close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

Choosing the right material matters, whether someone picks a kitchen sink or a surgical tool. Austenitic stainless steel alloys offer strong corrosion resistance, easy shaping, and clean surfaces. These alloys make up about 70% of all stainless steel produced worldwide because people trust them for durability and hygiene. Many use austenitic stainless steel in food processing, medical devices, and even building designs. Still, every material brings advantages and disadvantages. Readers should think about their own needs before deciding if austenitic stainless steel fits their project.

Austenitic stainless steel stands out for its excellent corrosion resistance properties. This makes it a top choice for environments where moisture or chemicals are present. The high chromium and nickel content in austenitic stainless steel helps form a thin, protective layer on the surface. This process, called passivation, shields the metal from rust and other forms of corrosion.

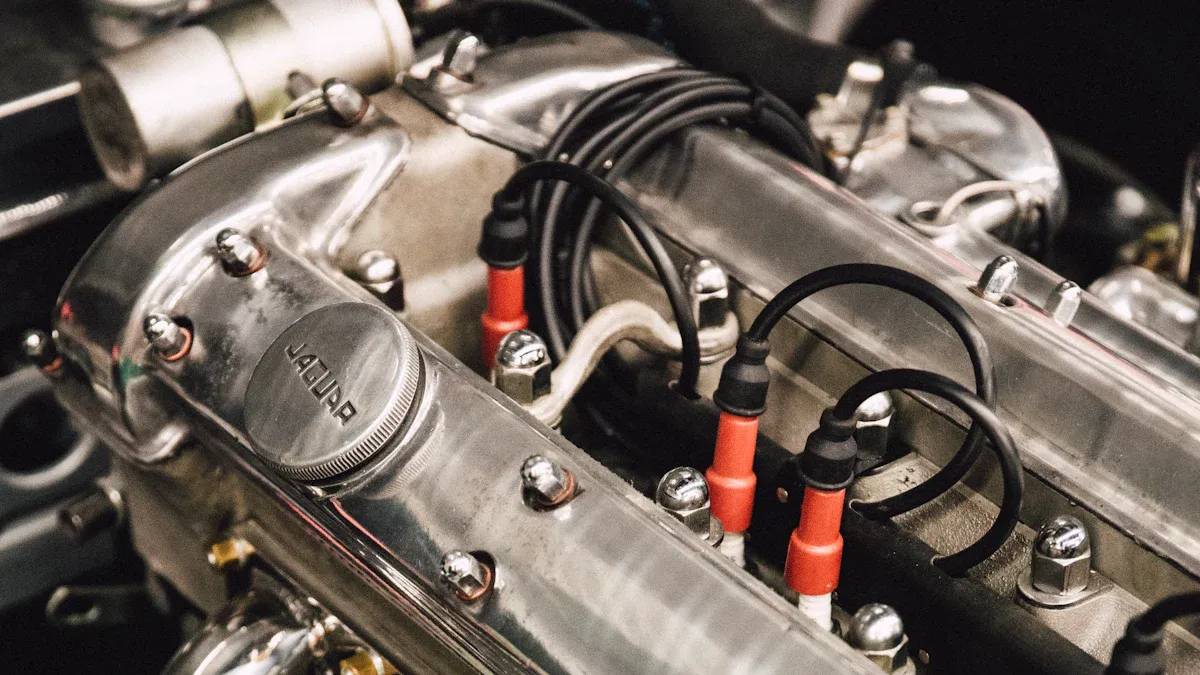

Many people use austenitic stainless steel in kitchens, bathrooms, and outdoor settings because it resists rust even when exposed to water. For example, a kitchen sink made from 304 stainless steel will not stain or corrode easily, even with daily contact with water. The passivation layer quickly reforms if scratched, keeping the surface protected.

Austenitic stainless steel also performs well in environments with oxidizing chemicals, such as cleaning agents or acidic foods. The chromium in the alloy reacts with oxygen to maintain the protective layer, which prevents damage from harsh substances. This makes it ideal for food processing equipment and medical tools that need to stay clean and rust-free.

Tip: The corrosion resistance of austenitic stainless steel depends on its grade. For example, 316L offers better resistance than 304, especially in salty or chemical-rich environments.

