close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-16 Origin: Site

Understanding stainless steel tube sizes is essential for making the right choice in 2025. The stainless steel tube sizes chart gives you a clear view of the most common dimensions used in construction, automotive, and manufacturing. You can read the chart by checking the outside diameter (OD), inside diameter (ID), wall thickness, and length. Standards and specifications, such as ASTM and ASME, define these sizes and tolerances. Using the stainless steel tube sizes chart helps you select the right tube for your needs and ensures your project meets industry requirements.

Use the stainless steel tube sizes chart to find the right outside diameter, wall thickness, inside diameter, and length for your project.

Outside diameter (OD) affects how tubes fit with connectors; inside diameter (ID) controls flow and pressure; wall thickness ensures strength and safety.

Standard tube lengths like 6, 12, and 20 feet save time and reduce waste, but custom lengths are available for precise needs.

Follow ASTM, ASME, and ISO standards to ensure your tubes meet quality, safety, and sizing requirements.

Choose the right tube shape—round, square, or rectangular—based on your application’s strength and design needs.

Know the difference between pipe and tube sizing: pipes use nominal sizes, tubes use actual outside diameter and wall thickness.

Confirm tube size availability early to avoid delays and extra costs; work with reliable suppliers and consider common sizes.

Match tube size and grade to your application’s pressure, flow, and environmental demands for best performance and durability.

You need a reliable stainless steel tube sizes chart to select the right tubing for your project in 2025. Manufacturers and standards organizations, such as Centerway Steel and Dongshang Stainless, provide up-to-date charts that cover a wide range of stainless steel tubes and pipes sizes. These charts include both imperial and metric units, making it easy for you to compare and choose the correct dimensions for your application.

The stainless steel tube sizes chart below shows typical standard dimensions for round tubing. You will find outside diameter (OD), wall thickness, inside diameter (ID), and available lengths. Tubing sizes range from small diameters for instrumentation to large sizes for structural use. Wall thicknesses vary to meet different strength and pressure needs. Lengths are often customized, so you can order tubing that fits your exact requirements.

| Outside Diameter (OD) | Wall Thickness | Inside Diameter (ID) | Standard Lengths |

|---|---|---|---|

| 0.125 in (3.18 mm) | 0.030 in | 0.065 in (1.65 mm) | 6 ft, 12 ft, custom |

| 0.250 in (6.35 mm) | 0.035 in | 0.180 in (4.57 mm) | 6 ft, 12 ft, custom |

| 0.500 in (12.7 mm) | 0.049 in | 0.402 in (10.21 mm) | 6 ft, 20 ft, custom |

| 1.000 in (25.4 mm) | 0.065 in | 0.870 in (22.1 mm) | 20 ft, custom |

| 2.000 in (50.8 mm) | 0.120 in | 1.760 in (44.7 mm) | 20 ft, custom |

| 4.000 in (101.6 mm) | 0.188 in | 3.624 in (92.1 mm) | 20 ft, custom |

| 10.750 in (273.05 mm) | 0.134-1.125 in | 8.5-10.4 in (varies) | Custom |

| 24.000 in (609.6 mm) | 0.250-1.000 in | Varies | Custom |

| 48.000 in (1219 mm) | 0.375-1.250 in | Varies | Custom |

You can find stainless steel tubes and pipes sizes with outside diameters from 0.125 inches up to 48 inches. Wall thicknesses start at 0.022 inches and can exceed 1 inch for heavy-duty applications. Inside diameters depend on the OD and wall thickness. Tubing lengths are not fixed, so you can request custom lengths for your project. Many manufacturers also offer metric sizes, such as diameters from 6mm to 219mm and wall thicknesses from 0.6mm to 5.0mm.

Tip: Always check the stainless steel tube sizes chart for the latest standard dimensions and available options. Manufacturers update their charts to match new industry standards and customer needs.

You need to understand each column in the stainless steel tube sizes chart to make the best choice. The chart lists the most important tubing dimensions and helps you compare different stainless steel tubes and pipes sizes quickly.

Outside Diameter (OD): This is the measurement across the outside of the tube. You use OD to match tubing with fittings and connectors. OD is usually listed in inches or millimeters.

Wall Thickness: This shows how thick the tube wall is. Wall thickness affects the strength, durability, and pressure rating of the tubing. You may see this value in inches, millimeters, or as a gauge number.

Inside Diameter (ID): This is the space inside the tube. You calculate ID by subtracting twice the wall thickness from the OD. ID is important for flow rate and for fitting internal components.

