close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

Stainless steel tubing stands out in modern industry for its strength, corrosion resistance, hygiene, and adaptability. Manufacturers rely on it across critical sectors, including automotive, industrial, food and beverage, medical, oil and gas, construction, aerospace, and energy. The table below shows stainless steel pipes and tubes account for about 19.5% of the global industrial tubing market by value.

| Market Segment | Value (USD Million) | Percentage of Total Industrial Tubing Market (2025) |

|---|---|---|

| Stainless Steel Pipes & Tubes | 36,270 | ~19.5% |

| Global Industrial Tubing Market | 186,280 | 100% |

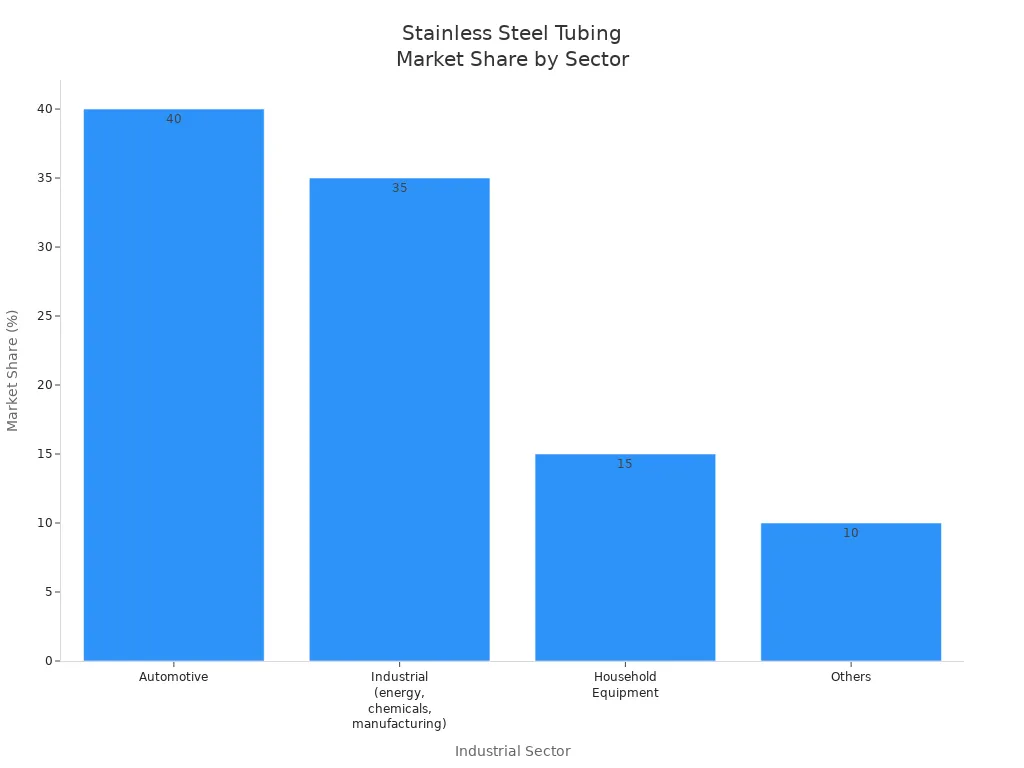

Automotive and industrial sectors lead in stainless steel tubing demand, as seen in this chart:

Key uses include:

Oil & Gas: Offshore drilling, pipelines, processing equipment, and chemical transfer.

Construction: HVAC, building façades, structural support, and plumbing.

Automotive: Exhaust systems, fuel lines, and lightweight components.

Stainless steel tubing plays a vital role in the medical device industry and the pharmaceutical industry. Its unique combination of strength, corrosion resistance, and hygienic properties makes it the material of choice for many critical applications.

Medical-grade stainless steel tubing is essential for devices such as catheters, needles, and surgical instruments. Manufacturers rely on its ability to maintain tight tolerances and uniform wall thickness. This precision supports safety and effectiveness in procedures. The smooth, polished surface of stainless steel tubing reduces bacterial adhesion, making cleaning and sterilization easier. These hygienic properties help prevent contamination and infection.

