close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

Austenitic stainless steel stands as a cornerstone in modern manufacturing and infrastructure. Its outstanding corrosion resistance, combined with unmatched durability and versatility, enables reliable performance in harsh environments. Industry data shows that austenitic stainless steel accounts for about 70% of worldwide stainless steel production, driven by demand in sectors such as food processing, chemical processing, construction, marine, and medical fields.

| Industrial Sector | Example Applications | Key Properties Utilized |

|---|---|---|

| Food Processing | Equipment, utensils | Corrosion resistance, hygiene |

| Chemical Processing | Storage tanks | Strength, corrosion resistance |

| Construction | Structural components | Ductility, weldability |

| Marine | Shipbuilding | Corrosion resistance |

| Medical | Surgical instruments | Biocompatibility, corrosion resistance |

Understanding austenitic stainless steel composition helps engineers and designers select materials that enhance safety, longevity, and efficiency across diverse industries.

Austenitic stainless steel offers a unique combination of properties that set it apart from other materials. Many industries select this alloy for its exceptional corrosion resistance. The self-repairing chromium oxide layer on its surface protects the metal from oxidation, acids, and pitting. This feature extends the life of equipment and structures, reducing the need for frequent replacements.

High corrosion resistance ensures long-term performance in harsh environments.

Superior surface finish provides an attractive appearance, making it ideal for architectural and decorative uses.

Ease of fabrication and machining allows manufacturers to shape complex parts without specialized tools.

Customizable chemical composition tailors the material for specific applications.

Excellent weldability enables joining with conventional methods, without requiring special skills.

Non-magnetic nature proves valuable in applications where low magnetic permeability is essential.

High ductility and toughness support easy forming and fabrication.

Good strength retention at elevated temperatures, up to 800°C, supports use in high-heat settings.

Hygienic and easy-to-clean surfaces make it a preferred choice in food and medical industries.

Austenitic stainless steel also stands out for its durability. Its resistance to corrosion and wear means lower maintenance costs over the product’s lifecycle. The material maintains its mechanical properties even at low or high temperatures, which is critical for demanding structural applications.

Note: The combination of corrosion resistance, strength, and aesthetic appeal makes austenitic stainless steel a top choice for both functional and decorative purposes.

Industries across the globe rely on austenitic stainless steel for a wide range of applications. Food processing plants use it for equipment and utensils because it resists corrosion and supports hygiene standards. The medical sector values its biocompatibility and ease of sterilization. Chemical and petrochemical industries depend on its ability to withstand aggressive substances and high temperatures.

Construction companies use it for structural components due to its strength and weldability.

Marine environments benefit from its resistance to saltwater corrosion.

Automotive and aerospace sectors choose it for parts that require both strength and a non-magnetic nature.

Energy and cryogenic industries rely on its performance at extreme temperatures.

The widespread use of austenitic stainless steel reflects its adaptability. Manufacturers can adjust its composition to meet specific needs, ensuring optimal performance in each application. Although the initial cost may be higher than some alternatives, the long-term savings from reduced maintenance and extended service life make it an economical choice.

Austenitic stainless steel composition forms the foundation for its unique properties. The main elements include iron, chromium, and nickel. Iron serves as the base metal, making up the majority of the alloy. Chromium, typically around 18%, creates a passive oxide layer that protects the steel from corrosion. Nickel, usually about 8%, stabilizes the austenitic structure and improves ductility and formability. These proportions define the popular 300-series grades, such as Type 304 and Type 316.

| Stainless Steel Grade | Chromium (%) | Nickel (%) | Iron (%) |

|---|---|---|---|

| Type 304 | ~18 | ~8 | Balance* |

| Type 316 | 16 - 18 | 11 - 14 | Balance* |

| General Austenitic | ≥16 | ≥6 | Balance* |

*Iron is the remainder of the alloy composition and is not explicitly quantified.

In addition to these primary elements, austenitic stainless steel composition often includes small amounts of other elements. Manganese, molybdenum, nitrogen, and carbon each play a specific role. For example, molybdenum increases resistance to localized corrosion, while nitrogen enhances strength and pitting resistance. Carbon content remains low to prevent carbide precipitation, which could reduce corrosion resistance.

Note: The careful balance of these elements ensures that austenitic stainless steel composition delivers both mechanical strength and chemical stability.

The effects of alloying elements in austenitic stainless steel composition extend beyond basic corrosion resistance. Each element influences the steel’s mechanical and chemical behavior in distinct ways.

| Alloying Element | Mechanical Properties | Chemical Properties |

|---|---|---|

| Chromium (Cr) | Increases oxidation resistance | Improves general corrosion resistance |

| Nickel (Ni) | Boosts ductility and toughness | Reduces corrosion rate in acidic environments |

| Molybdenum (Mo) | Slightly increases strength | Enhances resistance to uniform and localized corrosion |

| Nitrogen (N) | Strengthens solid solution | Improves pitting and intergranular corrosion resistance |

| Manganese (Mn) | Improves hot ductility | Increases nitrogen solubility, can replace nickel |

| Carbon (C) | Raises strength, may reduce toughness | High levels can lower corrosion resistance |

| Niobium (Nb) | Improves high-temperature strength | Prevents intergranular corrosion |

Nitrogen stands out as a powerful austenite former and solid-solution strengthener. It increases mechanical strength without sacrificing ductility. Nitrogen also enhances resistance to pitting and intergranular corrosion, making it vital for demanding environments. Manganese can substitute for some nickel, helping to stabilize the austenitic phase and reduce costs. Low carbon content, especially in grades like 316L, prevents carbide precipitation and maintains corrosion resistance, which is essential for medical and food applications.

