lifespan and reduced maintenance, making it cost-effective for marine use.

Note: For coastal environments, chemical piping, and outdoor structures exposed to de-icing salts, always specify 316 stainless steel. You protect your investment and avoid costly repairs.

You see both 304 stainless steel and 316 stainless steel in many industries, but the choice depends on the environment and performance needs. The table below summarizes where each grade excels and why:

| Industry/Application Area | Preference for 304 Stainless Steel Reasoning |

|---|---|

| Kitchen equipment | 304 is preferred due to its excellent corrosion resistance in typical kitchen environments, cost-effectiveness, and good formability. |

| Architectural paneling | Chosen for its fabrication ease, good mechanical properties, and adequate corrosion resistance in less aggressive environments. |

| Chemical containers | 304 offers sufficient corrosion resistance and is more economical than 316 for many chemical storage applications. |

| Automotive and aerospace structural use | 304 is favored for its strength, corrosion resistance, and weldability in structural components where extreme corrosion is not expected. |

| Food processing equipment (especially 304L variant) | 304L is preferred for welded structures due to its lower carbon content improving weldability and corrosion resistance in food industry settings. |

You rely on 316 stainless steel for more demanding environments. You find it in marine hardware, chemical processing equipment, pharmaceutical equipment, and medical devices. Its superior corrosion resistance comes from the molybdenum content, which protects against pitting and acids. You also see it in surgical instruments, medical implants, and piping for aggressive chemicals.

304 stainless steel is commonly used in construction fasteners, curtain wall screws, cladding fasteners, and panel screws.

316 stainless steel is preferred in marine, chemical processing, and pharmaceutical industries, especially for valves and piping.

You choose 304 stainless steel when you need good corrosion resistance, easy fabrication, and lower cost.

You select 316 stainless steel when you need maximum durability in harsh or chloride-rich environments.

Callout: Always balance your choice between environmental exposure, corrosion resistance, and budget. For most general and food preparation uses, 304 stainless steel meets your needs. For surgical, medical, marine, and chemical processing equipment, 316 stainless steel delivers the best performance.

When you compare 304 and 316 stainless steel, you notice a clear difference in price. On average, 316 stainless steel costs about 20% more than 304. This price gap comes from the addition of molybdenum in 316, which boosts its corrosion resistance. However, the exact difference can change based on your location, how much you buy, and current market trends. You should always check with your supplier for the most accurate and up-to-date pricing. Over the past five years, no fixed average price difference has been recorded. Most industry experts agree that the price gap remains steady, but it can shift quickly due to changes in demand or raw material costs.

Tip: Always request a current quote from your stainless steel supplier. Prices can change quickly, and bulk orders may qualify for discounts.

| Stainless Steel Grade | Typical Price Range (per ton) | Relative Cost Increase |

|---|---|---|

| 304 | $2,500 – $3,200 | Baseline |

| 316 | $3,500 – $4,000 | +20% (approximate) |

You need to look beyond the initial price when choosing between 304 and 316 stainless steel. The long-term value depends on where and how you use the material. Here is what you should consider:

316 stainless steel contains molybdenum, which gives it superior corrosion resistance. You see the benefits most in harsh environments, such as marine or chemical settings.

This extra resistance means you spend less on maintenance and replacements over the years, even though you pay more upfront.

304 stainless steel works well for indoor or mild environments. You save money at the start, but you may face higher costs later if the material corrodes or needs frequent repairs.

In corrosive conditions, 304 stainless steel often leads to more maintenance and replacement expenses.

316 stainless steel usually costs about 40% more than 304, but it lasts longer and needs fewer repairs in tough environments.

If you want the best long-term value in areas exposed to salt, chemicals, or moisture, you should invest in 316 stainless steel. You reduce the risk of unexpected failures and lower your total cost of ownership.

Note: For projects in harsh or unpredictable environments, the higher initial investment in 316 stainless steel often pays off. You gain peace of mind and save money over the lifespan of your equipment.

You should always start by considering the environment where you plan to use stainless steel. The presence of corrosive elements like saltwater or chlorides plays a major role in your decision. 316 stainless steel contains molybdenum, which gives it superior corrosion resistance, especially in marine or saltwater settings. If your project faces constant exposure to saltwater—such as in marine hardware or coastal construction—316 stainless steel is the recommended choice. Laboratory salt spray tests show that 316 resists corrosion much better than 304 in these conditions.

For indoor or less aggressive environments, 304 stainless steel offers good corrosion resistance and is more cost-effective. However, both grades can develop surface rust if exposed to contaminants like salt or harsh chemicals. Regular cleaning and protective coatings help maintain their integrity. The higher cost of 316 is often balanced by its longer lifespan and reduced maintenance in harsh environments.