Implants such as orthopedic rods, bone screws, and joint replacements use stainless steel tubing because it is non-toxic and non-reactive. Biocompatibility ensures that the material does not trigger allergic responses or rejection by the body. The table below highlights why different grades are chosen for specific medical applications:

| Stainless Steel Grade | Key Properties and Uses |

|---|---|

| 304 | Common, cost-effective; good corrosion resistance; used in non-implantable devices. |

| 316 | Higher corrosion resistance, especially in chloride environments; used in surgical implants and pharma. |

| 316LVM | Vacuum melted for purity; immune to sensitization; ideal for implants and critical medical devices. |

| 17-7 PH | Precipitation hardened; used in orthopedic and high-strength applications. |

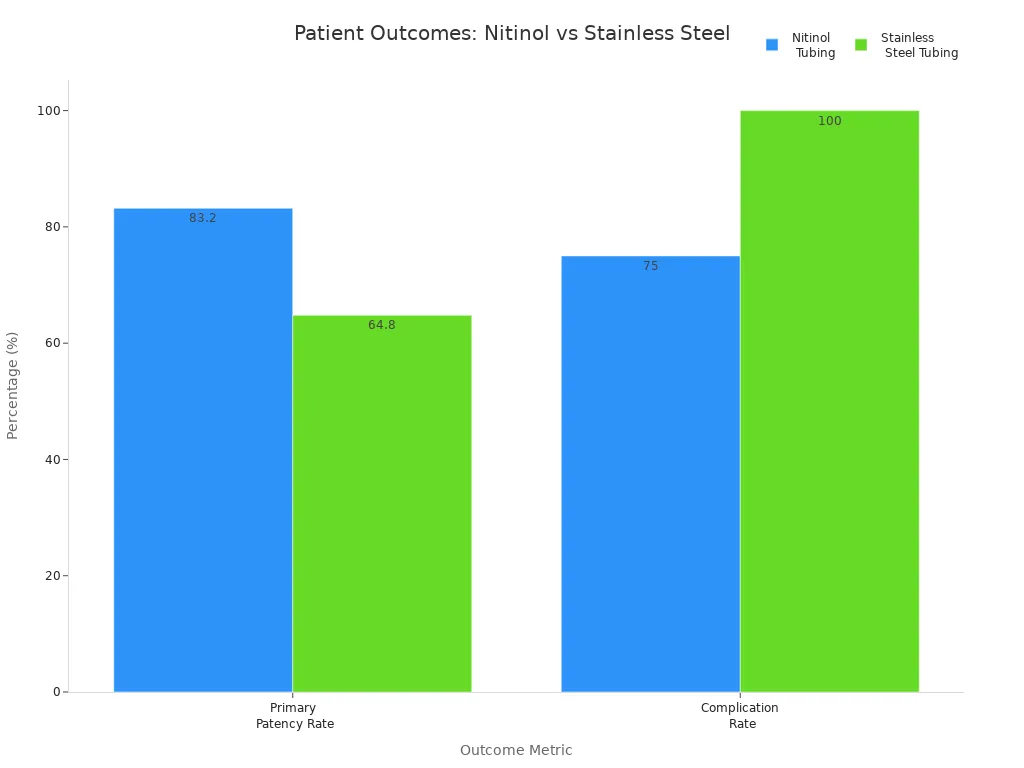

Stainless steel tubing provides structural stability and durability in static implants. The chart below compares patient outcomes for stainless steel and nitinol tubing in medical implants:

The pharmaceutical industry depends on stainless steel tubing for processing lines, transfer systems, and storage vessels. These applications require materials that withstand repeated sterilization cycles. Stainless steel tubing resists damage from autoclaving and chemical disinfection. Electropolished or passivated finishes further reduce microbial adhesion, supporting strict hygiene standards.

