close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-06-30 Origin: Site

In the realm of advanced materials engineering, Hastelloy C276 stands out as a paragon of corrosion-resistant alloys. Renowned for its exceptional performance in harsh environments, this nickel-molybdenum-chromium alloy with the addition of tungsten has become indispensable in industries subjected to aggressive chemical and thermal conditions. This article delves into the intricate properties, applications, and advantages of Hastelloy C276, elucidating why it is the alloy of choice for the most demanding industrial tasks.

For those seeking materials that can endure the rigors of extreme environments, understanding the nuances of Hastelloy C276 is essential. Its unique chemical composition and mechanical properties not only offer superior corrosion resistance but also provide remarkable strength and durability. This discourse aims to present a comprehensive analysis, backed by data and practical insights, into why Hastelloy C276 is trusted for tough jobs across various sectors.

At the heart of Hastelloy C276's remarkable properties lies its complex chemical composition. The alloy primarily consists of nickel (57%), molybdenum (15-17%), and chromium (14.5-16.5%), with the addition of tungsten (3-4.5%) and iron (4-7%). Trace elements such as cobalt, manganese, vanadium, and silicon are also present in controlled amounts. This meticulous balance of elements is pivotal in imparting the alloy with its superior corrosion resistance and mechanical strength.

The microstructure of Hastelloy C276 is characterized by a face-centered cubic (FCC) crystal lattice, typical of nickel-based alloys. The presence of molybdenum and tungsten enhances the alloy's resistance to pitting and crevice corrosion by stabilizing the passive oxide layer on its surface. Chromium contributes significantly to resisting oxidizing agents, while nickel provides overall corrosion resistance and ductility. This synergistic effect of its constituents makes Hastelloy C276 exceptionally resilient in various corrosive environments.

Hastelloy C276 exhibits a density of 8.89 g/cm³ at room temperature, making it relatively dense compared to other alloys. Its melting point ranges between 1,370°C and 1,425°C (2,500°F to 2,597°F), which allows it to maintain structural integrity at elevated temperatures commonly encountered in industrial applications.

One of the hallmark properties of Hastelloy C276 is its impressive mechanical strength. The alloy boasts a tensile strength of approximately 790 MPa (115,000 psi) and a yield strength around 355 MPa (52,000 psi). Its elongation at break is about 40%, indicating excellent ductility. Such mechanical properties are crucial when the material is subjected to high pressures and stress in applications like pressure vessels and piping systems.

Hastelloy C276 maintains its mechanical properties even at elevated temperatures. Its modulus of elasticity is approximately 205 GPa, and it retains significant strength up to temperatures nearing 1,000°C (1,832°F). This thermal stability is vital for applications involving rapid temperature fluctuations and high thermal stress.

The superior corrosion resistance of Hastelloy C276 is its most celebrated attribute. The alloy's ability to withstand both oxidizing and reducing media—even in the presence of chlorides—makes it unparalleled in harsh corrosive environments. This resistance is due to the high molybdenum and chromium content, which protects against pitting and crevice corrosion in saltwater and chemical processing conditions.

Moreover, the addition of tungsten enhances its overall corrosion resistance. Hastelloy C276 is resistant to a wide range of chemical environments, including ferric and cupric chlorides, chlorides, solvents, formic and acetic acids, acetic anhydride, seawater, brine solutions, and hypochlorite and chlorine dioxide solutions. This broad-spectrum resistance is crucial for materials used in aggressive and unpredictable corrosive conditions.

When evaluating materials for use in corrosive environments, it's essential to compare Hastelloy C276 with other alloys like Inconel 625, Stainless Steel 316L, and Hastelloy C22. While each material has its merits, Hastelloy C276 often outperforms others in terms of corrosion resistance and mechanical strength.

| Property | Hastelloy C276 | Inconel 625 | Stainless Steel 316L |

|---|---|---|---|

| Corrosion Resistance | Excellent in both oxidizing and reducing environments | Good, but less resistant to pitting | Moderate; susceptible to pitting in chlorides |

| Maximum Temperature | 1,000°C (1,832°F) | 982°C (1,800°F) | 870°C (1,598°F) |

| Mechanical Strength | High tensile and yield strength | High tensile strength; good ductility | Lower tensile strength compared to Hastelloy C276 |

This comparison underscores why Hastelloy C276 is often the preferred material for the most severe environments. Its enhanced properties provide a safety margin that is critical in applications where failure can lead to catastrophic consequences.