Austenitic stainless steel composition allows engineers to tailor properties for specific uses. By adjusting the levels of chromium, nickel, and other elements, manufacturers can optimize performance for environments ranging from chemical plants to surgical suites. This flexibility explains why austenitic stainless steel composition remains the preferred choice for critical applications.

Austenitic stainless steel demonstrates outstanding corrosion resistance, making it a preferred material in environments exposed to moisture, chemicals, and salt. The chromium content forms a stable, self-healing oxide layer on the surface. This passive film protects the underlying metal from oxidation and aggressive substances. Nickel and nitrogen further enhance the corrosion resistance, especially in chloride-rich or acidic conditions.

Engineers often select austenitic stainless steel for marine, chemical, and food processing industries because of its superior corrosion resistance. High-nitrogen alloys, such as 304NH and 316NH, show enhanced corrosion resistance in seawater. These alloys resist pitting and stress corrosion cracking, even under tensile stress or after heat treatment. Studies confirm that high-nitrogen grades form more stable passive films, which improve performance in harsh marine environments.

High nitrogen content reduces corrosion rate and increases resistance to pitting and stress corrosion cracking.

High-nitrogen alloys exhibit less stress corrosion cracking compared to traditional types.

Sensitization from welding or high temperatures can cause intergranular corrosion, but nitrogen helps mitigate this effect.

Types 304 and 316L are widely used in marine applications, while high-nitrogen variants excel in more demanding settings.

Electrochemical analyses show that high-nitrogen alloys develop more stable passive films in chloride-rich seawater.

Nitrogen plays a critical role in stabilizing oxides in passive films, which facilitates passivation and re-passivation. Surface treatments like plasma ion nitriding and electropolishing can further improve the electrochemical resistance of super-austenitic stainless steels.

Austenitic stainless steel’s enhanced corrosion resistance ensures long service life for equipment exposed to aggressive chemicals or saltwater. This property reduces maintenance costs and downtime, supporting reliable operation in critical sectors.

Austenitic stainless steel stands out for its high ductility and excellent toughness. These mechanical properties allow the material to bend, stretch, and form into complex shapes without cracking. Manufacturers can fabricate intricate components for industrial and consumer products with ease.

The following table compares the ductility of austenitic stainless steel to ferritic and martensitic types:

| Stainless Steel Type | Ductility Description |

|---|---|

| Austenitic | High ductility; easy to form and fabricate; superior corrosion resistance |

| Ferritic | Moderate to good ductility; less than austenitic; can become brittle at low temperatures |

| Martensitic | Low ductility; high strength but low fracture resistance; can improve with tempering |

Austenitic stainless steels maintain high ductility and toughness even at low temperatures. This makes them suitable for cryogenic applications, such as liquefied natural gas storage and transport. The table below shows typical toughness values:

| Temperature Condition | Typical Toughness Range (Joules) |

|---|---|

| Room Temperature (~20°C) | Above 40 J |

| Cryogenic Temperature (-196°C) | Well above 100 J |

These values indicate that austenitic stainless steels do not experience a sharp brittle transition, even at extremely low temperatures. Their excellent toughness ensures safety and reliability in demanding environments, including construction, transportation, and energy sectors.

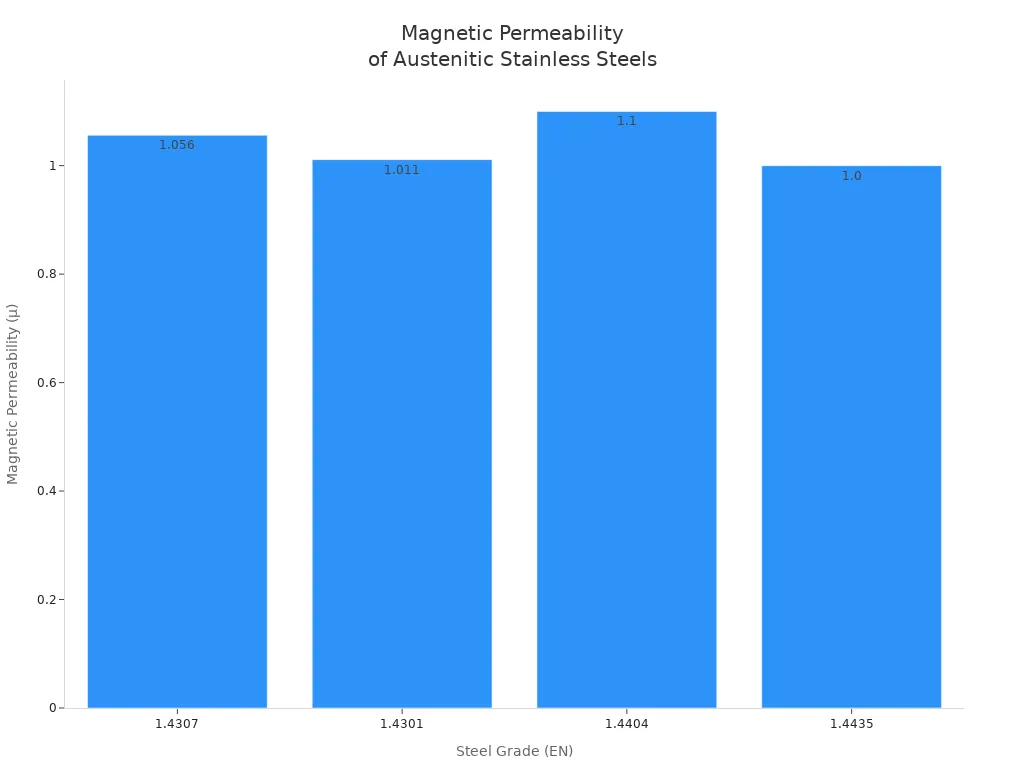

Austenitic stainless steel exhibits a non-magnetic or paramagnetic nature in its fully annealed state. This property results from its face-centered cubic (FCC) crystal structure, which does not support magnetism. The low magnetic permeability of common grades, such as 1.4301 and 1.4435, makes them ideal for applications where magnetic interference must be minimized.

