close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-16 Origin: Site

Selecting the proper stainless steel tube size ensures both safety and performance in any environment. A stainless steel tube dimensions chart gives users vital data for making informed decisions.

It lists essential measurements like outer diameter, wall thickness, and length, which help determine the correct size and weight class.

The chart references standards such as ASTM and ASME, supporting compliance and reliability.

Using precise information from the chart reduces errors, improves cost efficiency, and enhances project safety for engineers and homeowners.

Stainless steel tube size depends on outside diameter, wall thickness, and length, which affect strength and fit.

Tubes differ from pipes by using outside diameter for measurement and having thinner walls for precision uses.

Standard charts list tube dimensions, tolerances, and weights to help select the right tube safely and efficiently.

Both metric and imperial sizes exist; always use standard charts for accurate conversions and sizing.

Wall thickness impacts pressure resistance and flow; thicker walls mean more strength but less flow space.

Tolerances control size variations to ensure tubes fit properly and perform well in their applications.

Choosing the right tube size requires considering the application, pressure, load, material grade, and environment.

Professional advice and custom sizes help meet special project needs and ensure compliance with standards.

Understanding the key difference between pipes and tubes is essential for selecting the right product for any project. Stainless steel tubes and stainless steel pipes serve different purposes and follow distinct measurement systems.

| Feature | Stainless Steel Pipes | Stainless Steel Tubes |

|---|---|---|

| Measurement | Measured by Nominal Pipe Size (NPS) and schedule (wall thickness); focus on inside diameter (ID) | Measured by outside diameter (OD) and wall thickness with tighter tolerances |

| Shape | Mostly round and cylindrical | Can be round, square, or rectangular |

| Wall Thickness | Generally thicker walls for pressure resistance | Usually thinner walls, allowing for precision and flexibility |

| Applications | Primarily used for fluid and gas transport | Used for structural, mechanical, and precision applications |

| Fabrication | Easier to weld and thread | Requires more precise machining and finishing |

| Cost | Generally lower cost per unit length | More expensive due to precision and customization |

| Rigidity | More rigid due to thicker walls and welding | Less rigid, suitable for low to medium pressure uses |

| Size Range | Larger diameters, typically ½ inch to 48 inches | Smaller diameters, typically 1/8 inch to 12 inches |

Pipes are measured by inside diameter, while stainless steel tubes use outside diameter and wall thickness.

Pipes usually have thicker walls and are more rigid, making them ideal for high-pressure fluid and gas transport.

Stainless steel tubes offer higher dimensional accuracy and are often custom-made for structural, mechanical, and medical applications.

The difference between stainless steel pipe and tube also affects fabrication. Pipes are easier to weld and thread, while tubes require more precise machining.

The pipe and tube differences impact cost, with pipes generally being less expensive per unit length.

Note: The difference between stainless steel pipe and tube is not just about shape or size. It also involves how each product is measured, fabricated, and used in real-world applications.

Stainless steel tubes come in a variety of shapes to meet diverse industrial and residential needs. The most common shapes include round, square, and rectangular profiles. These shapes provide strength and corrosion resistance, making them suitable for construction, architecture, and mechanical systems.

Round tubes are widely used in pipelines, columns, and structural frameworks.

Square and rectangular tubes are popular in building frames, supports, and furniture.

Specialized shapes, such as triangle tubes, are available for unique industrial applications.

Stainless steel pipes, on the other hand, are typically round. This circular shape allows for even pressure distribution, which is crucial for transporting liquids and gases. While pipes focus on function, stainless steel tubes often balance both structural and aesthetic requirements.

International standards define the size range for stainless steel tubes. According to ASTM, GB, DIN, JIS, and GOST, stainless steel tubes are available with outside diameters from approximately 4.78 mm (0.188 inch) up to 203.2 mm (8 inch). These tubes come in various wall thicknesses and meet standards such as ASTM A213, A249, A268, A269, A270, A554, A688, A789, EN 10357, EN 10217-7, and EN 10216-5.

Stainless steel pipe sizes typically range from ½ inch to 48 inches in diameter, following the Nominal Pipe Size system. Stainless steel tubes, however, are available in fractional, metric, and imperial units, ensuring compatibility with international requirements. This flexibility allows engineers and builders to select the right size for any application, whether for structural support or precise mechanical systems.

A stainless steel tube dimensions chart serves as a vital reference for engineers, builders, and fabricators. This chart organizes essential data in a clear, tabular format, making it easy to compare and select the right tube for any application. The structure of the chart ensures that users can quickly identify the correct size, weight, and tolerance for each stainless steel tube. By following international standards, the chart guarantees compatibility and safety across a wide range of projects.