Pharmaceutical processing often involves exposure to aggressive chemicals and high temperatures. Grades like 316L and 904L offer excellent corrosion resistance, even in harsh environments. The table below shows common applications for stainless steel tubes in pharmaceutical equipment:

| Stainless Steel Grade | Key Properties | Common Pharmaceutical Applications |

|---|---|---|

| 316L | Low carbon content; excellent resistance to pitting and crevice corrosion; hygienic; affordable and accessible | Process piping and equipment in contact with fluids |

| 304 | Versatile; corrosion resistant; easy to fabricate and weld | Tanks, piping, storage vessels |

| 316Ti | Titanium addition improves resistance to intergranular corrosion and sensitization at high temperatures | Reactors and high-temperature process equipment |

| 904L | High alloy content including molybdenum, nickel, copper; excellent corrosion resistance in aggressive acidic environments | Equipment and piping handling strong acids or chloride-neutral aggressive environments |

| 2205 Duplex | Combination of austenitic and ferritic phases; excellent strength and corrosion resistance | Reactors and pressure vessels requiring high strength |

Tip: Selecting the right grade of stainless steel tubing ensures long service life, reduces maintenance, and maintains product purity.

The advantages of stainless steel tubing in these industries include corrosion resistant performance, ease of cleaning, and compliance with strict regulatory standards. These qualities make stainless steel tubing the preferred choice for both the medical device industry and the pharmaceutical industry.

Stainless steel tubes play a central role in the food and beverage industry. Their use ensures safe, efficient, and hygienic processing from raw ingredients to finished products. These tubes appear in a wide range of applications, including processing lines, sanitary water delivery, and beverage dispensing systems.

Manufacturers choose stainless steel tubes for processing lines because of their sanitary design. The smooth, non-porous surfaces of these tubes prevent bacteria and fungi from attaching and growing. This feature helps maintain food safety and product quality. Grades such as 304 and 316 are common applications for stainless steel tubes in food processing. These alloys contain high levels of chromium and nickel, which provide excellent corrosion resistance. The tubes do not react with food or cleaning agents, so they prevent chemical leaching and preserve the integrity of the product.

Note: Stainless steel tubes comply with strict regulatory standards in the food and beverage industry, supporting both safety and quality.

Cleaning efficiency is a major advantage of stainless steel tubes. Their surfaces allow for quick and thorough cleaning, which reduces contamination risks. Many processing facilities use electrolytic polishing to further smooth the tube interiors, improving fluid flow and cleaning effectiveness. Stainless steel tubes withstand harsh cleaning chemicals and high temperatures during sterilization. This durability extends equipment lifespan and reduces maintenance costs.

Key benefits of stainless steel tubes in processing lines:

Excellent corrosion resistance

Non-reactive, hygienic surfaces

Durability under harsh conditions

Prevention of bacterial contamination

Consistent product taste and quality

A comparison of material lifespans in food and beverage applications highlights the advantages of stainless steel tubes:

| Material | Estimated Lifespan (years) | Key Characteristics |

|---|---|---|

| 304 Stainless Steel | 20-50 | Corrosion resistant, common in food & beverage |

| 316 Stainless Steel | Longer than 304 | Higher corrosion resistance, preferred in harsh settings |

| Galvanized Steel | 20-50 | Prone to rust |

| Copper | 50-70 | May develop pinhole leaks |

| Brass | 80-100 | Durable, may contain trace lead |

| Plastic (PVC) | 50-100 | No corrosion, temperature sensitive |

| Cast Iron | 50-100 | Durable, can rust over time |

Stainless steel tubes are essential in beverage dispensing systems. The non-reactive nature of stainless steel tubing ensures that drinks retain their original flavor. Polished surfaces minimize bacterial adherence, which helps maintain hygiene and prevents off-tastes. The chromium film on stainless steel provides self-healing corrosion resistance, further protecting beverage quality.

Durability stands out as a key reason for using stainless steel tubes in beverage dispensing. Grades 304 and 316 resist corrosion and withstand varying pressures and temperatures. These tubes last for decades with proper maintenance, outperforming many alternative materials. Electrochemical polishing reduces crevices where bacteria could hide, making cleaning easier and improving sanitation. Stainless steel tubes also meet FDA and other hygiene standards, ensuring safe contact with food and beverages.

Tip: Proper selection of tube size, thickness, and surface finish enhances both operational efficiency and hygiene in beverage systems.

Stainless steel tubing supports sanitary water delivery and other critical applications in the food and beverage industry. Its advantages include long service life, low maintenance, and consistent product quality. These features make stainless steel tubes the preferred choice for manufacturers seeking reliability and safety.

