close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-12 Origin: Site

You need to choose the right schedule 40 stainless steel pipe by matching its size, schedule, and grade to your project’s needs. Always consider the pressure the pipe must handle and the temperature it will face. Wall thickness and inner diameter affect the pipe’s strength and flow, so check these details on a pipe chart before you buy.

Tip: Always confirm the pipe meets industry standards and certifications for safety and reliability.

Schedule 40 stainless steel pipes offer a strong, cost-effective choice for medium-pressure projects with balanced flow and durability.

Choosing the right pipe size, wall thickness, and grade ensures your system handles pressure, temperature, and corrosion safely.

Grades 304 and 316 are common; grade 316 resists harsh chemicals and saltwater better due to added molybdenum.

Always check pipe dimensions like inside diameter and wall thickness using a pipe chart to match your flow and pressure needs.

Verify that pipes meet ASTM, ASME, and ISO standards with proper certifications to guarantee quality and safety.

Define your application clearly before buying to select the correct pipe schedule, size, and grade for your project.

Avoid common mistakes like mismatching pipe schedules, ignoring pressure or temperature limits, and overlooking corrosion resistance.

Choose suppliers carefully by checking their reputation, product quality, pricing, and customer support to ensure a smooth purchase.

You often see schedule 40 stainless steel pipe in many modern projects. This type of pipe follows the ASME B36.19M standard, which sets the dimensions for industrial stainless steel pipes. The "schedule 40" label refers to a specific wall thickness for each nominal pipe size. This thickness gives the pipe enough strength to handle internal pressure in medium-pressure systems. The schedule number does not tell you the material grade but shows the wall thickness series. For example, you might use ASTM A312 Grade 316L with schedule 40 thickness. This standardization helps you choose pipes that meet your project's pressure and safety needs.

Schedule 40 stainless steel pipe stands out because of its balance between strength and cost. You get a medium wall thickness, which means the pipe can handle moderate pressure without being too heavy or expensive. The pipe has a larger internal diameter than higher schedules, so it allows more fluid to flow through. This makes it a popular choice for many applications. The table below compares schedule 40 with other schedules:

Schedule Type | Wall Thickness | Pressure Ratings | Flow Capacity | Typical Use Cases |