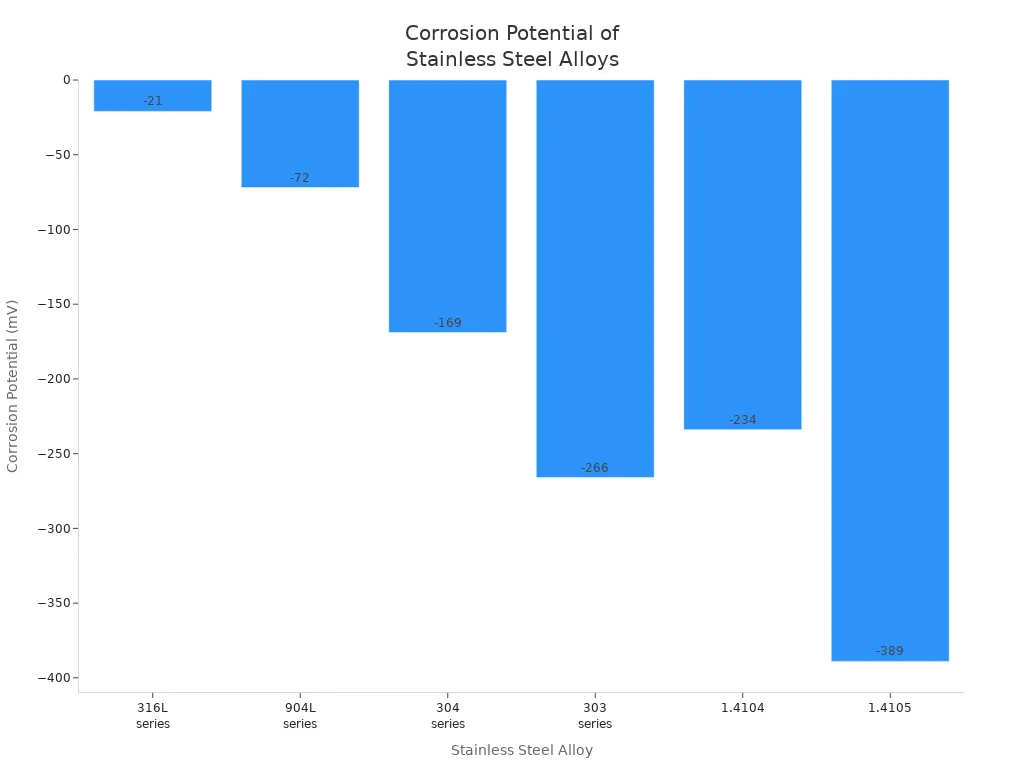

Below is a table comparing the corrosion potential of different stainless steel alloys in artificial sweat. Less negative values mean better corrosion resistance.

| Stainless Steel Alloy | Corrosion Potential (Ecorr, mV) in Artificial Sweat |

|---|---|

| 316L series | Approximately -21 mV (higher corrosion resistance) |

| 904L series | Approximately -72 mV (better corrosion resistance than many others) |

| 304 series | Approximately -169 mV |

| 303 series | Approximately -266 mV |

| 1.4104 | Approximately -234 mV |

| 1.4105 | Approximately -389 mV (lower corrosion resistance) |

Austenitic stainless steel alloys like 316L and 904L show higher corrosion resistance properties compared to other types. The combination of chemical composition, manufacturing, and heat treatment can affect the overall resistance and nickel release. Localized corrosion, such as pitting or crevice corrosion, may still occur in very harsh conditions, but most everyday uses benefit from the strong resistance of austenitic stainless steel.

Austenitic stainless steel is known for its high formability. Manufacturers can easily shape and bend it into complex forms without cracking or breaking. This makes it a popular choice for products that require detailed designs or smooth curves.

Austenitic stainless steel can be pressed, rolled, or drawn into many shapes. For example, companies use it to make deep sinks, curved railings, and intricate kitchen utensils. The high nickel content gives the alloy its flexibility and allows for easy fabrication.

Workers can bend austenitic stainless steel without much risk of fracture. This property is especially useful in construction and manufacturing, where parts often need to fit together precisely. The alloy’s structure allows it to handle repeated bending and forming.