The oil and gas industry depends on stainless steel pipes for reliable fluid transport and offshore operations. These pipes handle some of the harshest environments on earth, where performance and safety cannot be compromised.

Stainless steel pipes play a central role in moving oil, gas, and chemicals through pipelines. The oil and gas industry faces many challenges in fluid transport systems:

Corrosion resistance is essential, especially in buried or underwater environments where stainless steel pipes outperform carbon steel.

These pipes withstand variable pressures and temperatures found in oil and gas applications.

Durability in harsh marine and offshore settings ensures long service life.

Pipeline integrity prevents leaks and failures, which protects both people and the environment.

Seismic stability requires robust design and flexible joints to handle earthquakes.

Transporting piping materials to remote locations presents logistical challenges.

Advanced manufacturing and material selection reduce maintenance costs and extend pipeline lifespan.

New technologies, such as sensor-based monitoring and improved coatings, increase reliability.

Stainless steel pipes resist corrosion by forming a protective oxide layer. This layer, created by high chromium content, shields the pipe from saltwater and aggressive chemicals. As a result, stainless steel pipes prevent leaks and maintain system integrity in harsh environments. Grades like 316 and Duplex stainless steel offer even greater corrosion resistance, making them ideal for critical oil and gas applications. Although the initial cost of stainless steel pipes is higher, the reduced need for repairs and replacements lowers long-term maintenance expenses. This reliability means less downtime and fewer operational interruptions.

Fluid transport in the oil and gas industry often involves high-pressure conditions. Seamless stainless steel pipes provide uniform strength and eliminate weak points, making them suitable for high-pressure applications. Welded stainless steel pipes also serve in many systems, offering flexibility and cost-effectiveness for lower-pressure uses. Both types deliver the durability needed to handle demanding environments.

Offshore oil and gas platforms rely on stainless steel pipes for many critical functions. These applications demand materials that can withstand constant exposure to saltwater, wind, and extreme weather.

Stainless steel pipes last for decades in offshore environments. The high chromium content forms a passive oxide layer that prevents corrosion, even when exposed to saltwater and chemicals. Super duplex stainless steel reduces pipe weight and size requirements, which leads to cost savings and easier installation. The durability of stainless steel pipe means fewer repairs and less frequent replacement, which lowers maintenance costs and keeps operations running smoothly.

Safety remains a top priority in offshore oil and gas applications. Stainless steel pipes resist cracking and stress corrosion, which helps maintain infrastructure integrity. This resistance reduces the risk of leaks and failures, protecting both workers and the environment. The reliability of stainless steel pipes supports safe and efficient operations, even under extreme conditions.

Tip: Choosing the right grade of stainless steel pipe for each application ensures maximum performance, safety, and cost savings in the oil and gas industry.

Stainless steel tubing has become a staple in the construction industry. Its unique properties make it suitable for both structural support and decorative elements in modern buildings and infrastructure. Builders and architects value its strength, high strength-to-weight ratio, and resistance to fire and corrosion.

Stainless steel square tubing is a popular choice for structural support in construction projects. Its hollow, four-sided profile provides excellent strength and durability while keeping weight low. This combination allows engineers to design support beams, frames, and mounting brackets that can handle heavy loads without adding unnecessary mass. Common applications include bridge structures, building facades, and architectural framing. These uses take advantage of stainless steel’s ability to maintain structural integrity over long periods, even in demanding environments.

Typical structural applications:

Bridge structures

Building facades

Interior supports such as handrails, railings, and decorative columns

Stainless steel tubing offers natural fire resistance. It does not burn or emit toxic fumes when exposed to high temperatures. This property makes it a safe choice for critical infrastructure and high-rise buildings. Fire resistance also means that structures built with stainless steel tubing can maintain their shape and function during emergencies, providing extra time for evacuation and reducing damage.

Architects often select stainless steel tubing for its visual appeal. The material comes in a variety of finishes, including brushed, mirror polish, satin, and textured patterns. These options allow designers to create sleek, modern looks or blend with traditional materials like timber and concrete. Stainless steel tubing appears in handrails, railings, decorative columns, and even iconic structures like the Louvre Pyramid, where it supports glass panes while adding a reflective, elegant touch.