|---|---|---|---|---|

10 | Thin | Low | High | Low-pressure, light-duty |

40 | Medium | Medium | Moderate | General-purpose, medium-pressure |

80 | Thick | High | Lower | High-pressure, heavy-duty |

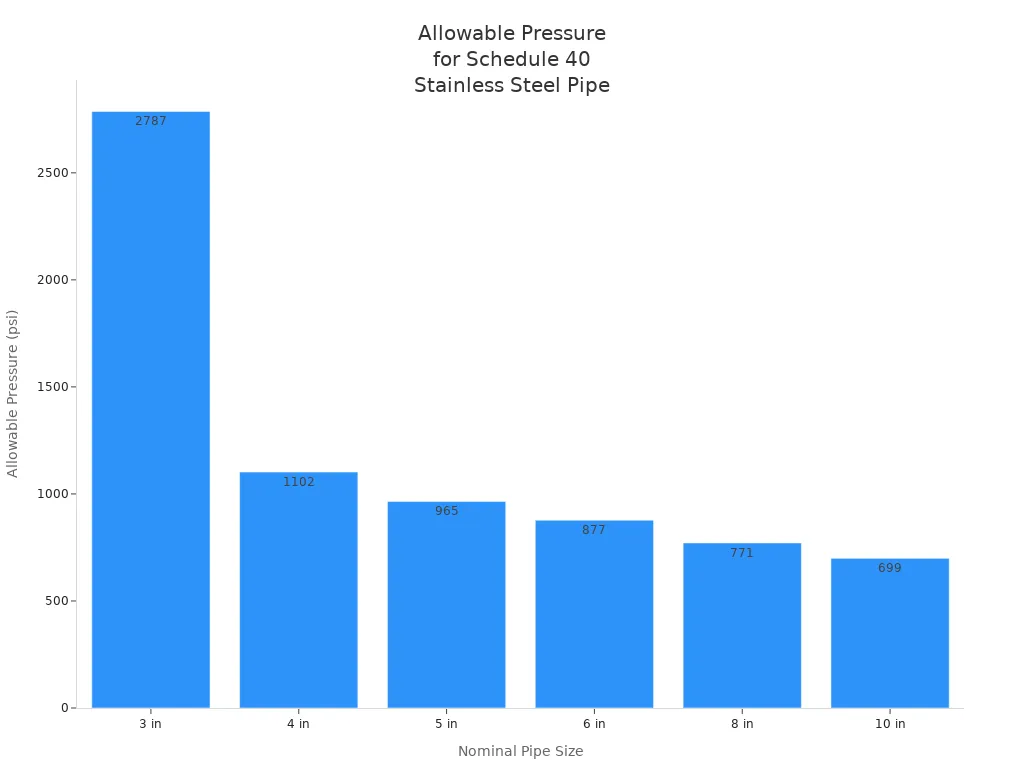

You can see that schedule 40 offers a good mix of durability and flow, making it ideal for general-purpose and medium-pressure systems. The pipe's pressure ratings depend on its size and wall thickness. For example, a 3-inch schedule 40 pipe can handle up to 2,787 psi at 100°F, while a 6-inch pipe can handle 877 psi at the same temperature. These ratings help you match the pipe to your system's needs.

You will find schedule 40 stainless steel pipe in many commercial and industrial settings. It works well in HVAC systems, fire sprinkler systems, and plumbing. Many water treatment and desalination plants use this pipe because it resists corrosion and lasts a long time. The pipe also supports structures in buildings and factories. In the food, beverage, and pharmaceutical industries, you need pipes that do not contaminate products and can handle cleaning chemicals. Schedule 40 meets these needs with its pressure capacity and corrosion resistance. You can rely on industrial stainless steel pipes for safe fluid transport, strong structural support, and long service life in medium- and high-pressure environments.

You often see austenitic stainless steel pipes in modern projects because they offer a unique combination of strength, resistance, and durability. These industrial stainless steel pipes contain high levels of chromium and nickel, which form a protective oxide layer. This layer gives the pipes exceptional resistance to corrosion and chemical attack. You can use these pipes in many industries, including food and beverage, chemical processing, and water treatment. Their austenitic structure provides excellent ductility and formability, so you can shape and weld them easily. The smooth surface of these pipes also helps maintain hygiene, which is important for food, beverage, and pharmaceutical applications.

Austenitic stainless steel pipes have:

Exceptional corrosion resistance due to a chromium-based passive oxide layer.

Strong mechanical strength and durability, even under high pressure and temperature.

Excellent heat resistance, tolerating temperatures up to about 870°C.

Great ductility, formability, and weldability for easy fabrication.

Hygienic surfaces, making them ideal for food and medical industries.

Reliable performance for schedule 40 applications in corrosive environments.

You can trust industrial stainless steel pipes to deliver long-lasting service in harsh conditions.

You will most often choose between grades 304 and 316 for industrial stainless steel pipes. Both grades belong to the austenitic family, but they have different chemical compositions that affect their performance.

Grade 304 stainless steel contains about 18% chromium and 8% nickel. This combination gives it strong resistance to corrosion and oxidation. Grade 316 stainless steel contains around 16% chromium, 11% nickel, and 2-3% molybdenum. The addition of molybdenum makes grade 316 more resistant to pitting and crevice corrosion, especially in chemical and marine environments. If your project involves exposure to aggressive chemicals or saltwater, you should consider grade 316.

Element | Grade 304 Composition (%) | Grade 316 Composition (%) |

|---|---|---|

Chromium (Cr) | ~18 | 16 - 18 |

Nickel (Ni) | ~8 | 10 - 14 |

Molybdenum (Mo) | None or trace | 2 - 3 |

Carbon (C) | Small amounts | Small amounts |

Manganese (Mn) | Small amounts | Small amounts |

Silicon (Si) | Small amounts | Small amounts |

Phosphorus (P) | Small amounts | Small amounts |

Sulfur (S) | Small amounts | Small amounts |

The key difference is the molybdenum in grade 316, which boosts its resistance to chemical attack. Both grades work well for schedule 40 pipes, but grade 316 offers extra protection in tough chemical environments.

When you use austenitic industrial stainless steel pipes, you gain several important benefits. These pipes provide outstanding resistance to corrosion and oxidation, which is essential in chemical processing and food and beverage industries. You also get high strength at elevated temperatures, so the pipes perform well in demanding settings. The smooth, hygienic surface prevents contamination, making these pipes perfect for food and beverage production.

Key benefits include:

Exceptional resistance to chemical and environmental attack.

High durability and strength-to-weight ratio.

Resistance to stress corrosion cracking under pressure.

Long service life, even in harsh chemical environments.

Easy shaping and forming due to high ductility.

Hygienic properties for safe food and beverage handling.

You can rely on industrial stainless steel pipes for safe, clean, and efficient transport of fluids in chemical processing, food, and beverage applications. Their durability and resistance make them a smart choice for any project that demands long-term performance.

