close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-11-14 Origin: Site

Here are the top 10 applications for stainless steel tube schedule 10 in 2025: chemical processing, food and beverage, pharmaceuticals, water treatment, oil and gas, marine, construction and architecture, automotive, cryogenics, and aerospace. You see stainless steel piping as a smart choice because it resists corrosion, reduces weight, and handles moderate pressure. The market for stainless steel piping keeps growing, especially in automotive and industrial sectors. Asia Pacific leads in demand, while North America grows fastest. Consider stainless steel tube schedule 10 for your next project if you want reliable, high-performance solutions.

Schedule 10 stainless steel tubes have thin walls, making them lightweight and easy to install in low-pressure systems.

These tubes offer excellent corrosion resistance, ideal for industries like chemical processing, food, pharmaceuticals, and marine.

Stainless steel piping supports hygiene and safety with smooth surfaces that prevent bacteria buildup and simplify cleaning.

Duplex and super duplex grades provide extra strength and corrosion resistance for harsh environments like desalination and offshore oil platforms.

Choosing the right material grade, size, and certification ensures long-lasting performance and compliance with industry standards.

Regular inspection, proper handling, and working with trusted suppliers help maintain pipe quality and prevent failures.

Stainless steel tubes are recyclable, supporting sustainability and reducing environmental impact in projects.

Applications span many sectors including automotive, aerospace, construction, cryogenics, and water treatment, showing their versatility and growing demand.

You often see stainless steel piping in many industries because of its reliability and versatility. Schedule 10 refers to a specific wall thickness for pipes and tubes. This schedule offers a thinner wall compared to higher schedules, making it ideal for low-pressure applications. Most commonly, you find schedule 10 pipes in sizes ranging from 1/8 inch to 4 inches in diameter. The most popular grades are 304 and 316, which provide excellent corrosion resistance and strength.

Here are some standard specifications you should know:

ASTM A312: Seamless and welded austenitic stainless steel pipes.

ASTM A999: General requirements for alloy and stainless steel pipe.

ASTM A269 and A213: Seamless and welded stainless steel tubing for general and heat exchanger service.

For example, a 3-inch schedule 10 pipe has an outer diameter of 3.5 inches and a wall thickness of 0.12 inches. These pipes are usually welded and unthreaded, which makes them suitable for welded connections in many systems.

| Specification | Schedule 10 (3" Nominal) |

|---|---|

| Outer Diameter | 3.5 inches |

| Wall Thickness | 0.12 inches |

| Common Grades | 304, 304L |

| Tensile Strength | 85 KSI |

| Yield Strength | 35 KSI |

| Elongation | 55% in 2 inches |

When you choose stainless steel piping, you benefit from several key features. Schedule 10 tubes stand out because they are lightweight and flexible. You can bend them more easily than thicker pipes, which reduces the need for extra fittings. The smooth inner surface helps lower pressure losses and keeps fluids moving efficiently.

Here is a quick comparison:

| Property/Feature | Schedule 10 Stainless Steel Tubes | Other Schedules (e.g., 40, 80) |

|---|---|---|

| Wall Thickness | Thinner | Thicker |

| Weight | Lightweight | Heavier |

| Flexibility | More flexible | Less flexible |

| Pressure Suitability | Low-pressure | Medium to high-pressure |

| Corrosion Resistance | Excellent | Excellent |

| Installation Cost | Lower | Higher |

You also get outstanding corrosion resistance, which is vital in chemical, marine, and food processing environments. Stainless steel piping is easy to clean, making it perfect for hygienic applications. Its durability means you spend less on maintenance and replacements over time.

Tip: If you want a piping system that lasts and stays clean, schedule 10 stainless steel piping is a smart choice.

In 2025, you will notice several trends shaping the use of stainless steel piping. Industries like power generation, chemical processing, and HVAC are driving demand for high-quality tubes. New manufacturing technologies allow for more precise and efficient production, which means you get better performance and reliability.

You also see a strong push for sustainability. Manufacturers now focus on eco-friendly production methods and recycled materials. Environmental regulations are stricter, so companies prefer stainless steel piping for its long life and low environmental impact.

