close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-03 Origin: Site

In 2025, super austenitic stainless steel set new industry standards by delivering higher corrosion resistance and durability. The global stainless steel market for nuclear applications reached USD 763 million, with a projected CAGR of 6.8%. This rapid growth results from rising nuclear power capacity and stricter safety regulations. Nickel and molybdenum contents in alloys like 904L play a key role in meeting these demands. These developments immediately improve material performance and expand application possibilities. Industry professionals should consider how these changes can enhance reliability in their operations.

New 6-Mo super austenitic stainless steel grades offer better corrosion resistance and safer welding by lowering sigma phase formation.

Additive manufacturing improves strength and ductility by controlling grain structures and adding ceramic particles like titanium carbide.

Super austenitic stainless steel excels in chemical processing, nuclear power, and marine applications due to its high corrosion resistance and durability.

Advanced manufacturing techniques reduce material waste and energy use, supporting cost savings and environmental sustainability.

Incorporating nanoparticles and hybrid materials enhances hardness, wear resistance, and thermal stability for demanding conditions.

The global market for super austenitic stainless steel is growing rapidly, driven by infrastructure, energy, and automotive sectors, especially in Asia-Pacific.

Researchers use cutting-edge testing methods to better understand corrosion and mechanical properties, guiding improved alloy design.

Sustainable production practices and recyclability make super austenitic stainless steel a green choice for future industrial needs.

Researchers introduced new 6-Mo super austenitic stainless steel grades in 2025, focusing on optimizing the sigma solvus temperature. The sigma phase, a brittle intermetallic compound, can form at certain temperatures and reduce toughness. By lowering the sigma solvus temperature, engineers improved the alloy’s stability during welding and high-temperature service. This adjustment allows for safer fabrication and longer service life, especially in demanding environments.

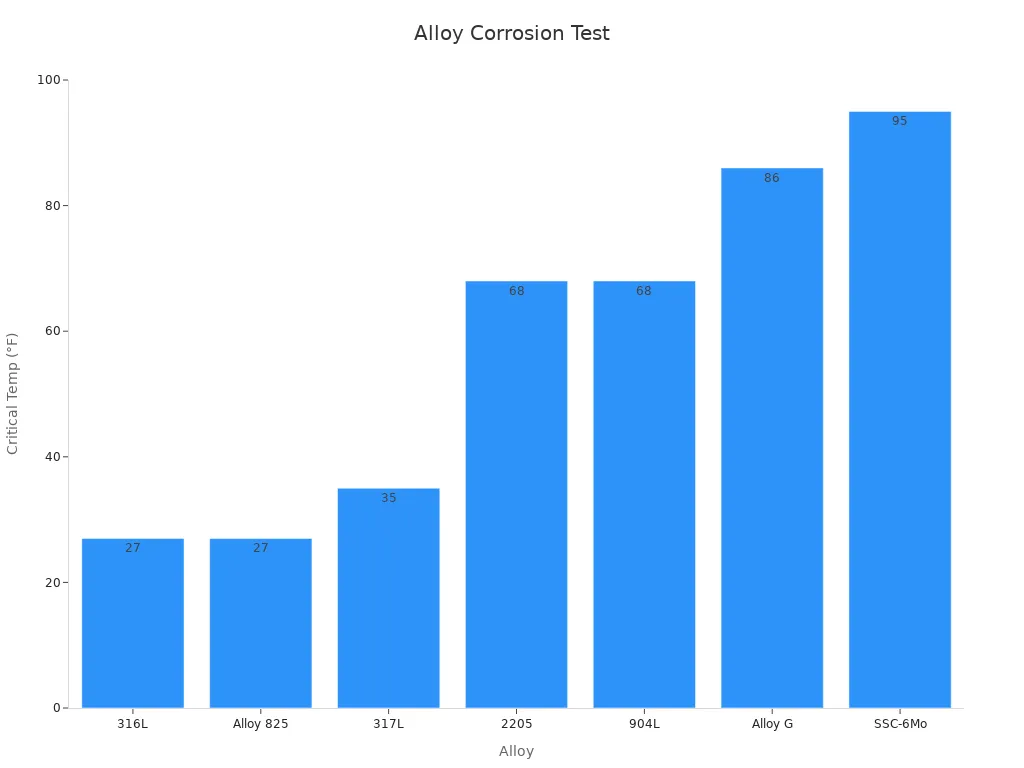

The latest 6-Mo grades demonstrate exceptional resistance to localized corrosion, such as pitting and crevice corrosion. The Critical Crevice Corrosion Temperature (CCCT) test results highlight this improvement. For example, SSC-6MO resists crevice corrosion up to 95°F (35°C), outperforming other common alloys:

| Alloy | Critical Crevice Corrosion Temp (°F) | Temp (°C) |

|---|---|---|

| 316L | 27 | -2 |

| Alloy 825 | 27 | -2 |

| 317L | 35 | 2 |

| 2205 | 68 | 20 |

| 904L | 68 | 20 |

| Alloy G | 86 | 30 |

| SSC-6Mo | 95 | 35 |

This superior performance results from a carefully balanced chemical composition. SSC-6MO contains about 6.5% molybdenum, 24% nickel, 21% chromium, and 0.22% nitrogen. These elements work together to resist chloride-induced pitting, crevice corrosion, and stress corrosion cracking. The alloy’s high Pitting Resistance Equivalent Number (PREN) confirms its advantage over standard grades. Engineers now use these new grades as cost-effective alternatives to expensive nickel-based alloys in aggressive environments.

Advances in alloy design focus on optimizing molybdenum content. Molybdenum, at around 6%, boosts resistance to localized corrosion and improves mechanical strength. High molybdenum levels, combined with nickel and chromium, help the alloy withstand harsh chemicals and high temperatures. Researchers also use thermodynamic software tools to fine-tune compositions, ensuring phase stability and minimizing the risk of sigma phase formation.

Microstructure engineering plays a key role in the performance of super austenitic stainless steel. Scientists study how different alloying elements affect grain size, phase distribution, and precipitation. For example, controlling the levels of chromium, molybdenum, and titanium helps suppress the formation of detrimental sigma phase precipitates. The result is a material with higher toughness, better weldability, and improved long-term reliability. Alumina-forming austenitic (AFA) steels, which combine ultrafine precipitate strengthening with a stable alumina scale, show promise for high-temperature applications above 600°C.

Note: Modern alloy design uses advanced modeling tools like ThermoCalc and JMatPro to predict microstructural changes and optimize properties for specific industrial needs.

Additive manufacturing, especially laser powder bed fusion (LPBF), has transformed the production of super austenitic stainless steel components. In the past, engineers struggled to balance strength and ductility. Recent breakthroughs address this challenge by manipulating grain structures and introducing special grain boundaries. Bimodal grain structures, with both coarse and fine grains, improve both strength and ductility. The addition of ceramic particles, such as titanium carbide (TiC), further refines the microstructure and enhances mechanical performance.

New processing techniques in additive manufacturing enable the direct fabrication of complex geometries with high precision. Engineers now achieve high relative density (about 99%) and control microstructural features like dislocation pile-ups and deformation nanotwins. By adjusting the stacking fault energy through alloy composition, they promote the formation of beneficial grain boundaries and nanotwins. These features distribute strain more evenly and prevent premature failure.

| Improvement Aspect | Description and Data |

|---|---|

| Additive Manufacturing Technique | Laser Powder Bed Fusion (LPBF) enables direct fabrication of complex geometries with controlled microstructures. |

| Grain Structure | Bimodal grain structures with coarse and fine austenite grains (~152 μm coarse grains observed). |

| Grain Boundary Engineering (GBE) | Introduction of special grain boundaries (e.g., Σ3 twin boundaries) and nanotwins to enhance ductility and strength. |

| Ceramic Particle Reinforcement | Addition of micron-sized TiC particles and in-situ nanoparticles to refine grains and strengthen matrix. |

| Microstructural Observations | High relative density (~99%), dislocation pile-ups at sub-grain boundaries, deformation nanotwins. |

| Mechanisms for Strength-Ductility | Enhanced dislocation behavior, heterogeneous deformation induced (HDI) strengthening, improved strain distribution. |

| Stacking Fault Energy (SFE) | Manipulation of SFE via alloy composition (Ni and N content) to promote GBE and nanotwin formation. |

These improvements allow manufacturers to produce parts with tailored properties for demanding applications. The synergy between advanced alloy design and additive manufacturing opens new possibilities for super austenitic stainless steel in industries that require both high strength and excellent corrosion resistance.