You must always start by considering the application when choosing a schedule 40 stainless steel pipe. The way you plan to use the pipe will decide the wall thickness, pressure rating, corrosion resistance, temperature tolerance, mechanical strength, and cost-effectiveness you need. Schedule 40 pipes offer a medium wall thickness, which balances strength and cost. This makes them a good fit for general fluid handling, plumbing, HVAC, and industrial process lines.

Different applications require different schedules and grades. For example, if you need a pipe for decorative handrails, you can use a lighter schedule. If you work with chemical processing, steam, or high-pressure systems, you need a thicker schedule and a grade with higher resistance. The type of fluid, the environment, and fabrication needs like weldability also guide your choice.

Tip: Always match the pipe schedule and grade to your application to optimize performance, safety, and cost.

Here is a quick reference table to help you match applications with the right schedule:

Application Type | Recommended Schedule | Reason |

|---|---|---|

Decorative handrails | SCH 5 | Lightweight and easy to install |

Sanitary fluid lines | SCH 10 | Clean finish, suitable for welding |

General water distribution | SCH 40 | Balanced strength and cost |

Steam or compressed air lines | SCH 80 | Withstands high pressure and temperature |

Chemical processing or abrasive flow | SCH 80 / SCH 160 | Thick walls resist internal wear |

Nuclear or military piping | SCH 160 / XXS | Maximum pressure resistance and reliability |

You can see how the application shapes your decision. Always check the requirements for pressure, corrosion, and chemical exposure before you choose.

Pressure and temperature are two of the most important factors in pipe selection. Schedule 40 stainless steel pipe can handle a wide range of pressures and temperatures, but you must know the limits for your application. The pressure rating depends on the pipe’s diameter, wall thickness, and the grade of stainless steel. Smaller diameter pipes can handle higher pressures. For example, in oil and gas or industrial settings, schedule 40 pipes can handle pressures up to 2000 psi in upstream processes.

The temperature rating also matters. Stainless steel pipes made from 304 or 316 grades can withstand temperatures up to 1600 °F. This is possible because of the chromium oxide layer that protects the pipe from heat and chemical attack. Stainless steel pipes offer higher temperature tolerance than carbon steel pipes, which are only rated up to 850 °F for high-temperature service.

Key points to remember:

Always check the pressure ratings for your pipe size and grade.

Higher pressure or high-temperature applications may require thicker schedules or special grades.

Use a pipe chart to confirm the pressure capacity for your chosen pipe.

Note: Pressure ratings drop as temperature increases, so always check both values for your application.

Corrosion resistance is critical for many applications, especially in chemical processing, water treatment, food, and beverage industries. The grade of stainless steel you choose will affect how well the pipe resists corrosion. Schedule 40 T304/304L stainless steel pipe offers good corrosion resistance for general-purpose uses. It works well in chemical, food, and architectural applications. You can use it in paper and chemical industries, as well as in cryogenic services. This grade is non-magnetic and easy to weld, making it a popular choice for sanitary and architectural uses.

If you need higher resistance, consider duplex or 316 grades. Duplex stainless steel provides very high resistance, especially in chloride-rich environments. Ferritic and martensitic grades have lower corrosion resistance and are less common in schedule 40 pipes for demanding applications.

Stainless Steel Family | Corrosion Resistance Level | Typical Grades Used in Schedule 40 Pipes |

|---|---|---|

Austenitic | High | 304, 316 |

Duplex | Very High | 318L, LDX 2101, 2507 |

Ferritic | Medium | 409, 430 |

Martensitic & Precipitation Hardening | Moderate to Good | 410, 420 |

You should always match the corrosion resistance of your pipe to the chemicals, water, and environmental conditions in your application. This ensures long-term durability and safety.

When you select a schedule 40 stainless steel pipe, you need to pay close attention to the inner diameter (ID). The ID is the open space inside the pipe where fluids move. This measurement directly affects how much liquid or gas can pass through the pipe at any given time.

A larger inner diameter allows more fluid to flow. It also reduces the speed of the fluid and lowers the pressure drop along the pipe. This means your system can move liquids or gases more efficiently. If you choose a pipe with a small ID, you may see higher fluid velocity and greater pressure loss. This can lead to problems like noise, vibration, or even damage from water hammer.

Tip: For most process piping, increasing the pipe diameter can help reduce pressure surges and lower the risk of hydraulic transients. These benefits are most noticeable in pipes that are 12 inches or smaller.

You should always check the pipe chart for the exact ID of the schedule 40 pipe you plan to use. The wall thickness and the nominal pipe size together determine the ID. For example, a 2-inch schedule 40 stainless steel pipe has an ID of about 2.067 inches, while a 4-inch pipe has an ID of about 4.026 inches.