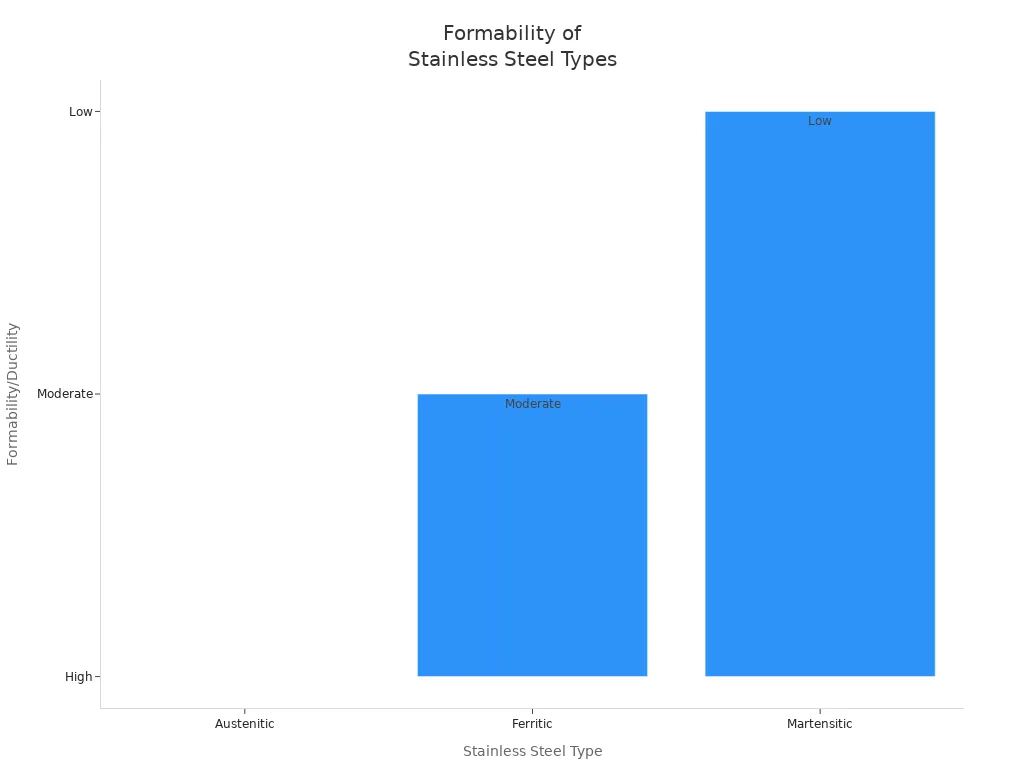

The table below shows how austenitic stainless steel compares to ferritic and martensitic types in terms of formability:

| Stainless Steel Type | Ductility/Formability |

|---|---|

| Austenitic | High - easy to form and fabricate |

| Ferritic | Moderate - less formable than austenitic |

| Martensitic | Low - can be brittle if over-hardened |

Austenitic stainless steel stands out for its ability to be formed into many shapes, making it the preferred material for items that require both strength and flexibility.

Austenitic stainless steel offers excellent weldability, which means workers can join pieces together using common welding methods. This property supports its use in construction, manufacturing, and repair work.

Welders often use methods like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding to join austenitic stainless steel. These methods create strong, clean welds that maintain the corrosion resistance properties of the base metal. The presence of a small amount of delta ferrite in common grades like 304 and 316 helps prevent hot cracking during welding.

Common welding methods for austenitic stainless steel:

Gas Metal Arc Welding (GMAW)

Shielded Metal Arc Welding (SMAW)

TIG welding (including pulsed current and activated flux TIG)

Laser welding

Friction stir welding

While austenitic stainless steel is easy to weld, some care is needed. The alloy’s low thermal conductivity means welders must control heat input to avoid distortion. Impurities like sulfur and phosphorus can cause hot cracking, but using the right filler metals and shielding gases helps prevent this. Welded joints usually show good strength and ductility, with only a slight reduction in fatigue life compared to the base metal.

Note: Proper welding techniques and filler materials help maintain the corrosion resistance and mechanical properties of austenitic stainless steel, making it reliable for demanding applications.

Austenitic stainless steel stands out for its impressive mechanical strength and toughness. These properties make it a reliable choice for many demanding applications, from kitchen equipment to structural supports.

Tensile strength measures how much force a material can handle before it breaks. Austenitic stainless steel, especially grades like 304 and 316, offers high tensile strength. This means it can support heavy loads and resist breaking under tension. The following tables show the typical tensile strength and elongation values for common austenitic stainless steel grades:

| Category | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| 316 Bar & Section | 500 - 700 | 40 min |

| 316 Sheet | 530 - 680 | 40 min |

| 316 Plate | 520 - 670 | 45 min |

| Grade | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|

| 304 | 500 - 700 | 45 min |

| 316 | 400 - 620 | 45 min |

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Ultimate Tensile Strength (psi) | ~73,200 | ~79,800 |

| Elongation at Break (%) | 70 | 60 |

Both 304 and 316 grades show tensile strength values ranging from about 515 to 700 MPa. The high nickel and chromium content in austenitic stainless steel helps maintain this strength even after shaping or welding.