Recent industry reports highlight several trends:

Advancements in alloy compositions for better corrosion resistance and mechanical strength.

Adoption of additive manufacturing for complex, high-performance parts.

Sustainable practices and increased traceability in production.

Development of new grades like 6Mo super austenitic stainless steel with superior properties.

Active R&D and strategic expansions by leading industry players.

Chemical plants rely on advanced materials to manage aggressive acids and corrosive solutions. Super austenitic stainless steel offers outstanding resistance to pitting and crevice corrosion, especially in environments containing chlorides and strong acids. The addition of molybdenum increases corrosion resistance in both acids and chloride solutions, making these alloys ideal for acid handling systems. Titanium and niobium further enhance resistance to intergranular attack, which helps maintain the integrity of process vessels and pipework.

Extensive laboratory testing and decades of plant experience have established predictable corrosion rates for these alloys. Specialized grades, such as NAG 18/10, perform exceptionally well in nitric acid environments, supporting their use in process vessels and piping where high corrosion resistance and ease of decontamination are essential.

High-temperature chemical processes demand materials that can withstand both heat and corrosive attack. Stabilized grades containing titanium or niobium improve creep resistance and maintain strength at elevated temperatures. Low carbon variants, such as 304L and 316L, offer better weldability and reduced risk of weld decay. These features support the fabrication of complex equipment for chemical processing.

Molybdenum-rich alloys deliver reliable performance in high-temperature acid systems.

Austenitic stainless steels can be welded easily using inert gas welding, which simplifies the construction of large reactors and heat exchangers.

Nuclear reactors require materials with high strength, corrosion resistance, and predictable performance under radiation. Super austenitic stainless steel meets these demands, providing durability for reactor internals and structural supports. The alloy’s resistance to stress corrosion cracking ensures long-term reliability in the harsh environment of a reactor core.

Cooling water systems in nuclear plants face constant exposure to chlorides and fluctuating temperatures. The superior corrosion resistance of these alloys prevents pitting and crevice corrosion, reducing maintenance needs and extending service life.

Operators choose these materials for their proven track record in resisting corrosion and maintaining mechanical properties over decades of use.

Offshore oil and gas platforms operate in some of the world’s most aggressive environments. Super austenitic stainless steel provides the necessary combination of strength and corrosion resistance for critical components.

Duplex stainless steel welds, such as E2209, show higher tensile and impact strength compared to austenitic welds.

These welds also exhibit superior pitting corrosion resistance, confirmed by laboratory analysis.

Renewable energy systems, including offshore wind turbines and tidal generators, require materials that can withstand saltwater exposure and mechanical stress.

Welds made with duplex fillers demonstrate higher hardness and better corrosion resistance, supporting the use of these alloys in marine renewable energy structures.

The combination of strength, ductility, and corrosion resistance ensures long-term performance in demanding marine environments.

Market surveys show increasing demand for these alloys in traditional sectors like petrochemical and energy, as well as emerging fields such as automotive and aerospace. Growth is driven by stricter environmental regulations, government incentives, and technological advancements, especially in the Asia-Pacific region.

Manufacturers have made significant progress in substrate integration for super austenitic stainless steel. They now use advanced joining and cladding techniques to bond stainless steel directly to less expensive substrates. This approach reduces the amount of high-alloy material required for each component. As a result, companies see a sharp drop in material waste during fabrication.

Engineers use precision laser cladding and roll bonding to apply thin, uniform layers of super austenitic stainless steel.

Automated cutting and forming systems help minimize offcuts and scrap.

Factories recover and recycle unused alloy, supporting a circular economy.

By focusing on efficient substrate integration, the industry achieves both cost savings and environmental benefits. Stainless steel’s 100% recyclability ensures that even production scrap returns to the supply chain without loss of performance.