Nominal Pipe Size (inches) | Schedule 40 Wall Thickness (inches) | Inner Diameter (inches) |

|---|---|---|

1 | 0.133 | 1.049 |

2 | 0.154 | 2.067 |

4 | 0.237 | 4.026 |

6 | 0.280 | 6.065 |

You can use this table to compare different sizes and see how the ID changes. Always match the pipe’s ID to your system’s flow requirements. If you need to move a large volume of fluid, pick a pipe with a bigger ID. If your system needs to control flow speed or pressure, you may need a smaller ID.

Key points to remember:

Larger ID = higher flow rate, lower pressure drop.

Smaller ID = higher velocity, more pressure loss.

Benefits of increasing ID are most significant for pipes 12 inches or smaller.

By understanding how inner diameter affects flow, you can design a piping system that works efficiently and safely. Always use a pipe chart and consider your application’s needs before making a final choice.

When you look at stainless steel pipe sizes, you will see the term Nominal Pipe Size (NPS) used often. NPS is a standard system that helps you identify the general size of a pipe, but it does not always match the actual outside diameter. For schedule 40 stainless steel pipes, NPS starts as small as 1/8 inch and goes up to 36 inches. This wide range lets you choose the right pipe for almost any project, from small plumbing jobs to large industrial systems.

NPS (inches) | Typical Applications |

|---|---|

1/8 – 1 | Instrumentation, lab use |

1 1/4 – 6 | Plumbing, HVAC, process |

8 – 36 | Water mains, industry, plant |

You can see how stainless steel pipe sizes cover both small and large needs. The NPS system makes it easier for you to compare pipes and select the right one for your application.

Understanding the outside diameter (OD) and inside diameter (ID) is key when working with stainless steel pipe sizes. The OD is the measurement across the outside of the pipe. This measurement stays the same for a given NPS, no matter the wall thickness. The ID is the open space inside the pipe, which changes depending on the wall thickness.

The OD helps you match pipes with fittings and connectors. If you pick the wrong OD, your fittings will not fit.

The ID tells you how much fluid can flow through the pipe. A larger ID means more flow and less pressure drop.

You need to use tools like calipers or bore gauges to measure these dimensions accurately.

Matching the correct OD and ID ensures your system is leak-free and safe, especially in high-pressure situations.

Dimension | Description |

|---|---|

Outside Diameter (OD) | The external width of the pipe; remains constant regardless of wall thickness. Critical for selecting compatible fittings. |

Wall Thickness (Schedule) | Defines the pipe's wall thickness; schedule 40 indicates a specific thickness affecting ID and pressure capacity. |

Inside Diameter (ID) | Calculated by subtracting twice the wall thickness from the OD; determines flow capacity and fitting connection integrity. |

You should always check both OD and ID when reviewing stainless steel pipe sizes. This helps you avoid mistakes and ensures your fittings and flow rates are correct.