Durability refers to how well a material withstands wear, pressure, or damage over time. Austenitic stainless steel keeps its strength and toughness in a wide range of temperatures. It resists cracking and breaking, even when bent or stretched. Compared to low-carbon steel, austenitic stainless steel has higher strength and hardness. High-carbon steel can be stronger, but it is often more brittle and less tough. Austenitic stainless steel alloys balance strength and toughness, making them less likely to fail suddenly.

| Steel Type | Carbon Content (%) | Strength and Toughness Characteristics |

|---|---|---|

| Low Carbon Steel | Up to 0.3 | Lower strength and hardness, high ductility and toughness |

| Medium Carbon Steel | 0.3 to 0.6 | Medium strength, ductility, and toughness |

| High Carbon Steel | 0.6 to 2.0 | High strength and hardness, but lower ductility and toughness (more brittle) |

Austenitic stainless steel’s toughness comes from its ductility, which allows it to bend without breaking. This property is important for products that face impacts or need to last for many years.

Note: The combination of mechanical strength and toughness in austenitic stainless steel makes it a top choice for applications that demand both reliability and long service life.

Austenitic stainless steel is generally non-magnetic. This unique property sets it apart from other types of stainless steel, such as ferritic and martensitic grades.

Many electronic devices require materials that do not interfere with magnetic fields. Austenitic stainless steel has a magnetic permeability close to 1.0, which means it does not attract magnets or disrupt sensitive equipment. This feature makes it ideal for use in electronic housings, connectors, and scientific instruments.

The non-magnetic nature of austenitic stainless steel proves valuable in several industries:

Medical devices and implants, including MRI-compatible tools and surgical instruments, rely on non-magnetic materials for safety.

Electronic equipment and precision instruments need minimal magnetic interference.

Food and beverage processing equipment benefits from both corrosion resistance and non-magnetic properties.

Marine and coastal applications use austenitic stainless steel to avoid interference with navigational devices.

Chemical processing plants choose non-magnetic alloys to prevent equipment malfunctions.

Austenitic stainless steel alloys maintain their non-magnetic state unless altered by cold working or phase changes. Nitrogen-bearing and high-nickel grades show the lowest magnetic permeability.

Austenitic stainless steel is well-known for its hygienic qualities. Its smooth surface and resistance to corrosion make it easy to clean and sanitize.

The non-porous surface of austenitic stainless steel prevents bacteria and dirt from sticking. Cleaning crews can easily wipe down surfaces, reducing the risk of contamination. Surface treatments like electropolishing further improve cleanability and help prevent bacterial growth.

Food and medical industries trust austenitic stainless steel for its safety and cleanliness. Several standards and certifications support its use:

The FDA requires stainless steel used in food contact surfaces to contain at least 16% chromium for corrosion resistance and safety.

NSF certification ensures that food equipment meets strict hygiene and environmental health standards.

ASTM and ANSI provide guidelines for material quality and sanitation in food handling and medical equipment.

Grades 304 and 316 are the most common choices, offering excellent corrosion resistance and biocompatibility.

Austenitic stainless steel is non-toxic and safe for implants and surgical tools.

Tip: The high chromium and nickel content in austenitic stainless steel alloys ensures both mechanical strength and hygiene, making them ideal for environments where cleanliness is critical.

Austenitic stainless steel contains high amounts of nickel and chromium. These alloying elements give the material its famous corrosion resistance and help form the passivation layer. However, nickel is the most expensive part of the alloy. Chromium, added as ferrochrome, is also costly and essential for stainless steel production. The need for these elements increases the price of austenitic stainless steel compared to other types. Manufacturers must use more nickel and chromium to achieve the desired resistance and passivation, which raises the overall cost.

The price of austenitic stainless steel changes with the market prices of nickel and chromium. Nickel prices can swing wildly, sometimes jumping from $25,000 per ton to over $100,000 per ton in a single day. Chromium prices have also risen by more than 50% in recent years due to energy costs and supply issues. When these prices change, steel producers adjust alloy surcharges, which are extra fees added to cover raw material costs. These surcharges pass the cost changes directly to customers. As a result, the final price of austenitic stainless steel can rise or fall quickly, making budgeting difficult for large projects.

Note: Alloy surcharges help stabilize prices, but buyers still feel the impact of sudden changes in nickel and chromium costs.

Austenitic stainless steel shows strong general corrosion resistance, but it can suffer from stress corrosion cracking (SCC) in certain conditions. SCC happens when the metal faces both tensile stress and a corrosive environment, especially one with chloride ions. Common sources of chloride include seawater, road salt, and some industrial cleaners. Marine environments, steam systems, and chemical plants with chloride-rich solutions present the highest risk for SCC. Grades like 304, 316, and 321 are more likely to crack in these settings.

