close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-06-12 Origin: Site

The oil and gas industry is one of the most demanding sectors when it comes to material performance. From offshore platforms exposed to salt-laden sea spray to subsea pipelines subjected to high pressures and corrosive fluids, components must endure extreme environmental and chemical conditions. Materials not only need to withstand mechanical stress but must also resist aggressive corrosion mechanisms that threaten long-term reliability and safety.

Among the many engineering materials available today, duplex stainless steel has emerged as an ideal solution for oil and gas applications, especially in corrosive environments. Combining high mechanical strength with exceptional corrosion resistance, duplex steel offers a robust alternative to traditional austenitic or carbon steel, particularly in chloride-rich and sour service conditions.

Oil and gas production environments are inherently hostile to most materials. The combination of moisture, salinity, high pressure, elevated temperatures, and aggressive chemicals makes corrosion a constant threat. Three of the most pressing challenges include:

Chloride ions, abundant in seawater and produced water, are particularly aggressive toward many stainless steel grades. In austenitic stainless steels like 304 and 316, chloride exposure can lead to stress corrosion cracking (SCC)—a failure mode that occurs under tensile stress and corrosive conditions. SCC can initiate undetected and result in catastrophic failure with little warning.

Localized corrosion, such as pitting and crevice corrosion, can occur when passive oxide layers on the steel surface are breached, often in environments with stagnant seawater, mud, or chloride-laden fluids. These corrosion forms are insidious because they penetrate deeply while leaving little surface indication.

Hydrogen sulfide (H₂S), commonly found in oil and gas reservoirs, is both toxic and highly corrosive. When steel is exposed to sour environments, it can suffer from sulfide stress cracking (SSC) or hydrogen-induced cracking (HIC), which compromise the integrity of pressure-containing components.

Given these corrosive threats, material selection becomes a mission-critical task in ensuring the longevity, reliability, and safety of oilfield operations.

Duplex stainless steel, particularly grades like UNS S31803 (2205) and UNS S32750 (2507), offers a compelling suite of benefits that make it exceptionally well-suited to combat the environmental challenges in oil and gas applications.

Duplex steels are engineered with higher chromium (22–25%), molybdenum (3–4%), and nitrogen content, giving them a significantly higher Pitting Resistance Equivalent Number (PREN) than standard austenitic stainless steels. The PREN is a calculated value used to predict the resistance of stainless steel to pitting corrosion, particularly in chloride environments.

2205 duplex steel has a PREN of approximately 35, compared to 25 for 316 stainless steel

2507 super duplex steel boasts a PREN of over 40, making it ideal for extremely aggressive conditions

This high PREN translates into excellent resistance to pitting and crevice corrosion, even in warm, chloride-rich seawater or brine injection systems. This makes duplex steel a reliable choice for subsea and offshore applications, where exposure to chlorides is unavoidable.

Duplex stainless steels are known for their high yield strength—approximately twice that of austenitic stainless steels. For example:

Yield strength of 2205 duplex steel: ~450 MPa

Yield strength of 316 stainless steel: ~220 MPa

This allows engineers to design lighter, thinner-walled components without compromising structural integrity. In weight-sensitive applications like offshore rigs and subsea pipelines, reducing material thickness not only saves weight but also lowers material and fabrication costs, improves ease of installation, and increases payload capacity.

Moreover, the superior mechanical strength of duplex steel offers better resistance to abrasion, impact, and fatigue, which are critical factors in dynamic environments such as drilling operations and fluid transport systems.

Duplex steels also demonstrate strong resistance to sulfide stress corrosion cracking (SSCC) and hydrogen embrittlement, making them suitable for use in sour service conditions, as defined by NACE MR0175/ISO 15156 standards.

The balanced microstructure of duplex stainless steel (roughly 50% austenite and 50% ferrite) plays a key role in this resistance. Ferritic phases tend to reduce susceptibility to hydrogen-induced cracking, while the austenitic phases maintain toughness and ductility.

With proper heat treatment and fabrication, duplex steels meet the stringent demands of sour service, providing long-term durability in H₂S-containing environments such as:

Deep wells

Acid gas injection systems

Gas gathering and separation units

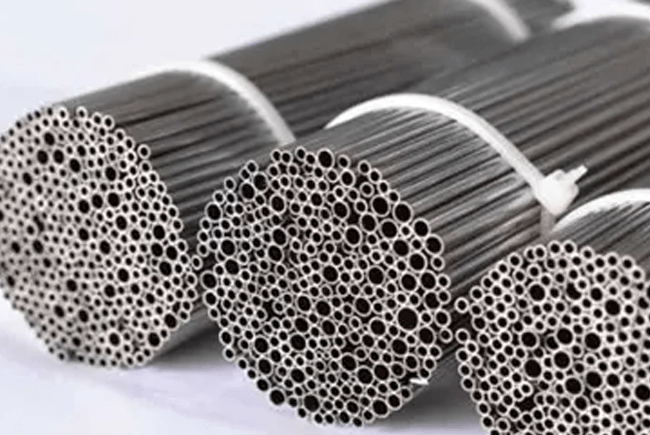

Duplex stainless steels have become indispensable in various components and infrastructure throughout the oil and gas value chain. Here are some of the most impactful applications:

Subsea pipelines are constantly exposed to high internal pressures and corrosive transported fluids, while the external surface is in contact with cold, saline seawater. Duplex steel’s combination of high strength and chloride resistance makes it ideal for:

Flowlines and risers

Umbilicals and jumpers

Water injection and chemical transport pipelines

By using duplex steel, operators can reduce pipeline wall thickness, cutting down installation and material costs while ensuring performance over a 20–30 year lifecycle.

Offshore oil rigs face extreme weather, salt spray, and chemical exposure, demanding materials that can endure corrosive marine environments and mechanical stresses.

Duplex stainless steel is used in:

Structural supports and handrails

Heat exchangers and pressure piping

Desalination and cooling systems

Firewater systems and ballast tanks

The material’s resistance to pitting, crevice corrosion, and SCC ensures the long-term reliability of safety-critical systems.

High-pressure vessels and separators in upstream and midstream facilities are subject to internal corrosive fluids, often including sour gas, water, and solids. Failure in such equipment could result in operational downtime or environmental disaster.

Duplex steels, particularly super duplex grades, offer:

High pressure tolerance

Resistance to sulfide stress cracking

Extended service life

This makes them well-suited for:

Gas-liquid separators

Slug catchers

Heat exchangers

Scrubbers and desulfurization units

Additionally, duplex stainless steel's good weldability and toughness ensure safe fabrication and installation of complex pressure-containing components.

In a sector where downtime is costly and safety is non-negotiable, the material you choose can make all the difference. Duplex stainless steel has proven itself as a robust, high-performance solution for oil and gas environments characterized by chloride attack, sour service, and mechanical wear.

With its:

Superior localized corrosion resistance

High strength-to-weight ratio

Reliable sour service performance

Reduced maintenance and lifecycle costs

Duplex stainless steel offers a compelling return on investment in even the harshest conditions.

At Zhejiang Xintongda Special Steel Manufacturing Co., Ltd., we provide a wide range of duplex and super duplex stainless steel products, including plates, pipes, flanges, and fittings, all manufactured to meet international oil and gas industry standards. Our materials are thoroughly tested and certified for demanding environments to ensure maximum performance and reliability.

Explore our product range at www.xtd-stainless.com, or contact our technical team today to discuss how we can support your oil and gas projects with industry-leading stainless steel solutions.