Standard Lengths: This column shows the most common lengths available. Many suppliers offer custom lengths to fit your project.

You will see both imperial and metric units in stainless steel tube sizes charts. Always check which unit system the chart uses before making a selection.

When you read a stainless steel tube sizes chart, you will see several common abbreviations and symbols:

OD: Outside Diameter

ID: Inside Diameter

WT: Wall Thickness

in: Inches

mm: Millimeters

ft: Feet

Custom: Custom length available

Gauge: Standardized thickness number (lower gauge = thicker wall)

You may also see references to standards, such as ASTM A213 or ISO 1127, which confirm that the tubing meets specific quality and dimension requirements.

Note: Always match the tubing dimensions with your system’s requirements. Check compatibility with fittings, pressure ratings, and flow needs. Consult with engineers or suppliers if you have questions about stainless steel tubes and pipes sizes.

You can use the stainless steel tube sizes chart to compare different tubing options. Look at the OD for fitting compatibility, check the wall thickness for strength, and use the ID to estimate flow capacity. Custom lengths let you order tubing that fits your installation perfectly. By understanding these dimensions, you can select stainless steel tubes and pipes that meet your project’s technical and safety needs.

You need to understand the outside diameter when working with stainless steel tubing dimensions. The outside diameter is the actual measurement across the tube’s exterior. This measurement is not a nominal value; it matches the true physical size of the tube. For example, a tube labeled as 1.25 inches has an outside diameter of exactly 1.25 inches. This differs from pipe sizing, where nominal sizes do not always match the real diameter. The outside diameter is a key factor in selecting fittings and ensuring compatibility with other components.

You measure the outside diameter using calipers or micrometers. Always measure across the widest part of the tube. Stainless steel tubing dimensions use this measurement to define the tube’s size. Manufacturers list outside diameter in both inches and millimeters. This method gives you precise control over your selection. The outside diameter directly affects how the tube fits with connectors and how much space it occupies in your system.

Here is a table showing how different outside diameter categories impact performance and compatibility:

| Outside Diameter (OD) Category | OD (mm) | Typical Wall Thickness (mm) | Impact on Performance and Compatibility |

|---|---|---|---|

| Small Diameter | 6 | 0.5 - 1 | Used in precision instruments and small fluid systems requiring exact fit and strength |

| Small Diameter | 10 | 1 - 1.5 | Suitable for laboratory and hydraulic lines needing compatibility with small connectors |

| Small Diameter | 12 | 1 - 2 | Fits small machinery and compact fluid systems where OD ensures proper integration |

| Medium Diameter | 25 | 1.5 - 3 | Provides structural strength for support columns and mid-sized fluid transport |

| Medium Diameter | 38 | 2 - 4 | Used in handrails and machinery frameworks requiring durability and standard fittings |

| Medium Diameter | 50 | 2.5 - 5 | Supports larger structural components and industrial piping with higher pressure tolerance |

| Large Diameter | 76 | 3 - 6 | Suitable for heavy-duty structural supports and large-scale fluid transport systems |

| Large Diameter | 100 | 4 - 8 | Used in major piping and chemical processing where OD ensures compatibility and strength |

| Large Diameter | 150 | 5 - 10 | Designed for high-capacity transport and heavy industrial applications requiring robust tubing |

Tip: Always check the outside diameter before ordering to ensure your tube fits your application and meets all compatibility requirements.

The inside diameter is the distance across the inner opening of the tube. You calculate it by subtracting twice the wall thickness from the outside diameter. The inside diameter is a critical part of stainless steel tubing dimensions because it determines how much material or fluid can pass through the tube. Manufacturers often list both outside and inside diameters to help you compare sizes and select the right tube for your needs.

The inside diameter has a direct effect on flow rate and pressure. A larger inside diameter allows more fluid to move through the tube, which increases flow rate. A smaller inside diameter restricts flow and raises resistance, causing a higher pressure drop along the tube’s length. If you need to move large volumes of fluid or reduce pressure loss, choose a tube with a larger inside diameter. This is especially important in industries like oil and gas, medical, and instrumentation, where precise flow control matters.

Wall thickness is the measurement of the tube’s wall from the outside surface to the inside surface. You will see wall thickness listed in millimeters, inches, or as a gauge number. The wall thickness is one of the most important dimensions for stainless steel tubing. It affects strength, durability, and pressure capacity. Standards such as ASTM A554, ASTM A270, and ASME B36.19 define acceptable wall thicknesses for different applications. Tubes come in various wall thicknesses, often grouped by schedules like SCH 5, SCH 10, SCH 40, and SCH 80. Higher schedules mean thicker walls.

