close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-16 Origin: Site

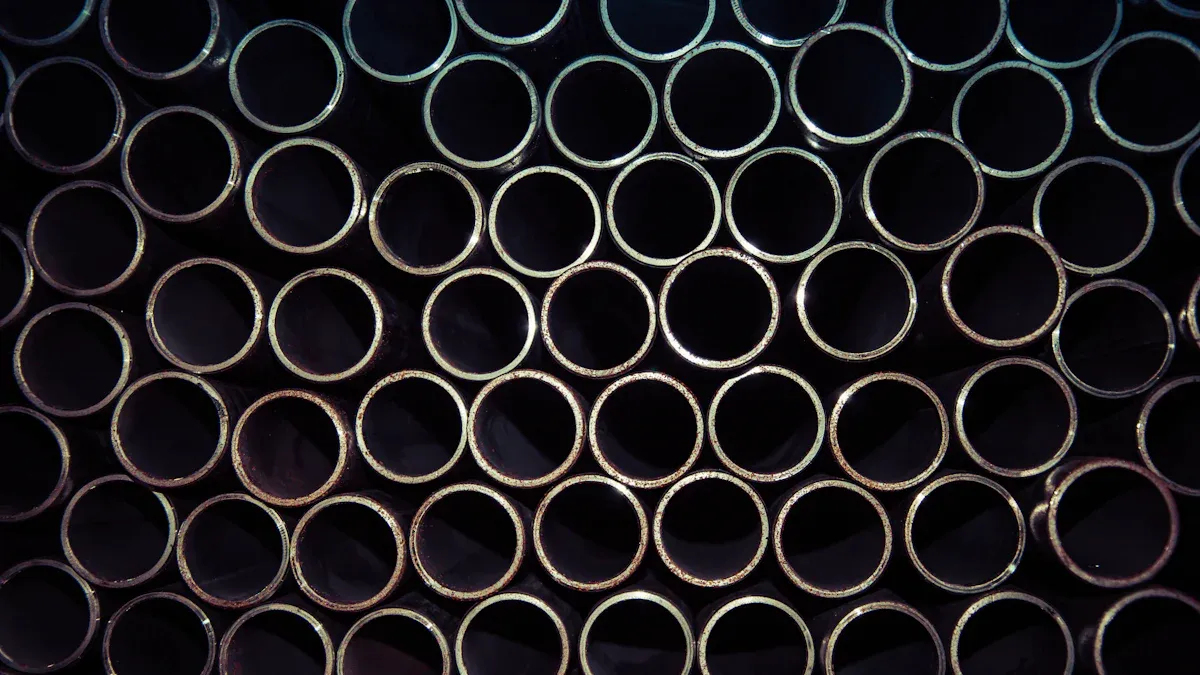

Stainless steel tube schedule 40 defines a standardized wall thickness for stainless steel pipes, ensuring predictable strength and compatibility across industries. Schedule 40 offers a medium wall thickness, which balances cost and durability for general fluid handling, plumbing, and industrial process lines. For example, over 50% of steel pipes in the oil and gas sector and 90% of fire sprinkler systems use this schedule. Accurate understanding of these dimensions and standards allows professionals to specify the correct stainless steel tube schedule 40 for safe and efficient system design.

Schedule 40 defines a standard wall thickness for stainless steel pipes, balancing strength and cost for many applications.

Nominal Pipe Size (NPS) is a trade name and does not match the actual pipe diameter; always check outside and inside diameters.

Wall thickness affects pipe strength and pressure capacity; thicker walls handle higher pressures but add weight and cost.

Stainless steel grades 304 and 316 offer corrosion resistance, with 316 better for harsh chemical or marine environments.

Industry standards like ASTM and ASME ensure pipe dimensions and materials meet safety and quality requirements.

Use dimension charts to verify pipe size, wall thickness, and weight for proper fit and system performance.

Clear communication of NPS, schedule number, grade, and length helps avoid ordering mistakes and installation issues.

Matching pipe size and schedule to application needs ensures safety, durability, and efficient fluid flow in piping systems.

Schedule 40 refers to a standardized wall thickness for pipes, including stainless steel tube schedule 40. This schedule ensures that each pipe size has a consistent wall thickness, which simplifies selection and compatibility across different systems. The term "Schedule 40S" specifically identifies stainless steel pipe, where the "S" stands for stainless steel. Both Schedule 40 and Schedule 40S share the same nominal pipe sizes, outer diameters, and wall thicknesses. However, stainless steel tube schedule 40 offers unique advantages due to its material composition. Stainless steel contains at least 10.5% chromium, which forms a protective oxide layer. This layer prevents rust and corrosion, making these pipes suitable for harsh environments. In contrast, standard Schedule 40 pipes made from carbon steel or PVC rely on coatings that can deteriorate over time. Stainless steel pipe also provides higher pressure ratings and a longer lifespan, often lasting 70-80 years.

Note: The 'S' in Schedule 40S always indicates stainless steel, distinguishing it from other materials.

Engineers and contractors select stainless steel tube schedule 40 for its balance of strength, durability, and corrosion resistance. The thicker wall compared to lighter schedules, such as Schedule 10, allows these pipes to handle higher pressures and temperatures. This makes them ideal for demanding industrial and commercial applications. Stainless steel pipe resists corrosion from chemicals, salts, and moisture, which is critical in environments where other materials would fail. The robust construction ensures system integrity and safety, even under stress. Although these pipes are heavier and more challenging to install, their reliability and long service life reduce maintenance and replacement costs. Schedule 40 pipes comply with industry standards, ensuring quality and safety in every installation.

Key reasons for choosing Schedule 40 stainless steel pipe include:

High pressure and temperature tolerance

Superior corrosion resistance

Long service life and reduced maintenance

Compliance with industry codes and standards

Reliable performance in critical applications

Stainless steel tube schedule 40 serves a wide range of industries due to its versatility and performance. Manufacturers use these pipes in both welded and seamless forms, often choosing grades like 304 or 316 for added corrosion resistance. The following table highlights typical industries and applications:

| Industry | Typical Applications and Reasons |

|---|---|

| Oil and Gas | Pipelines, equipment; withstands high pressure, temperature, and corrosive environments. |

| Chemical and Petrochemical | Transport of aggressive chemicals; high corrosion resistance; used in processing plants and refineries. |

| Food and Beverage | Sanitary transport and processing; easy to clean; used in mixers, breweries, and dairy operations. |

| Water and Wastewater | Clean and wastewater transport; resistant to chlorine and chemicals; used in treatment plants. |

| Construction and Architecture | Structural support, decorative elements; weather and corrosion resistant for outdoor use. |

| Automotive and Transportation | Exhaust systems, fuel and brake lines; withstands high temperatures and pressures. |

| Mining and Minerals | Slurry transportation, chemical processing, structural components; abrasion and corrosion resistant. |

| Medical and Pharmaceutical | Sterile fluid and gas transport; maintains sterile conditions; used in pharmaceutical processes. |

Stainless steel pipe sizes in Schedule 40 are common in water supply systems, HVAC installations, and industrial processing. Their durability and resistance to harsh conditions make them a preferred choice for critical infrastructure.