Every stainless steel tube dimensions chart includes several critical parameters. These measurements help users determine the suitability of a tube for specific structural or mechanical needs. The most important data points found in the chart include:

Outside Dimensions: The width and height of the tube, usually listed in inches or millimeters.

Wall Thickness: The thickness of the tube wall, which affects strength and weight.

Tolerances for Outside Dimensions: Allowable variation in the outside size, often ranging from 0.020 inches to 1% depending on the tube's size.

Wall Thickness Tolerance: Typically set at 10% of the nominal thickness, excluding the weld area.

Maximum Twist: Limits on how much the tube can twist per length, such as 0.062 to 0.112 inches per 3 feet.

Length Tolerances: Permitted over or under lengths, for example, 1/2 inch over and 1/4 inch under for tubes up to 22 feet.

Maximum Outside Corner Radii: The outside corner should not exceed three times the nominal wall thickness.

Squareness and Straightness: Adjacent sides may deviate by ±2 degrees, with straightness variation allowed based on length.

| Parameter | Description |

|---|---|

| Outside Dimensions | Width and height of the tube, typically in inches or millimeters |

| Wall Thickness | Thickness of the tube walls, critical for weight and strength |

| Tolerances for Outside Dimensions | Vary by size, e.g., 0.020 to 1% depending on dimension range |

| Wall Thickness Tolerance | Typically 10% of nominal thickness excluding weld area |

| Maximum Twist | Limits on twist per length, e.g., 0.062 to 0.112 inches per 3 feet |

| Length Tolerances | Allowable over/under lengths, e.g., 1/2 inch over and 1/4 inch under |

| Maximum Outside Corner Radii | Not to exceed three times the nominal wall thickness |

| Squareness and Straightness | Adjacent sides may deviate ±2 degrees; straightness variation allowed |

A stainless steel tube dimensions chart also lists the weight per unit length, which is essential for material estimation and cost calculation. The chart may specify the stainless steel grade, as this affects both density and weight. Engineers rely on these measurements to ensure dimensional accuracy and structural integrity.

Tip: Always check the tolerances and wall thickness when selecting a tube. These factors influence both the strength and the fit of the tube in your project.