Global infrastructure investments boost demand for stainless steel piping in water management and gas pipelines.

Specialized sectors such as pharmaceuticals and renewable energy require pipes with top corrosion resistance and precision.

The automotive industry seeks lightweight, strong materials to improve fuel efficiency, which increases the use of schedule 10 tubes.

Food and beverage companies need hygienic piping to prevent contamination, making stainless steel piping essential.

Market experts predict steady growth, with the stainless steel tube market expected to reach over USD 46.5 billion by 2032.

You can expect stainless steel piping to play a bigger role in lightweight, hygienic, and high-performance applications as these trends continue.

You often see schedule 10 stainless steel piping used for fluid transport in industrial and chemical processing plants. These tubes move acids, solvents, and other chemicals safely. You choose schedule 10 because it offers a balance between strength and weight. The thinner wall reduces cost and makes installation easier, especially in large systems.

Proper material selection is critical in chemical processing. You must consider the type of chemicals, temperature, and pressure. Stainless steel piping resists many types of corrosion, which helps prevent leaks and failures. You also benefit from smooth inner surfaces that keep fluids moving efficiently and reduce buildup.

Corrosive environments present some of the biggest challenges in industrial and chemical processing. You face risks like:

Uniform and localized corrosion, which can damage pipes over time.

External corrosion and cracking, especially from chloride concentration on pipe surfaces.

Contamination during storage, shipment, or fabrication, which can lead to hidden pitting corrosion.

Corrosion under insulation, where trapped moisture and chemicals speed up damage.

Manufacturing defects, such as poor welding, that weaken the system.

You can address these risks by choosing the right grade of stainless steel, such as dual-grade options for better strength and corrosion resistance. You should also work with trusted suppliers and follow strict quality control during installation. Regular inspections and proper handling help maintain the protective chromium oxide layer on the pipe surface.

Tip: Always check for signs of contamination and corrosion, especially in areas exposed to chlorides or insulation.

In the food and beverage industry, you need piping that keeps products safe and clean. Schedule 10 stainless steel piping is a top choice for sanitary systems. You benefit from high-quality grades like 304L and 316L, which resist corrosion and are easy to clean. The smooth, crevice-free surfaces prevent bacteria from hiding and make sterilization simple.

You also find that these tubes meet strict sanitary standards, such as FDA, EHEDG, and 3-A. Their design supports clean-in-place (CIP) systems, so you can maintain hygiene without taking apart the system. This reduces downtime and keeps your production running smoothly.

You must follow strict regulations in the food and beverage industry. Stainless steel piping helps you meet these requirements. The non-porous surface resists bacteria and chemical reactions, making it safe for transporting food and beverages. You can rely on these pipes to handle acidic and alkaline substances without breaking down.

Stainless steel piping stands out because it meets FDA sanitary codes and supports proper drainage. You can trust it to prevent microbial growth and contamination. This makes it one of the most common applications for stainless steel piping in modern food and beverage facilities.

Pharmaceutical manufacturing demands the highest levels of cleanliness. You use schedule 10 stainless steel tubes for high-purity lines that carry water for injection (WFI), clean steam, and other sensitive fluids. Grades like 316L offer superior chemical resistance and reduce the risk of contamination.

You often choose electropolished tubes for these lines. The smooth, polished surfaces make cleaning easier and help you maintain strict sanitary conditions. The thinner wall of schedule 10 tubes also makes them cost-effective for low-pressure applications.

Controlling contamination is essential in pharmaceutical environments. You rely on schedule 10 stainless steel piping because it provides smooth welds and hygienic surfaces. These features help you maintain sterile conditions and prevent unwanted particles from entering the system.

You also benefit from finishing processes like pickling and passivation, which enhance corrosion resistance. These steps ensure your piping meets industry standards and supports safe, reliable pharmaceutical production. Schedule 10 tubes are easy to weld and install, making them a practical choice for clean room and process piping.

Note: Always select the right grade and finish for your pharmaceutical piping to ensure compliance and product safety.