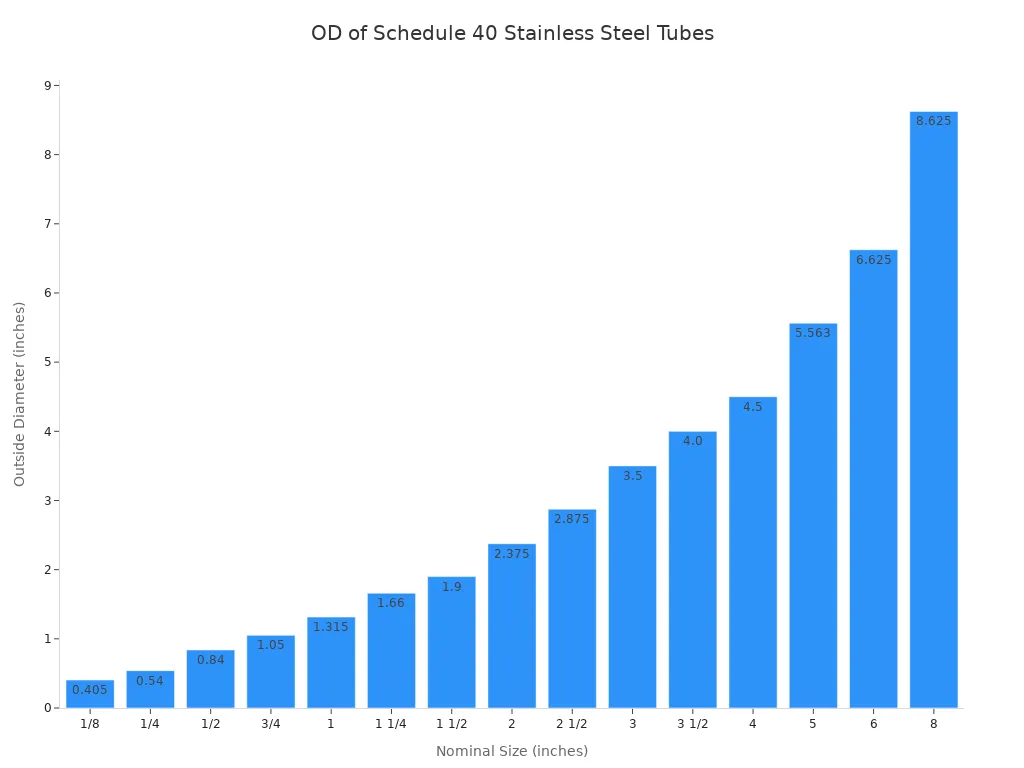

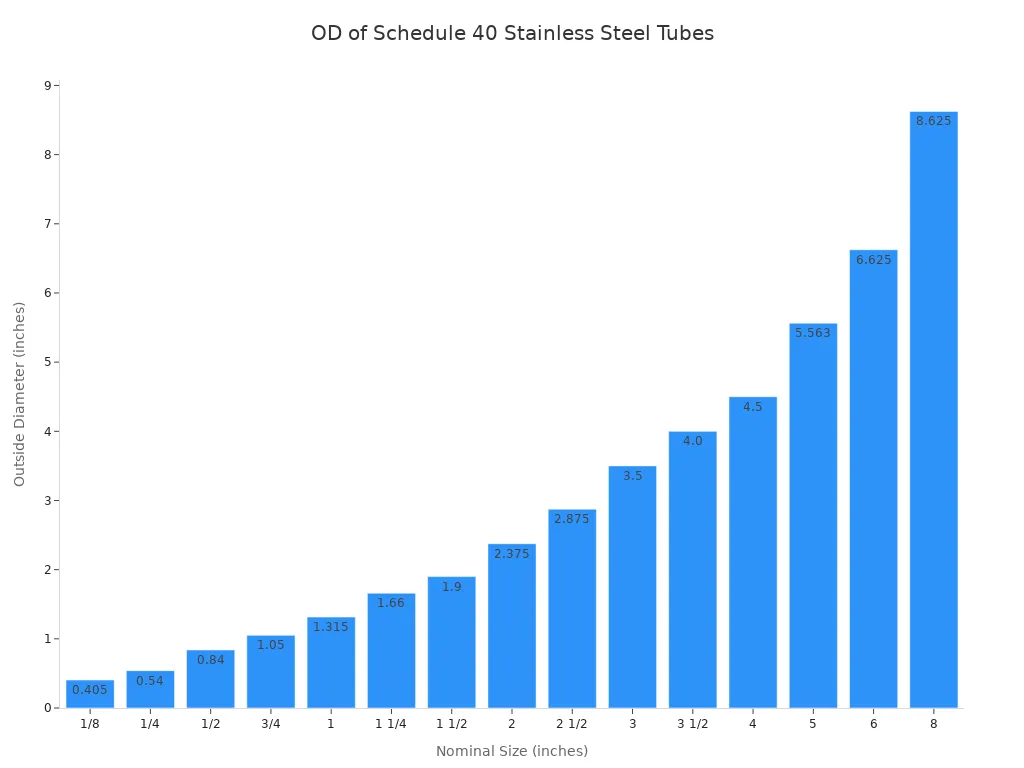

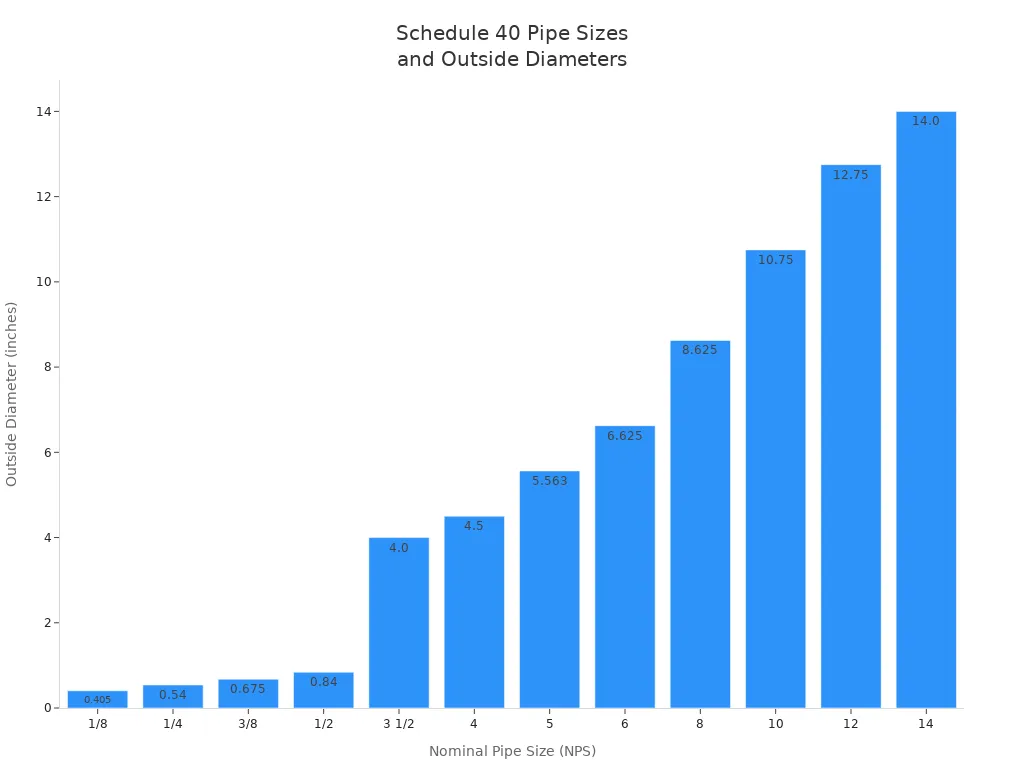

The outside diameter (OD) is a fundamental measurement for stainless steel tube dimensions. Manufacturers measure the OD according to ASME B36.10M and ASME B36.19M standards. For Schedule 40 stainless steel pipe, the OD remains constant for each nominal pipe size, even though the actual number does not always match the nominal size. This consistency ensures compatibility with fittings and other system components.

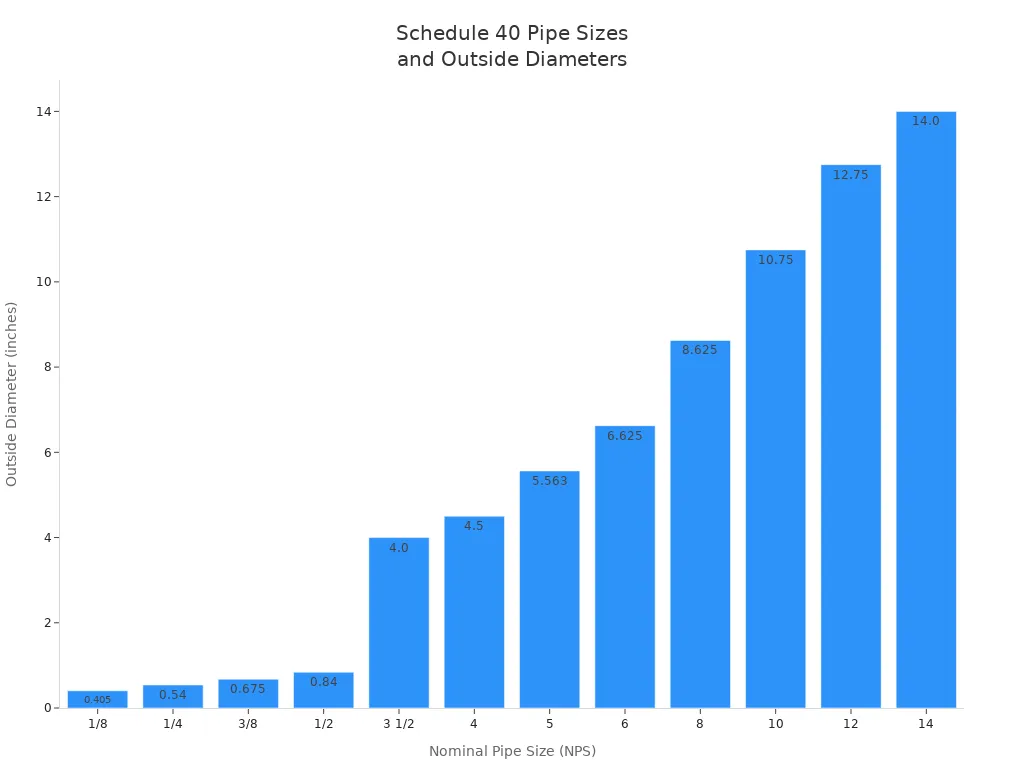

The following table lists standard OD values for common Schedule 40 stainless steel pipe sizes:

| Nominal Size (inches) | Outside Diameter (inches) | Wall Thickness (inches) |

|---|---|---|

| 1/8 | 0.405 | 0.068 |

| 1/4 | 0.540 | 0.088 |

| 1/2 | 0.840 | 0.109 |

| 3/4 | 1.050 | 0.113 |

| 1 | 1.315 | 0.133 |

| 1 1/4 | 1.660 | 0.140 |

| 1 1/2 | 1.900 | 0.145 |

| 2 | 2.375 | 0.154 |

| 2 1/2 | 2.875 | 0.203 |

| 3 | 3.500 | 0.216 |

| 3 1/2 | 4.000 | 0.226 |

| 4 | 4.500 | 0.237 |

| 5 | 5.563 | 0.258 |

| 6 | 6.625 | 0.280 |

| 8 | 8.625 | 0.322 |

The OD is critical for system design, as it determines how pipes fit together and connect with valves or fittings. Engineers rely on these standardized dimensions to ensure leak-free and secure installations.