Process optimization has become a top priority for stainless steel producers. They add stabilizing elements like niobium to prevent unwanted phase changes during hot rolling. This adjustment shortens annealing times and lowers the energy needed for heat treatment. Plants that adopt these methods report reduced carbon footprints and improved energy efficiency.

The Global Efficiency Intelligence report (April 2022) highlights the steel industry’s need for technological development to cut greenhouse gas emissions. By refining production routes and using advanced alloy design, manufacturers lower emissions and promote sustainability.

Companies now focus on total cost of ownership (TCO) instead of just upfront costs. They select higher-strength, cost-effective grades that offer long-term savings and better performance in demanding environments.

The integration of silicon carbide (SiC) nanoparticles into super austenitic stainless steel marks a major leap in composite technology. These nanoparticles act as strong reinforcements within the metal matrix. They improve hardness, wear resistance, and thermal stability.

SiC nanoparticles distribute evenly throughout the alloy, blocking dislocation movement and increasing strength.

The composite resists deformation under high loads, making it ideal for components exposed to extreme stress.

Researchers continue to refine dispersion techniques to ensure consistent properties across large-scale production.

Hybrid materials combine super austenitic stainless steel with other advanced phases or reinforcements. This strategy creates alloys with tailored properties for specific applications.

Engineers blend ceramic particles, metallic fibers, or even graphene into the steel matrix.

These hybrids deliver a balance of toughness, corrosion resistance, and lightweight performance.

Hybrid composites open new possibilities for marine, energy, and chemical processing sectors. They extend the service life of critical components and reduce maintenance needs.

Manufacturers who adopt these advances position themselves at the forefront of innovation, meeting both performance and sustainability goals in 2025 and beyond.

The super austenitic stainless steel market continues to show strong growth in 2025. Market analysts project a compound annual growth rate (CAGR) between 6.0% and 6.7% through 2030. Revenues are expected to rise from about USD 110-117 billion in the early 2020s to nearly USD 197 billion by 2030. This expansion reflects robust investments in real estate, infrastructure, automotive, and consumer goods. Government subsidies and supportive policies further drive this upward trend.

| Metric/Segment | Value/Projection |

|---|---|

| Market Size (2022) | USD 110.48 billion |

| Market Size (2023) | USD 117.63 billion |

| Market Size (2030, projected) | USD 197.29 billion |

| CAGR (2024-2030) | 6.7% |

| Asia Pacific Market Share (2023) | Over 68% |

| Duplex Stainless Steel CAGR | 8.5% |

| Flat Products Revenue Share (2023) | Over 73% |

| 300 Series Segment Share (2023) | Over 59% |

| Consumer Goods Segment Share (2023) | Over 37% |

Asia Pacific leads the global market, holding more than 68% share in 2023. Heavy investments in construction and infrastructure, especially in China and India, fuel this dominance. The market also benefits from the recovery of construction and manufacturing activities after the COVID-19 pandemic. Analysts expect continued growth as urbanization and industrialization accelerate worldwide.

Note: The duplex stainless steel segment shows the highest CAGR, signaling new opportunities for advanced grades in demanding applications.

Several factors drive the adoption of super austenitic stainless steel across industries:

Flat stainless steel products remain essential in automotive, construction, and industrial equipment due to their strength and corrosion resistance.

The 300 Series grades are widely used in food processing, medical devices, and chemical equipment for their formability and resistance to harsh environments.

Infrastructure growth in Asia-Pacific, aerospace and automotive demand in North America, and advanced manufacturing in Germany and Japan all contribute to rising consumption.

The automotive sector, especially electric vehicles, increases demand for lightweight, high-strength stainless steel components that improve fuel efficiency and emissions compliance.

Government infrastructure projects in developing countries boost the need for durable, high-performance materials.

Technological advancements play a key role in shaping market trends:

Manufacturers adopt additive manufacturing (3D printing) to produce complex, precise stainless steel parts with less waste, benefiting medical and aerospace sectors.

New lightweight, high-strength alloys enhance performance in automotive and aeronautical applications.