You play a key role in ensuring safe and reliable water delivery. Schedule 10 stainless steel piping is a top choice for water and wastewater treatment plants. You benefit from its corrosion resistance, which helps prevent leaks and contamination. The smooth inner surface keeps water flowing efficiently and reduces buildup of minerals or bacteria.

You often see schedule 10 stainless steel tubes in municipal water distribution systems. These tubes handle moderate pressure and last for decades with minimal maintenance. You can install them quickly because they are lightweight and easy to weld. This reduces downtime and labor costs.

Stainless steel piping also supports sustainability goals. You can recycle it at the end of its service life, which reduces environmental impact. Many cities now upgrade old systems with stainless steel tubes to improve water quality and reliability.

Desalination plants face some of the harshest conditions in the water and wastewater treatment sector. You need materials that resist corrosion from saltwater and chemicals. Schedule 10 stainless steel tubes, especially those made from duplex and super duplex grades, offer outstanding performance in these environments.

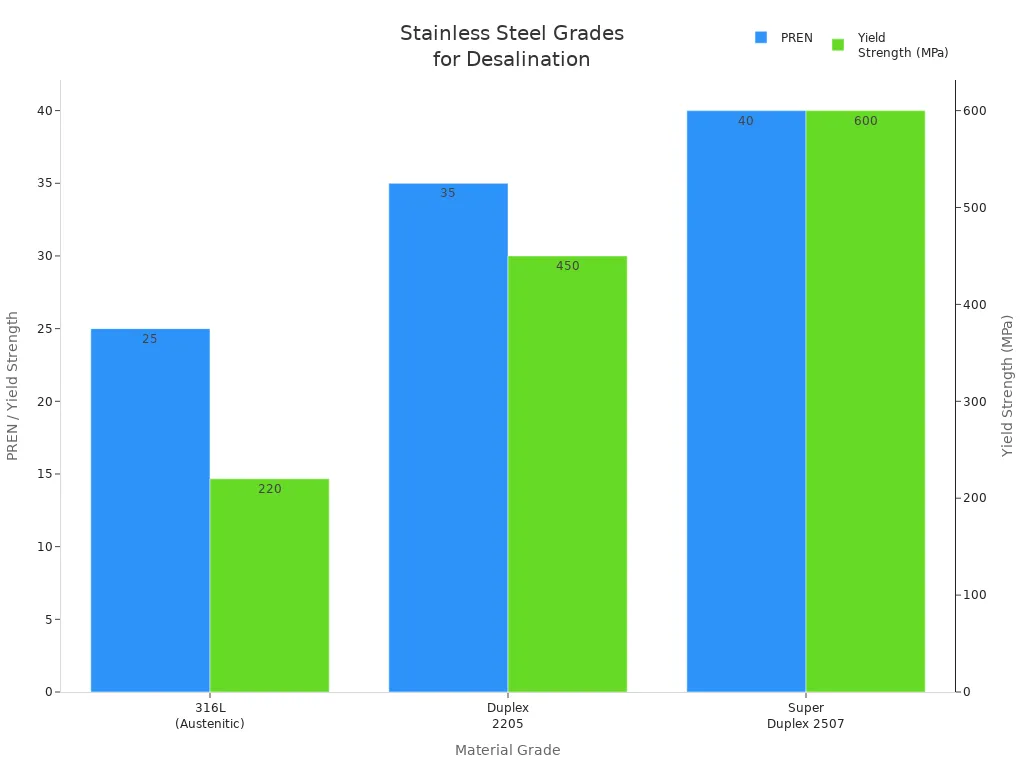

Here is a comparison of common stainless steel grades used in desalination:

| Material Grade | Pitting Resistance Equivalent Number (PREN) | Yield Strength (MPa) | Typical Application in Desalination |

|---|---|---|---|

| 316L (Austenitic) | ~25 | ~220 | Low-pressure zones, pre-treatment, product water lines |

| Duplex 2205 | ~35 | ~450 | High-pressure seawater reverse osmosis (SWRO) lines, pump manifolds |

| Super Duplex 2507 | >40 | >600 | Most aggressive zones such as high-pressure brine concentrate lines |

You can see that duplex stainless steels like 2205 and 2507 provide much higher resistance to chloride-induced pitting and stress corrosion cracking than 316L. The higher yield strength of duplex grades allows you to use thinner pipe walls, which reduces weight and installation costs. Carbon steel fails quickly in desalination plants due to chloride corrosion, so it is not suitable.