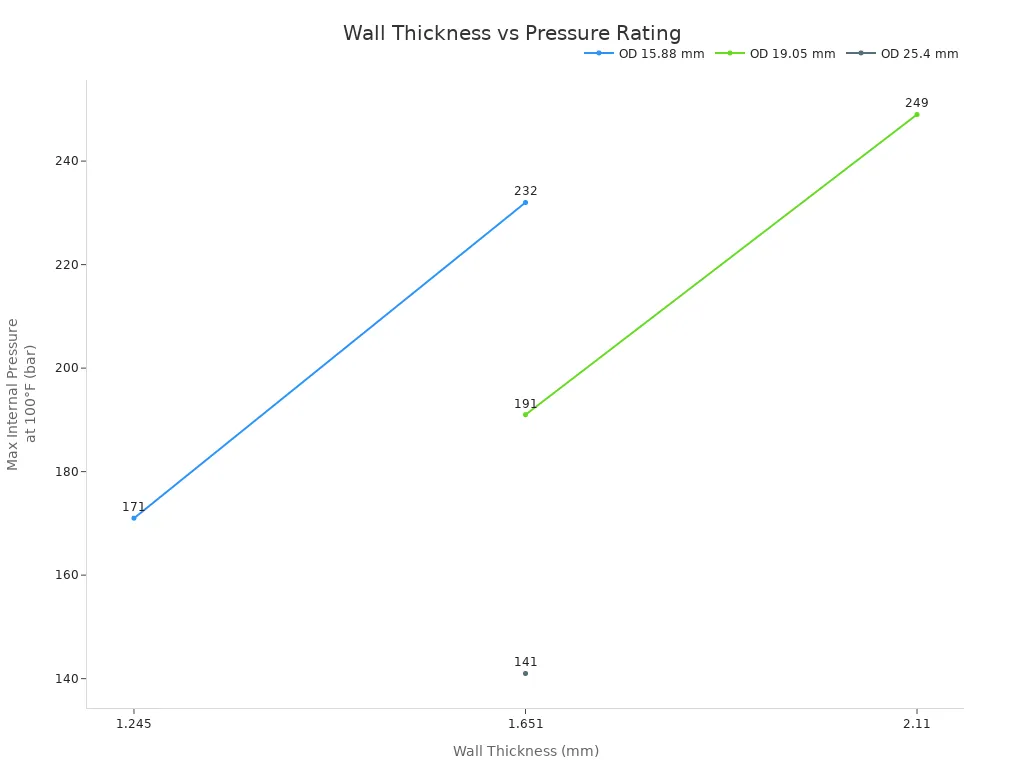

Wall thickness plays a major role in how much pressure the tube can handle. Thicker walls provide more strength and allow the tube to withstand higher internal pressures. This is important for safety and performance in demanding environments. Even a small increase in wall thickness can greatly improve pressure capacity. The chart below shows how increasing wall thickness raises the maximum internal pressure for stainless steel tubes of different diameters:

Note: Always select the correct wall thickness for your application. This ensures your tube meets strength and safety requirements.

When you choose stainless steel tubing, focus on these key parameters:

Outside diameter for fit and compatibility

Inside diameter for flow and pressure

Wall thickness for strength and safety

These dimensions help you match the tube to your project’s needs and industry standards.

When you select stainless steel tubing, tube length becomes a key factor. Standard lengths help you plan your project and reduce waste. Most suppliers keep popular sizes in stock, so you can get what you need quickly. In 2025, you will find that many manufacturers offer standard tube lengths, but the exact numbers can vary. Common standard lengths include 6 feet, 12 feet, and 20 feet. Some suppliers may also provide 24-foot or even 40-foot tubes for large-scale projects.

You should always check with your supplier to confirm which standard lengths they have available. Companies like M&M International keep a wide range of standard tubing sizes in inventory, especially in the 300 series stainless steel. This makes it easy for you to order tubes that fit most common applications, such as construction, automotive, or manufacturing.

Tip: Using standard lengths can save you time and money. You avoid extra cutting fees and reduce material waste.

Standard lengths work well for many projects. They fit most racks, storage systems, and transport methods. If your design matches these lengths, you can speed up installation and keep costs down.