| Stainless Steel Grade (EN) | Magnetic Permeability (μ) |

|---|---|

| 1.4307 | Approximately 1.056 |

| 1.4301 | Approximately 1.011 |

| 1.4404 | Approximately 1.100 |

| 1.4435 | Approximately 1.000 |

Austenitic stainless steels retain their non-magnetic properties after annealing. However, cold working, welding, or microstructural changes can introduce some magnetic response. For most industrial and medical applications, the magnetic permeability remains close to 1.0, which is essential for sensitive electronic equipment, MRI machines, and other devices that require non-magnetic materials.

Austenitic stainless steel demonstrates excellent heat resistance, making it a preferred material for applications exposed to elevated temperatures. The alloy maintains its mechanical properties and structural integrity even when subjected to continuous or intermittent heating. This performance results from the stable austenitic microstructure and the presence of elements like chromium and nickel.

Engineers often select austenitic stainless steel for environments where high-temperature strength is essential. Industrial furnaces, heat exchangers, and exhaust systems rely on this material to withstand thermal cycling and prevent deformation. The alloy resists scaling and oxidation up to temperatures of 800°C (1472°F), which ensures reliable operation in demanding settings.

The following table highlights the heat resistance of common austenitic stainless steel grades:

| Grade | Maximum Service Temperature (°C) | Notable Properties |

|---|---|---|

| 304 | 870 | Good oxidation resistance |

| 316 | 870 | Improved resistance to acids |

| 321 | 870 | Stabilized against carbide precipitation |

| 310 | 1150 | Superior high-temperature strength |

Grade 310 stands out for its superior high-temperature strength and resistance to thermal fatigue. This grade performs well in furnace parts, kilns, and other extreme environments. Grade 321 contains titanium, which stabilizes the alloy and prevents carbide formation during prolonged heating. This property makes it suitable for exhaust manifolds and heat shields.

Tip: When selecting austenitic stainless steel for high-heat applications, consider both the maximum service temperature and the specific properties required for the environment.

Austenitic stainless steel also resists creep, which is the tendency of a material to deform permanently under constant stress at high temperatures. This resistance ensures that components retain their shape and function over long periods, even in power generation or petrochemical plants.

Cleanability remains a critical property for austenitic stainless steel, especially in industries where hygiene and contamination control are priorities. The smooth, non-porous surface of this alloy prevents the accumulation of dirt, bacteria, and other contaminants. This feature supports environments that demand materials that are both hygienic and easily cleaned.

Food processing, pharmaceutical manufacturing, and medical device production all benefit from the cleanability of austenitic stainless steel. Workers can sanitize equipment quickly and thoroughly, reducing the risk of product contamination. The alloy’s corrosion resistance also means that frequent cleaning with harsh chemicals does not degrade its surface or compromise its properties.

Key advantages of austenitic stainless steel in clean-critical environments include:

Smooth surface finish that resists bacterial growth

Compatibility with a wide range of cleaning agents

Retention of mechanical and chemical properties after repeated cleaning cycles

Hospitals and laboratories often specify austenitic stainless steel for surgical instruments, sinks, and work surfaces. The material’s ability to maintain a sterile environment supports patient safety and product quality.

Note: The combination of corrosion resistance and cleanability makes austenitic stainless steel the material of choice for sectors where cleanliness is non-negotiable.

Grade 304 stands as the most widely used among the common grades of austenitic stainless steel. This grade belongs to the 300 series stainless steel family and offers a balance of properties that suit a broad range of applications. Manufacturers value Grade 304 for its good weldability, high strength, and excellent corrosion resistance in many environments.

The table below summarizes the key chemical and mechanical properties of Grade 304:

| Property Category | Property / Characteristic | Details / Values |

|---|---|---|

| Chemical Composition | Carbon (C) | Up to 0.08% |

| Chromium (Cr) | 18-20% | |

| Nickel (Ni) | 8-10.5% | |

| Manganese (Mn) | Around 2% | |

| Iron (Fe) | Balance | |

| Mechanical Properties | Tensile Strength | 210 MPa (annealed) to 1050 MPa (full-hard) |

| Modulus of Elasticity | 183-200 GPa | |

| Density | 7,900 kg/m³ | |

| Corrosion Resistance | General Resistance | Excellent in many environments |

| Limitations | Susceptible to pitting in warm chlorides; stress corrosion cracking above 60°C | |

| Variants | 304L, 304H | Adjusted for low/high carbon content, affecting strength and corrosion resistance |

Grade 304 provides good weldability, making it easy to fabricate and join. However, it may not perform well in environments with high chloride concentrations, where pitting and stress corrosion cracking can occur. Variants like 304L and 304H offer options for improved corrosion resistance or higher strength, depending on the application.

Grade 316 is another member of the 300 series stainless steel group. It contains molybdenum, which enhances its resistance to corrosion, especially in chloride-rich environments. This grade is often chosen when Grade 304 does not provide enough protection against aggressive chemicals or saltwater.