Many engineers use a zone-based material selection strategy. You can use duplex grades in aggressive, high-pressure zones and more economical grades like 316L in less aggressive areas. This approach optimizes both cost and performance.

A real-world example shows the value of this strategy. A manufacturer of containerized desalination units switched from 316L to Duplex 2205 stainless steel tubes after facing early failures from corrosion. This change allowed them to offer a 15-year warranty and improved their reputation. Customers preferred the higher reliability, even with a slightly higher price.

Tip: Always consider lifecycle cost analysis when choosing materials for desalination. The higher initial investment in duplex stainless steel often pays off through reduced maintenance and longer service life.

You encounter demanding conditions in the oil and gas industry. Schedule 10 stainless steel piping is a reliable solution for transporting crude oil and natural gas, especially in low to moderate pressure systems. You choose these tubes for their corrosion resistance, which protects against sour gas, water, and chemicals found in pipelines.

You also benefit from the lightweight nature of schedule 10 tubes. This makes installation easier, especially in remote or offshore locations. The smooth interior reduces friction losses, helping you maintain efficient flow rates.

In 2025, you see a trend toward using duplex stainless steel grades in pipelines. These grades offer higher strength and better resistance to stress corrosion cracking. You can reduce wall thickness and lower overall project costs while maintaining safety and reliability.

Offshore platforms present some of the toughest challenges in the oil and gas industry. You need materials that withstand saltwater, high winds, and constant vibration. Schedule 10 stainless steel piping, especially in 316L and duplex grades, meets these requirements.

You use these tubes for process piping, firewater systems, and utility lines. The corrosion resistance of stainless steel ensures long service life, even in harsh marine environments. You also benefit from the ease of fabrication and welding, which speeds up construction and maintenance.

Note: Regular inspection and maintenance help you extend the life of stainless steel piping on offshore platforms. Always follow best practices for welding and installation to prevent corrosion at joints.

You face unique challenges in marine environments. Saltwater causes rapid corrosion in many materials, but schedule 10 stainless steel tubes, especially those made from 316L, provide excellent protection. You use these tubes in seawater cooling systems, ballast water lines, and onboard plumbing.

Stainless steel 316 tubes contain chromium, nickel, and molybdenum, which resist saltwater corrosion and pitting.

These tubes maintain strength at high temperatures found in engine rooms.

They offer toughness and ductility, so they withstand vibration and mechanical stress.

You must clean them regularly to remove salt deposits and prevent corrosion.

These properties make schedule 10 stainless steel tubes a preferred choice for marine applications. You can rely on them for long-term performance and safety.

Ballast lines help you control the stability and trim of ships. You need piping that resists corrosion and mechanical wear. Schedule 10 stainless steel piping meets these needs. You benefit from its durability and ease of installation.

You often see these tubes used in both new ship construction and retrofits. The lightweight design reduces overall vessel weight, which can improve fuel efficiency. You also find that stainless steel piping requires less maintenance than traditional materials, saving you time and money over the vessel’s lifetime.

Tip: Always select the right grade of stainless steel for your marine systems. Regular cleaning and inspection help you maximize service life and prevent unexpected failures.

You see schedule 10 stainless steel piping used in many modern buildings. Its thin walls and corrosion resistance make it ideal for light structural applications. You often use these tubes for handrails, guardrails, supports, and even cladding on building exteriors. The material stands up well to weather, so you do not need to worry about rust or frequent repairs. You can also combine stainless steel piping with glass, wood, or concrete for unique architectural designs.