Sometimes, your project needs a tube that does not match a standard length. In these cases, you can order custom cut-to-length tubing. Many suppliers in 2025, such as Eagle Stainless Tube & Fabrication and Shaw Stainless & Alloy, offer precision cutting services. You can request tubes cut to your exact specifications, whether you need a short piece for a small device or a long tube for a special structure.

Custom options go beyond just length. Some companies can also bend, polish, or machine the tube to fit your needs. For example, Eagle Stainless Tube & Fabrication provides custom-fabricated components, including bending and machining, tailored to your requirements. Shaw Stainless & Alloy offers custom cutting and polishing, but you may need to meet a minimum order size.

Ordering custom lengths gives you flexibility. You can design your system without worrying about leftover material or extra joints. This is especially useful in industries where precision matters, such as medical devices, instrumentation, or aerospace.

Here are some benefits of choosing custom tube lengths:

You get exactly the size you need for your project.

You reduce the number of joints and connections.

You minimize waste and save on material costs.

You improve the appearance and function of your finished product.

Note: Always discuss your custom length needs with your supplier. Ask about minimum order quantities, lead times, and any extra services like bending or polishing.

When you select stainless steel tubes for your project, you need to understand the stainless steel tube standards that control their quality and dimensions. These standards help you compare products, ensure safety, and meet industry requirements. In 2025, you will see three main groups of standards: ASTM, ASME, and ISO. Each group covers different aspects of stainless steel tubes and pipes specifications.

ASTM standards set the foundation for stainless steel tube standards in the United States and many other countries. You will often see ASTM A213, A269, A270, and A312 listed in product specifications. These standards define the chemical composition, mechanical properties, and dimensional tolerances for stainless steel tubes.

ASTM A213 covers seamless and welded tubes with outside diameters from 6 mm to 114.3 mm and wall thicknesses from 0.8 mm to 4 mm. ASTM A269 focuses on seamless and welded austenitic stainless steel tubes for corrosion resistance and temperature service. ASTM A270 is important for sanitary tubing, often used in food and pharmaceutical industries. ASTM A312 covers pipe sizes from NPS 1/8 to NPS 30 and larger, with outside diameter tolerances between ±0.4 mm and ±4.8 mm, and wall thickness tolerances of +20% and -12.5%. These ASTM standards ensure you get tubes that meet strict stainless steel tubes and pipes specifications for size and quality.

You will also encounter ASME and ISO standards when working with stainless steel tubes. These standards add extra layers of safety and quality control.

ASME B36.19M focuses on stainless steel tube standards for pressure and mechanical engineering. This standard ensures that tubes can handle specific pressure and temperature conditions, which is critical for pressure vessels and piping systems.

ISO 1127 is one of the most common stainless steel tube standards worldwide. It specifies tube dimensions and tolerances, making sure you get consistent outside diameters, inside diameters, and wall thicknesses. ISO standards help you match tubes with fittings and maintain reliable performance. ISO 1127 also reduces the risk of system failure by keeping dimensions uniform across different manufacturers. You can trust that tubes meeting ISO standards will have the right mechanical properties and chemical composition for your application.

Here is a table comparing the main focus of ASTM, ASME, and ISO standards:

| Standard | Main Focus | Key Aspects Related to Stainless Steel Tube Sizing |

|---|---|---|

| ASTM | Material and dimensional specifications | Defines chemical composition, mechanical properties, dimensions, and testing requirements for stainless steel pipe and tube |

| ASME | Pressure and mechanical engineering codes | Ensures suitability of stainless steel pipe and tube for specific pressure and temperature conditions, focusing on pressure vessel and piping applications |

| ISO | Quality management and supplier certification | Emphasizes quality management systems and product consistency, ensuring supplier reliability rather than specific dimensional standards |

You need to check the markings on stainless steel tubes to confirm compliance with 2025 standards. Markings show the size, material grade, and heat code. In some markets, such as India, tubes must carry a certification mark from the Bureau of Indian Standards (BIS). This mark proves the tube meets stainless steel tubes and pipes specifications under IS 17875:2022 for seamless and IS 17876:2022 for welded tubes. The marking is mandatory for all manufacturers, sellers, and importers starting August 1, 2025. Products made only for export or for limited research use may be exempt, but you must keep records and report these cases. If you use tubes without proper markings, you risk penalties and project delays.

Always check for proper markings and certification before you buy or install stainless steel tubes. This step protects your project and ensures you meet all stainless steel tube standards.