Grade 316 is preferred in the following settings:

Chemical cisterns and piping

Marine components and boat fittings

Pharmaceutical manufacturing equipment

Outdoor electrical enclosures

Seafood and saline food processing facilities

The addition of molybdenum (2-3%) gives Grade 316 superior resistance to pitting and crevice corrosion. This makes it ideal for marine and chemical processing industries, where exposure to harsh substances is common. Grade 316 also maintains high strength and good weldability, supporting its use in demanding environments. While it costs more than Grade 304, its extended service life in corrosive settings often justifies the investment.

Grade 321 distinguishes itself from other common grades of austenitic stainless steel by its titanium stabilization. Titanium prevents carbide precipitation during welding, which helps maintain corrosion resistance and mechanical properties at elevated temperatures. Grade 321 is suitable for applications that require high strength and good weldability in moderate high-temperature environments.

Key features of Grade 321 include:

Resistance to intergranular corrosion after welding

Stability and strength up to 900°C (1652°F)

Reliable performance in exhaust systems, heat exchangers, and chemical processing equipment

Grade 321 is often selected for parts exposed to repeated heating and cooling cycles. Its properties make it a strong choice for industries that need both durability and resistance to thermal fatigue. While it does not match the extreme heat resistance of Grade 310, it offers a practical solution for many high-temperature applications.

Grade 310 stands out as a premium austenitic stainless steel designed for extreme temperature environments. Engineers often select this grade for its remarkable resistance to oxidation and scaling at temperatures up to 1150°C (2102°F). The alloy contains higher levels of chromium (24-26%) and nickel (19-22%) compared to other austenitic grades. This composition gives Grade 310 its superior performance in both oxidizing and reducing atmospheres.

| Property | Value/Description |

|---|---|

| Chromium Content | 24-26% |

| Nickel Content | 19-22% |

| Maximum Service Temp | Up to 1150°C (2102°F) |

| Key Features | High strength, oxidation resistance |

| Typical Uses | Furnace parts, kilns, heat exchangers |

Grade 310 maintains its mechanical integrity even under repeated thermal cycling. This makes it a preferred material for furnace components, burner tips, and heat treatment baskets. The alloy resists deformation and retains high strength at elevated temperatures, which is critical for industrial heating equipment.

Note: Grade 310 also offers good resistance to sulfidation and carburization, making it suitable for petrochemical and refinery applications.

Fabricators appreciate Grade 310 for its weldability and formability. However, the higher alloy content increases the cost compared to standard grades like 304 or 316. For applications where extreme heat and high strength are essential, Grade 310 delivers reliable, long-term performance.

Selecting the appropriate austenitic stainless steel grade depends on several factors. Each grade offers unique advantages tailored to specific environments and requirements. Engineers and designers should consider the following criteria:

Corrosion Environment

For general corrosion resistance, Grade 304 works well in most indoor and mild outdoor settings.

In chloride-rich or marine environments, Grade 316 provides better protection due to its molybdenum content.

For high-temperature or aggressive chemical exposure, Grade 310 or 321 may be more suitable.

Temperature Requirements

Grade 310 excels in continuous high-temperature service.

Grade 321 resists carbide precipitation during welding and thermal cycling.

Mechanical Properties

Applications needing high strength at elevated temperatures benefit from Grade 310.

For components requiring easy forming and welding, Grade 304 remains a practical choice.

Cost Considerations

Grade 304 offers a balance between performance and affordability.

Specialized grades like 316 and 310 cost more but provide extended service life in demanding conditions.

Regulatory and Hygiene Needs

Food, medical, and pharmaceutical industries often specify low-carbon or stabilized grades for safety and compliance.

Tip: Always match the grade to the specific demands of the application. Consulting with material specialists or suppliers can help ensure optimal performance and cost-effectiveness.

By understanding the strengths and limitations of each grade, decision-makers can select the most effective material for their projects. This approach maximizes durability, safety, and value across a wide range of industries.

Austenitic stainless steel plays a vital role in the food and beverage industry. Manufacturers rely on its corrosion resistance and cleanability to maintain hygiene and safety standards. Grades 304 and 316 are the most common choices for food and beverage equipment. Grade 304 offers affordability and durability, while grade 316 provides enhanced resistance to chlorides and acids, making it suitable for processing salty or acidic foods.

Key applications in this sector include:

Storage tanks and fermentation vats

Brewing vessels and beer kegs

Dairy tanks and milk tankers

Food mixers and conveyor systems

Industrial ovens and evaporator tubes

Confectionary equipment and syrup tanks

Stainless steel tubing, pipes, fittings, valves, and flanges

Food and beverage equipment must withstand frequent cleaning, exposure to high temperatures, and contact with a variety of chemicals. Austenitic stainless steel meets these demands due to its smooth, non-porous surface, which prevents bacterial buildup and supports easy sanitation. Electropolishing further enhances the surface, making cleaning more effective. The material’s durability reduces the risk of contamination and extends the lifespan of processing equipment.

Tip: Proper design and maintenance of food and beverage equipment, including regular cleaning and the use of correct disinfectants, help preserve the corrosion resistance and hygienic properties of austenitic stainless steel.