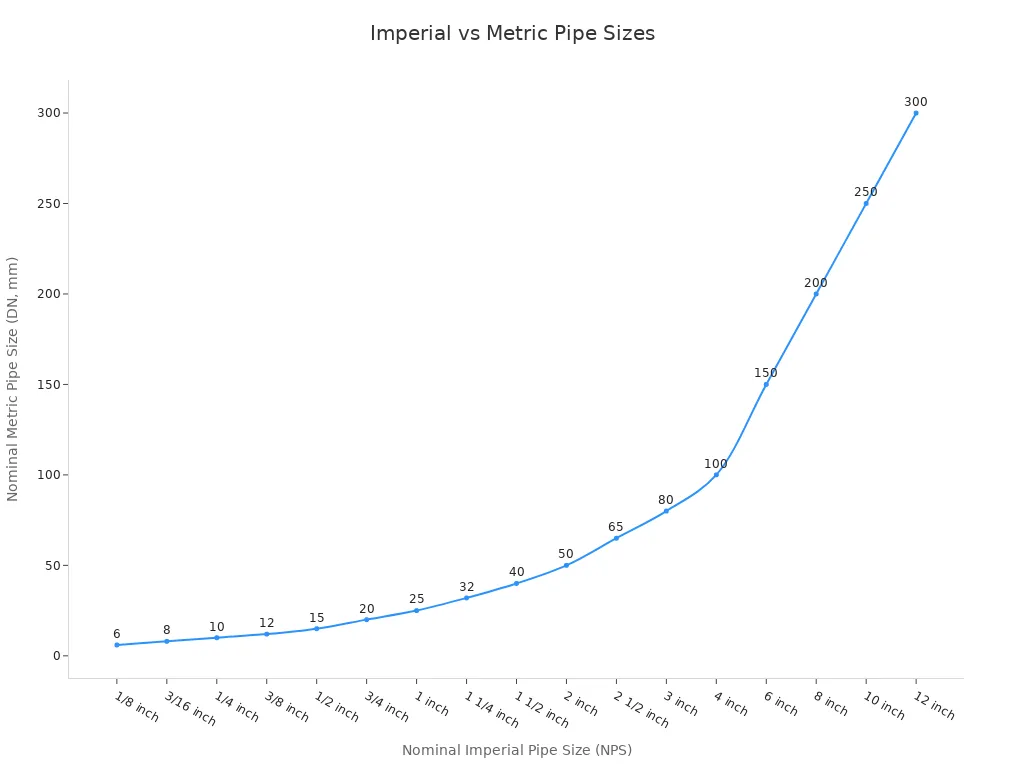

Stainless steel tube dimensions charts often present data in both metric and imperial units. This dual-system approach allows users from different regions to interpret the chart accurately. The imperial system uses inches and fractions, while the metric system uses millimeters. However, nominal sizes in each system do not always match exactly, so users must refer to standard tables for precise conversion.

| Nominal Imperial Pipe Size (NPS) | Nominal Metric Pipe Size (DN) |

|---|---|

| 1/8 inch | 6 mm |

| 3/16 inch | 8 mm |

| 1/4 inch | 10 mm |

| 3/8 inch | 12 mm |

| 1/2 inch | 15 mm |

| 3/4 inch | 20 mm |

| 1 inch | 25 mm |

| 1 1/4 inch | 32 mm |

| 1 1/2 inch | 40 mm |

| 2 inch | 50 mm |

| 2 1/2 inch | 65 mm |

| 3 inch | 80 mm |

| 4 inch | 100 mm |

| 6 inch | 150 mm |

| 8 inch | 200 mm |

| 10 inch | 250 mm |

| 12 inch | 300 mm |

The chart above demonstrates the relationship between imperial and metric nominal pipe sizes. Nominal Pipe Size (NPS) refers to the imperial system, while Diameter Nominal (DN) applies to the metric system. These sizes are nominal, meaning they do not always correspond to the actual outside diameter or wall thickness. Wall thickness varies by schedule, so users must consult the stainless steel tube dimensions chart for accurate data.

International standards play a key role in defining these dimensions. ASTM standards, such as ASTM A213, A269, and A270, specify the required dimensions, tolerances, and material properties for stainless steel tube products. ISO 1127 and ASME B36.19 also provide guidelines for both metric and imperial sizing, ensuring uniformity and safety in global markets.

Note: Always use a standard stainless steel tube dimensions chart for conversions. Direct unit conversion may lead to errors because nominal sizes and wall thicknesses follow specific industry conventions.

Understanding how to interpret a stainless steel tube dimensions chart is essential for selecting the right product for any application. The chart provides critical information about the tube's size, strength, and compatibility with fittings or systems. Each measurement in the chart plays a specific role in determining the tube's performance and suitability.

The three primary dimensions listed in any stainless steel tube chart are outside diameter (OD), inside diameter (ID), and wall thickness (WT). These measurements are mathematically related and directly impact the tube's function.

The outside diameter (OD) defines the tube's overall size and ensures proper fit with connectors and components. It also affects the tube's structural strength. The inside diameter (ID) determines the flow rate and fluid dynamics within the tube, which is crucial for applications that require precise fluid control. Wall thickness (WT) influences mechanical strength, pressure resistance, and durability. Thicker walls provide greater strength and pressure capacity but reduce the internal flow area. Thinner walls allow for increased flow but lower pressure resistance.

The relationship among these dimensions can be summarized as follows:

| Dimension | Relationship to Others | Effect on Performance | Application Considerations |

|---|---|---|---|

| Outside Diameter (OD) | OD = ID + (2 × WT) | Determines overall size and fitment | Critical for compatibility with fittings and space constraints |

| Inside Diameter (ID) | ID = OD – (2 × WT) | Directly impacts flow capacity and fluid dynamics | Important for flow rate, pressure drop, and instrumentation |

| Wall Thickness (WT) | WT = (OD – ID) / 2 | Affects pressure rating, mechanical strength, and durability | Main factor in pressure resistance and structural integrity |

Selecting the correct combination of OD, ID, and wall thickness depends on the application's requirements, environmental conditions, and industry standards. Changing one dimension affects the others and can alter the tube's overall performance.

Tip: Always verify the OD, ID, and wall thickness in the chart before making a selection. This ensures the tube will meet both mechanical and flow requirements.

Gauge and schedule are two terms that describe wall thickness in stainless steel tubes and pipes. Understanding these terms helps users select the right product for their needs.

Gauge refers to the wall thickness of a tube, usually expressed as a number followed by "SWG" (Standard Wire Gauge). A higher gauge number means a thinner wall. Gauge thickness can vary based on material and intended use, especially in environments that require corrosion resistance or high pressure. Gauge is important because it influences the tube's mechanical strength and suitability for specific applications.