Artificial intelligence improves process optimization, quality control, and predictive maintenance in steel production.

Companies focus on sustainable and green steel production, using recycled feedstock and energy-efficient processes to meet environmental regulations.

Strategic growth opportunities arise in electric vehicles, renewable energy, healthcare equipment, aerospace, and high-speed rail systems.

The market’s positive outlook for 2025 and beyond reflects a combination of industrial demand, technological innovation, and sustainability efforts. These trends position super austenitic stainless steel as a material of choice for the next generation of high-performance applications.

Researchers use advanced techniques to understand how new alloys resist corrosion. Auger Electron Spectroscopy (AES) and Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) help scientists examine the surface of metals at the nanoscale. These methods reveal how protective films form and how corrosion products develop over time. X-ray Absorption Spectroscopy (XAS) and Rutherford Backscattering Spectroscopy (RBS) provide information about the chemical state and thickness of surface layers. These insights help engineers design super austenitic stainless steel with better resistance to harsh environments.

| Technique | Key Insights | Application to Corrosion and Mechanical Properties |

|---|---|---|

| AES | Elemental and chemical state info up to ~5 nm depth | Studies corrosion product formation, film failure, and inhibitor adsorption |

| ToF-SIMS | High sensitivity for surface composition | Detects trace elements and profiles corrosion films and inhibitors |

| XAS | Element-specific, oxidation state, and local structure analysis | Identifies phases and studies corrosion mechanisms |

| RBS | Depth profiling and film thickness measurement | Analyzes corrosion mechanisms with depth-resolved data |

| XPEEM | Submicrometer imaging and chemical mapping | Examines phase transformations and surface chemistry |

| LEED | Crystallographic and phase identification | Studies multiphase formation and protective coatings |

| SANS/NR | Nanoscale surface morphology and inhibitor adsorption | Investigates inhibitor films and nanostructural changes |

Scientists often combine these techniques to gain a complete picture of corrosion processes. This approach helps them overcome the limits of individual methods and leads to a deeper understanding of how protective layers work.

Mechanical analysis remains essential for evaluating new stainless steel grades. Researchers use tensile testing, hardness measurements, and impact tests to measure strength and ductility. Small-Angle Neutron Scattering (SANS) and Neutron Reflectometry (NR) allow scientists to study the nanoscale structure of alloys. These tools reveal how grain size, phase distribution, and nanoparticle additions affect mechanical performance. By linking microstructure to properties, engineers can develop alloys that meet strict industry standards.

In 2025, several journals released special issues focused on advanced stainless steels. Topics included corrosion resistance, additive manufacturing, and sustainable production. These publications highlighted new findings on alloy design and the use of multi-technique characterization. Many articles featured case studies on super austenitic stainless steel in chemical and energy sectors.

Journals such as Corrosion Science and Materials Characterization published reviews on the latest testing methods.

Special issues often included open-access datasets, helping researchers compare results and accelerate innovation.

Influential studies in 2025 explored the relationship between microstructure and performance. Researchers published work on the effects of molybdenum and nitrogen additions, as well as the benefits of hybrid materials. Many teams shared data on corrosion testing using AES, ToF-SIMS, and XAS. These studies provided clear guidelines for selecting alloys in aggressive environments.

The growing body of research supports the continued development of super austenitic stainless steel for demanding applications. Industry professionals rely on these findings to guide material selection and process improvements.

Manufacturers now prioritize green manufacturing in super austenitic stainless steel production. They adopt advanced machining techniques that reduce environmental impact and improve workplace safety. For example, minimum quantity lubrication (MQL) has emerged as a leading method. MQL uses a small amount of lubricant, which lowers cutting force, reduces tool wear, and keeps temperatures down during machining. This approach not only improves surface quality but also supports cleaner production. Studies show that MQL offers clear environmental and health benefits compared to traditional methods like dry or flooded machining. Researchers use frameworks such as the Pugh matrix environmental approach to assess sustainability, confirming that MQL stands out as the most sustainable option.