Advantages of stainless steel tubing for decorative use:

Cost efficiency due to long-term durability

Minimal maintenance with occasional cleaning

Aesthetic versatility for different design needs

Stainless steel tubing stands up to harsh weather conditions. Its corrosion resistance ensures that exterior elements, such as building facades and outdoor railings, retain their appearance and function for decades. This durability reduces the need for frequent repairs or replacements, saving resources and lowering costs over time.

Note: Stainless steel tubing is highly adaptable to custom fabrication. Builders can shape it into complex forms for unique architectural features. Its recyclability also supports sustainable construction practices. Stainless steel can be recycled repeatedly without losing its properties, and up to 92% of stainless steel used in buildings is recovered at the end of a structure’s life. This makes it a responsible choice for eco-friendly projects.

The construction industry relies on stainless steel tubing for its strength and durability, high strength, and ability to meet both structural and decorative needs. Its long lifespan, low maintenance, and recyclability align with modern sustainability goals, making it indispensable in today’s building projects.

Stainless steel tubes have become essential in the automotive and transportation industries. Manufacturers rely on these tubes for their strength, durability, and ability to withstand harsh conditions. The most common applications for stainless steel tubes include exhaust systems, brake lines, and fuel lines. These components benefit from the unique properties of stainless steel tubing, which help vehicles perform better and last longer.

Automotive exhaust systems face extreme temperatures every time a vehicle runs. Stainless steel tubes, especially those made from 304 grade, handle these high temperatures without losing their shape or strength. The chromium-nickel alloy in 304 stainless steel tubing protects against rust and heat damage. This protection reduces the risk of leaks and keeps the exhaust system working efficiently. Mandrel-bent stainless steel tubes also improve exhaust flow, which can boost horsepower and torque. Many high-performance vehicles use these tubes to ensure reliable operation under tough driving conditions.

Corrosion resistance is a key reason why automakers choose stainless steel tubes for exhaust systems. The chromium in the alloy forms a protective oxide layer that shields the metal from moisture, road salt, and acidic exhaust gases. This layer prevents rust and extends the life of the exhaust system. Compared to mild steel or aluminized steel, stainless steel tubes resist dents, warping, and fatigue caused by heat cycling and vibrations. Although stainless steel systems cost more upfront, they often last the lifetime of the vehicle, reducing the need for replacements.

Note: Approximately 68% of new vehicles worldwide use stainless steel tubing in their exhaust systems. In Europe, over 58% of new models feature stainless steel exhaust tubing.

Brake and fuel lines must deliver reliable performance to keep drivers and passengers safe. Stainless steel tubes provide a strong, corrosion resistant barrier that protects against leaks and failures. In brake systems, stainless steel lines do not stretch like rubber hoses. This feature ensures a firm pedal feel and consistent braking response. The braided construction of these tubes resists tears and damage from road debris, making them ideal for both everyday and performance vehicles. Stainless steel brake lines also maintain their integrity under hydraulic pressure, which improves driver control and confidence.

Longevity sets stainless steel tubes apart in brake and fuel line applications. These tubes resist corrosion from moisture, chemicals, and road salt, which can quickly degrade other materials. Protective coatings, such as PVC or polyvinyl fluoride, add another layer of defense against environmental damage. In North America, about 63% of vehicles use stainless steel tubing in their fuel and brake systems. This widespread adoption highlights the trust automakers place in the durability and reliability of stainless steel tubes.

| Region/System Type | Proportion of New Vehicles Using Stainless Steel Tubing |

|---|---|

| Exhaust Systems (Global) | Approximately 68% |

| Fuel and Brake Systems (North America) | About 63% |

| Exhaust Tubing (Europe) | Over 58% |

Stainless steel tubes continue to set the standard for performance, safety, and longevity in automotive and transportation applications. Their corrosion resistance, strength, and low maintenance needs make them the preferred choice for critical vehicle systems.

Stainless steel tubing plays a critical role in aerospace and defense. Engineers select this material for its strength, durability, and ability to perform under extreme conditions. Aircraft and military equipment rely on stainless steel tubing to ensure safety, reliability, and compliance with strict standards.