Key points to consider:

316 stainless steel is best for marine, coastal, or chemical-rich environments.

304 stainless steel works well indoors or in mild outdoor settings.

Both grades need regular maintenance to prevent surface rust.

Tip: Always match the grade to the environment. This ensures your investment lasts longer and performs better.

You need to evaluate the specific performance requirements of your project. If you require a material that handles general-purpose tasks with low to moderate exposure to corrosive elements, 304 stainless steel is a reliable and cost-effective option. It offers good weldability and is easy to fabricate, making it suitable for kitchen equipment, architectural features, and automotive parts.

For projects that demand superior corrosion resistance—such as those in marine, medical, or chemical processing fields—316 stainless steel is the better choice. The molybdenum in 316 enhances durability and protects against pitting and crevice corrosion. If your application involves exposure to saltwater, acids, or high temperatures, you should select 316. Keep in mind that welding 316 may require specialized rods to maintain its integrity.

304 stainless steel suits general-purpose, low-corrosion projects.

316 stainless steel excels in harsh, corrosive, or high-temperature environments.

Budget constraints may influence your decision, as 316 is typically 40% to 75% more expensive than 304.

Always balance performance, longevity, and cost for the best outcome.

Proper maintenance extends the lifespan of both 304 and 316 stainless steel. You should use optimized cleaning methods with non-abrasive, non-acidic cleaners to protect the steel’s passive layer. Applying protective coatings shields the material from corrosive environments, especially in marine or high-chloride areas. Routine inspections help you catch early signs of wear or corrosion, allowing for timely repairs.

Follow these steps for best results:

Clean surfaces regularly with mild detergents to maintain appearance and prevent corrosion.

Avoid harsh cleaners that can damage the protective oxide layer.

Inspect for signs of wear, corrosion, or damage and address issues promptly.

Apply protective coatings or linings in aggressive environments.

Handle and install stainless steel carefully to avoid scratches or dents.

Use proper welding and finishing techniques to reduce corrosion risk.

Environmental conditions such as humidity, temperature changes, and exposure to chemicals can accelerate corrosion. By controlling these factors and following a consistent maintenance routine, you maximize the durability and service life of your stainless steel components.

Note: Investing in regular maintenance saves you money in the long run by reducing repairs and extending the lifespan of your equipment.

Many people believe stainless steel never rusts. You might think that any grade will resist corrosion in all environments. This is not true. Stainless steel can corrode, especially when exposed to harsh chemicals or salty conditions. The main difference between 304 and 316 stainless steel is the addition of molybdenum in 316. This element gives 316 much better corrosion resistance, especially in environments with chlorides or acids. You should not assume all stainless steels perform the same.

Myth: Stainless steel never rusts.

Myth: All stainless steel grades have equal corrosion resistance.

Fact: Proper maintenance is necessary to keep stainless steel looking and performing its best.

Note: You must match the grade to the environment. For aggressive or salty conditions, 316 is the better choice. For milder settings, 304 often works well.

You may have heard that stainless steel is always non-magnetic. This is a common misconception. Both 304 and 316 stainless steels are austenitic, so they are non-magnetic in their annealed state. However, when you bend, shape, or cold work these steels, they can become slightly magnetic. This happens because some of the structure changes during mechanical processing.

Some people worry that magnetism means the steel is fake or low quality. In reality, slight magnetism after cold working is normal and does not affect corrosion resistance or safety. The magnetism you notice is much weaker than in regular steel and often fades after heating or use.

Tip: Do not use a magnet as your only test for stainless steel quality. Magnetism does not mean the steel is unsafe or inferior.

You might think that the higher price of 316 stainless steel always means better performance. This is not always true. While 316 offers superior corrosion resistance in harsh or chloride-rich environments, 304 is often enough for milder conditions. Over-specifying 316 when 304 would work leads to unnecessary costs without real benefits.

Myth: The most expensive grade is always the best choice.

Fact: 316 costs about 20-30% more than 304 because of added molybdenum.

Fact: In less demanding environments, 304 provides good protection at a lower cost.

You should always consider where and how you will use the material. A careful cost-benefit analysis helps you choose the right grade for your needs.

Callout: Choose 316 for marine or chemical settings. For general indoor or mild outdoor use, 304 is usually the more economical and effective option.

You may find it challenging to distinguish 304 from 316 stainless steel by appearance alone. Both grades look similar, but their performance differs greatly. In the field, you can use several reliable methods to identify the correct grade:

Spot tests for molybdenum: Commercial kits or homemade solutions can detect molybdenum, which is present in 316 but not in standard 304. These tests give quick results, but they may not be foolproof if 304 steel contains recycled scrap with trace molybdenum.