You will find round stainless steel tubes and pipes in many industrial applications. These tubes work well in automotive parts, hollow furniture, and commercial railings. Their cylindrical shape gives you excellent performance for bending and shaping. Round tubing is also common in food and beverage processing, chemical plants, and power generation. You can rely on their strength and corrosion resistance for projects that need durability and hygiene. In construction, round tubes support roofing, handrails, and external features. Their versatility makes them a top choice for both structural and fluid transport uses.

Tip: Choose round tubing when you need strong, formable material for demanding industrial applications.

Round stainless steel tubes and pipes come in a wide range of sizes. You can select outside diameters starting as small as 1/16 inch and going up to over 8 inches. Many suppliers offer intermediate sizes to match your project needs. Wall thicknesses vary, so you can pick tubing that meets your performance and pressure requirements. For metric sizes, diameters often start at about 2 mm and can reach 20 mm or more. This flexibility lets you use round tubing in everything from medical devices to large-scale industrial applications.

Square stainless steel tubes and pipes give you a modern look and strong support. You often see them in construction frames, art deco designs, and building reinforcement. Their shape provides strength across the flats, making them ideal for structural and architectural projects. Square tubing is popular in mechanical and industrial applications where you need both performance and visual appeal. You can use these tubes in furniture, support columns, and even in some sanitary systems because of their corrosion resistance.

Square tubes are a good choice when you want clean lines and reliable performance in your design.

Their strength helps reinforce buildings and machinery.

You can find square stainless steel tubes and pipes in many sizes and finishes. Common sizes range from small dimensions for light frames to larger sizes for heavy-duty support. Suppliers stock square tubing with outside diameters from about 5 mm up to 38.1 mm. This range covers most industrial applications, letting you match the tubing to your specific performance needs. You can also choose wall thicknesses that fit your strength and durability requirements.

Rectangular stainless steel tubes and pipes serve a wide variety of industrial applications. You will see them in building frames, bridges, and trailers. Their shape gives you strong reinforcement, especially in structures that need extra support. Rectangular tubing is also used in modern construction for both functional and decorative purposes. You can rely on their performance in environments where strength and corrosion resistance matter. These tubes are common in mechanical systems, architectural features, and even in some transportation equipment.

Note: Rectangular tubing offers excellent performance for structural frames and reinforcement in demanding industrial applications.

Rectangular stainless steel tubes and pipes are available in many sizes to fit your project. Typical outside diameters start at 5 mm and go up to 38.1 mm. You can select from a variety of wall thicknesses to achieve the performance you need. This size range supports both light-duty and heavy-duty industrial applications. You can also request custom sizes if your project has unique requirements.

Stainless steel tubes and pipes, whether round, square, or rectangular, give you the flexibility, strength, and corrosion resistance needed for top performance in industrial applications.

You will find that standard stainless steel tube sizes cover a wide range of diameters. Manufacturers group these tubes into small, medium, and large categories. Small diameter tubes usually start at 1/16 inch (about 1.6 mm) and go up to 1 inch (25.4 mm). These sizes work well for instrumentation, medical devices, and small hydraulic systems. Medium diameter tubes range from 1 inch to 6 inches (25.4 mm to 152.4 mm). You often use these for structural supports, handrails, and process piping. Large diameter tubes can reach up to 48 inches (1219 mm). These sizes are common in heavy industry, water treatment, and large-scale construction.

When you select a tube, you need to consider both the outside diameter and the wall thickness. Thicker walls increase strength and pressure resistance. For example, a 2-inch tube with a 0.120-inch wall thickness will handle more pressure than a thinner-walled tube of the same diameter. Always match the diameter and thickness to your application’s needs.

Tip: Check the stainless steel tube sizes chart to compare available diameters and wall thickness options for your project.

You will see two main sizing systems for standard stainless steel tube sizes: fractional and metric. Fractional tubing uses inch-based measurements, such as 1/4 inch or 1/2 inch outside diameter. This system is common in North America and often uses 304 or 316 stainless steel grades. Metric tubing, measured in millimeters, is popular in Europe and Asia. You might see sizes like 6 mm, 12 mm, or 25 mm outside diameter.

Both systems size tubes by outside diameter and wall thickness. Inside diameter does not define the size. Fractional tubing works well for general industrial use, while metric tubing is often chosen for high-pressure hydraulic and pneumatic systems. Metric sizes can be very small, starting at 1 mm and going up to 26 mm or more. Despite the different units, both systems rely on precise diameter and thickness measurements. You can easily compare dimensions between the two systems by checking the stainless steel tube sizes chart.