The chemical industry depends on austenitic stainless steel for its exceptional corrosion resistance and mechanical strength. Chemical processing environments often involve exposure to aggressive acids, alkalis, and high temperatures. Grades such as 304, 316, and specialized alloys like 317 and 20 (CN7N) are widely used in this sector.

| Alloy/Grade | Typical Applications | Corrosion Resistance Characteristics |

|---|---|---|

| 304 (CF8) | Flanges, rolls, sleeves, valve parts | Good corrosion resistance, strength, and ductility |

| 316 (CF8M) | Evaporator parts, pump parts, marine fittings | Superior resistance to chlorides and reducing corrosives |

| 317 (CG8M) | Centrifuge bowls, chemical processing equipment | Exceptional strength and corrosion resistance |

| 20 (CN7N) | Pump parts, ball valve bodies, centrifuge parts | Excellent resistance to sulphuric and hydrochloric acids |

Chemical plants use austenitic stainless steel for reactors, heat exchangers, piping systems, and stainless steel tubing. The passive chromium-rich oxide layer on the surface protects equipment from corrosion across a wide pH range. For example, 316 stainless steel shows almost no corrosion in acidic environments, making it ideal for handling aggressive chemicals. Thermochemical treatments can further improve wear resistance while maintaining corrosion resistance, extending the service life of critical components.

Routine use of premium-quality stainless steel tubing in chemical processing ensures reliable transport of corrosive fluids. This reduces maintenance costs and minimizes the risk of leaks or failures. The material’s versatility and resistance to both mechanical and chemical stress make it a preferred choice for demanding chemical industry applications.

Austenitic stainless steel is essential in the medical field due to its biocompatibility, corrosion resistance, and ability to withstand repeated sterilization. Grades 316 and 316L are especially popular for medical devices and implants. These alloys contain high levels of chromium, nickel, and molybdenum, which provide superior resistance to body fluids and cleaning agents.

Common medical applications include:

Orthopedic implants such as hip and knee replacements

Dental implants

Cardiovascular devices like stents and heart valves

Surgical instruments including scalpels and forceps

Trauma fixation devices such as screws, plates, and rods

Maxillofacial surgery implants

Spinal surgery instrumentation

Medical professionals trust austenitic stainless steel for its durability and safety. The material’s smooth surface prevents bacterial growth and supports thorough sterilization. Stainless steel tubing is widely used in medical devices, ensuring reliable fluid delivery and structural support. The ability to form complex shapes without compromising corrosion resistance allows manufacturers to produce intricate and precise medical components.

Note: The use of austenitic stainless steel in medical applications helps ensure patient safety, device longevity, and compliance with strict hygiene standards.

Austenitic stainless steel has become a staple in the construction industry. Builders and architects value its strength, corrosion resistance, and aesthetic appeal. These properties allow for innovative designs and long-lasting structures. Stainless steel tubing plays a crucial role in modern construction projects. It provides support in frameworks, handrails, and architectural features.

Many skyscrapers and bridges use austenitic stainless steel for cladding and structural elements. The material resists weathering and pollution, which helps maintain a clean appearance over time. Stainless steel tubing offers flexibility in design. Engineers use it for curtain walls, balustrades, and support columns. The tubing’s smooth surface makes cleaning easy, which is important for public spaces.

Construction teams often select austenitic stainless steel for roofing, facades, and elevator doors. The material’s durability reduces maintenance costs. It also meets fire safety standards, making it suitable for high-traffic buildings. Stainless steel tubing supports glass panels in atriums and walkways. This application combines strength with a modern look.

Tip: Using austenitic stainless steel in construction projects ensures longevity and reduces the need for frequent repairs. Its resistance to corrosion makes it ideal for both indoor and outdoor environments.

The automotive industry relies on austenitic stainless steel for both performance and safety. Manufacturers use it in exhaust systems, catalytic converters, and structural components. Stainless steel tubing is essential in these applications. It withstands high temperatures and corrosive exhaust gases.

Automakers choose austenitic stainless steel for fuel lines, brake lines, and chassis parts. The material’s ductility allows for complex shapes and tight bends. Stainless steel tubing provides leak-free connections, which improves vehicle reliability. The non-magnetic nature of austenitic grades benefits electric and hybrid vehicles by reducing electromagnetic interference.

Crash safety is another reason for its popularity. Austenitic stainless steel absorbs impact energy, which protects passengers during collisions. The material’s resistance to rust ensures that vehicles last longer, even in regions with harsh winters or coastal climates. Stainless steel tubing also appears in decorative trim and grilles, adding to a vehicle’s visual appeal.

Note: The use of austenitic stainless steel in automotive applications supports lightweight design and fuel efficiency. Its combination of strength and corrosion resistance meets the demands of modern vehicles.

The energy sector depends on austenitic stainless steel for critical infrastructure. Power plants, oil refineries, and renewable energy facilities all use this material. Stainless steel tubing is vital in transporting fluids and gases under high pressure and temperature.

Engineers install austenitic stainless steel in heat exchangers, boilers, and condensers. The material resists scaling and oxidation, which extends equipment life. Stainless steel tubing handles steam, water, and chemical flows in nuclear and fossil fuel plants. Its corrosion resistance ensures safe operation in aggressive environments.

Renewable energy projects, such as solar and wind farms, also benefit from austenitic stainless steel. The material withstands outdoor exposure and mechanical stress. Stainless steel tubing supports solar panel frames and wind turbine components. This application helps maintain efficiency and reduces downtime.

Tip: Selecting austenitic stainless steel for energy sector applications improves safety and reliability. Its ability to perform in extreme conditions makes it a preferred choice for engineers worldwide.

Austenitic stainless steel has become a staple in many consumer products. Manufacturers choose this material for its durability, corrosion resistance, and attractive appearance. These properties make it ideal for items that people use every day.