Stainless steel tubing provides high strength and durability, which are essential for aircraft systems. Although stainless steel is heavier than materials like aluminum or PEEK, its superior strength allows for thinner walls and smaller diameters in tubing. This design approach helps reduce the overall weight of hydraulic and fuel systems without sacrificing safety. In areas exposed to abrasion, heat, or high pressure, stainless steel tubing remains the preferred choice. For example, aircraft hydraulic systems often operate at pressures above 3,000 psi. Stainless steel tubing withstands these forces without deforming or failing.

Key uses of stainless steel tubing in aircraft systems:

Hydraulic lines

Fuel lines

Cooling systems

Landing gear assemblies

Stainless steel tubing in aircraft engines, such as the P&W GTF and CFM LEAP, handles fuel, air, and hydraulic lines with outer diameters ranging from ¼” to 2” and pressure capabilities up to 60,000 PSI.

Aircraft demand reliable performance in every flight. Stainless steel tubing delivers consistent results in harsh environments, including high temperatures and chemical exposure. Its resistance to corrosion and fatigue ensures long service life and reduces maintenance needs. Seamless stainless steel tubing can be bent and flanged for secure connections, supporting stable operation in critical systems. Certified fittings and tubing guarantee effective sealing and reliability, which are vital for flight safety.

| Application Area | Engine Examples | Uses | Stainless Steel Grades | Outer Diameter Range | Pressure Capability |

|---|---|---|---|---|---|

| Aircraft Fuel, Air, and Hydraulic Lines | P&W GTF Engine, CFM LEAP Engine | Fuel, air, and hydraulic lines in engines | 625, 321 | ¼” to 2” | Up to 60,000 PSI |

Military equipment faces some of the harshest environments. Stainless steel tubing provides the strength and corrosion resistance needed for reliable operation in extreme heat, cold, and chemically aggressive settings. Tubing in military vehicles and aircraft must withstand high pressures, vibration, and exposure to foreign objects. Stainless steel’s durability ensures that hydraulic and fuel systems remain intact during demanding missions. Its ability to tolerate high temperatures and resist chemical attack makes it ideal for engine and actuator applications.

Advantages of stainless steel tubing in military equipment:

Exceptional strength and durability

Resistance to deformation and failure under extreme forces

Long lifespan with reduced maintenance

Defense applications require strict adherence to quality and safety standards. The U.S. Department of Defense sets MIL-SPEC standards to ensure that stainless steel tubing and fittings meet rigorous requirements. Standards such as MIL-T-5695 and MIL-T-6845 cover fabrication, testing, and inspection methods. Surface treatments like passivation and electroplating, specified in MIL-T-8504, enhance corrosion resistance. Aerospace Material Specifications (AMS) such as AMS 5570 and AMS 5645 provide guidelines for precision, heat treatment, and performance.

| Standard Type | Standard Number | Focus Area |

|---|---|---|

| MIL-T | 5695 | Seamless and welded tubing requirements for aerospace |

| MIL-T | 6845 | Fabrication and testing methods for structural integrity |

| MIL-T | 8504 | Surface treatment and finishing for corrosion resistance |

| AMS | 5570 | Precision tubing with tight tolerances for aerospace |

| AMS | 5645 | Corrosion-resistant tubing with heat treatment guidelines |

Meeting these standards ensures that stainless steel tubing in military and aerospace systems delivers reliable performance, safety, and longevity under the most demanding conditions.

Stainless steel pipes play a vital role in the energy and power industry. Their strength, durability, and resistance to extreme conditions make them essential for both traditional power plants and renewable energy systems.

