close

Choose Your Site

Global

Social Media

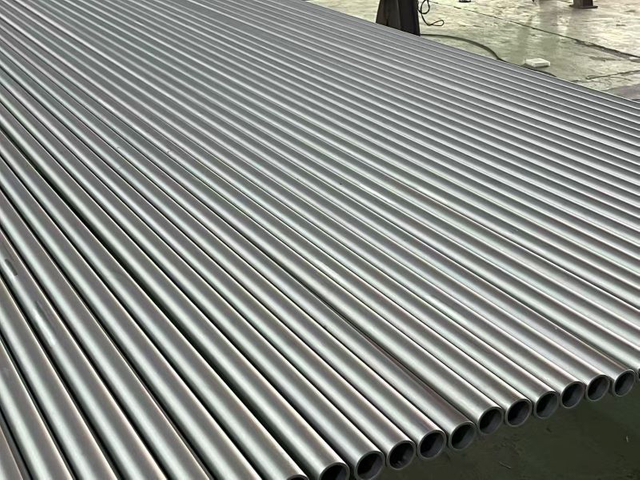

Seamless pipes are crucial in industries that demand strength and reliability. But how exactly are these durable pipes made? Understanding the manufacturing process of seamless pipes is key for selecting the right piping solution for critical applications.

In this article, you will learn about the steps involved in creating seamless pipes, the materials used, and their advantages over welded pipes.

A seamless pipe is a type of pipe that is produced from a single solid piece of metal, typically through a process of extrusion or rotary piercing. The key characteristic that sets seamless pipes apart from welded pipes is the absence of seams or joints. This feature allows seamless pipes to withstand higher pressures and stresses than welded pipes, making them ideal for industries where durability and reliability are essential. The lack of seams also means there are fewer potential weak points in the pipe, enhancing its performance and longevity.

Seamless pipes are used in various critical sectors:

● Oil and Gas: High-pressure systems demand pipes that can withstand extreme conditions.

● Automotive: Used in the manufacturing of high-strength components.

● Construction: Structural integrity is essential, especially for pipes used in construction and heavy machinery.

● Strength: Seamless pipes have a uniform structure, making them stronger and more reliable.

● Pressure Resistance: They can withstand higher pressures, making them ideal for critical applications like gas and oil pipelines.

● Corrosion Resistance: Without seams, seamless pipes have better corrosion resistance, especially in harsh environments.

The material used in the production of seamless pipes significantly influences their performance characteristics. Some of the most commonly used materials for seamless pipes include:

Material Type | Description | Common Applications | Benefits |

Carbon Steel | A common material for general use. | Industrial, construction | Cost-effective, good strength |

Alloy Steel | Contains alloying elements for strength. | High-stress and high-temperature applications | Enhanced strength and heat resistance |

Stainless Steel | Corrosion-resistant due to chromium. | Chemical processing, food industry | Superior corrosion resistance |

The composition of the steel determines the pipe's properties. For example, adding chromium enhances corrosion resistance, while adding carbon improves strength.

The chemical composition of the steel determines the pipe’s characteristics. For example:

● Chromium: When added to the steel, chromium improves its resistance to corrosion, making the pipe more durable in environments like chemical plants or offshore drilling operations.

● Carbon: The amount of carbon added to the steel influences the pipe's strength. High-carbon steels are stronger but may be more brittle, whereas low-carbon steels are more flexible but less strong.

● Molybdenum: This element is often added to enhance the steel’s ability to withstand high temperatures, making it ideal for use in power plants and other high-heat environments.

When selecting materials, factors like temperature, pressure, and exposure to chemicals must be considered. For example, stainless steel is ideal for high-corrosion environments, while alloy steel is better for applications requiring high tensile strength.

Process Step | Description | Key Purpose |

Extrusion | The steel billet is heated and formed into a hollow tube. | To create the initial pipe shape |

Rotary Piercing | A rotary piercing machine forms a hole in the center of the billet. | To hollow out the billet |

Mannesmann Process | The hollow tube is elongated by skew rolls. | To stretch the tube to desired length |

Heat Treatment & Sizing | The pipe is heated to adjust its mechanical properties, then sized. | To enhance strength and size accuracy |

Final Sizing and Cutting | The pipe is cut to length and finished as required. | To meet exact specifications |

The manufacturing of seamless pipes begins with the extrusion of a steel billet. The billet is heated and forced through a die to create a hollow tube. This process is essential for forming the basic structure of the seamless pipe.