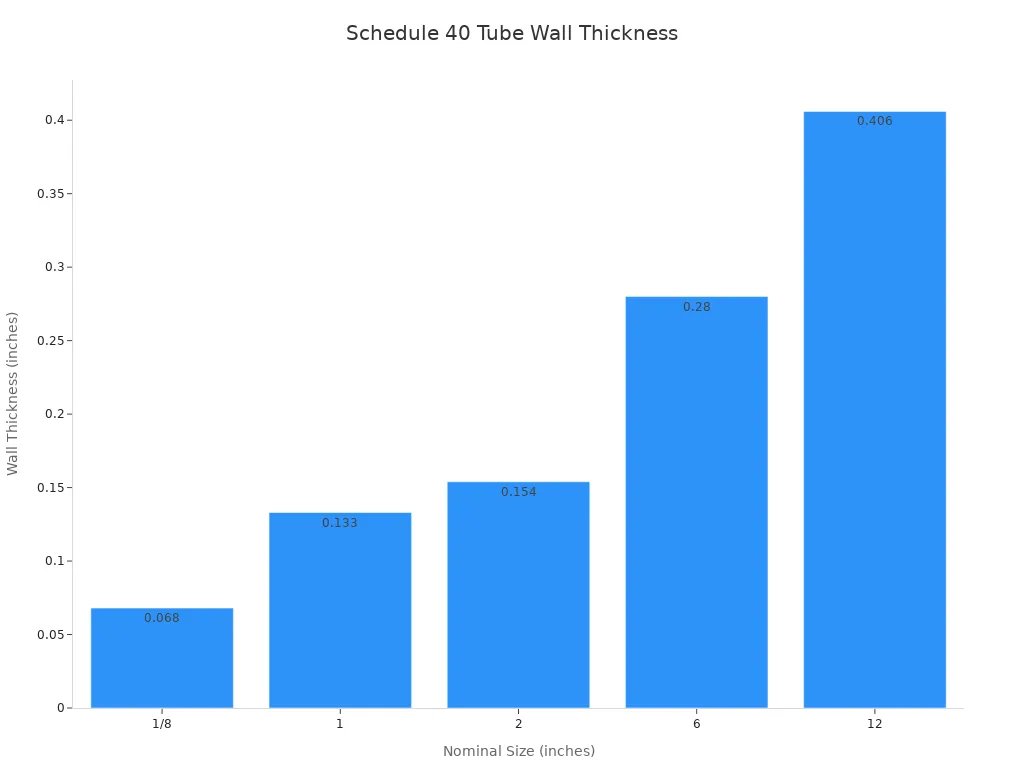

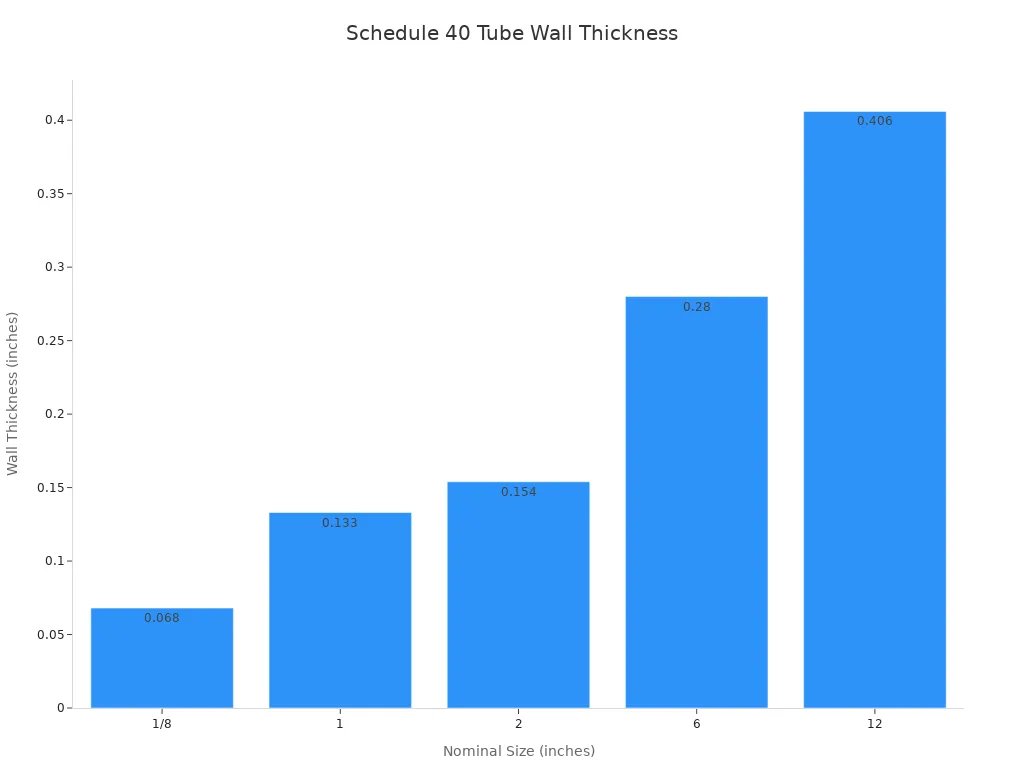

Wall thickness is another essential dimension for Schedule 40 stainless steel pipe. This measurement varies by nominal pipe size and directly affects the pipe's strength and pressure capacity. Thicker walls provide greater durability and allow the pipe to withstand higher internal pressures.

The table below shows typical wall thicknesses for several common sizes:

| Nominal Size (inches) | Wall Thickness (inches) | Wall Thickness (mm) |

|---|---|---|

| 1/8 | 0.068 | 1.73 |

| 1 | 0.133 | 3.38 |

| 2 | 0.154 | 3.91 |

| 6 | 0.280 | 7.11 |

| 12 | 0.406 | 10.31 |

Wall thickness impacts both the mechanical strength and the weight of the pipe. Thicker walls increase the pipe's ability to handle pressure but also add to the overall weight and cost. Selecting the correct wall thickness is crucial for balancing safety, performance, and budget in any application.

The inside diameter (ID) defines the open space within the pipe through which fluids or gases flow. Engineers calculate the ID by subtracting twice the wall thickness from the outside diameter:

ID = OD - 2 × wall thickness

For example, a 2-inch nominal pipe size Schedule 40 stainless steel pipe has an OD of 2.375 inches and a wall thickness of 0.154 inches. The resulting ID is 2.067 inches.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) (inches) | Wall Thickness (inches) | Inside Diameter (ID) (inches) |

|---|---|---|---|

| 2 | 2.375 | 0.154 | 2.067 |

The ID is a key factor in flow calculations. It determines the cross-sectional area available for fluid movement. Accurate knowledge of the ID allows engineers to calculate flow rates and velocities, which are essential for designing efficient piping systems. A larger ID enables higher flow rates, while a smaller ID restricts flow and increases velocity.

Tip: Always verify the ID when sizing pipes for fluid transport, as it directly affects system performance and efficiency.

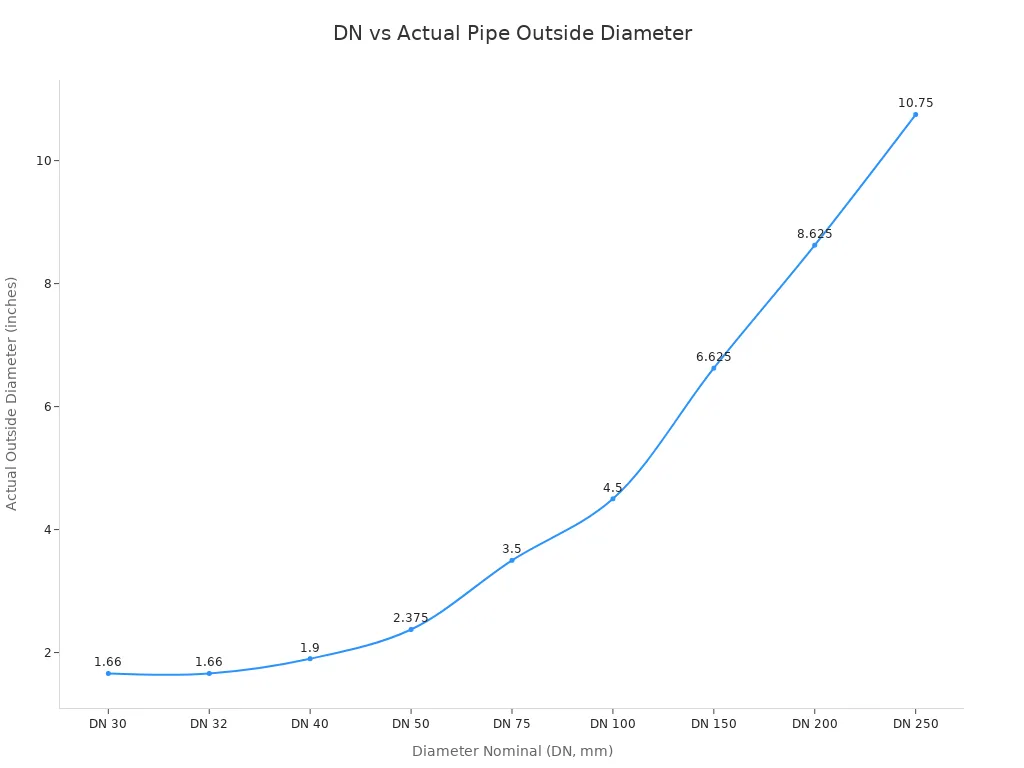

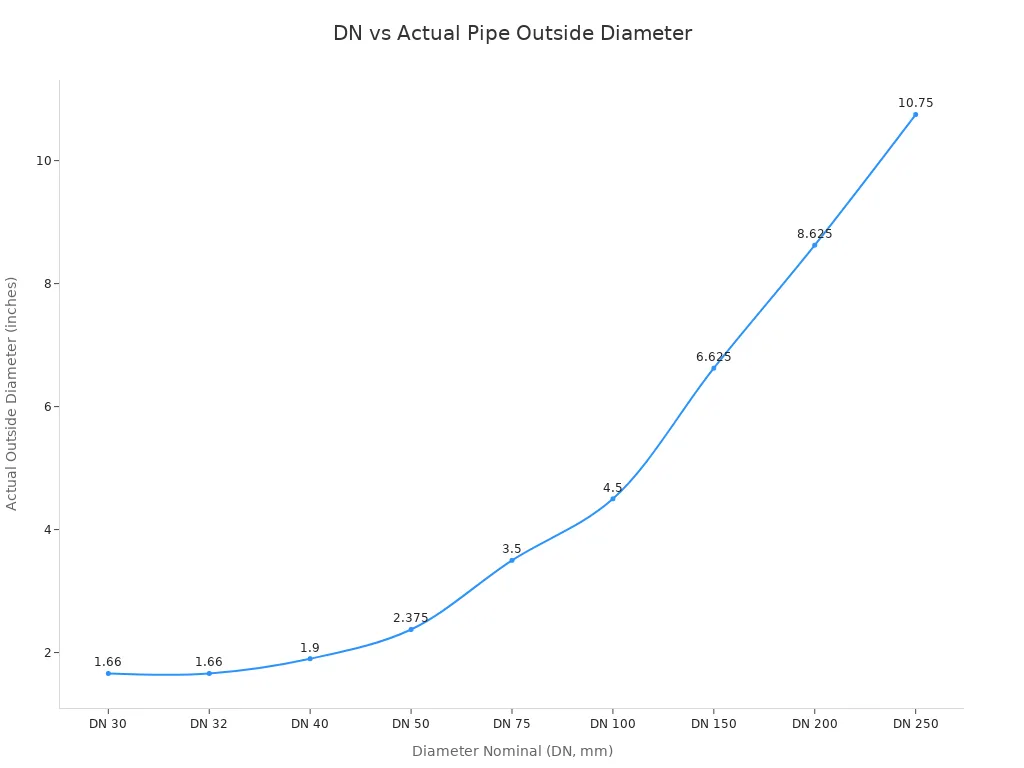

Nominal Pipe Size (NPS) and Diameter Nominal (DN) are two systems used to identify pipe sizes. NPS is the standard in North America and the UK, while DN is common in Europe and countries using the metric system. Both terms describe the size of a pipe, but they do not represent the actual diameter or precise dimensions of the pipe. Instead, they serve as standardized trade names that help engineers and contractors communicate about pipe sizes across different regions and industries.

NPS uses inches as its unit, while DN uses millimeters. For example, a pipe labeled as NPS 2 has a DN of 50. However, neither NPS nor DN matches the actual inside or outside diameter of the pipe. The actual outside diameter remains fixed for each nominal pipe size, even if the wall thickness changes with different schedules. This distinction is important because fittings, valves, and other components are designed to match these nominal sizes, not the exact measurements.

Tip: When selecting a pipe, always check the actual outside diameter and wall thickness in addition to the nominal pipe size or DN. This ensures compatibility with fittings and prevents costly installation errors.

The following table shows how NPS and DN relate to actual pipe dimensions:

| DN (mm) | NPS (inches) | Approximate Nominal Bore (inches) | Actual Outside Diameter (inches) |

|---|---|---|---|

| 30 | 1 1/4 | 1.25 | 1.660 |

| 32 | 1 1/4 | 1.25 | 1.660 |

| 40 | 1 1/2 | 1.5 | 1.900 |

| 50 | 2 | 2.0 | 2.375 |

| 75 | 3 | 3.0 | 3.500 |

| 100 | 4 | 4.0 | 4.500 |

| 150 | 6 | 6.0 | 6.625 |

| 200 | 8 | 8.0 | 8.625 |

| 250 | 10 | 10.0 | 10.750 |

This table highlights that the nominal pipe size and DN are close but not exact equivalents. The actual outside diameter often differs from both the nominal and DN values. For example, an NPS 2 pipe has an actual outside diameter of 2.375 inches, not exactly 2 inches.