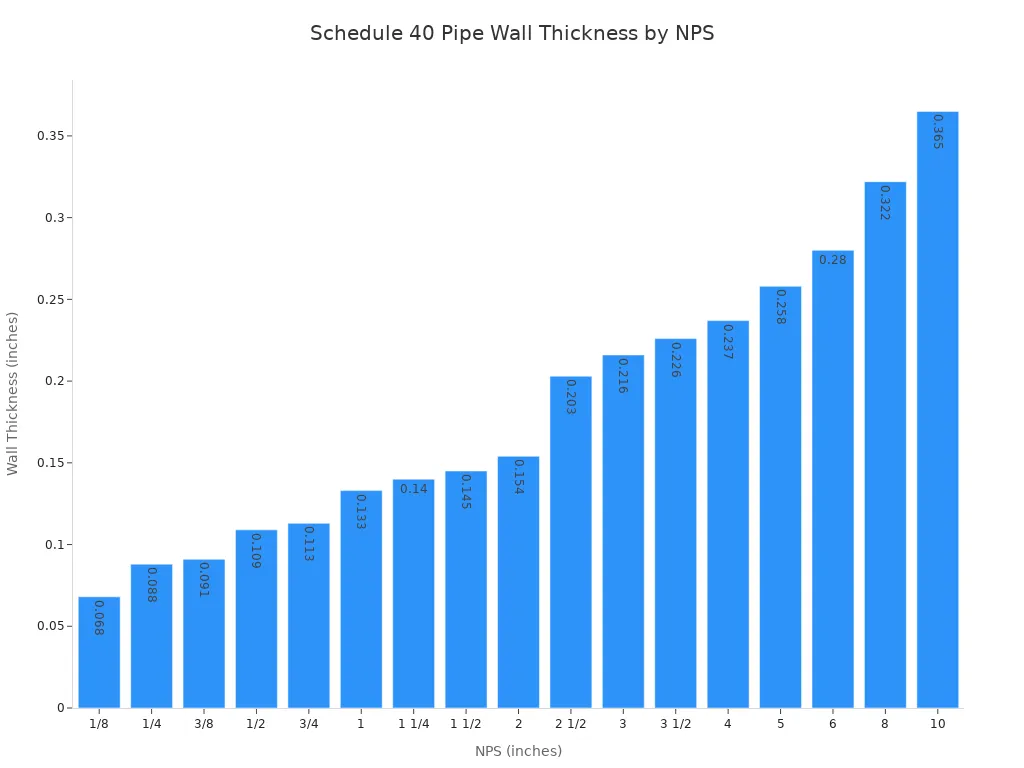

Wall thickness is another important part of stainless steel pipe schedules. The schedule number, such as schedule 40, tells you the wall thickness for each NPS. Thicker walls mean higher pressure ratings but smaller inside diameters. For schedule 40 stainless steel pipes, the wall thickness changes with the pipe size.

NPS (inches) | Schedule 40 Wall Thickness (inches) |

|---|---|

1/8 | 0.068 |

1/4 | 0.088 |

3/8 | 0.091 |

1/2 | 0.109 |

3/4 | 0.113 |

1 | 0.133 |

1 1/4 | 0.140 |

1 1/2 | 0.145 |

2 | 0.154 |

2 1/2 | 0.203 |

3 | 0.216 |

3 1/2 | 0.226 |

4 | 0.237 |

5 | 0.258 |

6 | 0.280 |

8 | 0.322 |

10 | 0.365 |

You can use this table to compare wall thicknesses across different stainless steel pipe sizes. Always check the wall thickness before you buy, because it affects both the strength and the flow of your system. Stainless steel pipe schedules help you find the right balance between pressure capacity and flow rate for your project.

Tip: Always use a pipe chart to confirm the exact dimensions and wall thickness for your chosen stainless steel pipe sizes. This ensures your system will work safely and efficiently.

You need to understand stainless steel pipe schedules to choose the right pipe for your project. The schedule number, such as 40 or 80, tells you the wall thickness for each pipe size. This number affects the pipe’s strength, pressure rating, and how much fluid can flow through it. When you look at stainless steel pipe sizes, you will see that the schedule works together with the nominal pipe size (NPS) to define the pipe’s dimensions.

A pipe schedule chart is your main tool for comparing stainless steel pipe schedules. This chart lists the NPS, outside diameter (OD), and wall thickness for each schedule. You use it to match your project’s needs with the correct pipe. Here is how you can use a pipe schedule chart:

Measure the outside diameter (OD) and wall thickness of the pipe you need.

Find the OD in the chart under the correct NPS.

Look across to the column for the schedule you want, such as Schedule 40.

Check the wall thickness and confirm it matches your requirements.

Make sure the pipe’s dimensions meet your system’s pressure and flow needs.

Tip: Always check the pipe schedule chart before you buy. This helps you avoid mistakes and ensures your pipe will handle the pressure and flow in your system.

Stainless steel pipe schedules help you compare different stainless steel pipe sizes quickly. For example, a 2-inch NPS pipe with Schedule 40 has a wall thickness of 0.154 inches, while Schedule 80 for the same size has a wall thickness of 0.218 inches. The thicker wall in Schedule 80 means it can handle higher pressure, but the inside diameter is smaller, so less fluid can flow through.

You should also pay attention to the standards that define stainless steel pipe schedules. The ASME B36.19 standard gives you the official dimensions for stainless steel pipe sizes and schedules. This standard ensures that pipes from different suppliers will fit together and perform as expected.

When you select a pipe, always consider these factors:

The operating pressure and temperature in your system.

The type of fluid or gas moving through the pipe.

The installation environment, such as indoor or outdoor use.

Your budget and the cost of installation.

By using a pipe schedule chart and understanding stainless steel pipe schedules, you can confidently choose the right pipe for your project. You will know the exact sizes and dimensions you need, and you can be sure your system will be safe and reliable.

You need to check ASTM standards when you select schedule 40 stainless steel pipe. ASTM sets the rules for how these pipes are made and tested. These standards help you make sure the pipe will work safely in your project. ASTM A312 is the main standard for schedule 40 stainless steel pipes. It covers seamless, welded, and heavily cold-worked austenitic stainless steel pipes. This standard tells you what chemical makeup, mechanical strength, and dimensional tolerances the pipe must have. It also lists the tests required to prove the pipe’s quality, such as tensile, flattening, hydrostatic, and electric tests.