Here is a table showing some common uses in construction and architecture:

| Use Category | Examples and Features |

|---|---|

| Structural Uses | Cladding, roofing, railings, supports, handrails, guardrails |

| Decorative Uses | Polished surfaces, laser cutting, etching, custom fabrication for aesthetic appeal |

| Safety and Control | Stainless steel bollards for traffic and pedestrian management |

| Load-Bearing Elements | Stainless steel gratings used for drainage, pathways, and areas requiring corrosion resistance |

| Material Properties | Corrosion resistance, durability, low maintenance, recyclability, compatibility with glass, wood, concrete |

You benefit from the durability and low maintenance of stainless steel piping. You also help the environment because you can recycle these tubes at the end of their life. In 2025, you see more architects choosing stainless steel piping for both safety and style.

You can use schedule 10 stainless steel piping for decorative trim in both interior and exterior spaces. Polished surfaces and custom shapes add a modern look to buildings. You might see laser-cut designs or etched patterns that make a space stand out. Stainless steel piping works well for door frames, window trims, and accent pieces.

You choose this material because it stays bright and clean with little effort. It resists fingerprints and stains, so you spend less time on upkeep. You also find that stainless steel piping matches well with other materials, giving you more design options.

Tip: If you want a building that looks great and lasts for years, consider using stainless steel piping for both structure and decoration.

You find schedule 10 stainless steel piping in many automotive exhaust systems. The thin walls help reduce vehicle weight, which improves fuel efficiency. You also get excellent corrosion resistance, so exhaust pipes last longer even in harsh weather. Manufacturers often use welded stainless steel tubes for exhausts because they are cost-effective and easy to shape.

Recent advances in manufacturing, like laser welding, improve the quality and durability of these pipes. You see fewer failures at the seams, and the pipes resist rust better than older designs. In 2025, more car makers use stainless steel piping to meet stricter emissions and durability standards.

You also see schedule 10 stainless steel piping used in automotive frames and chassis parts. These tubes help make vehicles lighter without sacrificing strength. You benefit from better crash protection because stainless steel piping absorbs energy during collisions. Hydroforming allows you to create complex shapes, which improves handling and safety.

By using advanced high-strength steel tubes, you can reduce the weight of a vehicle by up to 20%. This not only saves fuel but also lowers emissions. You help make cars safer and more efficient by choosing stainless steel piping for key structural parts.

Note: Stainless steel piping in cars is not just about strength. It also helps you meet new environmental rules and keeps vehicles running longer.

You need materials that stay strong and flexible at very low temperatures in cryogenic systems. Schedule 10 stainless steel piping performs well in these conditions. You use it to transport liquefied gases like nitrogen, oxygen, and argon. The piping does not become brittle, so you avoid leaks and failures.

You also benefit from the smooth inner surface, which keeps fluids moving efficiently. Stainless steel piping resists cracking and maintains its shape, even when exposed to extreme cold. In 2025, you see more use of stainless steel piping in medical, scientific, and industrial cryogenic applications.

Callout: Always check the grade of stainless steel piping before using it in cryogenic systems. Grades like 304L and 316L offer the best performance at low temperatures.

You now see why schedule 10 stainless steel piping remains one of the most common applications for stainless steel piping across many industries. Its unique properties make it a top choice for construction, automotive, and cryogenic uses.

You play a vital role in aerospace innovation when you choose schedule 10 stainless steel piping for lightweight structures. Aircraft designers always look for ways to reduce weight without sacrificing strength or safety. Schedule 10 tubes offer a thinner wall, which helps you cut down on overall aircraft mass. This weight reduction leads to better fuel efficiency and improved flight performance.

You often select grades like T 304, T 304L, T 316L, T 321, and T 347 for aerospace structures. These grades provide excellent corrosion resistance and mechanical strength. You can use them in parts such as exhaust stacks, manifolds, and even some structural supports. The ability to withstand high temperatures—up to 1200°F or even 1500°F for certain grades—means you can rely on these tubes in demanding environments.