Main causes of SCC in austenitic stainless steel:

Chloride exposure from seawater, salt, and cleaning agents

Residual or applied tensile stresses from welding or bending

High temperatures above 60°C (140°F) and high humidity

Chemical processing plants often use austenitic stainless steel for its corrosion resistance, but certain chemicals increase the risk of SCC. Chloride-containing agents and hydrogen sulfide can break down the passivation layer, making the alloy more vulnerable. High humidity and thermal cycling also speed up crack formation. Residual stresses from fabrication, such as welding or machining, make SCC more likely. Duplex stainless steels resist SCC better than austenitic grades because of their mixed structure and special alloying elements.

Tip: For harsh marine or chemical environments, duplex stainless steel may offer better protection against SCC than austenitic grades.

Austenitic stainless steel, including grades 304 and 316, has a typical hardness of 70 to 90 HRB in its annealed state. This makes it softer and more ductile than martensitic or ferritic stainless steels. The lower hardness means austenitic stainless steel does not resist abrasion and surface wear as well. In environments where parts rub or scrape against each other, this alloy wears down faster. The material cannot be hardened by heat treatment, only by cold working, which limits its use in high-wear applications.

Scientific studies confirm that austenitic stainless steel offers excellent corrosion resistance but lower yield strength and hardness. This leads to higher wear rates compared to harder stainless steel types. For applications where wear resistance is critical, martensitic grades provide better performance.

Austenitic stainless steel is not recommended for cutting tool applications. The alloy is tough and gummy, which causes it to work harden quickly during machining. This rapid hardening increases resistance to deformation and makes the material harder to cut. The low thermal conductivity of austenitic stainless steel causes heat to build up at the cutting edge, leading to tool wear and shorter tool life. Chips formed during machining are long and sticky, making chip control difficult and increasing the risk of damaging the tool.

Reasons austenitic stainless steel is not ideal for cutting tools:

Rapid work hardening during machining

Low thermal conductivity causes heat buildup

Long, gummy chips make chip control hard

High tool wear and short tool life

Ductility causes the material to stick to cutting tools

Specialized tools, coatings, and aggressive cutting parameters can help, but most machinists prefer martensitic or ferritic stainless steel for cutting tools. Austenitic stainless steel works best in applications where corrosion resistance and formability matter more than wear resistance or machinability.

Austenitic stainless steel alloys expand more than many other metals when heated. This property, called the coefficient of thermal expansion (CTE), measures how much a material grows in size as temperature increases. The CTE for austenitic stainless steels ranges from 16.2 to 18.4 (10^-6 in./in./°C), which is higher than many other stainless steel types.

| Stainless Steel Type | CTE Range (10^-6 in./in./°C) | CTE Range (10^-6 in./in./°F) |

|---|---|---|

| Austenitic Stainless Steels | 16.2 to 18.4 | 9.0 to 10.2 |

| Cast Stainless Steels | 11.5 to 18.7 | 6.4 to 10.4 |

High thermal expansion means austenitic stainless steel can warp or distort when exposed to heat. This issue often appears during welding or in environments with rapid temperature changes. For example, when welders join austenitic stainless steel to carbon steel, the difference in expansion rates can cause stress at the joint. This stress may lead to cracks or misalignment.

Distortion during welding is common because the metal expands and contracts more than other types.

Post-weld heat treatment (PWHT) is sometimes needed to relieve these stresses, but this process can lower corrosion resistance.

Builders often use special grades like 304-L or 347-L to reduce the risk of cracking and warping.

Thermal shock, which happens when the metal heats up or cools down quickly, can also damage austenitic stainless steel. The mismatch between the steel and its protective oxide layer causes the layer to peel off, speeding up corrosion and reducing the metal’s lifespan.

Tip: To manage warping, engineers may use buttering layers or select stabilized grades that handle thermal stress better.

Austenitic stainless steel can handle moderate heat, but its high thermal expansion limits its use in very high-temperature settings. When exposed to repeated heating and cooling, the metal can lose its shape and strength. This problem affects parts in furnaces, exhaust systems, and other equipment that faces extreme temperature swings.

High thermal expansion leads to increased thermal stresses, which can cause spallation (flaking) of protective layers.

These stresses reduce the mechanical stability of the metal during thermal cycling.

In high-temperature construction, engineers must consider these limits to avoid failures.