Schedule, on the other hand, is a system used mainly for pipes. It indicates wall thickness based on nominal pipe size and a schedule number. A higher schedule number means a thicker wall. Tubes are measured by outside diameter and gauge, while pipes use inside diameter and schedule. For a given gauge, wall thickness remains consistent across sizes, but for pipes, wall thickness changes with both nominal size and schedule.

Gauge defines the wall thickness of tubes, with a higher gauge number indicating a thinner wall.

Schedule indicates pipe wall thickness based on nominal pipe size and schedule number; a higher schedule means a thicker wall.

Tubes are measured by outside diameter (OD) and gauge, while pipes are measured by inside diameter (ID) and schedule.

Wall thickness for tubes is consistent across sizes for a given gauge, but pipe wall thickness varies with both nominal size and schedule.

These distinctions affect strength, pressure resistance, internal flow capacity, and fitting compatibility, which are critical for selecting the appropriate stainless steel tube or pipe.

Selecting the correct gauge or schedule ensures the tube or pipe will handle the required pressure and mechanical loads.

Tolerances define the allowable variation in dimensions during manufacturing. These limits ensure that stainless steel tubes fit and function correctly in their intended applications. Industry standards such as ASTM A312 and ASME B36.19M specify dimensional tolerances for stainless steel tubes, supporting compatibility and reliability.

Manufacturing tolerances control variations in outer diameter, wall thickness, and ovality. Wall thickness tolerance typically ranges around ±10%, with tighter tolerances available for precision applications. Ovality tolerance ensures the tube remains round enough to fit properly and maintain mechanical strength. Seamless tubes often have tighter tolerances than welded tubes due to uniform material and the absence of weld seams.

Industry standards define dimensional tolerances for stainless steel tubes, ensuring compatibility and reliability.

Quality control measures, including inspection and testing, verify dimensional accuracy and compliance.

Environmental factors such as temperature and pressure fluctuations can cause dimensional changes, impacting fit and function.

Proper handling and installation practices prevent deformation and maintain tolerance integrity.

Manufacturing tolerances control dimensional variations such as outer diameter, wall thickness, and ovality, which are critical for proper fit and function.

Wall thickness tolerance typically ranges around ±10%, with tighter tolerances (e.g., ±7.5%) available for precision applications.

Ovality tolerance ensures the tube remains sufficiently round to fit properly and maintain mechanical strength; excessive ovality can cause installation issues and reduce performance.

Seamless tubes have tighter tolerances than welded tubes due to uniform material and absence of weld seams.

Adherence to standards like ASTM A269, EN 10216-5, ASTM A312, and ASME B36.19M is essential to ensure safety, quality, and performance.

Deviations beyond specified tolerances can lead to premature failure, leaks, installation difficulties, and compromised mechanical strength.

Critical industries such as aerospace, pharmaceutical, oil and gas, and automotive require strict tolerance compliance to guarantee safety, reliability, and optimal performance.

Proper measurement techniques and quality control during manufacturing and installation are vital to maintain these tolerances.

Maintaining tight dimensional tolerances reduces the risk of assembly issues, mechanical failures, and costly rework. In critical industries, even minor deviations can compromise safety and performance. Balancing tolerance levels helps optimize cost, quality, and production speed, leading to improved reliability and customer satisfaction.

A typical stainless steel tube dimensions chart provides a clear overview of the most important measurements for both industrial and residential applications. These charts follow standards such as ASME B36.10M for welded pipes and ASME B36.19M for seamless pipes. They cover a wide range of nominal bore sizes, from 1/8 inch to 24 inches, and outside diameters from about 10.3 mm to 609.6 mm. The chart also includes wall thicknesses defined by schedules (like Schedule 10, 40, and 80), which directly affect the tube’s pressure capacity and strength. For example, a 4-inch Schedule 40 tube has a wall thickness of about 6 mm, while Schedule 80 increases this to roughly 8.5 mm, providing greater pressure tolerance.