Other ASTM standards you might see include:

ASTM A358: For electric-fusion-welded austenitic stainless steel pipes.

ASTM A269: For seamless and welded tubing in general service.

ASTM A270: For sanitary tubing in food and pharmaceutical industries.

ASTM A554: For welded mechanical tubing.

ASTM A789/A790: For duplex stainless steel pipes with high strength and corrosion resistance.

ASTM standards make sure your pipe has the right wall thickness, strength, and quality for schedule 40 use.

You should also look for ASME and ISO certifications on your stainless steel pipe. ASME (American Society of Mechanical Engineers) sets codes for pressure piping. These codes help you know the pipe will handle the pressure in your system. ASME B36.19M is the standard for stainless steel pipe dimensions, including schedule 40. This standard matches the ASTM rules, so you get the same quality and fit.

ISO (International Organization for Standardization) creates global standards for pipes. ISO standards help you use pipes from different countries in your project. ISO 1127 is one example for stainless steel pipes. When you see ASME and ISO marks, you know the pipe meets strict rules for safety and quality.

Standard | What It Covers | Why It Matters |

|---|---|---|

ASME | Pipe dimensions, pressure ratings | Safe, reliable systems |

ISO | International pipe standards | Global compatibility |

Always check for ASME and ISO certifications to ensure your pipe meets the highest quality standards.

You must meet special requirements if you use schedule 40 stainless steel pipe in food processing or pharmaceuticals. In these industries, you need pipes that prevent contamination and keep fluids safe. Pipes made from 304 stainless steel often meet these needs because they have a smooth, non-porous surface. This surface helps you keep the system clean and maintain hygiene.

For food and pharmaceutical use, you should only buy pipes that come with full material test reports and certifications. These documents prove the pipe’s quality and safety. The pipe must also meet ASTM A312 and other international standards. You need to choose suppliers with strong quality assurance and technical support. This helps you avoid problems and ensures your system meets strict industry rules.

Key requirements for food and pharmaceutical use:

Pipes must prevent contamination.

Surfaces must be smooth and easy to clean.

Full certifications and test reports are required.

Suppliers must show strong quality control.

Choosing the right standards and certifications protects your process and guarantees the quality of your finished product.

You should always start by defining the application before choosing a schedule 40 stainless steel pipe. This step helps you match the pipe to your project’s needs and ensures long-term quality. Follow these steps to define your application requirements:

Identify the type of fluid the pipe will carry. Water, chemicals, and gases each have different needs.

Determine the operating temperature of the fluid. High temperatures may require special materials.

Find out the operating pressure in your system. Pressure affects the wall thickness and strength you need.

Consider the cost and availability of the pipe material. Some materials are easier to find or more affordable.

Evaluate weldability and manufacturability. You want a pipe that is easy to fabricate for your application.

Assess material characteristics such as density, corrosion resistance, tensile strength, yield strength, elasticity, ductility, hardness, toughness, creep resistance, and fatigue resistance. These factors affect the pipe’s performance and quality.

Understand pipe schedule numbers. The schedule relates to wall thickness and strength. Make sure the schedule matches your design pressure and allowable stress.

Tip: Defining your application clearly helps you avoid costly mistakes and ensures the pipe will deliver the quality you expect.

After you define the application, you need to select the correct size and schedule for your pipe. The size and schedule affect how the pipe performs in different applications. You must consider pipe dimensions, pressure ratings, and material type. Stainless steel pipes come in schedules like 10S, 40S, and 80S. The schedule number tells you the wall thickness, which changes the pressure rating. Smaller pipes with thicker walls can handle higher pressures. For example, a small, thick-walled pipe may handle up to 2000 psi, while a larger, thin-walled pipe may only handle 200 psi. The outer diameter stays the same across schedules, so fittings remain compatible.

You should also think about velocity limits. High velocity can cause noise, erosion, and water quality problems. Stainless steel pipes can handle higher velocities, but you still need to check the fluid type and temperature. Keep the minimum velocity above 0.6 meters per second to prevent sediment buildup. Try to limit pressure drop per meter to avoid needing extra pumps, which add cost and maintenance. Sometimes, these factors conflict. Work with your project team to balance velocity and pressure drop, making sure your design fits the application and meets local standards.