The chart above illustrates how the actual outside diameter increases with DN size. This visual representation helps users understand that while DN and NPS provide a convenient way to refer to pipe sizes, the real-world dimensions must always be checked for precise engineering and installation.

To identify an unmarked pipe, measure the outside circumference with a string, calculate the diameter, and consult a sizing chart to find the closest nominal pipe size or DN. This method ensures the correct selection of pipes and fittings, especially when working with international standards.

Note: Tubing is measured by its exact outside diameter and wall thickness, unlike pipe, which uses nominal sizes. This difference is critical when specifying materials for a project.

Understanding the relationship between nominal pipe size, DN, and actual dimensions allows professionals to select compatible pipes, fittings, and valves, ensuring safe and efficient system performance.

Industry professionals rely on established standards to ensure consistency and safety in stainless steel pipe dimensions. Two main organizations set these standards: ASTM (American Society for Testing and Materials) and ASME (American Society of Mechanical Engineers). Their specifications cover both the physical dimensions and the material properties of Schedule 40 stainless steel pipe.

ASTM A312 defines the material requirements for Schedule 40 stainless steel pipe. This standard covers both seamless and welded pipes, specifying chemical composition, mechanical properties, and corrosion resistance.

ASME B36.19M outlines the standard dimensions for stainless steel pipe. It includes nominal pipe sizes (NPS), wall thicknesses (schedules), and tolerances for both seamless and welded types.

ASME B36.19M differs from ASME B36.10M, which applies to carbon steel pipes. The stainless steel standard includes specific schedules such as 10S, 40S, and 80S.

The schedule number, such as Schedule 40, indicates a series of wall thicknesses for each nominal size. This directly affects the pipe’s strength and pressure rating.

These standards ensure that stainless steel pipe dimensions remain consistent, interchangeable, and safe for use in a wide range of applications, including air, oil, water, and natural gas systems.

Tip: Always verify that the selected pipe meets both ASTM and ASME standards for your application.

The choice of material grade impacts the performance and durability of Schedule 40 stainless steel pipe. The most common grades are 304 and 316, each offering unique benefits for different environments.

| Grade | Carbon (C) % | Silicon (Si) % | Manganese (Mn) % | Phosphorus (P) % | Sulfur (S) % | Nitrogen (N) % | Chromium (Cr) % | Nickel (Ni) % | Molybdenum (Mo) % |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 17.5 - 19.5 | 8.0 - 10.5 | N/A |

| 316 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 16.5 - 18.5 | 10.0 - 13.0 | 2.0 - 2.5 |

Grade 304 offers a cost-effective solution with good corrosion resistance, making it suitable for most general applications. Grade 316 contains added molybdenum, which increases resistance to chloride ion stress corrosion and enhances mechanical strength. This makes 316 the preferred choice for marine, chemical, and high-salinity environments.

Manufacturers apply specific markings to each Schedule 40 stainless steel pipe to ensure traceability and compliance with standards. These markings typically include the pipe length, schedule number, and a unique heat number or manufacturer’s number. The heat number links each pipe to its production batch, chemical composition, and quality test records.

Additional symbols may indicate conformity to supplementary requirements or specific test methods, such as hydrostatic or non-destructive testing. Markings can appear as stenciling, stamping, or rolling, depending on the manufacturer’s process.

Note: Markings play a critical role in quality control. They allow users to trace the origin of the pipe, verify compliance with standards, and access test reports if issues arise. This traceability ensures accountability and safety throughout the supply chain.

A stainless steel pipe dimension chart provides essential information for selecting the right pipe for any application. Each column in the chart represents a specific property that helps engineers and specifiers make informed decisions. The most common columns include:

Nominal Pipe Size (NPS): This column lists the standard trade size of the pipe, which does not always match the actual diameter.

Outside Diameter (OD): Shows the true external diameter of the pipe, critical for fitting and compatibility.

Wall Thickness (WT): Indicates the thickness of the pipe wall, which affects strength and pressure rating.

Inside Diameter (ID): Calculated by subtracting twice the wall thickness from the OD, this value determines the flow capacity.

Weight (lb/ft or kg/m): Provides the mass per unit length, important for handling and support calculations.

Pressure Rating: Some charts include the maximum allowable pressure for each size and schedule.

A typical pipe size chart will display these columns in both metric and imperial units, making it easier to compare and select the correct pipe across different standards.

Engineers and specifiers rely on the stainless steel pipe dimension chart to select the correct Schedule 40 pipe for their projects. The process involves several key steps:

Identify the required nominal pipe size using the nominal pipe size chart.

Check the outside diameter and wall thickness to ensure compatibility with fittings and pressure requirements.

Confirm the inside diameter to verify that the pipe will provide adequate flow for the intended application.

Review the weight column to plan for support structures and installation logistics.

Ensure the selected pipe meets the necessary standards, such as ASME B36.19 or ASTM A312.

For example, when choosing a 4-inch Schedule 40 stainless steel pipe, the chart shows an OD of 114.30 mm and a wall thickness of 6.02 mm. This information allows the engineer to determine if the pipe can handle the required pressure and flow. Using the pipe size chart ensures safety, cost-efficiency, and compliance with industry standards.

Tip: Always cross-reference the stainless steel pipe dimension chart with project specifications to avoid costly errors.

Dimension charts use several abbreviations and notations that help users interpret the data quickly. Understanding these notations is crucial for accurate selection and communication.

| Notation | Meaning | Interpretation |

|---|---|---|

| NPS | Nominal Pipe Size | Standard trade size; not the actual diameter |

| Sch. or Sched. | Schedule | Indicates wall thickness (e.g., Schedule 40) |

| NB | Nominal Bore | Metric equivalent to DN; refers to nominal internal diameter |

| DN | Diamètre Nominal | Metric nominal diameter, used interchangeably with NB |

| OD | Outside Diameter | Actual external diameter of the pipe |

| ID | Inside Diameter | Internal diameter, calculated from OD minus twice the wall thickness |

| WT | Wall Thickness | Thickness of the pipe wall, varies with schedule number |

| Weight (lb/ft) | Weight per foot | Mass of pipe per unit length, varies with size and wall thickness |

These notations appear in every stainless steel pipe dimension chart and pipe size chart. They help users interpret the data and select the correct pipe for their needs.

A comprehensive pipe size chart helps engineers and installers select the correct stainless steel pipe for any application. The chart below lists the most frequently used Schedule 40 sizes, including nominal pipe size (NPS), outside diameter (OD), wall thickness, inside diameter (ID), and weight. Each value appears in both imperial and metric units for easy reference.

| Nominal Pipe Size (NPS) | Outside Diameter (in) | Outside Diameter (mm) | Wall Thickness (in) | Wall Thickness (mm) | Inside Diameter (in) | Inside Diameter (mm) | Weight (lb/ft) | Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|

| 1/8 | 0.405 | 10.29 | 0.049 | 1.24 | 0.307 | 7.80 | 0.24 | 0.36 |

| 1/4 | 0.540 | 13.72 | 0.065 | 1.65 | 0.410 | 10.41 | 0.42 | 0.63 |

| 3/8 | 0.675 | 17.15 | 0.065 | 1.65 | 0.545 | 13.84 | 0.57 | 0.85 |

| 1/2 | 0.840 | 21.34 | 0.065 | 1.65 | 0.710 | 18.03 | 0.85 | 1.27 |

| 3/4 | 1.050 | 26.67 | 0.083 | 2.11 | 0.864 | 21.95 | 1.13 | 1.68 |

| 1 | 1.315 | 33.40 | 0.109 | 2.77 | 1.097 | 27.89 | 1.68 | 2.50 |

| 1 1/2 | 1.900 | 48.26 | 0.145 | 3.68 | 1.610 | 40.89 | 2.72 | 4.05 |

| 2 | 2.375 | 60.33 | 0.154 | 3.91 | 2.067 | 52.50 | 3.66 | 5.45 |

| 3 1/2 | 4.000 | 101.60 | 0.083 | 2.11 | 3.834 | 97.41 | 5.62 | 8.37 |

| 4 | 4.500 | 114.30 | 0.237 | 6.02 | 4.026 | 102.31 | 7.29 | 10.86 |

| 5 | 5.563 | 141.30 | 0.258 | 6.55 | 5.047 | 128.19 | 9.62 | 14.32 |

| 6 | 6.625 | 168.28 | 0.280 | 7.11 | 6.065 | 154.15 | 12.00 | 17.86 |

| 8 | 8.625 | 219.08 | 0.250 | 6.35 | 8.125 | 206.38 | 18.97 | 28.25 |

| 10 | 10.750 | 273.05 | 0.250 | 6.35 | 10.250 | 260.35 | 24.66 | 36.71 |

| 12 | 12.750 | 323.85 | 0.250 | 6.35 | 12.250 | 311.15 | 29.74 | 44.27 |

| 14 | 14.000 | 355.60 | 0.250 | 6.35 | 13.500 | 342.90 | 32.55 | 48.45 |

Note: The values above follow ASME/ANSI B36.10/19 standards for stainless steel pipe dimensions. Always verify the latest standards for critical projects.

The chart above visually compares outside diameters for the most common Schedule 40 stainless steel pipe sizes. This visual aid helps users quickly identify the right pipe for their needs.

Stainless steel pipe dimensions appear in both metric and imperial units on every professional pipe size chart. This dual presentation ensures global compatibility and simplifies communication between suppliers and engineers.

Most charts display nominal pipe size (NPS) in inches and diameter in millimeters.

Wall thickness and inside diameter also appear in both units, allowing for easy conversion and comparison.

The outside diameter remains constant for each NPS up to 12 inches, while the inside diameter changes with the schedule.

For NPS 14 inches and above, the outside diameter increases with the schedule number.

Standard references such as ASME B36.19 provide authoritative data for both metric and imperial systems.

Engineers rely on these charts to ensure system compatibility, especially when projects involve international standards or cross-border supply chains. The use of both unit systems in stainless steel pipe dimensions charts helps prevent costly errors and ensures that every pipe fits precisely with its intended fittings and components.

Tip: When reviewing a pipe size chart, always check both the metric and imperial columns to confirm the correct pipe size and dimensions for your application.

Accurate specification is essential when ordering Schedule 40 stainless steel tubes. Suppliers require clear and complete information to deliver the correct product. The following details should always be included in an order:

Tube size, including both outside diameter and wall thickness

Schedule number, which defines wall thickness and pressure rating

Stainless steel grade, such as ASTM A312 TP316L

Tube length, either standard or custom

Required certifications or test reports

Traceability details, like heat number and manufacturer information

Compliance with relevant industry standards

Any custom sizing or wall thickness requirements

Providing these details ensures the supplier delivers tubes that meet the project’s pressure, strength, and application needs. In regulated industries, traceability and certification markings are critical for compliance and quality assurance. Custom sizing requests should be communicated clearly to avoid delays or errors.