Below is a sample layout of a stainless steel tube dimensions chart:

| Nominal Size (NPS/DN) | Outside Diameter (mm/inch) | Wall Thickness (mm/inch) | Schedule | Weight (kg/m) | Typical Use Case |

|---|---|---|---|---|---|

| 1/2" (DN 15) | 21.3 / 0.84 | 2.77 / 0.109 | 40 | 1.27 | Residential plumbing |

| 1" (DN 25) | 33.4 / 1.315 | 3.38 / 0.133 | 40 | 2.68 | Food & beverage processing |

| 2" (DN 50) | 60.3 / 2.375 | 3.91 / 0.154 | 40 | 5.44 | Chemical transport |

| 4" (DN 100) | 114.3 / 4.5 | 6.02 / 0.237 | 40 | 13.56 | Industrial fluid systems |

| 4" (DN 100) | 114.3 / 4.5 | 8.56 / 0.337 | 80 | 18.97 | High-pressure applications |

Charts like this support both metric and imperial units, making them useful for global projects. They also include conversions between Nominal Pipe Size (NPS) and Nominal Diameter (DN) to ensure compatibility across different systems.

Specialized industries use a wide range of tube sizes. For example:

Medical tubing can have diameters as small as 0.3 mm.

Food and beverage tubes often range from 12.7 mm to 50.8 mm in diameter.

Automotive and aerospace tubes typically use diameters from 1.5 inches to 3 inches.

Architectural tubes may be square or rectangular, such as 25x25 mm or 50x25 mm.

Selecting the correct stainless steel tube involves several key steps. The following process helps engineers, builders, and homeowners use the dimensions chart effectively:

Define the Application

Identify the function and environment. For example, choose stainless steel for corrosion resistance in chemical or food processing.

Select the Tube Shape

Decide between round, square, or rectangular tubes based on load requirements and design needs.

Review the Chart for Dimensions

Locate the required outside diameter, wall thickness, and length. Consider the schedule for pressure and strength needs.

Choose the Stainless Steel Grade

Pick the grade (such as 304 or 316) that matches the chemical and mechanical demands of the project.

Check Compliance with Standards

Ensure the selected tube meets industry standards like ASME or ASTM for safety and compatibility.

Consult with Suppliers

Confirm availability, custom sizes, and any additional specifications such as surface finish or weldability.

Tip: Always verify that the tube’s dimensions and grade match both the mechanical and environmental requirements of the application. For high-pressure or specialized uses, select thicker walls and seamless tubes.

By following these steps, users can confidently select the right stainless steel tube for any industrial or residential project.

Industrial projects rely on a wide range of stainless steel tubes and stainless steel pipes. Manufacturers supply seamless stainless steel tubes in sizes from as small as 1/16 inch up to 16 inches in outside diameter. Wall thicknesses can be as thin as 0.001 inch or as thick as 2 inches. These tubes meet ASTM standards such as A213, A269, and A511, which cover everything from thin-walled instrumentation tubes to heavy structural tubing. Instrumentation tubes often range from 1/8 inch to 1-1/2 inches in outside diameter, while heavy wall hollow bars can reach up to 16 inches. Wall thicknesses follow standardized schedules, including 5S, 10S, 40, 80, and XXH, which help engineers select the right tube for each application. Stainless steel pipes are also sized by outside diameter and wall thickness, making them suitable for both small-scale and large-scale industrial systems.

Seamless stainless steel pipes and welded stainless steel pipes both play important roles in industry. Seamless stainless steel tubes offer higher strength and better pressure resistance, making them ideal for applications requiring robustness. Welded stainless steel tubes provide cost-effective solutions for less demanding environments and can be produced with thinner walls and larger diameters.

Stainless steel tubes serve a broad range of industrial applications. High-performance sectors such as aerospace, automotive, chemical processing, oil and gas, power generation, and construction all depend on these tubes. Stainless steel tubes deliver excellent corrosion resistance, high-temperature strength, and pressure integrity. In oil and gas, chemical, and power generation industries, seamless stainless steel pipes and tubes are preferred for their ability to withstand aggressive environments, including exposure to chlorides, acids, and seawater. Aerospace applications require tubes that can handle drastic pressure and temperature changes. Automotive manufacturers use stainless steel tubes in exhaust systems for durability and optimal flow.

Construction projects use stainless steel pipes and tubes for frameworks, supports, and architectural features. Food and beverage, pharmaceutical, and semiconductor industries require tubes that are easy to clean and maintain sanitary conditions. Heat exchanger stainless steel tubes are essential in power plants and chemical facilities, where they transfer heat efficiently while resisting corrosion. These applications of stainless steel pipes and tubes highlight their versatility and reliability in demanding environments.

Stainless steel tubes and pipes reduce maintenance needs and improve safety by resisting corrosion and deformation, even under extreme temperatures and pressures.