Note: Always confirm which sizing system your project requires. Mixing fractional and metric sizes can cause fitting and compatibility issues.

You may need precision or sanitary tubing for specialized applications. Precision stainless steel tubing features exact outside diameter and wall thickness with tight tolerances. You can find these tubes in round, square, rectangular, or oval shapes. Precision tubing is ideal for mechanical systems, pressure equipment, and fabrication projects where accuracy matters.

Sanitary stainless steel tubing is designed for hygienic environments. You will see these tubes in food processing, pharmaceutical, and biotech industries. Sanitary tubing uses only round shapes and must have a smooth, polished interior to prevent bacterial growth and allow easy cleaning. These tubes meet strict standards, such as ASTM A270 and JIS G3447, and use corrosion-resistant grades like 304 and 316. The manufacturing process includes seamless construction and extra polishing, which increases cost but ensures the highest quality.

Here is a table comparing precision and sanitary tubing:

| Characteristic | Precision Stainless Steel Tubing | Sanitary Stainless Steel Tubing |

|---|---|---|

| Measurement | Exact diameter and wall thickness, tight tolerances | Exact diameter and wall thickness, plus smooth interior finish |

| Shape | Round, square, rectangular, oval | Round only |

| Surface Finish | High quality control | Polished for hygiene |

| Material Grades | 304, 316 | 304, 316 |

| Tolerances | Tighter than pipe | Highest, with finish inspection |

| Connections | Plain, welded | Flanges, clamps |

| Application Focus | Mechanical, fabrication, pressure equipment | Food, pharmaceutical, biotech |

| Production Speed | Moderate | Longer, due to extra polishing |

| Cost | Moderate | Higher |

Sanitary tubing must meet strict standards for cleanliness and corrosion resistance. Always choose the right type for your application to ensure safety and performance.

You will notice that stainless steel tubes and pipes use different sizing systems. Pipes use the Nominal Pipe Size (NPS) system, which focuses on the inside diameter and a schedule number for wall thickness. Tubes use the actual outside diameter and wall thickness for sizing. This difference means you cannot use the same size for both pipes and tubes, even if the numbers look similar.

Here is a table to help you compare the two systems:

| Feature | Stainless Steel Pipe | Stainless Steel Tube |

|---|---|---|

| Sizing Convention | Nominal Pipe Size (NPS) & Schedule (wall thickness) | Outside Diameter (OD) & Wall Thickness |

| Dimension Reference | Nominal size, not actual dimensions, focuses on internal diameter | Actual outside diameter and wall thickness, precise measurements |

| Tolerances | Less precise, nominal sizing | Tighter tolerances, precise sizing |

| Typical Shapes | Round only | Round, square, rectangular, and other shapes |

| Common Applications | Fluid transport | Structural and precision uses |

You should always check the stainless steel tubes and pipes sizes chart before making a selection. This helps you avoid mistakes and ensures your system works as planned.