Common Consumer Applications:

Kitchenware: Sinks, cutlery, cookware, and appliances often feature austenitic stainless steel. The material resists staining and rust, even after repeated washing. Its smooth surface makes cleaning easy and helps prevent bacterial growth.

Home Appliances: Refrigerators, dishwashers, ovens, and washing machines use stainless steel panels and internal parts. The alloy maintains its finish and strength, even with frequent use and exposure to moisture.

Personal Accessories: Watches, jewelry, eyeglass frames, and mobile phone cases benefit from the alloy’s non-tarnishing surface and hypoallergenic qualities. These products remain safe for skin contact and retain their shine over time.

Furniture and Fixtures: Designers use austenitic stainless steel for modern furniture, lighting fixtures, and bathroom fittings. The material supports sleek designs and withstands daily wear.

| Product Category | Examples | Key Benefits Provided |

|---|---|---|

| Kitchenware | Sinks, pots, pans, cutlery | Hygiene, corrosion resistance |

| Appliances | Refrigerators, ovens, washers | Durability, easy maintenance |

| Personal Accessories | Watches, jewelry, eyeglass frames | Hypoallergenic, aesthetic appeal |

| Furniture/Fixtures | Chairs, tables, faucets | Strength, modern design, longevity |

Austenitic stainless steel supports innovation in consumer product design. Manufacturers can form it into thin sheets or complex shapes without losing strength. This flexibility allows for creative and functional products.

Tip: Consumers should look for products made with austenitic stainless steel when they want long-lasting performance and easy care.

The non-magnetic nature of this alloy also plays a role in electronics and sensitive devices. It prevents interference with magnetic fields, which is important for certain gadgets and appliances.

Many companies choose austenitic stainless steel for its environmental benefits. The material is fully recyclable. At the end of a product’s life, manufacturers can recover and reuse the steel, reducing waste and conserving resources.

The wide range of applications in consumer products highlights the value of austenitic stainless steel. Its combination of strength, beauty, and safety ensures that it remains a top choice for both manufacturers and consumers.

Ferritic and austenitic stainless steels differ in composition, structure, and performance. Ferritic grades contain primarily iron and chromium, while austenitic grades include higher levels of nickel and chromium. This difference in alloying elements leads to distinct properties.

| Aspect | Austenitic Stainless Steel | Ferritic Stainless Steel |

|---|---|---|

| Composition | Rich in chromium and nickel | Primarily iron and chromium |

| Corrosion Resistance | Exceptional, suitable for aggressive environments and rigorous sanitation | Good, especially against hot water and atmospheric corrosion |

| Susceptibility | Less prone to stress corrosion cracking | More prone to stress corrosion cracking in chloride environments at high temperatures |

Austenitic stainless steels show superior corrosion resistance, especially in environments with acids or chlorides. Their microstructure also provides better formability and weldability. Ferritic grades, while offering good resistance to hot water and atmospheric conditions, tend to be more susceptible to stress corrosion cracking in harsh chloride environments. Manufacturers sometimes choose ferritic alloys for cost reasons, but austenitic grades remain the standard for demanding applications.

Note: Austenitic stainless steels are preferred in food processing and chemical industries due to their high resistance to corrosion and ease of cleaning.

Martensitic stainless steels stand out for their high hardness and strength. They achieve these properties through higher carbon content and the ability to be hardened by heat treatment. In contrast, austenitic stainless steels offer excellent ductility, toughness, and corrosion resistance, but cannot be hardened by heat treatment.

| Property | Martensitic Stainless Steel | Austenitic Stainless Steel |

|---|---|---|

| Carbon Content | Higher, leading to increased hardness and strength | Lower, resulting in better ductility and corrosion resistance |

| Hardness | High, can be increased by heat treatment | Cannot be hardened by heat treatment; strength improved by cold working |

| Tensile Strength | Higher (up to ~1970 MPa for some grades) | Generally lower than martensitic grades |

| Ductility (Elongation) | Lower (as low as 2-5%) | Higher, indicating better formability and toughness |

| Corrosion Resistance | Lower due to higher carbon and lower chromium | Excellent, especially in acidic and chloride environments |

| Magnetism | Magnetic | Typically non-magnetic (except slight magnetism after cold working) |

| Weldability | Poor, due to brittleness and high carbon content | Good, improved by low carbon and nitrogen content |

Martensitic grades are ideal for tools, knives, and surgical instruments where hardness and wear resistance are critical. However, their lower corrosion resistance and ductility limit their use in environments where chemical attack or forming is required. Austenitic stainless steels, with their superior resistance to corrosion and better weldability, are chosen for food equipment, chemical plants, and architectural features.

Martensitic steels provide high strength but are brittle and less resistant to corrosion.

Austenitic steels excel in applications needing high ductility, formability, and corrosion resistance.

Duplex stainless steels combine roughly equal amounts of austenite and ferrite in their microstructure. This dual-phase structure gives duplex grades a unique balance of properties.

| Property | Austenitic Stainless Steel (e.g., 304, 316) | Duplex Stainless Steel (e.g., 2205, 2507) |

|---|---|---|

| Microstructure | 100% Austenite | Approximately 50% Austenite / 50% Ferrite |

| Yield Strength | Moderate (~200–300 MPa) | High (~450–600 MPa), nearly double |

| Corrosion Resistance | Excellent (especially 316) | Superior, especially in chloride-rich environments |

| Stress Corrosion Cracking | Prone | Resistant |

| Weldability | Excellent | More technically challenging |

| Toughness at Low Temp | Excellent | Moderate |

| Magnetic Properties | Non-magnetic | Slightly magnetic |

| Cost | Higher (due to higher nickel content) | Lower nickel content, more stable pricing |

Duplex stainless steels offer higher yield strength and improved resistance to stress corrosion cracking, especially in chloride-rich environments. Their lower nickel content makes them less sensitive to price fluctuations. However, duplex grades can be more challenging to weld and may not match the low-temperature toughness of austenitic grades. Engineers often select duplex stainless steels for offshore, marine, and chemical processing applications where both strength and corrosion resistance are vital.