Mistakes in specifying pipe sizes can lead to costly delays, safety risks, or system failures. The most common errors include:

Confusing nominal pipe sizes with actual outside or inside diameters.

Omitting the schedule number, which results in incorrect wall thickness.

Failing to specify the stainless steel grade, leading to material incompatibility.

Overlooking the need for certifications or traceability, especially in regulated sectors.

Not confirming the required length or custom sizing.

Tip: Always double-check the order against the project specifications and the stainless steel pipe dimension chart. This step helps prevent mismatches and ensures the correct pipe sizes are supplied.

Clear communication with suppliers and project teams helps avoid misunderstandings. Use precise terminology and reference recognized standards. When discussing pipe sizes, always specify:

Nominal pipe size (NPS) and schedule number

Stainless steel grade and standard (e.g., ASTM A312)

Required length and any special requirements

A sample order might look like this:

2-inch Schedule 40 stainless steel pipe, ASTM A312 TP316L, 6 meters long, with mill test certificate and heat number marked on each length.

Note: Sharing a copy of the relevant pipe size chart with the supplier can further reduce errors and ensure everyone uses the same reference.

Consistent and detailed communication ensures the correct pipe sizes arrive on site, ready for installation.

NPS, or Nominal Pipe Size, serves as the standard for pipe sizing in North America. It uses inches as the unit of measurement, but the number does not always match the actual diameter of the pipe. DN, or Diamètre Nominal, is the international metric equivalent, expressed in millimeters. Both NPS and DN act as nominal designations, meaning they provide a convenient way to refer to pipe sizes without representing the exact physical dimensions. For example, a 2-inch NPS pipe has an outside diameter of about 2.375 inches, while its DN equivalent is 50. ISO 6708 defines DN as a dimensionless number, which helps standardize pipe sizing across different regions.

NPS and DN simplify communication between engineers, suppliers, and installers. They allow teams to match pipes and fittings even when working with different measurement systems. However, the actual outside diameter for NPS sizes 1/8 to 12 does not equal the nominal size. For sizes 14 and above, NPS matches the outside diameter in inches. Conversion tables and a nominal pipe size chart help users find the correct match between NPS and DN for any project.

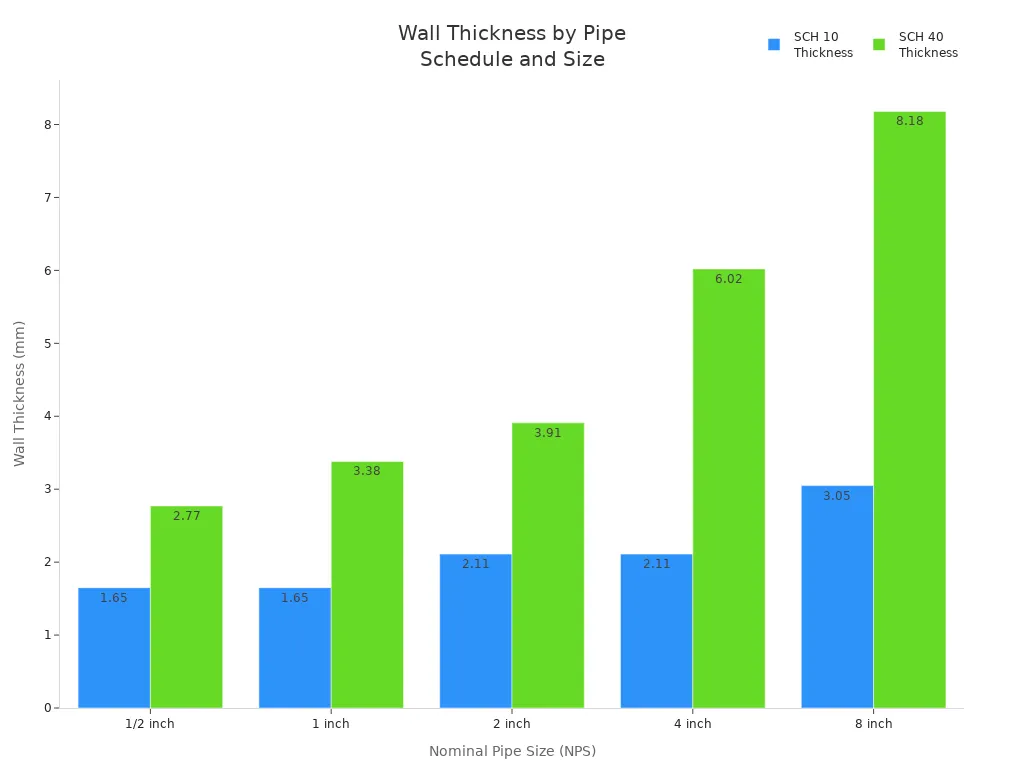

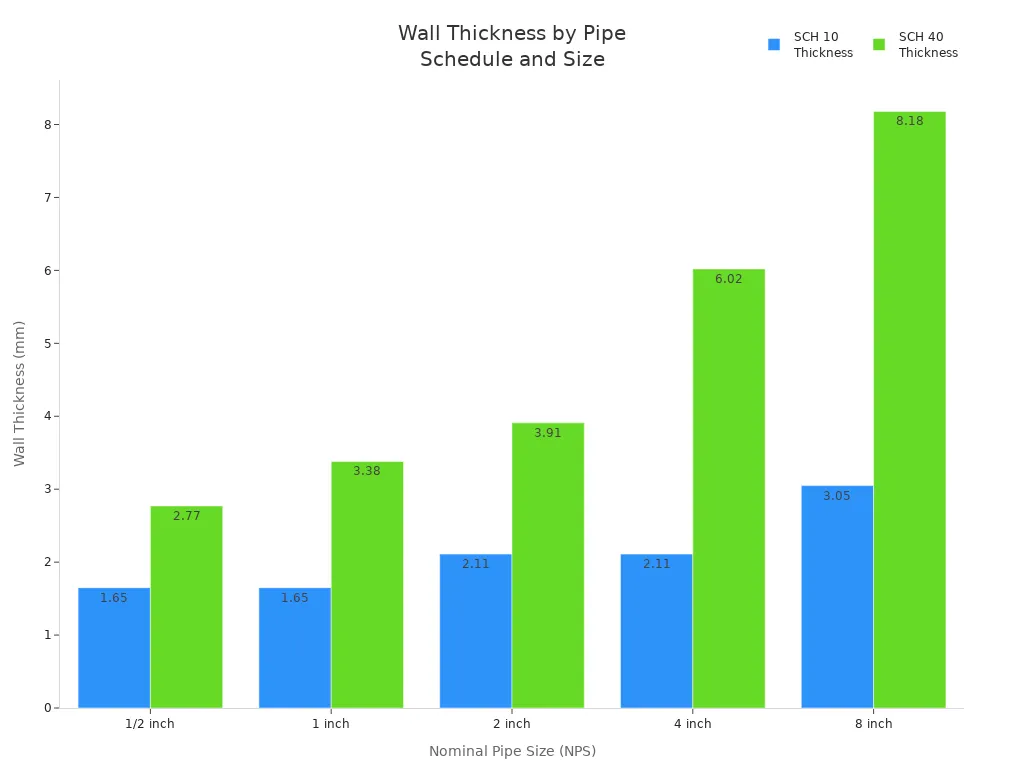

Schedule numbers indicate the wall thickness of a pipe. The schedule system, such as Schedule 10 or Schedule 40, works alongside NPS or DN to define the pipe’s dimensions. Higher schedule numbers mean thicker walls, which increase the pipe’s pressure rating and reduce the inside diameter. For stainless steel tubes, thinner schedules like 5S and 10S are common due to the material’s corrosion resistance.

The table below compares wall thickness for different schedules and nominal pipe sizes:

| Nominal Pipe Size (NPS) | SCH 10 Thickness (mm) | SCH 40 Thickness (mm) |

|---|---|---|

| 1/2 inch | ~1.65 | ~2.77 |

| 1 inch | ~1.65 | ~3.38 |

| 2 inch | ~2.11 | ~3.91 |

| 4 inch | ~2.11 | ~6.02 |

| 8 inch | ~3.05 | ~8.18 |

The schedule number does not directly indicate pressure rating, but thicker walls generally support higher pressures. For each nominal pipe size, the outside diameter stays the same, but the inside diameter decreases as the schedule increases.

Understanding the differences between NPS, DN, and schedule numbers is essential for selecting the right stainless steel tube. NPS and DN provide a common language for specifying pipe size, while the schedule number determines wall thickness and, therefore, pressure capacity and flow rate. For a given nominal pipe size, the outside diameter remains constant, but the inside diameter changes with the schedule. This affects how much fluid the pipe can carry and how much pressure it can withstand.

Selecting the correct combination ensures that the pipe meets the requirements for flow, pressure, and structural integrity. This is especially important for stainless steel tubes used in high-pressure or corrosive environments. Using a nominal pipe size chart helps engineers and contractors match pipes and fittings accurately, reducing the risk of leaks or failures. Proper selection also ensures compatibility with international standards, which is critical for global projects.

Tip: Always confirm both the nominal pipe size and schedule number when ordering or specifying stainless steel tubes. This practice helps avoid costly mistakes and ensures system safety.

Selecting the correct Schedule 40 stainless steel tube size for a specific application requires careful consideration of several factors. Engineers and installers should evaluate the following:

Pressure and temperature requirements: Thicker walls are necessary for high-pressure or high-temperature systems to ensure safety and durability.

Flow rate and capacity: The inside diameter determines how much fluid or gas can move through the tube. Larger inside diameters reduce friction and pressure loss.

Corrosion resistance: Different stainless steel grades offer varying levels of protection against harsh chemicals or environments.

Installation and compatibility: Pipe dimensions must match existing fittings, valves, and flanges to prevent installation issues.

Compliance with industry standards: Adhering to standards such as ASTM A312, ASTM A269, ANSI B36.19, and ISO 1127 ensures the tube meets the intended application’s requirements.

Tip: Always review project specifications and consult dimension charts before finalizing tube selection.

Schedule 40 stainless steel tubes provide standardized wall thicknesses that vary by nominal size. As the pipe size increases, wall thickness also increases to maintain mechanical strength. However, the pressure rating per unit area often decreases with larger diameters due to geometric factors. The following table illustrates how wall thickness and allowable pressure change with size:

| Nominal Size (in) | Wall Thickness (in) | Allowable Pressure at 100°F (psig) |

|---|---|---|

| 1 | 0.133 | 2205 |

| 4 | 0.237 | 1102 |

| 14 | 0.156 | 404 |

| 24 | 0.250 | 265 |

Smaller diameter pipes can withstand higher pressures, even with thinner walls, because of the way stress distributes across the pipe. Larger pipes require thicker walls to maintain structural integrity, but their pressure ratings decrease as diameter increases. Engineers must balance these factors to ensure safe and efficient system performance.