Once the billet is heated, it is pierced using a rotary piercing machine. This process creates a hole through the center of the billet, forming a hollow tube that is ready for further elongation.

In the Mannesmann process, the hollow billet is elongated by passing it through a series of rotary skew rolls. This process stretches the billet into a longer pipe, allowing it to achieve the desired dimensions.

After elongation, the pipe undergoes heat treatment to adjust its mechanical properties. This process ensures the pipe has the required strength and flexibility. The pipe is then sized to meet the necessary diameter and wall thickness.

In the final step, the pipe is cut to the desired length. The pipe may undergo additional finishing processes like polishing or coating to meet specific requirements.

Tip: Quality control measures during heat treatment ensure the seamless pipe meets all performance standards for pressure and temperature resistance.

The quality of seamless pipes is crucial for their performance. Several inspection methods are used to ensure the pipes meet the required standards:

● Ultrasonic Testing: Detects any internal defects or voids.

● Hydrostatic Testing: Tests the pipe's ability to withstand high-pressure environments.

● Visual Inspection: Ensures the pipe's surface is free from defects like cracks or impurities.

Every pipe is tested to ensure it maintains consistent strength across its entire length. This is vital for applications that require the pipe to maintain integrity under pressure.

Seamless pipes must meet strict international standards such as ASTM (American Society for Testing and Materials) or API (American Petroleum Institute) specifications. These standards ensure that the pipes can withstand the extreme conditions they are often subjected to.

The lack of seams in the pipe's construction makes it inherently stronger than welded pipes. This strength allows seamless pipes to endure extreme conditions, such as high pressure and fluctuating temperatures.

Seamless pipes perform exceptionally well in extreme conditions, where welded pipes might fail due to the risk of seam rupture. Whether used in offshore oil drilling or high-pressure chemical processes, seamless pipes provide a reliable and safe solution. Their ability to withstand high pressure, fluctuating temperatures, and corrosive environments makes them essential in industries where pipe failure is not an option.

Seamless pipes are particularly beneficial in environments where corrosion is a concern. The absence of seams eliminates the possibility of weld failure, ensuring the pipe remains intact over extended periods.

Tip: For industries like oil and gas, choose seamless pipes for their unmatched performance in extreme conditions.

The production of seamless pipes is more complex and energy-intensive compared to welded pipes. The process involves several high-tech stages, including extrusion, rotary piercing, and heat treatment, which require specialized equipment and skilled labor. As a result, seamless pipes tend to be more expensive than their welded counterparts.

The manufacturing process of seamless pipes involves multiple steps, including extrusion, rotary piercing, and elongation. Each step requires high precision to ensure the final product meets the necessary standards.

The production of seamless pipes consumes a significant amount of energy, especially during the extrusion and heat treatment processes. Manufacturers are constantly working to improve energy efficiency to reduce costs and minimize the environmental impact of the production process.

Seamless pipes are made through a precise and complex manufacturing process. From extrusion to final sizing, each step ensures high strength and durability. These pipes are ideal for industries requiring reliability under extreme conditions. Zhejiang Xintongda Special Steel Manufacturing Co., Ltd. offers high-quality seamless pipes designed to meet the demands of various industries, providing exceptional strength and performance for critical applications.

A: A seamless pipe is typically made from carbon steel, alloy steel, or stainless steel. These materials provide the strength and durability required for high-pressure applications.

A: Seamless pipes are made through processes like extrusion, rotary piercing, and elongation, followed by heat treatment and final sizing.

A: Seamless pipes have no seams or joints, making them stronger and more resistant to high pressure, corrosion, and fatigue compared to welded pipes.

A: Seamless pipes offer higher strength, better corrosion resistance, and the ability to withstand extreme temperatures and pressures.

A: Yes, seamless pipes are generally more expensive due to the complex manufacturing process involved, but they provide greater reliability and durability.