Tip: Duplex stainless steels provide a cost-effective solution for high-stress, corrosive environments, but austenitic grades remain the top choice for applications requiring maximum toughness and ease of fabrication.

Selecting the right stainless steel grade requires a careful evaluation of the application’s demands. Engineers and designers must weigh several factors to ensure optimal performance, safety, and cost-effectiveness. Each stainless steel family—austenitic, ferritic, martensitic, and duplex—offers unique strengths and limitations. The following criteria guide the selection process:

Austenitic stainless steels excel in environments with high moisture, acids, or chlorides. They resist corrosion in food processing, marine, and chemical settings.

Ferritic grades perform well in less aggressive conditions, such as indoor architectural features or automotive trim.

Martensitic steels suit dry or mildly corrosive environments, where hardness matters more than corrosion resistance.

Duplex grades provide superior resistance in chloride-rich or brackish water, making them ideal for offshore and chemical plants.

Austenitic steels offer high ductility and toughness, even at low temperatures. They work well for cryogenic tanks and structural components.

Martensitic grades deliver high strength and hardness, which benefits cutting tools and wear-resistant parts.

Duplex steels combine strength and moderate ductility, supporting pressure vessels and pipelines.

Ferritic steels provide moderate strength and good formability for less demanding applications.

Austenitic grades maintain strength and corrosion resistance at both high and low temperatures. They serve well in heat exchangers and furnace parts.

Ferritic and martensitic steels may lose toughness at low temperatures.

Duplex steels handle moderate temperature ranges but may not match austenitic grades in extreme heat or cold.

Austenitic stainless steels are easy to weld and form. They suit complex shapes and assemblies.

Ferritic and martensitic grades can be more challenging to weld due to brittleness or risk of cracking.

Duplex steels require skilled welding but offer good fabrication for heavy-duty structures.

Ferritic and martensitic steels generally cost less due to lower nickel content.

Austenitic and duplex grades may have higher upfront costs but offer longer service life in harsh environments.

Austenitic grades meet strict hygiene standards for food, medical, and pharmaceutical industries.

Other grades may not satisfy these requirements due to lower corrosion resistance or cleanability.

Tip: Always match the stainless steel grade to the specific environment and mechanical demands. Consulting with material specialists or suppliers can help avoid costly mistakes and ensure long-term success.

The table below summarizes key selection factors:

| Criteria | Austenitic | Ferritic | Martensitic | Duplex |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Moderate | Superior |

| Strength | Good | Moderate | High | High |

| Ductility/Toughness | Excellent | Good | Low | Moderate |

| Weldability | Excellent | Good | Poor | Good |

| Cost | Higher | Lower | Lower | Moderate |

| Hygiene Suitability | High | Moderate | Low | Moderate |

Choosing the right stainless steel ensures safety, durability, and value. Each project benefits from a tailored approach based on these criteria.

Austenitic stainless steel delivers excellent performance, but it comes at a higher price than many other stainless steel types. The cost difference often influences material selection, especially for large-scale projects or budget-sensitive industries. The following table shows the approximate base prices per pound for common stainless steel types:

| Stainless Steel Type | Approximate Base Price (per pound) |

|---|---|

| Type 430 (Ferritic) | $0.79 |

| Type 303 (Free-machining) | $1.40 |

| Type 316 (Austenitic) | $1.92 |

Type 304, the most common austenitic grade, typically costs around $1.55 per pound for sheet steel. Type 316, which contains more nickel and molybdenum, is even more expensive. Scrap prices reflect this difference as well, with 316 scrap fetching about $0.78 per pound compared to $0.56 per pound for 304 scrap. These figures show that austenitic stainless steels generally cost $0.5 to $1.1 more per pound than ferritic or free-machining types. The higher price results from the alloying elements, especially nickel and molybdenum, which improve performance but increase production costs.

Tip: For projects where cost is a major concern, engineers often select Type 304 for general use and reserve Type 316 for environments that demand extra resistance.

Austenitic stainless steel exhibits a strong tendency to work harden during forming, machining, or cold working. When the material undergoes deformation, its hardness and strength increase rapidly. This property can present challenges during manufacturing, such as increased tool wear, higher cutting forces, and the need for more frequent tool changes. Operators may also notice that the material becomes more difficult to bend or shape as work progresses.

To manage work hardening, manufacturers often use sharp tools, slower cutting speeds, and adequate lubrication. Annealing between forming steps can restore ductility and reduce hardness, making further processing easier. Training workers in proper techniques helps prevent excessive hardening and ensures consistent product quality.

Use sharp, high-quality tools to minimize friction.

Apply proper lubrication to reduce heat and tool wear.

Consider intermediate annealing for complex shapes.

Note: Understanding work hardening behavior allows manufacturers to optimize processes and extend tool life.

Stress corrosion cracking (SCC) poses a significant risk for austenitic stainless steel, especially in chloride-rich or high-stress environments. SCC occurs when tensile stress and a corrosive environment act together, causing cracks to form and propagate through the material. This type of failure can happen even when the overall corrosion rate appears low.