Ensuring fittings compatibility with Schedule 40 stainless steel tubes is essential for leak-free and reliable connections. Fittings should match the tube’s material type to prevent issues caused by differences in hardness or thermal expansion. Using fittings and adapters that comply with the same thread standards—such as JIC, NPT, or AN—helps avoid leaks and mechanical failures. Precision in thread cutting, whether manual, electric, or CNC, is crucial for maintaining the tube’s structural integrity and corrosion resistance. Quality assurance during threading and installation ensures the pipe system remains dependable under operational stresses.

Note: Always verify the stainless steel grade and thread specifications before installation to maintain system reliability.

Schedule 40 defines a standard wall thickness for stainless steel pipes, balancing strength and cost for many applications.

Nominal Pipe Size (NPS) is a trade name and does not match the actual pipe diameter; always check outside and inside diameters.

Wall thickness affects pipe strength and pressure capacity; thicker walls handle higher pressures but add weight and cost.

Stainless steel grades 304 and 316 offer corrosion resistance, with 316 better for harsh chemical or marine environments.

Industry standards like ASTM and ASME ensure pipe dimensions and materials meet safety and quality requirements.

Use dimension charts to verify pipe size, wall thickness, and weight for proper fit and system performance.

Clear communication of NPS, schedule number, grade, and length helps avoid ordering mistakes and installation issues.

Matching pipe size and schedule to application needs ensures safety, durability, and efficient fluid flow in piping systems.

Schedule 40 refers to a standardized wall thickness for pipes, including stainless steel tube schedule 40. This schedule ensures that each pipe size has a consistent wall thickness, which simplifies selection and compatibility across different systems. The term "Schedule 40S" specifically identifies stainless steel pipe, where the "S" stands for stainless steel. Both Schedule 40 and Schedule 40S share the same nominal pipe sizes, outer diameters, and wall thicknesses. However, stainless steel tube schedule 40 offers unique advantages due to its material composition. Stainless steel contains at least 10.5% chromium, which forms a protective oxide layer. This layer prevents rust and corrosion, making these pipes suitable for harsh environments. In contrast, standard Schedule 40 pipes made from carbon steel or PVC rely on coatings that can deteriorate over time. Stainless steel pipe also provides higher pressure ratings and a longer lifespan, often lasting 70-80 years.

Note: The 'S' in Schedule 40S always indicates stainless steel, distinguishing it from other materials.

Engineers and contractors select stainless steel tube schedule 40 for its balance of strength, durability, and corrosion resistance. The thicker wall compared to lighter schedules, such as Schedule 10, allows these pipes to handle higher pressures and temperatures. This makes them ideal for demanding industrial and commercial applications. Stainless steel pipe resists corrosion from chemicals, salts, and moisture, which is critical in environments where other materials would fail. The robust construction ensures system integrity and safety, even under stress. Although these pipes are heavier and more challenging to install, their reliability and long service life reduce maintenance and replacement costs. Schedule 40 pipes comply with industry standards, ensuring quality and safety in every installation.

Key reasons for choosing Schedule 40 stainless steel pipe include:

High pressure and temperature tolerance

Superior corrosion resistance

Long service life and reduced maintenance

Compliance with industry codes and standards

Reliable performance in critical applications

Stainless steel tube schedule 40 serves a wide range of industries due to its versatility and performance. Manufacturers use these pipes in both welded and seamless forms, often choosing grades like 304 or 316 for added corrosion resistance. The following table highlights typical industries and applications:

| Industry | Typical Applications and Reasons |

|---|---|

| Oil and Gas | Pipelines, equipment; withstands high pressure, temperature, and corrosive environments. |

| Chemical and Petrochemical | Transport of aggressive chemicals; high corrosion resistance; used in processing plants and refineries. |

| Food and Beverage | Sanitary transport and processing; easy to clean; used in mixers, breweries, and dairy operations. |

| Water and Wastewater | Clean and wastewater transport; resistant to chlorine and chemicals; used in treatment plants. |

| Construction and Architecture | Structural support, decorative elements; weather and corrosion resistant for outdoor use. |

| Automotive and Transportation | Exhaust systems, fuel and brake lines; withstands high temperatures and pressures. |

| Mining and Minerals | Slurry transportation, chemical processing, structural components; abrasion and corrosion resistant. |

| Medical and Pharmaceutical | Sterile fluid and gas transport; maintains sterile conditions; used in pharmaceutical processes. |

Stainless steel pipe sizes in Schedule 40 are common in water supply systems, HVAC installations, and industrial processing. Their durability and resistance to harsh conditions make them a preferred choice for critical infrastructure.

The outside diameter (OD) is a fundamental measurement for stainless steel tube dimensions. Manufacturers measure the OD according to ASME B36.10M and ASME B36.19M standards. For Schedule 40 stainless steel pipe, the OD remains constant for each nominal pipe size, even though the actual number does not always match the nominal size. This consistency ensures compatibility with fittings and other system components.

The following table lists standard OD values for common Schedule 40 stainless steel pipe sizes:

| Nominal Size (inches) | Outside Diameter (inches) | Wall Thickness (inches) |

|---|---|---|

| 1/8 | 0.405 | 0.068 |

| 1/4 | 0.540 | 0.088 |

| 1/2 | 0.840 | 0.109 |

| 3/4 | 1.050 | 0.113 |

| 1 | 1.315 | 0.133 |

| 1 1/4 | 1.660 | 0.140 |

| 1 1/2 | 1.900 | 0.145 |

| 2 | 2.375 | 0.154 |

| 2 1/2 | 2.875 | 0.203 |

| 3 | 3.500 | 0.216 |

| 3 1/2 | 4.000 | 0.226 |

| 4 | 4.500 | 0.237 |

| 5 | 5.563 | 0.258 |

| 6 | 6.625 | 0.280 |

| 8 | 8.625 | 0.322 |

The OD is critical for system design, as it determines how pipes fit together and connect with valves or fittings. Engineers rely on these standardized dimensions to ensure leak-free and secure installations.

Wall thickness is another essential dimension for Schedule 40 stainless steel pipe. This measurement varies by nominal pipe size and directly affects the pipe's strength and pressure capacity. Thicker walls provide greater durability and allow the pipe to withstand higher internal pressures.

The table below shows typical wall thicknesses for several common sizes:

| Nominal Size (inches) | Wall Thickness (inches) | Wall Thickness (mm) |

|---|---|---|

| 1/8 | 0.068 | 1.73 |

| 1 | 0.133 | 3.38 |

| 2 | 0.154 | 3.91 |

| 6 | 0.280 | 7.11 |

| 12 | 0.406 | 10.31 |

Wall thickness impacts both the mechanical strength and the weight of the pipe. Thicker walls increase the pipe's ability to handle pressure but also add to the overall weight and cost. Selecting the correct wall thickness is crucial for balancing safety, performance, and budget in any application.

The inside diameter (ID) defines the open space within the pipe through which fluids or gases flow. Engineers calculate the ID by subtracting twice the wall thickness from the outside diameter:

ID = OD - 2 × wall thickness

For example, a 2-inch nominal pipe size Schedule 40 stainless steel pipe has an OD of 2.375 inches and a wall thickness of 0.154 inches. The resulting ID is 2.067 inches.

| Nominal Pipe Size (NPS) | Outside Diameter (OD) (inches) | Wall Thickness (inches) | Inside Diameter (ID) (inches) |

|---|---|---|---|

| 2 | 2.375 | 0.154 | 2.067 |

The ID is a key factor in flow calculations. It determines the cross-sectional area available for fluid movement. Accurate knowledge of the ID allows engineers to calculate flow rates and velocities, which are essential for designing efficient piping systems. A larger ID enables higher flow rates, while a smaller ID restricts flow and increases velocity.

Tip: Always verify the ID when sizing pipes for fluid transport, as it directly affects system performance and efficiency.

Nominal Pipe Size (NPS) and Diameter Nominal (DN) are two systems used to identify pipe sizes. NPS is the standard in North America and the UK, while DN is common in Europe and countries using the metric system. Both terms describe the size of a pipe, but they do not represent the actual diameter or precise dimensions of the pipe. Instead, they serve as standardized trade names that help engineers and contractors communicate about pipe sizes across different regions and industries.

NPS uses inches as its unit, while DN uses millimeters. For example, a pipe labeled as NPS 2 has a DN of 50. However, neither NPS nor DN matches the actual inside or outside diameter of the pipe. The actual outside diameter remains fixed for each nominal pipe size, even if the wall thickness changes with different schedules. This distinction is important because fittings, valves, and other components are designed to match these nominal sizes, not the exact measurements.

Tip: When selecting a pipe, always check the actual outside diameter and wall thickness in addition to the nominal pipe size or DN. This ensures compatibility with fittings and prevents costly installation errors.

The following table shows how NPS and DN relate to actual pipe dimensions:

| DN (mm) | NPS (inches) | Approximate Nominal Bore (inches) | Actual Outside Diameter (inches) |

|---|---|---|---|

| 30 | 1 1/4 | 1.25 | 1.660 |

| 32 | 1 1/4 | 1.25 | 1.660 |

| 40 | 1 1/2 | 1.5 | 1.900 |

| 50 | 2 | 2.0 | 2.375 |

| 75 | 3 | 3.0 | 3.500 |

| 100 | 4 | 4.0 | 4.500 |

| 150 | 6 | 6.0 | 6.625 |

| 200 | 8 | 8.0 | 8.625 |

| 250 | 10 | 10.0 | 10.750 |

This table highlights that the nominal pipe size and DN are close but not exact equivalents. The actual outside diameter often differs from both the nominal and DN values. For example, an NPS 2 pipe has an actual outside diameter of 2.375 inches, not exactly 2 inches.

The chart above illustrates how the actual outside diameter increases with DN size. This visual representation helps users understand that while DN and NPS provide a convenient way to refer to pipe sizes, the real-world dimensions must always be checked for precise engineering and installation.

To identify an unmarked pipe, measure the outside circumference with a string, calculate the diameter, and consult a sizing chart to find the closest nominal pipe size or DN. This method ensures the correct selection of pipes and fittings, especially when working with international standards.

Note: Tubing is measured by its exact outside diameter and wall thickness, unlike pipe, which uses nominal sizes. This difference is critical when specifying materials for a project.

Understanding the relationship between nominal pipe size, DN, and actual dimensions allows professionals to select compatible pipes, fittings, and valves, ensuring safe and efficient system performance.