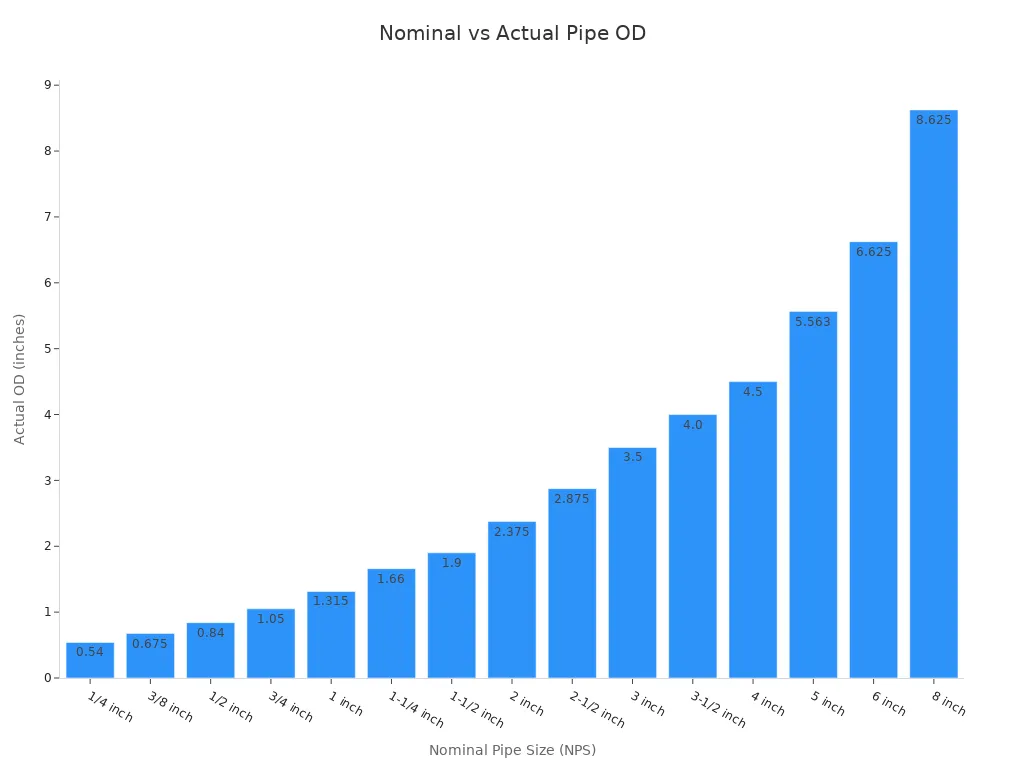

When you look at stainless steel tubes and pipes sizes, you will see both nominal and actual sizes. For pipes, the nominal size does not match the real outside diameter. For example, a 1-inch pipe has an actual outside diameter of 1.315 inches. The wall thickness changes with the schedule, so the inside diameter also changes. Tubes use the actual outside diameter and wall thickness, so a 1-inch tube really measures 1 inch across the outside.

Here is a table showing the difference between nominal pipe size and actual outside diameter:

| Nominal Pipe Size (NPS) | Actual Outside Diameter (OD) |

|---|---|

| 1/4 inch | 0.540 inch |

| 3/8 inch | 0.675 inch |

| 1/2 inch | 0.840 inch |

| 3/4 inch | 1.050 inch |

| 1 inch | 1.315 inch |

| 1-1/4 inch | 1.660 inch |

| 1-1/2 inch | 1.900 inch |

| 2 inch | 2.375 inch |

| 2-1/2 inch | 2.875 inch |

| 3 inch | 3.500 inch |

| 3-1/2 inch | 4.000 inch |

| 4 inch | 4.500 inch |

| 5 inch | 5.563 inch |

| 6 inch | 6.625 inch |

| 8 inch | 8.625 inch |

You need to remember that stainless steel tubes and pipes sizes are not interchangeable. Always use the stainless steel tubes and pipes sizes chart to confirm the correct measurements for your project.

Wall thickness is a key factor in the performance of stainless steel tubes and pipes. As wall thickness increases, the tube or pipe becomes stronger and can handle more pressure. At the same time, thicker walls mean more material, which increases the weight. For pipes, different schedules like Standard (STD), Extra Strong (XS), and Double Extra Strong (XXS) show how thick the wall is for each nominal size. For tubes, you select the wall thickness directly.

You should always check the stainless steel tubes and pipes sizes chart to find the right wall thickness for your needs. If you choose a thicker wall, you get more strength but also more weight. This matters for both safety and cost, especially in large projects.

Tip: Always match the wall thickness to your application. Thicker walls give you more strength, but they also add weight and cost. Use the stainless steel tubes and pipes sizes chart to balance these factors.

You need to start by understanding your project’s requirements. Every application has unique demands, so you must identify what matters most for your situation. Think about the environment where you will use the stainless steel tubes and pipes. Will they face high temperatures, strong chemicals, or heavy pressure? These factors affect your choice.

Measure and confirm the exact size and dimensions you need.

Consider the wall thickness and diameter for a proper fit and strong performance.

Check if the tubes will carry fluids, gases, or solids. The type of material moving through the tube changes the specifications you need.

Think about the temperature range and chemical resistance required for your application.

Review any regulatory or safety requirements that apply to your project.

You should also consider the complexity of your project. Large or specialized projects may need expert advice to ensure you meet all stainless steel tube standards and specifications.

You must match your tube selection to the right standards and grades. Stainless steel tubes and pipes must meet strict specifications for safety and performance. Look for products that comply with recognized standards like ASTM, ISO, or ASME. These standards set the rules for dimensions, tolerances, and quality.

Check if your project requires compliance with specific stainless steel tube standards.

Make sure the tubes meet the correct ISO or ASTM specifications for your industry.

Choose the right stainless steel grade for your environment. Some grades resist corrosion better, while others handle higher temperatures or pressure.