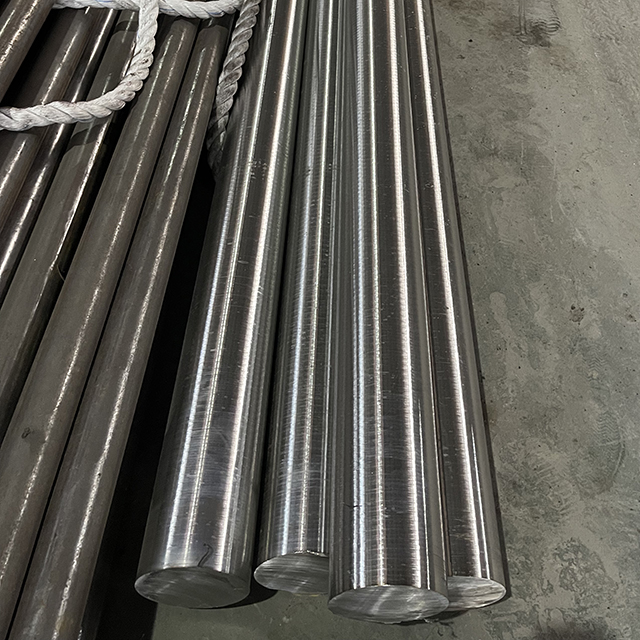

In the chemical processing industry, equipment is frequently exposed to highly corrosive chemicals at various temperatures and pressures. Hastelloy C276 is extensively used in reactors, heat exchangers, columns, and pipelines where contact with aggressive substances is routine. Its resistance to a wide range of acids—including sulfuric, hydrochloric, and phosphoric acids—makes it invaluable. Additionally, components like hastelloy c276 round bars are commonly employed in constructing durable and reliable equipment.

The oil and gas industry faces challenges such as sour gas environments, high pressures, and temperatures that can lead to rapid material degradation. Hastelloy C276’s resistance to sulfide stress cracking and stress corrosion cracking makes it an ideal choice for downhole tubulars, valve components, and other critical applications. Its durability ensures operational safety and integrity in offshore and onshore drilling operations.

In pulp and paper production, the processing equipment must withstand harsh chemicals like chlorine compounds used in bleaching processes. Hastelloy C276’s resistance to wet chlorine gas, hypochlorite, and chlorine dioxide solutions helps prevent equipment corrosion, thereby reducing downtime and maintenance costs.

Power plants, especially those utilizing fossil fuels, generate flue gases that can be highly corrosive. Hastelloy C276 is employed in flue gas desulfurization systems, scrubbers, and reheaters, where it endures acidic gases and high temperatures. Its application ensures longevity and reliability of components critical to emission control systems.

Hastelloy C276 is known for its excellent fabrication characteristics. It can be readily formed using conventional methods. When it comes to welding, the alloy exhibits good weldability due to its low carbon content, which minimizes carbide precipitation during welding, thereby maintaining corrosion resistance in the heat-affected zones.

However, certain precautions are necessary to avoid compromising its properties:

Preheating is not required, but inter-pass temperatures should be controlled.

Post-weld heat treatment is generally not necessary.

Use matching filler materials to ensure uniform corrosion resistance.

These practices ensure that the integrity of the alloy is maintained throughout the fabrication process.

To maximize the service life of equipment made from Hastelloy C276, proper maintenance is essential. Regular inspections should be conducted to detect signs of wear or corrosion, especially in joints and welded areas. Cleaning should be performed using appropriate non-abrasive methods to prevent surface damage that could initiate corrosion sites. By adhering to maintenance best practices, industries can ensure the continued reliability of their Hastelloy C276 components.

Hastelloy C276 has unequivocally proven itself as a trusted alloy for tough jobs across various demanding industries. Its exceptional resistance to a multitude of corrosive environments, coupled with robust mechanical properties, makes it an indispensable material for critical applications. Whether in chemical processing, oil and gas exploration, or power generation, Hastelloy C276 delivers reliable performance where lesser materials would fail. Understanding its properties and proper application is crucial for engineers and industry professionals dedicated to safety, efficiency, and longevity in their operations.

Hastelloy C276's unique chemical composition—including high amounts of nickel, molybdenum, chromium, and the addition of tungsten—provides exceptional resistance to both oxidizing and reducing environments. Its ability to withstand pitting, crevice corrosion, and stress corrosion cracking surpasses many other alloys, making it ideal for extremely corrosive conditions.

Yes, Hastelloy C276 is highly resistant to corrosion in seawater and brine solutions. Its composition protects against the corrosive effects of chlorides found in marine environments, making it suitable for seawater handling equipment and offshore applications.

Hastelloy C276 maintains its mechanical integrity at elevated temperatures up to approximately 1,000°C (1,832°F). Its thermal stability is beneficial in processes involving high temperatures, such as chemical reactors and flue gas systems, where material failure due to thermal stress is a concern.

While Hastelloy C276 is more challenging to machine than common stainless steels due to its work-hardening tendency, it can be successfully fabricated using appropriate tooling and machining techniques. It is advisable to use low cutting speeds, adequate depth of cut, and sharp tools to minimize work hardening and ensure precision.

Hastelloy C276 is available in various forms, including sheets, plates, bars, wires, fittings, and pipes. Components like hastelloy c276 round bars are widely used for their versatility in fabrication and application across different industrial equipment.

The nickel content in Hastelloy C276 provides excellent resistance to stress corrosion cracking, especially in chloride-containing solutions. The alloy's overall composition minimizes the formation of precipitates that can lead to intergranular corrosion, thereby enhancing its resistance under tensile stress conditions.

Post-weld heat treatment is generally not required for Hastelloy C276 due to its low carbon content, which reduces carbide precipitation. This characteristic helps maintain corrosion resistance in the heat-affected zones after welding, simplifying fabrication and reducing processing time.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Exploring the Magnetism of Stainless Steel for Modern Applications

Super austenitic stainless steel outperforms in real-world acid tests

Emerging Manufacturing Techniques for Austenitic Stainless Steel Bars

Exploring The Role of 18-8 Austenitic Stainless Steel in Modern Manufacturing And Homes

Top 10 Austenitic Stainless Steel Grades and Their Everyday Uses