Industry professionals rely on established standards to ensure consistency and safety in stainless steel pipe dimensions. Two main organizations set these standards: ASTM (American Society for Testing and Materials) and ASME (American Society of Mechanical Engineers). Their specifications cover both the physical dimensions and the material properties of Schedule 40 stainless steel pipe.

ASTM A312 defines the material requirements for Schedule 40 stainless steel pipe. This standard covers both seamless and welded pipes, specifying chemical composition, mechanical properties, and corrosion resistance.

ASME B36.19M outlines the standard dimensions for stainless steel pipe. It includes nominal pipe sizes (NPS), wall thicknesses (schedules), and tolerances for both seamless and welded types.

ASME B36.19M differs from ASME B36.10M, which applies to carbon steel pipes. The stainless steel standard includes specific schedules such as 10S, 40S, and 80S.

The schedule number, such as Schedule 40, indicates a series of wall thicknesses for each nominal size. This directly affects the pipe’s strength and pressure rating.

These standards ensure that stainless steel pipe dimensions remain consistent, interchangeable, and safe for use in a wide range of applications, including air, oil, water, and natural gas systems.

Tip: Always verify that the selected pipe meets both ASTM and ASME standards for your application.

The choice of material grade impacts the performance and durability of Schedule 40 stainless steel pipe. The most common grades are 304 and 316, each offering unique benefits for different environments.

| Grade | Carbon (C) % | Silicon (Si) % | Manganese (Mn) % | Phosphorus (P) % | Sulfur (S) % | Nitrogen (N) % | Chromium (Cr) % | Nickel (Ni) % | Molybdenum (Mo) % |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 17.5 - 19.5 | 8.0 - 10.5 | N/A |

| 316 | 0.07 | 1.00 | 2.00 | 0.045 | 0.015 | 0.10 | 16.5 - 18.5 | 10.0 - 13.0 | 2.0 - 2.5 |

Grade 304 offers a cost-effective solution with good corrosion resistance, making it suitable for most general applications. Grade 316 contains added molybdenum, which increases resistance to chloride ion stress corrosion and enhances mechanical strength. This makes 316 the preferred choice for marine, chemical, and high-salinity environments.

Manufacturers apply specific markings to each Schedule 40 stainless steel pipe to ensure traceability and compliance with standards. These markings typically include the pipe length, schedule number, and a unique heat number or manufacturer’s number. The heat number links each pipe to its production batch, chemical composition, and quality test records.

Additional symbols may indicate conformity to supplementary requirements or specific test methods, such as hydrostatic or non-destructive testing. Markings can appear as stenciling, stamping, or rolling, depending on the manufacturer’s process.

Note: Markings play a critical role in quality control. They allow users to trace the origin of the pipe, verify compliance with standards, and access test reports if issues arise. This traceability ensures accountability and safety throughout the supply chain.

A stainless steel pipe dimension chart provides essential information for selecting the right pipe for any application. Each column in the chart represents a specific property that helps engineers and specifiers make informed decisions. The most common columns include:

Nominal Pipe Size (NPS): This column lists the standard trade size of the pipe, which does not always match the actual diameter.

Outside Diameter (OD): Shows the true external diameter of the pipe, critical for fitting and compatibility.

Wall Thickness (WT): Indicates the thickness of the pipe wall, which affects strength and pressure rating.

Inside Diameter (ID): Calculated by subtracting twice the wall thickness from the OD, this value determines the flow capacity.

Weight (lb/ft or kg/m): Provides the mass per unit length, important for handling and support calculations.

Pressure Rating: Some charts include the maximum allowable pressure for each size and schedule.

A typical pipe size chart will display these columns in both metric and imperial units, making it easier to compare and select the correct pipe across different standards.

Engineers and specifiers rely on the stainless steel pipe dimension chart to select the correct Schedule 40 pipe for their projects. The process involves several key steps:

Identify the required nominal pipe size using the nominal pipe size chart.

Check the outside diameter and wall thickness to ensure compatibility with fittings and pressure requirements.

Confirm the inside diameter to verify that the pipe will provide adequate flow for the intended application.

Review the weight column to plan for support structures and installation logistics.

Ensure the selected pipe meets the necessary standards, such as ASME B36.19 or ASTM A312.

For example, when choosing a 4-inch Schedule 40 stainless steel pipe, the chart shows an OD of 114.30 mm and a wall thickness of 6.02 mm. This information allows the engineer to determine if the pipe can handle the required pressure and flow. Using the pipe size chart ensures safety, cost-efficiency, and compliance with industry standards.

Tip: Always cross-reference the stainless steel pipe dimension chart with project specifications to avoid costly errors.

Dimension charts use several abbreviations and notations that help users interpret the data quickly. Understanding these notations is crucial for accurate selection and communication.

| Notation | Meaning | Interpretation |

|---|---|---|

| NPS | Nominal Pipe Size | Standard trade size; not the actual diameter |

| Sch. or Sched. | Schedule | Indicates wall thickness (e.g., Schedule 40) |

| NB | Nominal Bore | Metric equivalent to DN; refers to nominal internal diameter |

| DN | Diamètre Nominal | Metric nominal diameter, used interchangeably with NB |

| OD | Outside Diameter | Actual external diameter of the pipe |

| ID | Inside Diameter | Internal diameter, calculated from OD minus twice the wall thickness |

| WT | Wall Thickness | Thickness of the pipe wall, varies with schedule number |

| Weight (lb/ft) | Weight per foot | Mass of pipe per unit length, varies with size and wall thickness |

These notations appear in every stainless steel pipe dimension chart and pipe size chart. They help users interpret the data and select the correct pipe for their needs.

A comprehensive pipe size chart helps engineers and installers select the correct stainless steel pipe for any application. The chart below lists the most frequently used Schedule 40 sizes, including nominal pipe size (NPS), outside diameter (OD), wall thickness, inside diameter (ID), and weight. Each value appears in both imperial and metric units for easy reference.

| Nominal Pipe Size (NPS) | Outside Diameter (in) | Outside Diameter (mm) | Wall Thickness (in) | Wall Thickness (mm) | Inside Diameter (in) | Inside Diameter (mm) | Weight (lb/ft) | Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|

| 1/8 | 0.405 | 10.29 | 0.049 | 1.24 | 0.307 | 7.80 | 0.24 | 0.36 |

| 1/4 | 0.540 | 13.72 | 0.065 | 1.65 | 0.410 | 10.41 | 0.42 | 0.63 |

| 3/8 | 0.675 | 17.15 | 0.065 | 1.65 | 0.545 | 13.84 | 0.57 | 0.85 |

| 1/2 | 0.840 | 21.34 | 0.065 | 1.65 | 0.710 | 18.03 | 0.85 | 1.27 |

| 3/4 | 1.050 | 26.67 | 0.083 | 2.11 | 0.864 | 21.95 | 1.13 | 1.68 |

| 1 | 1.315 | 33.40 | 0.109 | 2.77 | 1.097 | 27.89 | 1.68 | 2.50 |

| 1 1/2 | 1.900 | 48.26 | 0.145 | 3.68 | 1.610 | 40.89 | 2.72 | 4.05 |

| 2 | 2.375 | 60.33 | 0.154 | 3.91 | 2.067 | 52.50 | 3.66 | 5.45 |

| 3 1/2 | 4.000 | 101.60 | 0.083 | 2.11 | 3.834 | 97.41 | 5.62 | 8.37 |

| 4 | 4.500 | 114.30 | 0.237 | 6.02 | 4.026 | 102.31 | 7.29 | 10.86 |

| 5 | 5.563 | 141.30 | 0.258 | 6.55 | 5.047 | 128.19 | 9.62 | 14.32 |

| 6 | 6.625 | 168.28 | 0.280 | 7.11 | 6.065 | 154.15 | 12.00 | 17.86 |

| 8 | 8.625 | 219.08 | 0.250 | 6.35 | 8.125 | 206.38 | 18.97 | 28.25 |

| 10 | 10.750 | 273.05 | 0.250 | 6.35 | 10.250 | 260.35 | 24.66 | 36.71 |

| 12 | 12.750 | 323.85 | 0.250 | 6.35 | 12.250 | 311.15 | 29.74 | 44.27 |

| 14 | 14.000 | 355.60 | 0.250 | 6.35 | 13.500 | 342.90 | 32.55 | 48.45 |

Note: The values above follow ASME/ANSI B36.10/19 standards for stainless steel pipe dimensions. Always verify the latest standards for critical projects.

The chart above visually compares outside diameters for the most common Schedule 40 stainless steel pipe sizes. This visual aid helps users quickly identify the right pipe for their needs.

Stainless steel pipe dimensions appear in both metric and imperial units on every professional pipe size chart. This dual presentation ensures global compatibility and simplifies communication between suppliers and engineers.

Most charts display nominal pipe size (NPS) in inches and diameter in millimeters.

Wall thickness and inside diameter also appear in both units, allowing for easy conversion and comparison.

The outside diameter remains constant for each NPS up to 12 inches, while the inside diameter changes with the schedule.

For NPS 14 inches and above, the outside diameter increases with the schedule number.

Standard references such as ASME B36.19 provide authoritative data for both metric and imperial systems.

Engineers rely on these charts to ensure system compatibility, especially when projects involve international standards or cross-border supply chains. The use of both unit systems in stainless steel pipe dimensions charts helps prevent costly errors and ensures that every pipe fits precisely with its intended fittings and components.

Tip: When reviewing a pipe size chart, always check both the metric and imperial columns to confirm the correct pipe size and dimensions for your application.

Accurate specification is essential when ordering Schedule 40 stainless steel tubes. Suppliers require clear and complete information to deliver the correct product. The following details should always be included in an order:

Tube size, including both outside diameter and wall thickness

Schedule number, which defines wall thickness and pressure rating

Stainless steel grade, such as ASTM A312 TP316L

Tube length, either standard or custom

Required certifications or test reports

Traceability details, like heat number and manufacturer information

Compliance with relevant industry standards

Any custom sizing or wall thickness requirements

Providing these details ensures the supplier delivers tubes that meet the project’s pressure, strength, and application needs. In regulated industries, traceability and certification markings are critical for compliance and quality assurance. Custom sizing requests should be communicated clearly to avoid delays or errors.

Mistakes in specifying pipe sizes can lead to costly delays, safety risks, or system failures. The most common errors include:

Confusing nominal pipe sizes with actual outside or inside diameters.

Omitting the schedule number, which results in incorrect wall thickness.

Failing to specify the stainless steel grade, leading to material incompatibility.

Overlooking the need for certifications or traceability, especially in regulated sectors.

Not confirming the required length or custom sizing.

Tip: Always double-check the order against the project specifications and the stainless steel pipe dimension chart. This step helps prevent mismatches and ensures the correct pipe sizes are supplied.