Confirm that the tubes have the proper markings and certifications. This step helps you avoid problems with inspections or future repairs.

Matching the right standards and grades ensures your tubes will perform well and last longer in your application.

You need to select the correct size parameters for your stainless steel tubes and pipes. The main factors include outside diameter, wall thickness, and length. These measurements affect the tube’s performance, flow rate, and pressure capacity.

Choose a larger diameter if you need a higher flow rate.

Pick a thicker wall for applications with high pressure or heavy loads.

Select the right length to fit your installation and reduce waste.

Always check the specifications for each size. Make sure the tubes meet the required standards for your project. You should also verify that the tubes are available in the sizes you need. If you have special requirements, ask your supplier about custom options.

Tip: When you select stainless steel tubes and pipes, always balance performance, cost, and availability. This approach helps you get the best results for your project.

Before you finalize your stainless steel tube size, you need to confirm that your chosen size is available when you need it. Availability plays a major role in keeping your project on schedule and within budget. In 2025, supply chain reliability has become more important than ever. You cannot afford delays caused by out-of-stock sizes or long lead times.

Timely delivery depends on your supplier’s inventory and their ability to manage disruptions. If you select a tube size that is hard to find or only available from a single source, you risk project setbacks and extra costs. You should always check with your supplier to see which sizes they keep in stock and how quickly they can deliver. Ask about their inventory management and shipping options. Reliable suppliers will have clear answers and can help you plan for any potential delays.

Market conditions also affect tube availability. Raw material prices can change quickly. Geopolitical events and supply chain disruptions may limit access to certain sizes or grades. When you choose a tube size, consider how stable its supply and price have been over the past year. Tube sizes that are popular and widely used tend to be more available and less affected by sudden market changes. This stability helps you stick to your project timeline and budget.

You can take several steps to reduce the risk of supply problems:

Check supply chain risks, such as geopolitical issues or supplier reliability, before you order.

Work with more than one supplier. Sourcing from different regions helps you avoid disruptions if one supplier faces delays.

Choose tube sizes that are common and easy to find from multiple suppliers. Rare or custom sizes may take longer to deliver.

Ask about your supplier’s logistics. Efficient shipping routes and methods can shorten lead times and help you get your tubes faster.

Consider bulk purchasing if your project allows. Buying in larger quantities can save money and ensure you have enough material on hand.

Design your project for material efficiency. Using standard sizes can lower costs and make sourcing easier.

Tip: Always communicate with your suppliers early in the planning process. Ask about current stock levels, expected delivery times, and any possible supply chain challenges. This helps you avoid surprises and keeps your project moving forward.

By confirming availability before you order, you make sure your stainless steel tubes arrive on time and in the right quantity. This step protects your schedule, controls costs, and helps you deliver a successful project in 2025.

You need to use the stainless steel tube sizes chart to achieve the best performance in your projects. The right tube size improves performance in every application. You should check the chart and follow the latest specifications. This step helps you meet performance goals and avoid mistakes. You can boost performance by matching tube size to your needs. Always ask suppliers or engineers about performance and compliance. Staying updated with 2025 standards ensures top performance and reliable results. Performance depends on your choices at every step.

For the highest performance, always review the chart and specifications before you order.

You measure tubes by their actual outside diameter and wall thickness. Pipes use nominal sizes that do not match the real diameter. Always check the chart before you order to avoid mistakes.

You select wall thickness based on pressure, strength, and application needs. Thicker walls handle higher pressure and offer more durability. Use the chart and consult your supplier for the best choice.

Yes, you can order custom lengths from most suppliers. Custom lengths help you reduce waste and fit your project exactly. Ask your supplier about minimum order quantities and lead times.

You should check ASTM, ASME, and ISO standards. These standards ensure quality, correct sizing, and safety. Always confirm that your tubes meet the required specifications for your industry.

You will find 304 and 316 as the most common grades. Grade 304 works well for general use. Grade 316 offers better corrosion resistance, especially in harsh environments.

You can use a conversion chart or calculator. For example, 25.4 mm equals 1 inch. Always double-check your measurements to ensure compatibility with fittings and system requirements.

Tube markings show size, material, and heat code. These markings prove compliance with standards and help you trace the product. Always check markings before installation to avoid problems.

Yes, but you must use sanitary or precision tubing. These tubes have smooth finishes and meet strict standards like ASTM A270. Always confirm the tube’s certification for hygienic use.