Industrial applications demand strict adherence to recognized standards. ASTM standards such as A312, A269, and A554 define chemical composition, mechanical properties, and testing requirements for stainless steel pipe and tube products. ASME codes, including BPVC Section VIII and B31.3, ensure that stainless steel pipes and tubes meet pressure and temperature requirements for process piping and pressure vessels. Aerospace and defense sectors follow AMS and MIL specifications, which set higher criteria for strength and reliability. ISO certifications, such as ISO 9001, guarantee consistent quality management across suppliers.

| Standard | Focus / Key Features | Typical Applications |

|---|---|---|

| ASTM (A312, A269, A554) | Material, dimensions, testing requirements | General industrial, oil & gas, chemical, architecture |

| ASME (BPVC, B31.1, B31.3) | Pressure and temperature codes | Pressure vessels, process piping |

| AMS, MIL | Aerospace and military specifications | Aerospace, defense |

| ISO 9001 | Quality management and consistency | All industries |

Seamless stainless steel pipes and tubes are often required for critical applications, while welded stainless steel pipes and tubes are suitable for less extreme conditions. Adhering to these standards ensures safety, performance, and compatibility in all pipe and tube applications.

Residential projects often use stainless steel tubes in smaller diameters compared to industrial settings. Most homes require tube sizes ranging from 1/8 inch up to 2 inches in outside diameter. These dimensions match the needs of plumbing, heating, and gas distribution systems. Stainless steel pipe sizes in residential work also fall within this range, making them easy to integrate with standard fittings and fixtures. Tubes with thinner walls provide flexibility for tight spaces, while thicker walls offer extra strength for exposed or high-traffic areas. Homeowners and contractors select these sizes to ensure compatibility with common appliances and fixtures.

Stainless steel tubes serve many purposes in residential environments. Builders use them for water supply lines, where corrosion resistance and durability are essential. Stainless steel pipe also appears in natural gas lines, ensuring safe and long-lasting connections. Homeowners often choose stainless steel tubes for radiant floor heating systems because they resist scaling and maintain water purity. In kitchens and bathrooms, stainless steel pipe supports both hot and cold water delivery. Some homes feature stainless steel tubes in handrails, balustrades, and decorative elements due to their sleek appearance and low maintenance. HVAC systems rely on these tubes for refrigerant lines and air conditioning connections, taking advantage of their strength and resistance to temperature changes.

Stainless steel tubes and pipes help prevent leaks and reduce maintenance costs in residential plumbing. Their resistance to rust and corrosion makes them a reliable choice for long-term installations.

Selecting the right fittings ensures that stainless steel tubes and stainless steel pipe perform well in residential applications. Most standard tube sizes, from 1/8 inch to 2 inches, accept a wide range of compatible fittings. The most common fitting types include:

Male connectors

Elbows and reducing elbows

Tees and unions

Bulkhead connectors

Compression fittings (single and double ferrule designs)

Manufacturers typically produce these fittings in stainless steel grades 304 and 304L, which provide excellent corrosion resistance and weldability. End connections come in several styles, such as threaded (NPT, BSPT, BSPP), welded, and JIC, allowing for flexible installation options. Compression fittings work especially well for low-pressure systems, such as water filtration or instrumentation lines. All these fittings conform to international standards like ASTM, ASME, DIN, and BS, ensuring quality and compatibility with stainless steel pipe and tubes used in homes.

Tip: Always match the fitting type and grade to the specific tube size and application. This practice helps maintain system integrity and prevents leaks.

Selecting the correct stainless steel tube size starts with a clear understanding of the application’s requirements. Engineers and builders must consider the intended use, whether for structural support, fluid transport, or decorative purposes. Accurate measurement of wall thickness, diameter, and length ensures a perfect fit and optimal performance. Precision in sizing directly impacts the effectiveness of the tubing in its role.

Review the specific function of the tube, such as carrying fluids, supporting loads, or serving as a framework.

Identify any unique project requirements, including flow rates or tight tolerances.

Choose tubes when precise dimensions are critical, while pipes may suit high-pressure needs due to thicker walls.

Evaluate if standard sizes meet the project’s needs or if a custom solution is necessary for specialized applications.

Standard square and rectangular tubes simplify design and integration, especially for framing and load-bearing. However, custom dimensions allow for tailored solutions that balance cost and performance. Offering a wide range of sizes ensures the tube meets both durability and load-bearing demands.

Tip: Always match the tube’s size and shape to the specific application to maximize safety and efficiency.