Choosing the right grade of schedule 40 stainless steel pipe is key for quality and safety in your application. Start by looking at the environment where you will use the pipe. Grades like 304 and 316 are common. Grade 316 contains molybdenum, which gives better resistance to chlorides. This makes it a good choice for marine or chemical applications. Grade 304 works well for many general applications, but it may not last as long in harsh environments.

Check the nominal pipe size, outside diameter, and inside diameter to make sure the pipe fits your system. The wall thickness, shown by the schedule number, affects the pipe’s strength and pressure rating. You should also look at mechanical properties like yield strength and tensile strength. These tell you how the pipe will perform under load.

Think about the service conditions. If you expect a lot of corrosion, pick a grade with higher resistance. Decide if you need seamless or welded pipe. Seamless pipes offer higher strength and better corrosion resistance, which is important for high-pressure or aggressive applications. Welded pipes cost less but may not work as well in tough environments.

Note: Always match the pipe grade to your application for the best quality and performance.

You need to make sure your schedule 40 stainless steel pipe meets all required standards before you use it in your project. Start by asking your supplier for the right documentation. This includes certificates of compliance, material test reports (MTRs), and traceability records. These documents prove that the pipe follows ASTM standards, such as ASTM A240, which sets rules for chemical composition and mechanical properties. You should also check for ISO 9001 certification. This shows the supplier uses a quality management system.

Follow these steps to verify standards:

Ask for the manufacturer's certification. Look for UL/FM certifications and proof of compliance with ASTM standards.

Inspect the pipe's physical dimensions. Measure wall thickness, outer diameter, and straightness to confirm they match schedule 40 specifications.

Review the material test reports. These reports list the chemical makeup and mechanical properties, such as yield strength and tensile strength.

Check for non-destructive testing results. This includes ultrasonic testing for internal flaws, magnetic particle inspection for surface defects, and hydrostatic testing for pressure integrity.

Perform a visual inspection. Look for surface defects and make sure the pipe has proper markings, such as grade, size, ASTM standard, and manufacturer details.

Confirm the pipe ends are prepared correctly. They should be grooved, threaded, or plain, depending on your jointing system.

Inspect any protective coatings. Make sure coatings are uniform and well-adhered, especially if the pipe will be underground or in wet areas.

Tip: Always keep copies of all documentation. This helps you prove compliance if you face an audit or inspection.

By following these steps, you can trust that your schedule 40 stainless steel pipe meets all safety and quality requirements.

Choosing the right supplier is just as important as picking the right pipe. You want a supplier who offers quality products, fair prices, and reliable service. Use the following criteria to compare your options:

Criteria Category | Key Considerations & Details |

|---|---|

Pricing Transparency | Watch for hidden fees, such as extra processing or shipping charges. Understand pricing terms and negotiate payment options. |

Supplier Reputation & Experience | Look for suppliers with at least 10 years in business. Check for specialization in stainless steel pipes and read customer reviews. |

Product Quality | Make sure the supplier offers the grades you need and provides proof of compliance with standards. Check for product testing and traceability. |

Delivery & Logistics | Ask about shipping options, stock availability, and order tracking. Make sure the supplier can handle your delivery needs. |

Product Range & Customization | Choose a supplier who offers a wide range of pipe types and can provide custom sizes if needed. |

Customer Support & After-Sales | Test how quickly the supplier responds to questions. Look for technical support and clear warranty policies. |

You should always ask for references or testimonials. A good supplier will have a strong reputation and positive feedback from other customers. Make sure the supplier provides all required documentation and supports you through the buying process. If you need help with installation or compliance, choose a supplier who offers technical support.

Note: Comparing suppliers carefully helps you avoid delays, extra costs, and quality problems in your project.

You can run into serious problems if you do not match the pipe to your specific applications. Many failures in stainless steel piping systems happen because of simple mismatches. For example, you might choose a pipe elbow with the wrong diameter, which can cause leaks or reduce flow. If you select a material thickness that does not meet your pressure or durability needs, the pipe may fail under stress. Always check that the pressure rating matches your system. Using the wrong connection method, such as threaded fittings when welding is required, can also lead to leaks or mechanical failure.

Here are some common mismatches to avoid:

Picking elbows or tees that do not fit your piping system.

Ignoring the wall thickness and pressure rating.

Using the wrong connection method for your application.

Assuming all dimensions are the same across different materials.

Not matching flange thickness to the pipe schedule, which can cause leaks or flow problems.

Tip: Always follow proper installation practices. Clean surfaces, use the right sealants, and make sure everything lines up. This helps prevent stress and damage in your stainless steel piping systems.