Here is a table that shows how different grades of stainless steel piping support aerospace needs:

| Stainless Steel Tube Grade | Aerospace Uses | Key Properties Supporting Selection |

|---|---|---|

| T 304, T 304L, T 316L, T 321, T 347 | Aircraft structural parts, exhaust stacks, manifolds | Corrosion resistance, heat resistance, weldability, mechanical strength |

| AMS 5565, AMS 5566, AMS 5570, AMS 5571 | Aircraft hydraulic line tubing, structural parts | Corrosion resistance, heat resistance up to ~1500°F, strength, ductility |

You benefit from the weldability of these tubes. You can fabricate complex shapes and join sections easily, which is essential for custom aerospace designs. The durability of stainless steel piping ensures that your aircraft structures last longer and require less maintenance.

Tip: When you design for aerospace, always consider the balance between weight and strength. Schedule 10 stainless steel piping gives you both.

You also depend on schedule 10 stainless steel piping for fluid systems in aerospace applications. Aircraft need reliable tubing for hydraulic and pneumatic systems. These systems control landing gear, brakes, and flight surfaces. You must use materials that handle high pressure and resist corrosion from hydraulic fluids and environmental exposure.

You often choose grades like T 321 and T 347 for fluid lines because they offer both heat resistance and weldability. Specifications such as MIL-T-6845, MIL-T-8808, and MIL-T-8973 guide your selection. These standards ensure that the stainless steel piping you use meets strict aerospace requirements for safety and performance.

You see schedule 10 stainless steel piping in high-pressure hydraulic lines, fuel lines, and pneumatic systems. The smooth inner surface of these tubes helps maintain efficient fluid flow and reduces the risk of blockages. You can trust these tubes to perform under extreme conditions, including rapid temperature changes and vibration during flight.

In 2025, you notice a trend toward using advanced stainless steel piping in both commercial and military aircraft. Manufacturers want materials that last longer and require less maintenance. You help achieve these goals by selecting schedule 10 tubes that meet the latest aerospace standards.

Note: Always verify that your stainless steel piping meets the required aerospace specifications before installation. This step ensures safety and reliability in every flight.

When you select stainless steel piping for your project, you need to understand the different material grades. Each grade offers unique benefits for specific environments and applications. The most common grades for stainless steel tube schedule 10 are 201, 304, and 316. You can compare their properties and uses in the table below:

| Material Grade | Composition Highlights | Advantages | Typical Applications |

|---|---|---|---|

| 201 Stainless Steel | 16-18% Chromium, 3.5-5.5% Nickel, high Mn | Lower cost, good corrosion resistance, formability | Furniture, fences, sanitary ware |

| 304 Stainless Steel | 18-20% Chromium, 8-10.5% Nickel | Excellent corrosion and oxidation resistance, versatile | Industrial, medical, residential, commercial |

| 316 Stainless Steel | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum | Superior corrosion resistance, durability, heat resistance | Food processing, automotive, chemical, pharmaceutical, extreme temperatures |

You should choose 304 for most general uses because it balances cost and corrosion resistance. If you work in harsh or chemical-rich environments, 316 is a better choice due to its added molybdenum, which boosts resistance to chemicals and saltwater. Grade 201 works well for less demanding applications where cost is a bigger concern.

Tip: Always match the grade to your environment and performance needs to ensure long-lasting results.

Choosing the right size for your stainless steel piping is critical for safety and performance. You need to follow industry standards to ensure compatibility and reliability. The main standards for sizing include ASTM A312 and ASME B36.19M. These standards set the rules for outer diameter, wall thickness, and length.

ASTM A312 covers seamless, welded, and cold-worked stainless steel pipes. It gives you clear guidelines for dimensions and tolerances.

ASME B36.19M lists the standard sizes, wall thicknesses, and weights for stainless steel pipes. This helps you match pipes with fittings and other system parts.