Pressure and load requirements play a major role in determining the right tube size. The wall thickness and inside diameter must support the expected structural and load-bearing capacity. For high-pressure systems, thicker walls and larger diameters prevent bursting or deformation. The inside diameter is crucial for calculating the pressure rating, ensuring the tube can withstand operating conditions.

Assess the maximum load the tube must support, including static and dynamic forces.

Calculate the required wall thickness to maintain structural integrity under both pressure and load.

Understand that a smaller inside diameter increases strength but may limit flow, while a larger diameter can risk buckling if not properly supported.

For pipelines carrying steam or high-pressure fluids, select tubes with thicker walls and larger diameters to handle operational demands.

Pressure requirements directly influence the choice of tube dimensions. Custom tube sizes may be necessary for projects with unique load or pressure needs, ensuring both safety and long-term performance.

Material grade and environmental conditions significantly affect tube selection. Different stainless steel grades offer varying levels of strength, durability, and resistance to heat and corrosion. For example, austenitic grades like 304 and 316 can operate at temperatures up to 870°C, making them suitable for high-temperature environments. Duplex stainless steels provide extra strength and corrosion resistance in harsh settings such as marine or petrochemical industries.

Select the material grade based on strength, heat resistance, and corrosion resistance required by the application.

Consider environmental factors like temperature, acidity, chloride concentration, and exposure to corrosive agents.

Evaluate fabrication needs, as some grades require precise welding or forming to maintain their properties.

Balance cost and availability with performance, especially when custom grades or sizes are needed.

Environmental conditions dictate the need for corrosion resistance and durability. Custom tube solutions allow engineers to address unique challenges, ensuring the tube performs reliably throughout its service life.

Selecting stainless steel tubes for any project requires careful consideration of several factors. In complex or large-scale projects, professional advice becomes essential. Experts in stainless steel fabrication and installation help navigate the many available options. They recommend the right grades and specifications and ensure compliance with industry standards and regulations. Their experience reduces the risk of costly errors and improves long-term safety.

For long-term durability and safety, professionals suggest the following steps:

Choose the right stainless steel grade for the environment. Grades 304 and 316 are popular because they resist corrosion and tolerate high temperatures. Grade 316, with added molybdenum, offers superior resistance to chlorides.

Prioritize mechanical properties. Evaluate tensile strength, ductility, and hardness. Austenitic grades like 303, 304, 316, and 321 provide good toughness due to their nickel content.

Consider form and fabrication processes. Cutting, bending, welding, and CNC machining all affect tube performance. Proper handling, such as removing burrs after cutting and maintaining correct bend radius, extends tube life.

Specify surface finish requirements. Surface finishes like annealed and pickled or bright annealed improve corrosion resistance and hygiene.

Manage material cost and availability. Standard sizes cost less and are easier to source. Seamless tubes offer better strength but cost more than welded tubes.

Consult experienced suppliers with ISO certifications. Suppliers with ISO 9001 or ISO 13485 certifications ensure quality management and reliable guidance.

Tip: Always seek expert input for projects with unique requirements or when working with unfamiliar materials. This approach ensures the best results and compliance with safety standards.

Many projects require custom sizes or shapes that standard tubes cannot provide. Manufacturers offer a wide range of custom options to meet specific needs. The table below outlines the available choices and important considerations:

| Aspect | Options / Details | Limitations / Considerations |

|---|---|---|

| Length | Custom lengths from 0.030 to 480 inches | Longer lengths may need extra support or special alloys for strength; may affect finishing quality |

| Outside Diameter (O.D.) | Range from 0.030 to 1.50 inches | Smaller diameters suit precision uses; larger diameters needed for strength and flow |

| Inside Diameter (I.D.) | Range from 0.008 to 1.375 inches | Tight I.D. tolerances are critical for consistent flow |

| Wall Thickness | Range from 0.002 to 0.280 inches | Thin walls for lightweight uses; thick walls for durability and pressure resistance |

| Shapes | Round, rectangular, square, oval, slot | Shape affects strength and application suitability |

| Tolerances | O.D. tolerance as tight as 0.0003 inches; I.D. ±0.0005 inches; wall ±0.0003 inches; length ±0.001 inches | Achieving tight tolerances requires advanced manufacturing and quality control |

| Fabrication Processes | Bending, CNC machining, laser cutting, welding, capping, chamfering | Complex processes may increase lead time and cost |

| Lead Time | Typically 4 to 8 weeks depending on complexity and material availability | Longer lead times for complex or highly customized orders |

| Cost | Higher than standard tubes due to customization and specialized manufacturing | Cost increases with complexity and precision requirements |

| Industry Standards | ASTM, ANSI, ISO, and others guide quality and specifications | Compliance necessary to ensure performance and acceptance |

| Tube Types | Seamless (stronger, no weld seam) and welded (cost-effective, available in larger sizes) | Weld seam may be a weak point; choice affects strength, cost, and availability |

Custom stainless steel tubes must meet industry standards such as ASTM, ANSI, and ISO to ensure material integrity and dimensional accuracy. The choice between seamless and welded tubes depends on the application. Seamless tubes work best for high-pressure or critical uses, while welded tubes offer cost advantages and larger size options.