Scientific studies show that vanadium-base alloys expand much less than austenitic stainless steels. This difference means austenitic stainless steel faces higher thermal stresses and degrades faster under thermal shock conditions.

Note: For applications with frequent or extreme temperature changes, other materials with lower thermal expansion may perform better.

Austenitic stainless steel is known for its tendency to work harden. Work hardening happens when the metal becomes harder and stronger as it is deformed, such as during machining or forming. While this property can improve strength, it also creates challenges in manufacturing.

Machining austenitic stainless steel is more difficult than machining many other metals. As the cutting tool moves through the metal, the surface hardens quickly. This hard layer increases resistance, making it tougher for the tool to cut through.

Work hardening raises the hardness and strength of the surface, but lowers ductility.

The process produces tough, long chips that are hard to break and remove.

Notch wear and built-up edge (BUE) form on cutting tools, causing rapid tool wear and poor surface finish.

Relative machinability is about 60% compared to easier metals like low alloy steels or copper.

Manufacturers often need to use sharp cutting tools with positive rake angles and wear-resistant coatings. They must also control cutting speeds and feed rates to avoid excessive heat and stress. High-pressure coolant helps remove heat and improve chip removal.

Tip: Machinists should use constant cutting depths and avoid light rubbing cuts to minimize work hardening.

Drilling holes in austenitic stainless steel presents similar challenges. The metal hardens around the drill bit, increasing friction and heat. This effect can cause the drill to dull quickly or even break.

Drilling generates significant heat, which speeds up work hardening.

Chips become long and sticky, making them hard to clear from the hole.

Frequent tool changes and careful monitoring are necessary to maintain quality.

To improve drilling results, machinists use rigid setups, sharp drill bits, and effective cooling. Some grades include added sulfur to help with machinability, but this can lower corrosion resistance.

Note: Work hardening makes austenitic stainless steel less suitable for projects that require extensive machining or drilling. Proper techniques and tools can help, but planning is essential for success.

Austenitic stainless steel plays a major role in the food industry. Many food processing plants and kitchens rely on this material for equipment and surfaces. The main reason is its excellent corrosion resistance. This property comes from the high chromium and nickel content, which helps prevent rust and keeps surfaces clean. Grade 316 is often used for food preparation appliances because it resists chemicals found in food and cleaning agents. Some equipment uses lower nickel grades with added manganese for cost savings, while molybdenum improves resistance to pitting in salty or acidic foods.

Common uses in the food industry include:

Cookware and kitchenware

Cutlery and utensils

Kitchen sinks and countertops

Refrigerators, dishwashers, and ovens

Mixing bowls and measuring cups

Austenitic stainless steel provides hygienic surfaces that do not react with food. This makes cleaning easy and helps prevent contamination. The durability of these alloys means equipment lasts longer, even with frequent washing and exposure to harsh conditions. Food processing machinery often uses grades 304 and 316 because they combine corrosion resistance with non-reactivity, making them ideal for safe food handling.

Hospitals and clinics depend on austenitic stainless steel for many medical devices. This material offers a unique combination of strength, cleanliness, and safety. Grades like AISI 316L are common in implants and surgical tools. The chromium in the alloy forms a self-healing oxide layer, which stops micro cracks and blocks bacteria from growing. This helps keep medical environments sterile.

Austenitic stainless steel stands out for its formability. Manufacturers can shape it into complex medical devices and fixtures. The hard surface resists scratches and stains, keeping tools looking new and easy to disinfect. These alloys also handle impacts well, which is important for demanding healthcare settings. Some newer grades use high nitrogen and less nickel to reduce the risk of allergic reactions and improve corrosion resistance in body fluids. The non-porous surface makes cleaning easier and supports strict hygiene standards.