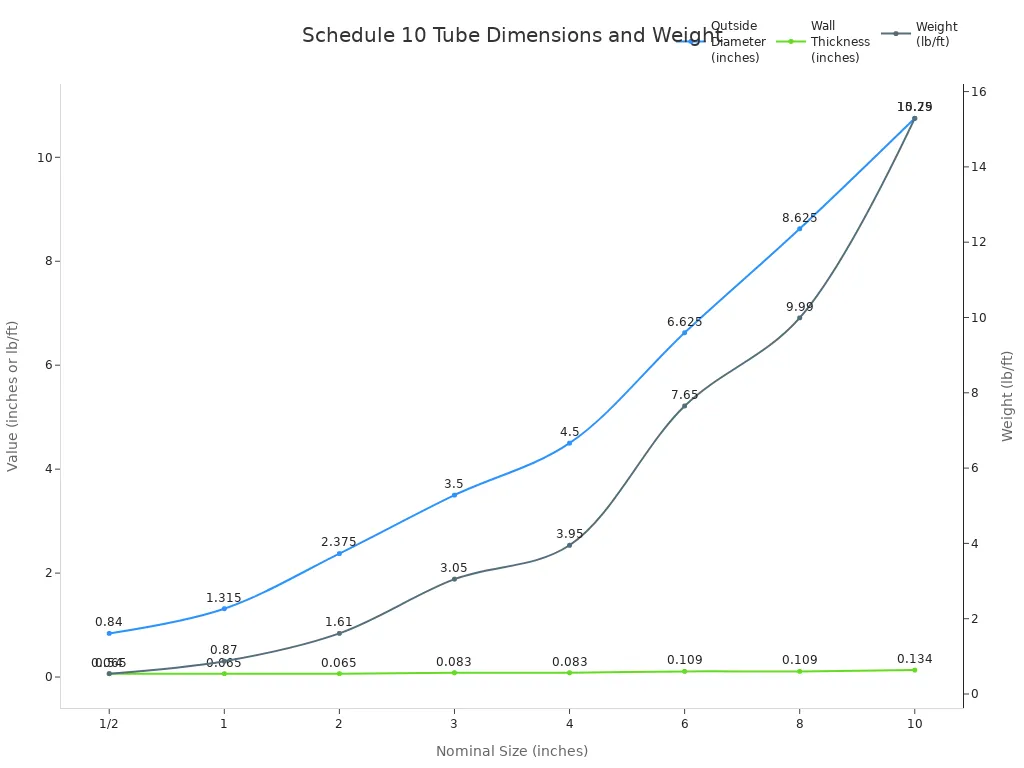

Here is a table showing common sizes for schedule 10 stainless steel tubes:

| Nominal Size (inches) | Outside Diameter (inches) | Wall Thickness (inches) | Weight (lb/ft) |

|---|---|---|---|

| 1/2 | 0.840 | 0.065 | 0.54 |

| 1 | 1.315 | 0.065 | 0.87 |

| 2 | 2.375 | 0.065 | 1.61 |

| 3 | 3.500 | 0.083 | 3.05 |

| 4 | 4.500 | 0.083 | 3.95 |

| 6 | 6.625 | 0.109 | 7.65 |

| 8 | 8.625 | 0.109 | 9.99 |

| 10 | 10.750 | 0.134 | 15.29 |

You can also see how outside diameter, wall thickness, and weight change with size in the chart below:

You must consider pressure ratings, as wall thickness affects how much pressure the pipe can handle. Always check that your chosen size matches the needs of your system and fits with other components.

Note: Environmental factors like temperature and pressure changes can affect pipe size due to expansion or stress. Always account for these when planning your system.

You need to make sure your stainless steel piping meets strict industry standards, especially in regulated fields like pharmaceuticals, food processing, and oil and gas. The most important certifications for schedule 10 stainless steel tubes are ASTM A312 and ASTM A270. These standards cover material properties, dimensions, and testing requirements such as hydrostatic, tensile, and impact tests.

Third-party inspections confirm that your tubes meet these standards. This step is vital for safety and for passing regulatory checks. Grades like TP304, TP304L, TP316, and TP316L are often required for specific environments to ensure corrosion resistance and sanitary performance.

You should always ask your supplier for certification documents. These prove that your stainless steel tube schedule 10 meets all necessary requirements for your application.

Callout: Certified stainless steel piping gives you peace of mind and helps you avoid costly compliance issues.