If you ignore pressure and temperature ratings, you put your entire system at risk. Using fittings with a lower pressure rating than your system can cause gasket failure or even a flange blow-out. When you mismatch pipe schedules, such as using schedule 40 pipe with fittings made for a different schedule, you may get poor welds or loose threads. This increases the chance of leaks.

Temperature also matters. If you do not consider how heat or cold affects your pipes, you may choose the wrong connection type. Vibration and corrosive media can make things worse. Always match the pipe schedule, pressure class, and connection method to your application. This ensures a reliable seal, strong mechanical performance, and a long service life.

Overlooking corrosion resistance can lead to major failures in stainless steel piping systems. If you use the wrong grade of pipe in water treatment or chemical applications, the pipe wall can thin over time. This thinning can cause leaks, structural failures, or even bursts. For example, a contractor once installed standard stainless steel pipes in a water treatment plant exposed to changing chloride levels. Over time, pitting corrosion caused a leak, which led to an emergency shutdown and damaged equipment. The cost of repairs and lost production far outweighed any savings from using a cheaper material.

Corrosion also makes the inside of the pipe rougher. This reduces flow efficiency and increases energy use because of higher friction. In industries like food processing or pharmaceuticals, corrosion can contaminate water or other process fluids. This can lead to product recalls and harm your company’s reputation. Mechanical damage, abrasive particles, and temperature swings can make corrosion worse, shortening the life of your pipes.

Note: Always select the right material for your applications, especially in water treatment and chemical environments. Good installation and regular maintenance help prevent costly failures and keep your system safe.

You might feel tempted to skip checking standards and certifications when you buy stainless steel pipes. This mistake can lead to big problems in your project. Standards exist to make sure your stainless steel piping systems work safely and last a long time. If you ignore these rules, you risk using pipes that do not meet quality or safety requirements.

When you skip standards, you may face these issues:

Unexpected Failures: Pipes that do not meet ASTM or ASME standards can crack, leak, or burst under pressure.

Legal Trouble: Many building codes require certified materials. Using uncertified pipes can lead to fines or failed inspections.

Incompatible Parts: Pipes without standard markings may not fit with other parts in your system. This can cause leaks or weak joints.

Shorter Lifespan: Non-standard pipes may corrode faster or wear out sooner, leading to costly repairs.

Tip: Always ask your supplier for documentation. Look for certificates, test reports, and markings on the pipe itself.

You should check for these key standards before you buy:

Standard | What It Proves | Why It Matters |

|---|---|---|

ASTM A312 | Pipe meets chemical and strength specs | Ensures safe, strong pipe |

ASME B36.19M | Pipe has correct size and wall thickness | Fits with other system parts |

ISO 9001 | Supplier uses quality management | Reduces risk of defects |

You can spot certified pipes by looking for clear markings. These markings show the grade, size, schedule, and standard. If you do not see these, ask your supplier for proof. Never accept pipes without proper paperwork.

Skipping standards can also affect your warranty. Many manufacturers will not honor claims if you use uncertified pipes. This can leave you with expensive repairs and no support.

You should always make standards and certifications a top priority. This step protects your investment and keeps your stainless steel piping systems safe and reliable.

You can select the right schedule 40 stainless steel pipe by following a few clear steps. First, define your application and check the pipe size, schedule, and grade. Always compare pipe specs to your project’s needs. Use a pipe chart to confirm wall thickness and inner diameter. Review pipe standards and certifications before you buy. A good pipe choice keeps your system safe and cost-effective. If you have questions, contact a pipe expert or supplier for help.

Schedule 40 refers to a specific wall thickness for pipes. This schedule gives you a balance between strength and flow capacity. You can use schedule 40 pipes in many medium-pressure applications.

Yes, you can use these pipes outdoors. Stainless steel resists rust and corrosion. You should still check for exposure to harsh chemicals or saltwater, which may require a higher grade.

You should look for markings on the pipe. Ask your supplier for certificates and test reports. These documents prove the pipe meets ASTM, ASME, or ISO standards for stainless steel piping systems.

Seamless pipes have no weld seam. They offer higher strength and better corrosion resistance. Welded pipes cost less and work well for many general uses. You should choose based on your pressure and quality needs.

You need to match the grade to your environment. Grade 304 works for most uses. Grade 316 resists chemicals and saltwater better. Always check your application’s needs before you decide.

You should avoid mixing schedules. Different wall thicknesses can cause leaks or weak joints. Always use the same schedule throughout your stainless steel piping systems for safety and reliability.

You can use the pipe’s inner diameter and a flow calculator. Many online tools help you find the flow rate. Always check the pipe chart for exact dimensions before you start your calculations.

Tip: Always consult a professional if you have doubts about your stainless steel piping systems.