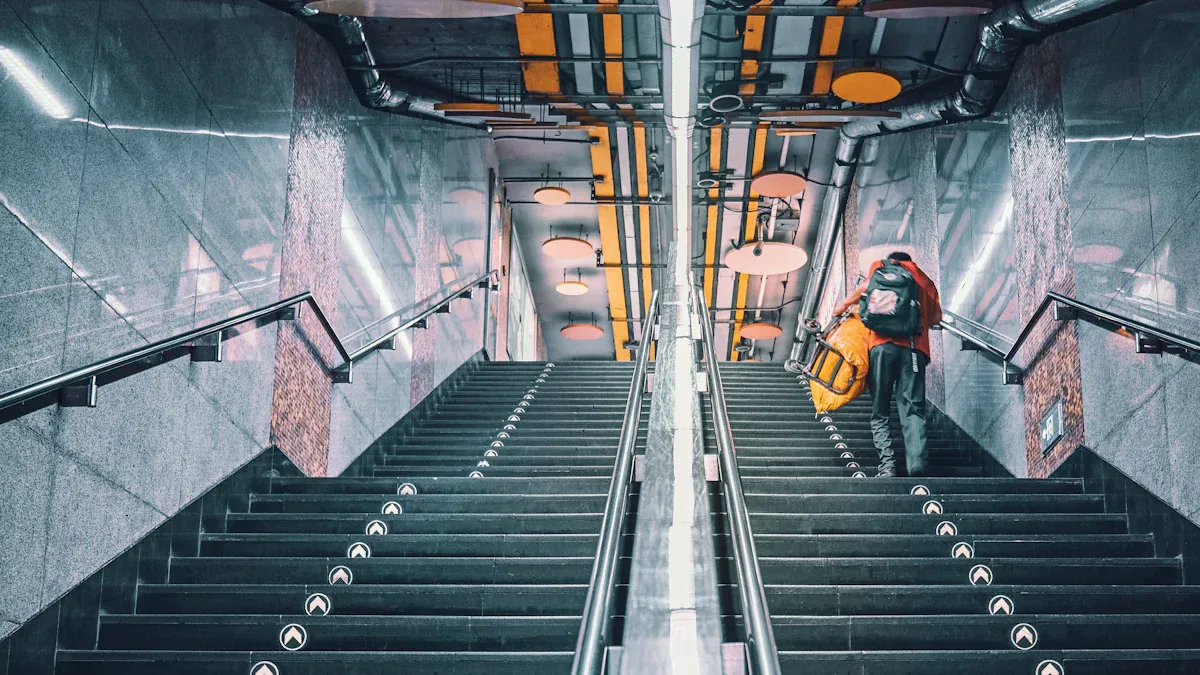

Architects choose austenitic stainless steel for both structural and decorative purposes. This material offers high corrosion resistance, thanks to the protective oxide layer formed by chromium. Buildings with stainless steel cladding or roofing stand up well to weather, UV rays, and moisture. The high tensile strength allows for lightweight yet strong structures.

Austenitic stainless steel keeps its shape and appearance under extreme temperatures and environmental stress. Maintenance is simple—regular cleaning with non-abrasive materials keeps surfaces looking polished. The material’s versatility allows for many finishes, from shiny to textured, fitting different design needs. Compared to traditional building materials, austenitic stainless steel provides better durability and lower maintenance. It also resists environmental damage better than other types of stainless steel, making it a top choice for modern architecture and industrial applications.

Cleanrooms require strict control over dust, germs, and other contaminants. Many industries, such as electronics, pharmaceuticals, and biotechnology, use cleanrooms to protect sensitive products. Austenitic stainless steel fits these applications well because it resists corrosion and does not release particles into the air. Workers can clean and disinfect surfaces made from this material quickly and thoroughly.

Austenitic stainless steel offers a smooth, non-porous surface. This feature prevents bacteria and dirt from sticking. Cleanroom designers often choose this material for benches, tables, storage racks, and wall panels. The alloy’s durability means it stands up to frequent cleaning with harsh chemicals. It also resists scratches, which helps keep surfaces free from places where germs can hide.

Tip: Many cleanroom applications require materials that do not react with cleaning agents. Austenitic stainless steel meets this need and keeps the environment safe for sensitive work.

Austenitic stainless steel also works well in cleanrooms because it does not attract magnets. This property helps protect electronic devices from interference. The material’s high strength allows for lightweight yet sturdy furniture and fixtures. Many companies rely on austenitic stainless steel for cleanroom applications because it combines hygiene, durability, and safety.

Not every project benefits from using austenitic stainless steel. Some situations make other materials a better choice. The following points explain when to avoid these alloys.

Austenitic stainless steel costs more than many other metals. Projects with tight budgets may find the price too high. The high nickel and chromium content raises the cost. Price changes in the metals market can also make budgeting difficult. For low-cost applications, other types of stainless steel or coated metals may work better.

Some applications require materials that resist wear and abrasion. Austenitic stainless steel does not offer high hardness. It wears down faster in places where parts rub together or face constant friction. For cutting tools, gears, or heavy machinery, harder alloys like martensitic stainless steel perform better.

Austenitic stainless steel resists many chemicals, but not all. Strong acids, chlorides, and some industrial cleaners can damage the protective layer. In chemical plants or marine environments with high salt levels, stress corrosion cracking may occur. For these applications, duplex stainless steel or special alloys provide better protection.