Clear communication with suppliers and project teams helps avoid misunderstandings. Use precise terminology and reference recognized standards. When discussing pipe sizes, always specify:

Nominal pipe size (NPS) and schedule number

Stainless steel grade and standard (e.g., ASTM A312)

Required length and any special requirements

A sample order might look like this:

2-inch Schedule 40 stainless steel pipe, ASTM A312 TP316L, 6 meters long, with mill test certificate and heat number marked on each length.

Note: Sharing a copy of the relevant pipe size chart with the supplier can further reduce errors and ensure everyone uses the same reference.

Consistent and detailed communication ensures the correct pipe sizes arrive on site, ready for installation.

NPS, or Nominal Pipe Size, serves as the standard for pipe sizing in North America. It uses inches as the unit of measurement, but the number does not always match the actual diameter of the pipe. DN, or Diamètre Nominal, is the international metric equivalent, expressed in millimeters. Both NPS and DN act as nominal designations, meaning they provide a convenient way to refer to pipe sizes without representing the exact physical dimensions. For example, a 2-inch NPS pipe has an outside diameter of about 2.375 inches, while its DN equivalent is 50. ISO 6708 defines DN as a dimensionless number, which helps standardize pipe sizing across different regions.

NPS and DN simplify communication between engineers, suppliers, and installers. They allow teams to match pipes and fittings even when working with different measurement systems. However, the actual outside diameter for NPS sizes 1/8 to 12 does not equal the nominal size. For sizes 14 and above, NPS matches the outside diameter in inches. Conversion tables and a nominal pipe size chart help users find the correct match between NPS and DN for any project.

Schedule numbers indicate the wall thickness of a pipe. The schedule system, such as Schedule 10 or Schedule 40, works alongside NPS or DN to define the pipe’s dimensions. Higher schedule numbers mean thicker walls, which increase the pipe’s pressure rating and reduce the inside diameter. For stainless steel tubes, thinner schedules like 5S and 10S are common due to the material’s corrosion resistance.

The table below compares wall thickness for different schedules and nominal pipe sizes:

| Nominal Pipe Size (NPS) | SCH 10 Thickness (mm) | SCH 40 Thickness (mm) |

|---|---|---|

| 1/2 inch | ~1.65 | ~2.77 |

| 1 inch | ~1.65 | ~3.38 |

| 2 inch | ~2.11 | ~3.91 |

| 4 inch | ~2.11 | ~6.02 |

| 8 inch | ~3.05 | ~8.18 |

The schedule number does not directly indicate pressure rating, but thicker walls generally support higher pressures. For each nominal pipe size, the outside diameter stays the same, but the inside diameter decreases as the schedule increases.

Understanding the differences between NPS, DN, and schedule numbers is essential for selecting the right stainless steel tube. NPS and DN provide a common language for specifying pipe size, while the schedule number determines wall thickness and, therefore, pressure capacity and flow rate. For a given nominal pipe size, the outside diameter remains constant, but the inside diameter changes with the schedule. This affects how much fluid the pipe can carry and how much pressure it can withstand.

Selecting the correct combination ensures that the pipe meets the requirements for flow, pressure, and structural integrity. This is especially important for stainless steel tubes used in high-pressure or corrosive environments. Using a nominal pipe size chart helps engineers and contractors match pipes and fittings accurately, reducing the risk of leaks or failures. Proper selection also ensures compatibility with international standards, which is critical for global projects.

Tip: Always confirm both the nominal pipe size and schedule number when ordering or specifying stainless steel tubes. This practice helps avoid costly mistakes and ensures system safety.

Selecting the correct Schedule 40 stainless steel tube size for a specific application requires careful consideration of several factors. Engineers and installers should evaluate the following:

Pressure and temperature requirements: Thicker walls are necessary for high-pressure or high-temperature systems to ensure safety and durability.

Flow rate and capacity: The inside diameter determines how much fluid or gas can move through the tube. Larger inside diameters reduce friction and pressure loss.

Corrosion resistance: Different stainless steel grades offer varying levels of protection against harsh chemicals or environments.

Installation and compatibility: Pipe dimensions must match existing fittings, valves, and flanges to prevent installation issues.

Compliance with industry standards: Adhering to standards such as ASTM A312, ASTM A269, ANSI B36.19, and ISO 1127 ensures the tube meets the intended application’s requirements.

Tip: Always review project specifications and consult dimension charts before finalizing tube selection.

Schedule 40 stainless steel tubes provide standardized wall thicknesses that vary by nominal size. As the pipe size increases, wall thickness also increases to maintain mechanical strength. However, the pressure rating per unit area often decreases with larger diameters due to geometric factors. The following table illustrates how wall thickness and allowable pressure change with size:

| Nominal Size (in) | Wall Thickness (in) | Allowable Pressure at 100°F (psig) |

|---|---|---|

| 1 | 0.133 | 2205 |

| 4 | 0.237 | 1102 |

| 14 | 0.156 | 404 |

| 24 | 0.250 | 265 |

Smaller diameter pipes can withstand higher pressures, even with thinner walls, because of the way stress distributes across the pipe. Larger pipes require thicker walls to maintain structural integrity, but their pressure ratings decrease as diameter increases. Engineers must balance these factors to ensure safe and efficient system performance.

Ensuring fittings compatibility with Schedule 40 stainless steel tubes is essential for leak-free and reliable connections. Fittings should match the tube’s material type to prevent issues caused by differences in hardness or thermal expansion. Using fittings and adapters that comply with the same thread standards—such as JIC, NPT, or AN—helps avoid leaks and mechanical failures. Precision in thread cutting, whether manual, electric, or CNC, is crucial for maintaining the tube’s structural integrity and corrosion resistance. Quality assurance during threading and installation ensures the pipe system remains dependable under operational stresses.

Note: Always verify the stainless steel grade and thread specifications before installation to maintain system reliability.

Selecting the correct Schedule 40 stainless steel tube requires attention to several key details. Engineers and installers should remember these important points:

Nominal Pipe Size (NPS) serves as a guideline for pipe diameter but does not match the actual inside or outside diameter.

The schedule number, such as 40 or 40s, indicates wall thickness. Higher schedule numbers mean thicker walls and greater pressure capacity.

Stainless steel pipe schedules use an “s” suffix (e.g., 40s) to show thinner walls than carbon steel pipes, yet they provide similar strength due to the material’s properties.

For sizes below 12" NPS, the outside diameter is larger than the nominal size. For 14" NPS and above, the outside diameter equals the nominal size.

Tubes are measured by outside diameter and wall thickness, not by nominal size. Tubes maintain a constant outside diameter regardless of wall thickness, which is important for structural applications.

Stainless steel tubes offer tighter manufacturing tolerances and can be round, square, or rectangular.

Tip: Always check both the nominal size and the schedule number to ensure the pipe or tube meets the application’s pressure and fit requirements.

Industry standards ensure consistency, safety, and compatibility when working with Schedule 40 stainless steel tubes. The most essential standards and references include:

ASME/ANSI B36.10/19: Defines pipe dimensions and schedules for carbon, alloy, and stainless steel pipes.

ASTM International: Provides material specifications for steel pipes and tubes.

ASME B31 Pressure Piping Codes: Covers design, fabrication, inspection, and testing of pressure piping systems.

ASME/ANSI B16 Standards: Addresses pipes and fittings made from various materials.

International Standards: DIN, ISO, and BSi offer additional guidelines for stainless steel tubes.

The ANSI/ASME B36.10M-1995 standard remains the primary reference for dimensional data, ensuring that all pipes and fittings are compatible and meet industry requirements.

The following checklist and table provide a fast way to confirm the most important details when specifying or selecting Schedule 40 stainless steel tubes:

Checklist for Selection

Confirm Nominal Pipe Size (NPS) or tube outside diameter

Specify schedule number (e.g., 40, 40s) for wall thickness

Choose the correct stainless steel grade (e.g., 304, 316)

Verify compliance with ASME/ANSI and ASTM standards

Check required length and any special tolerances

Ensure compatibility with fittings and system requirements

Sample Reference Table

| Parameter | Pipe (NPS) | Tube (OD) |

|---|---|---|

| Sizing Method | Nominal Pipe Size | Outside Diameter |

| Wall Thickness | Schedule Number | Measured Directly |

| Tolerance | Standard | Tighter |

| Common Shapes | Round | Round, Square, Rect. |

| Key Standards | ASME B36.10/19, ASTM | ASTM, ISO, DIN |

Note: Using this quick reference helps prevent errors and ensures the selected pipe or tube matches the project’s technical and safety needs.

Understanding Schedule 40 stainless steel tube dimensions plays a vital role in safe and effective system design. Dimension charts and standards such as ASME B36.10M and B36.19M offer several benefits:

They ensure consistent pipe sizes and wall thickness.

They clarify nominal pipe size and diameter for accurate specification.

They support compatibility and interchangeability in piping systems.

They provide a common technical language for all stakeholders.

Engineers should consult these charts and standards regularly. For deeper technical guidance, resources like ASTM A312, ASTM A269, and VINMAY’s technical guides offer detailed information on grades, tolerances, and manufacturing processes.

Schedule 40 defines a specific wall thickness for each nominal pipe size. This standard ensures predictable strength and compatibility. Engineers use Schedule 40 for its balance of durability, pressure rating, and cost.

NPS (Nominal Pipe Size) uses inches and appears mainly in North America. DN (Diamètre Nominal) uses millimeters and appears internationally. Both serve as reference sizes, but neither matches the actual outside or inside diameter.

Yes. Schedule 40 stainless steel tubes withstand moderate to high pressures. The exact pressure rating depends on the tube’s size, wall thickness, and material grade. Always consult pressure charts for precise values.

Pipe sizing uses nominal sizes and schedule numbers. Tube sizing uses actual outside diameter and wall thickness. Tubes often have tighter tolerances and may appear in round, square, or rectangular shapes.

Grades 304 and 316 are most common. Grade 304 offers general corrosion resistance. Grade 316 provides enhanced resistance to chlorides and harsh chemicals. Selection depends on the application environment.

Measure the outside diameter with a tape or string. Calculate the diameter. Compare the measurement to a dimension chart. This method helps match the tube to the correct nominal size and schedule.

Yes. Schedule 40 stainless steel tubes match standard fittings designed for the same nominal size and schedule. Always verify compatibility with both the fitting’s material and thread type.

Wall thickness determines the tube’s strength, pressure capacity, and weight. Thicker walls support higher pressures but increase cost and weight. Proper selection ensures safety and system efficiency.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Stainless Steel Tube Dimensions Chart Explained for Industrial And Residential Uses

Top 10 Applications for Stainless Steel Tube Schedule 10 in 2025

Top 10 Stainless Steel Tube Fittings for Marine And Industrial Applications

Comparing Stainless Steel Tube Suppliers for Your Next Project

A Comprehensive Guide To Stainless Steel Tube Schedule 40 Dimensions And Charts