Pitting and SCC are most common in chemical plants, marine structures, and piping systems exposed to saltwater or aggressive chemicals. Selecting higher alloyed grades, such as Type 316, helps reduce the risk. Proper manufacturing and heat treatments can lower residual stresses, while protective coatings add another layer of defense. Good design practices, such as minimizing sharp corners and avoiding stagnant areas, also help prevent SCC.

Engineers should regularly inspect equipment for early signs of cracking or pitting. Routine maintenance, including cleaning and environmental control, further reduces the risk. By combining careful material selection, precise fabrication, and proactive maintenance, industries can extend the service life of austenitic stainless steel in challenging environments.

Tip: Always match the stainless steel grade to the specific environment and monitor for early signs of stress corrosion cracking to ensure long-term reliability.

Austenitic stainless steel offers impressive durability, but regular maintenance remains essential for preserving its performance and appearance. Even though this alloy resists corrosion and staining, neglect can lead to surface discoloration, pitting, or contamination. Industries that use austenitic stainless steel must implement effective cleaning and inspection routines to ensure long service life.

Key Maintenance Considerations:

Routine Cleaning:

Frequent cleaning removes dirt, grease, and contaminants that may compromise the protective oxide layer. Warm water and mild detergents work well for most applications. For stubborn residues, non-abrasive cleaners or soft brushes help prevent scratching.

Avoiding Chlorides:

Chloride ions, found in salt and some cleaning agents, can cause pitting and crevice corrosion. Facilities should avoid using bleach or chloride-based products on stainless steel surfaces. If accidental exposure occurs, immediate rinsing with clean water reduces the risk of damage.

Surface Inspection:

Regular visual inspections help identify early signs of corrosion, discoloration, or mechanical damage. Maintenance teams should pay close attention to welds, joints, and areas exposed to harsh chemicals or moisture.

Passivation:

Passivation treatments restore the chromium-rich oxide layer that protects the steel. This process involves cleaning the surface and applying a mild acid solution. Passivation proves especially useful after fabrication, welding, or repairs.

Preventing Cross-Contamination:

Contact with carbon steel tools or particles can introduce rust spots on stainless steel. Using dedicated stainless steel tools and cleaning equipment prevents this issue.

Tip: Establish a maintenance schedule tailored to the specific environment and application. High-humidity or marine settings may require more frequent cleaning and inspection.

Common Maintenance Challenges and Solutions

| Challenge | Solution |

|---|---|

| Staining or discoloration | Clean promptly with appropriate agents |

| Pitting corrosion | Avoid chlorides, rinse after exposure |

| Surface scratches | Use non-abrasive tools and gentle cleaners |

| Rust spots from contamination | Use stainless-only tools, remove promptly |

| Loss of shine | Polish with approved stainless steel products |

Proper maintenance not only extends the lifespan of austenitic stainless steel but also ensures compliance with hygiene and safety standards in critical industries. Facilities that invest in regular care reduce downtime, lower replacement costs, and maintain the material’s aesthetic appeal.

Regular maintenance safeguards both the function and appearance of austenitic stainless steel. Consistent care supports reliable performance in demanding environments.

Austenitic stainless steel offers unmatched corrosion resistance, durability, and cleanability. Industries trust this material for critical applications in food, medical, and energy sectors. Its versatility supports both structural and decorative uses. Readers should consider consulting with materials experts or suppliers when selecting the right grade. For more information, industry guides and technical datasheets provide valuable insights.

Austenitic stainless steel contains higher levels of nickel and chromium. This composition gives it superior corrosion resistance, non-magnetic properties, and excellent ductility. These features set it apart from ferritic, martensitic, and duplex stainless steels.

Austenitic stainless steel resists rust due to its chromium content. However, exposure to harsh chemicals or saltwater without proper maintenance can cause surface discoloration or pitting. Regular cleaning helps maintain its corrosion resistance.

In its annealed state, austenitic stainless steel remains non-magnetic. Cold working or welding may introduce slight magnetism. Most applications still consider it effectively non-magnetic, making it suitable for sensitive electronic and medical equipment.

Austenitic stainless steel maintains strength and resists oxidation at elevated temperatures. Grades like 310 and 321 perform well in furnaces, heat exchangers, and exhaust systems. These grades withstand continuous service up to 1150°C.

Industries use austenitic stainless steel tubing in food processing, chemical plants, medical devices, construction, and automotive systems. Tubing provides corrosion resistance, cleanability, and durability for transporting fluids, gases, or supporting structural loads.

Use warm water and mild detergent for routine cleaning. Avoid abrasive tools and chloride-based cleaners. For stubborn stains, apply non-abrasive cleaners or soft brushes. Regular cleaning preserves the protective oxide layer and prevents contamination.

Yes, austenitic stainless steel is 100% recyclable. Manufacturers can recover and reuse the material without losing its properties. Recycling supports sustainability and reduces environmental impact in many industries.

Engineers consider corrosion environment, temperature, mechanical requirements, cost, and regulatory standards. Consulting with material specialists ensures the chosen grade matches the application’s demands for safety, durability, and performance.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Exploring the Magnetism of Stainless Steel for Modern Applications

Super austenitic stainless steel outperforms in real-world acid tests

Emerging Manufacturing Techniques for Austenitic Stainless Steel Bars

Exploring The Role of 18-8 Austenitic Stainless Steel in Modern Manufacturing And Homes

Top 10 Austenitic Stainless Steel Grades and Their Everyday Uses