Note: Always match the material to the environment. Austenitic stainless steel works best in applications that need hygiene, corrosion resistance, and easy cleaning, but it does not suit every situation.

Martensitic stainless steel stands out for its high strength and hardness. Manufacturers often choose this type for cutting tools, knives, and turbine blades. The main components include chromium and carbon, which allow the steel to be hardened by heat treatment. This process gives martensitic stainless steel its toughness and wear resistance. However, it does not match the corrosion resistance of austenitic stainless steel. In environments with moisture or chemicals, martensitic grades can rust or pit more easily.

Austenitic stainless steel, on the other hand, contains chromium and nickel. This combination creates a face-centered cubic structure, making the alloy non-magnetic and highly formable. It cannot be hardened by heat treatment, but it can be strengthened by cold working. Austenitic stainless steel offers excellent corrosion resistance, especially in food processing, chemical plants, and marine environments.

The table below highlights the main differences:

| Property | Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Crystal Structure | Face-centered cubic (FCC) | Body-centered tetragonal (BCT) |

| Main Components | Chromium + Nickel | Chromium + Carbon |

| Magnetism | Non-magnetic | Magnetic |

| Strength/Hardness | Lower (cold-workable) | Higher (heat-treatable) |

| Corrosion Resistance | Excellent | Poorer |

| Formability | Excellent | Poor |

| Weldability | Excellent | Poor |

| Heat Treatment | Not hardenable by heat | Hardenable by heat |

| Applications | Food, chemical, marine, medical | Knives, turbines, valves |

Note: Some scientific studies show that under special manufacturing methods, such as laser cladding, martensitic stainless steel can sometimes resist corrosion better than austenitic types. This result depends on the process and is not typical for most uses.

Duplex stainless steel combines features from both austenitic and martensitic types. It offers higher strength and better corrosion resistance than martensitic grades, making it a good choice for harsh environments.

Ferritic stainless steel provides a cost-effective option for many applications. It contains chromium but little or no nickel, which keeps the price lower than austenitic stainless steel. Ferritic grades are magnetic and have a body-centered cubic structure. They offer moderate corrosion resistance, better than carbon steel but less than austenitic stainless steel. Many people use ferritic stainless steel in automotive exhausts, kitchen appliances, and heat exchangers.

Austenitic stainless steel remains the top choice for environments that demand high corrosion resistance and easy fabrication. It is non-magnetic and highly ductile, which helps in forming complex shapes. Ferritic stainless steel, while less expensive, can become brittle when welded and does not match the ductility or weldability of austenitic grades.

The table below summarizes the key differences:

| Feature | Austenitic Stainless Steel | Ferritic Stainless Steel |

|---|---|---|

| Cost | Higher (due to nickel) | Lower (little or no nickel) |

| Corrosion Resistance | Excellent | Moderate |

| Magnetic Properties | Non-magnetic | Magnetic |

| Weldability | Excellent | Limited |

| Strength & Ductility | High strength, very ductile | Moderate strength, lower ductility |

| Common Applications | Marine, food, medical, architecture | Automotive, appliances, heat exchangers |

Duplex stainless steel again serves as a bridge between these two types. It provides better corrosion resistance and strength than ferritic stainless steel, while also offering improved weldability and toughness.

Tip: When selecting stainless steel, consider the environment, required strength, and budget. Duplex stainless steel often solves problems where neither austenitic nor ferritic grades alone can meet all needs.

Austenitic stainless steel alloys offer strong corrosion resistance, easy shaping, and high hygiene standards. These alloys work well in kitchens, hospitals, and cleanrooms. Higher cost, some corrosion risks, and work hardening can limit their use. Each project has different needs. Readers should compare these pros and cons before choosing a material. The best choice depends on the environment and the job.

Austenitic stainless steel contains more nickel and chromium. This combination gives it better corrosion resistance and formability. It also stays non-magnetic in most conditions.

Austenitic stainless steel resists rust very well. However, harsh chemicals or salty environments can cause some corrosion over time. Regular cleaning helps maintain its protective layer.

Yes, austenitic stainless steel is safe for food. The FDA approves grades like 304 and 316 for kitchen and food processing use. These alloys do not react with food or change its taste.

Nickel and chromium raise the price of austenitic stainless steel. Market changes can also affect costs. Projects with tight budgets may need to consider other materials.

Most welders find austenitic stainless steel easy to join. Common welding methods work well. Using the right filler metals and controlling heat input helps prevent problems.

Avoid using it in places with high wear, strong acids, or extreme salt exposure. Martensitic or duplex stainless steels may perform better in these situations.