When you choose a supplier for stainless steel piping, you need to look beyond just price and delivery time. The right supplier helps you avoid costly problems and ensures your system meets all safety and quality standards. Here are some important points to consider:

Marking Inspection: Always check that each pipe is clearly marked with the manufacturer’s name, material grade, size, pressure rating, and standard specification. This traceability helps you confirm that you are getting genuine stainless steel tube schedule 10 and not a substitute.

Special End-User Requirements: Some projects need extra features. For example, you may need carbon equivalent limits for better weldability or low-temperature tensile and impact testing if your system will face cold conditions. If you work in sour environments, look for pipes with sulfide stress corrosion cracking resistance. Ultra-low sulfur content and fine grain practice can also improve toughness and ductility.

You should also use a checklist to evaluate each supplier’s quality control process. Here is a step-by-step approach:

Dimensional Inspection: Measure the outer diameter, inner diameter, and wall thickness. This ensures the pipes fit your system and meet the required specifications.

Material Composition Verification: Ask for documentation that confirms the steel grade and specification. Reliable suppliers provide certificates and test reports.

Weight and Length Check: Weigh and measure the pipes to make sure they match your order.

Magnetic Testing: Use magnetic particle inspection to find surface or subsurface defects that could cause leaks or failures.

Non-Destructive Testing (NDT): Request ultrasonic, radiographic, or eddy current testing. These tests help you find hidden flaws inside the pipe.

Pressure Testing: Make sure the supplier performs hydrostatic pressure tests. This step checks that the pipes can handle your system’s maximum pressure without leaking.

Certification and Compliance: Only buy from suppliers who provide certifications like ASTM, API, or ISO. These documents prove that the stainless steel piping meets industry standards.

Tip: Build a long-term relationship with suppliers who have a strong track record for quality and compliance. This helps you avoid delays and ensures your projects run smoothly.

You can also compare suppliers using a table like this:

| Criteria | Why It Matters |

|---|---|

| Marking & Traceability | Confirms authenticity and compliance |

| Testing & Inspection | Ensures safety and performance |

| Certification | Proves adherence to industry standards |

| Special Requirements | Matches your unique project needs |

| Customer Support | Helps resolve issues quickly |

Choosing the right supplier for stainless steel piping protects your investment and keeps your system safe and reliable.

You see schedule 10 stainless steel tubes used in many industries because they offer strength, corrosion resistance, and easy cleaning. Their smooth interior and wide range of sizes make them perfect for food, water, chemical, and construction projects. The table below shows how these tubes fit different sectors:

| Industry | Key Benefit |

|---|---|

| Food & Beverage | Hygiene and purity |

| Oil & Gas | Corrosion resistance |

| Construction | Strength and durability |

| Pharmaceuticals | Sterility and safety |

Stay informed about new piping solutions. Always review your project needs and talk with experts to choose the best material.

You see "Schedule 10" as a standard for wall thickness. It means the tube has a thinner wall compared to higher schedules. This makes it lighter and easier to install in low-pressure systems.

Yes, you can weld schedule 10 tubes with standard welding methods. The thinner wall helps you make clean, strong welds. Always use the right filler material for the tube grade.

You find these tubes in food and beverage, chemical processing, water treatment, pharmaceuticals, oil and gas, marine, automotive, construction, cryogenics, and aerospace. Each industry values the tube’s corrosion resistance and easy cleaning.

You match the grade to your environment. Use 304 for general use. Choose 316 for harsh or chemical-rich settings. Pick duplex grades for high-pressure or aggressive environments. Always check your project’s needs.

Yes, you can use schedule 10 stainless steel tubes for drinking water. The smooth, non-porous surface resists bacteria and corrosion. Many water systems use these tubes to keep water clean and safe.

You must check the tube size and grade. Schedule 10 tubes handle low to moderate pressure. Always refer to manufacturer data for exact ratings. Never exceed the recommended limits for safety.

You clean the tubes regularly to remove dirt and deposits. Inspect for signs of corrosion or leaks. Use proper cleaning agents for your industry. Routine checks help you extend the life of your piping system.

Yes, you can recycle these tubes. Stainless steel is 100% recyclable. Recycling helps you reduce waste and supports sustainability in your projects.