Sustainable manufacturing practices extend beyond machining. Companies implement dry machining, cryogenic cooling, and nano cutting fluids to further reduce waste and energy use. They focus on key sustainability metrics, including energy consumption, waste reduction, worker safety, and cost efficiency. Cleaner production methods and lean manufacturing strategies help achieve net-zero emissions. By combining green and lean approaches, manufacturers minimize resource use and cut costs. These efforts not only protect the environment but also improve the bottom line.

Sustainable manufacturing rules emphasize minimal energy and material use, recycling, cleaner production, and reinvestment in renewable resources. Companies that follow these principles see better environmental performance and lower manufacturing costs.

Super austenitic stainless steel offers excellent recyclability. The material retains its properties even after multiple recycling cycles. Factories recover and reuse production scrap, which supports a circular economy. This practice reduces the need for raw materials and lowers the carbon footprint of the industry. Recyclability also aligns with global efforts to promote sustainable resource management. As demand for high-performance alloys grows, the ability to recycle and reuse materials becomes even more important.

Scaling up the production of super austenitic stainless steel presents several technical challenges. Different additive manufacturing processes, such as powder bed fusion and directed energy deposition, create diverse microstructures. These variations affect both mechanical strength and corrosion resistance. Powder feedstocks often contain higher levels of oxygen and nitrogen than traditional wrought materials. Elevated gas content can lead to defects like solidification cracking and oxide inclusions. These defects introduce uncertainty in performance, especially under extreme conditions.

The complexity of alloy composition, heat input, and energy source further complicates manufacturing. Existing tools, such as Schaeffler diagrams, help predict microstructure but offer limited guidance for large-scale production. Manufacturers must carefully control process parameters to ensure consistent quality.

Market barriers also impact the widespread adoption of super austenitic stainless steel. Variability in microstructure and defect rates leads to inconsistent product performance. This inconsistency makes it difficult for manufacturers to guarantee the reliability required in critical applications. The lack of explicit quantitative production metrics, such as yield and defect rates, adds to the challenge. Companies must invest in advanced quality control and process optimization to overcome these obstacles. As the industry continues to innovate, addressing these barriers will be key to unlocking the full potential of super austenitic stainless steel in global markets.

The 2025 breakthroughs in super austenitic stainless steel have reshaped industry standards and performance.

| Aspect | Summary |

|---|---|

| Technological Innovations | Additive manufacturing and digital solutions drive efficiency and product quality. |

| Regulatory and Trade Policy Impact | New tariffs and policies influence procurement and supply chain strategies. |

| Sustainability Practices | Closed-loop recycling and low-emission processes support environmental goals. |

| Market Segmentation | Industry-specific needs guide material selection and application. |

| Industry Impact | These factors shape investment and operational decisions. |

Professionals can leverage these advancements by adopting digital tools, investing in sustainable practices, and aligning with evolving market needs.

Future R&D will focus on digital transformation, advanced manufacturing, and sustainability.

Collaboration and scenario planning will guide innovation in sectors like green hydrogen and carbon capture.

Ongoing research promises even greater opportunities for growth and resilience.

Super austenitic stainless steel contains higher levels of nickel, chromium, and molybdenum. These elements give it superior corrosion resistance and strength. Engineers use it in environments where standard stainless steel would fail.

Molybdenum increases resistance to pitting and crevice corrosion. It also improves strength at high temperatures. Alloys with about 6% molybdenum perform well in harsh chemical and marine environments.

Yes, manufacturers can recycle this material multiple times without losing its properties. Recycling helps reduce raw material use and supports sustainability goals.

Additive manufacturing allows precise control over microstructure. It enables the production of complex shapes with high strength and ductility. This process reduces waste and shortens lead times.

Industries use it in chemical processing, nuclear power, and marine applications. It performs well in acid handling, reactor components, and offshore structures.

Producers must control microstructure and defect rates. Variations in powder quality and process parameters can affect performance. Advanced quality control helps ensure consistent results.

Scientists use advanced techniques like Auger Electron Spectroscopy and X-ray Absorption Spectroscopy. These methods reveal surface chemistry and help engineers design better alloys.

Rising demand in energy, infrastructure, and transportation

Advances in alloy design and manufacturing

Focus on sustainability and recyclability

These trends push adoption in both established and emerging sectors.