Custom metal fabrication services allow for unique tube shapes and tight tolerances. These services support industries that need precision, such as aerospace, medical, and food processing. Custom metal fabrication also enables the creation of specialized fittings and assemblies, improving system performance and reliability.

Note: Custom solutions often require longer lead times and higher costs. Early planning and clear communication with suppliers help manage expectations and ensure timely delivery.

Selecting the correct stainless steel tube size remains essential for both industrial and residential projects. A well-organized dimensions chart provides the foundation for safe, efficient, and cost-effective installations. Users who follow best practices can avoid costly mistakes and ensure long-term reliability.

Key takeaways for using a stainless steel tube dimensions chart:

Understand critical dimensions such as Outer Diameter (OD), Inner Diameter (ID), Wall Thickness (WT), and Length. These measurements determine fit, flow, strength, and suitability for each application.

Use precise measurement tools. Digital or vernier calipers measure OD and ID, micrometers check wall thickness, and tape measures confirm length.

Take multiple measurements at different points along the tube. This approach helps identify irregularities and improves overall accuracy.

Identify the tubing type—round, square, or rectangular. Each shape requires a specific measurement method.

Calculate wall thickness when only OD and ID are available. The formula is:Wall Thickness = (OD - ID) / 2

Clean tubing ends before measuring. Removing debris or corrosion prevents errors and ensures reliable results.

Follow industry standards such as ASTM A269 or A213. These standards guarantee compliance with safety and performance requirements.

Consider customization options. Custom tube dimensions may better suit unique project needs.

Accurate measurement and adherence to standards protect structural integrity and system performance. These practices help users achieve the best results in any environment.

Engineers, builders, and homeowners who apply these steps can confidently select stainless steel tubes that match their project requirements. Proper use of the dimensions chart supports safety, efficiency, and long-term value. Customization and professional guidance further enhance outcomes, especially for complex or demanding applications.

By mastering these fundamentals, anyone can navigate stainless steel tube selection with confidence and precision.

Selecting the right stainless steel tube starts with understanding key dimensions like OD, ID, and wall thickness. Users should match tube size and grade to the specific demands of each application, considering factors such as pressure, temperature, and corrosion resistance. For specialized projects, they benefit from identifying performance needs, choosing the correct alloy, and verifying quality standards.

Consult material experts or trusted suppliers for guidance on alloy selection and compliance with industry standards.

Download a stainless steel tube dimensions chart or reach out to professionals to ensure project success and safety.

Stainless steel tubes use outside diameter and wall thickness for measurement. Pipes use nominal size and schedule. Tubes offer tighter tolerances and suit structural or precision work. Pipes handle fluid transport and higher pressure.

Use a caliper or micrometer to measure the distance between the outer and inner surfaces. Subtract the inside diameter from the outside diameter, then divide by two. This method gives accurate wall thickness.

Manufacturers supply tubes worldwide. Metric sizes fit international standards. Imperial sizes match North American systems. Dual sizing ensures compatibility for global projects and simplifies replacement or repairs.

"Schedule" refers to the wall thickness of pipes. Higher schedule numbers indicate thicker walls. Schedule affects pressure rating and strength. Tubes use gauge or direct wall thickness instead of schedule.

Yes. Stainless steel tubes resist corrosion and do not leach harmful substances. Grades like 304 and 316 are safe for potable water. Always confirm compliance with local plumbing codes.

Seamless tubes have no weld seam. They offer higher strength and better pressure resistance. Industries use seamless tubes for critical applications, such as chemical processing or high-pressure systems.

First, define the application and load requirements. Next, check the dimensions chart for outside diameter and wall thickness. Consider pressure, temperature, and environment. Consult industry standards and seek expert advice if needed.

Yes. Manufacturers offer custom lengths, diameters, and wall thicknesses. Custom tubes meet unique project needs. Lead times and costs may increase. Always verify that custom tubes meet industry standards.