Magnetic testing: Both 304 and 316 are nonmagnetic in their annealed state. Magnetic tests confirm you have stainless steel, but they cannot tell you which grade you have.

Positive Material Identification (PMI): Portable X-ray fluorescence (XRF) analyzers provide the most reliable non-destructive method. PMI devices measure the alloying elements and can confirm if molybdenum is present.

Mill Test Reports (MTRs) and Certificates: For critical projects, always review MTRs and certificates of compliance from trusted suppliers. Combine these with random PMI checks for the highest confidence.

Chemical analysis: Laboratory testing gives definitive results, but it is costly and impractical for most field applications.

Tip: For high-risk or regulated environments, always request documentation and consider random PMI checks to ensure you receive the correct stainless steel grade.

Proper care keeps your stainless steel looking new and performing well. You should follow these best practices to prevent corrosion and surface damage:

Clean surfaces regularly with warm water and a soft microfiber cloth, wiping along the grain.

For greasy spots, add a small amount of mild dish soap, then rinse and dry thoroughly with a soft towel to avoid water spots.

Avoid using steel wool, abrasive scrubbers, bleach, chlorine-based cleaners, or acidic products on polished surfaces.

Use only non-abrasive cloths, microfiber towels, and pH-neutral cleaners designed for stainless steel.

Wipe up spills or stains immediately to prevent permanent marks.

For 316 stainless steel, a vinegar and water mixture works well for regular cleaning. Never use chlorine-based cleaners, as they can cause pitting.

For 304 stainless steel, stick to mild soap or detergent with warm water.

Keep surfaces free from contact with chlorides, iron particles, and harsh chemicals.

Consider passivation treatments to remove free iron and enhance the protective oxide layer, especially in demanding environments.

Note: Consistent cleaning and gentle products help preserve the protective chromium oxide layer that gives stainless steel its corrosion resistance.

You can avoid many problems by steering clear of these frequent mistakes when working with or caring for 304 and 316 stainless steel:

Neglecting workplace safety. Always use protective gear and proper lifting techniques to prevent injuries from sharp edges or heavy sheets.

Applying excessive heat during welding. Too much heat causes discoloration, warping, and loss of corrosion resistance. Control heat input and use cooling methods.

Skipping surface preparation. Failing to clean surfaces before welding or coating leads to weak welds and corrosion. Always clean with stainless-safe products and dry thoroughly.

Using harsh chemicals for cleaning. Strong acids or bleach damage the protective layer and surface finish. Choose pH-neutral detergents and rinse well.

Allowing contaminants in the workspace. Iron particles or dust can introduce rust. Designate clean work areas and use dedicated tools for stainless steel.

️ Callout: Careful handling, regular cleaning, and the right tools protect your investment and extend the life of your stainless steel components.

You now understand the key differences between 304 and 316 stainless steel. Choose 304 for general, indoor, or mild environments. Select 316 for marine, chemical, or harsh settings. Always match your material to the environment and application. Use this checklist:

Identify exposure to salt, chemicals, or moisture.

Consider required strength and durability.

Balance cost with long-term value.

If you feel unsure, consult a materials expert to ensure the best choice for your project.

You will find that 316 stainless steel contains molybdenum, which gives it better corrosion resistance, especially in saltwater or chemical environments. 304 stainless steel does not have molybdenum and works best in less aggressive settings.

You can use 304 stainless steel outdoors in mild environments. However, in coastal or high-chloride areas, you should choose 316 stainless steel for better protection against rust and pitting.

If your application faces harsh chemicals, saltwater, or high humidity, 316 stainless steel justifies its higher price. You gain longer service life and lower maintenance costs in demanding environments.

Use a portable XRF analyzer to check for molybdenum. 316 stainless steel will show its presence, while 304 will not. Visual inspection alone cannot distinguish them.

Both grades are nonmagnetic in their annealed state. Cold working can make 304 slightly magnetic. 316 remains mostly nonmagnetic, even after forming.

You can weld both grades using standard techniques. For best results, use filler metals that match the base material. Always clean and passivate welds to maintain corrosion resistance.

You should choose 304 stainless steel for most food processing equipment. It offers excellent corrosion resistance, easy cleaning, and does not react with food. For highly acidic or salty foods, 316 may provide extra protection.

Clean regularly with mild soap and water.

Avoid abrasive pads and harsh chemicals.

Dry surfaces after cleaning to prevent water spots.

Consistent care preserves the protective oxide layer and keeps your stainless steel looking new.