Power plants operate under intense heat and pressure. Stainless steel pipes handle these conditions with ease. Engineers use them in boilers, heat exchangers, condensers, steam turbines, and nuclear reactors. Each component requires specific stainless steel grades to ensure safety and efficiency.

| Power Plant Component | Stainless Steel Grades | Key Functional Roles in High-Temperature Environments |

|---|---|---|

| Boilers | 304, 316 | Provide high-temperature resistance to withstand steam generation processes |

| Heat Exchangers | 321, 347 | Offer corrosion resistance under thermal cycling and fluid exposure |

| Condensers | 904L | Resist stress corrosion cracking in cooling and condensation stages |

| Steam Turbines | 304, 310 | Ensure durability under high pressure and temperature conditions |

| Nuclear Reactors | 316L, 347H | Maintain integrity under radiation and high-temperature stress |

Stainless steel pipes maintain their shape and strength even when exposed to superheated steam and high-pressure fluids. Their ability to resist thermal cycling and chemical attack helps reduce maintenance costs and downtime. Alloying elements like molybdenum and titanium boost their performance, making them reliable for long-term use.

Nuclear power plants demand materials that can withstand both high temperatures and radiation. Stainless steel pipes, especially grades like 316L and 347H, keep their structural integrity in these harsh environments. Their durability ensures safe operation and protects workers and equipment from leaks or failures. The use of stainless steel pipe in these settings supports efficient energy transfer and reliable power generation.

Note: Stainless steel pipes are 100% recyclable, which supports environmental sustainability in the energy sector.

Renewable energy systems, such as wind, solar, and hydropower, rely on stainless steel pipes for their corrosion resistance and strength. These systems often face harsh weather, saltwater, and temperature changes. Stainless steel pipes in wind turbines, solar panel frames, and hydropower stations resist rust and wear, even in challenging environments.

Wind energy uses stainless steel pipes in turbine shafts, hubs, bolts, and tower components. These parts must handle mechanical stress and exposure to saltwater, especially offshore.

Solar power systems use stainless steel pipe for mounting structures and frames. The material resists rain, snow, and heat, keeping solar panels stable and efficient.

Hydropower plants use stainless steel pipes in turbine blades, penstocks, and generator shafts. Their strength and corrosion resistance ensure reliable operation in wet, high-pressure settings.

Stainless steel pipes offer long service life with minimal upkeep. Their durability means fewer replacements and less downtime, which saves money and resources. The corrosion resistant nature of these pipes reduces the need for frequent inspections or repairs. This reliability makes them a smart choice for both new and existing energy projects.

Stainless steel pipes help lower operational costs by reducing maintenance needs.

Their long lifespan supports sustainable infrastructure and reduces waste.

The material’s recyclability aligns with green energy goals.

Tip: Choosing stainless steel pipes for energy and power systems improves efficiency, safety, and environmental responsibility.

Stainless steel tubing supports modern industry in seven key areas, from healthcare to energy. Its durability and corrosion resistance, hygienic surface, and fabrication versatility make it a top choice for demanding environments. The cost-effectiveness of stainless steel tubing comes from low maintenance, long service life, and recyclability. Industries benefit from fewer repairs and reduced downtime. As global demand rises, stainless steel tubing will continue to drive innovation and support sustainable, efficient industrial growth.

Stainless steel tubing resists corrosion and rust. It lasts longer in harsh environments. Carbon steel tubing may cost less, but it often needs more maintenance and replacement.

Yes, stainless steel tubing is 100% recyclable. Most stainless steel products contain a high percentage of recycled material. This helps reduce waste and supports sustainable industry practices.

The automotive, oil and gas, construction, food and beverage, medical, aerospace, and energy industries use the most stainless steel tubing. Each industry values its strength, hygiene, and corrosion resistance.

Manufacturers clean stainless steel tubing with steam, hot water, or chemical solutions. They often use electropolishing to smooth surfaces. This process removes contaminants and helps prevent bacteria from sticking.

Grades 304 and 316 are the most common. Grade 304 works well for general use. Grade 316 offers better corrosion resistance, especially in salty or chemical-rich environments.

Stainless steel tubing needs little maintenance. Regular cleaning keeps it looking new and prevents buildup. Inspections help spot any damage early. Most tubing lasts for decades with basic care.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Exploring the Magnetism of Stainless Steel for Modern Applications

Super austenitic stainless steel outperforms in real-world acid tests

Emerging Manufacturing Techniques for Austenitic Stainless Steel Bars

Exploring The Role of 18-8 Austenitic Stainless Steel in Modern Manufacturing And Homes

Top 10 Austenitic Stainless Steel Grades and Their Everyday Uses