close

Choose Your Site

Global

Social Media

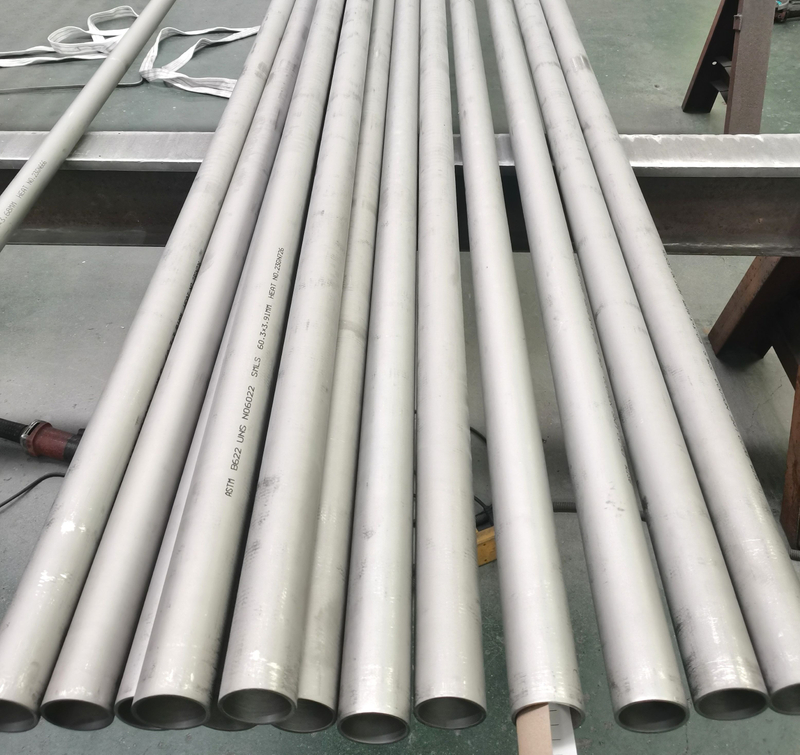

Seamless pipes are a vital part of many industries, known for their exceptional strength, durability, and versatility. These pipes are used in applications where high pressure, extreme temperatures, and resistance to corrosion are required. In this article, we’ll explore the various uses of seamless pipes in different sectors, including oil and gas, aerospace, power generation, automotive, and construction. By the end, you’ll understand why seamless pipes are often the preferred choice in critical applications.

Industry/Area | Seamless Pipe Use |

Oil and Gas | High-pressure pipelines, offshore rigs |

Aerospace | Aircraft components, fuel and hydraulic lines |

Power Generation | Steam transport, high-temperature systems |

Automotive | Engine components, exhaust systems |

Construction | Structural components, water and sewage systems |

In the oil and gas industry, seamless pipes are the go-to solution for high-pressure applications. Since seamless pipes do not have welded seams, they are inherently stronger and more resistant to internal and external pressures. This makes them ideal for transporting oil, natural gas, and other fluids under high pressure over long distances. Whether it's offshore drilling rigs or onshore pipelines, seamless pipes ensure the safe and reliable transportation of these valuable resources.

Offshore rigs are subjected to harsh environmental conditions, including salty seawater, extreme temperatures, and high pressures. Seamless pipes are ideal for these applications due to their ability to withstand corrosion and mechanical stress. They are used in critical parts of offshore rigs, such as drilling equipment, risers, and blowout preventers, ensuring durability and long-term performance even in challenging environments.

Seamless pipes play a crucial role in the exploration and extraction of oil and gas. They are used in various parts of the extraction process, such as well casings, drill pipes, and blowout preventers. These pipes must endure high pressure and temperatures, as well as potential exposure to corrosive substances. The superior strength of seamless pipes ensures they can handle these extreme conditions safely and effectively.

When working with oil and gas pipelines, selecting seamless pipes ensures that your system can withstand high-pressure environments, improving safety and performance.

In the aerospace industry, seamless pipes are used for parts that require a combination of high strength, low weight, and resistance to extreme conditions. Seamless pipes are integral in aircraft construction, where components like fuel lines, hydraulic systems, and engine parts demand materials that can withstand high stress and temperatures while maintaining a lightweight profile. Seamless pipes ensure that these components are both strong and durable.

Fuel and hydraulic lines in aircraft need to perform reliably in demanding conditions. Seamless pipes are used for these lines because they provide uniformity in wall thickness, ensuring smooth fluid flow without weak points. This uniformity is essential in aerospace applications, where even a small defect can lead to failure. The absence of seams in the pipes also prevents leaks, making seamless pipes a crucial part of aircraft safety.

Aerospace applications involve extremely high temperatures, particularly in engine components. Seamless pipes are used in areas where high-temperature resistance is essential, such as in jet engines or turbine systems. These pipes maintain their structural integrity even when exposed to intense heat, ensuring reliable performance and reducing the risk of failure.

For aerospace components, seamless pipes are a reliable choice for their combination of strength, durability, and heat resistance.

In power plants, seamless pipes are used to transport high-pressure steam, a key element in energy generation. Seamless pipes are perfect for these applications due to their ability to handle both high pressure and extreme temperatures. In thermal power plants, seamless pipes are used in boiler systems and steam turbines, ensuring efficient and safe steam transportation.

Seamless pipes are essential in power generation plants, particularly in environments where high temperatures are common. These pipes can withstand the heat generated by the combustion of fossil fuels or nuclear reactions. Their resistance to high temperatures and pressure ensures that power plants operate efficiently, providing a steady supply of energy.

Power plants operate in challenging environments, with exposure to high temperatures, chemicals, and constant mechanical stress. Seamless pipes are designed to endure these harsh conditions, offering superior durability and longevity. This makes them an ideal choice for critical infrastructure in power generation, where reliability is essential.

In power generation applications, seamless pipes ensure the safe and efficient transport of steam and fluids, crucial for maintaining plant performance.

Seamless pipes are used in automotive engine components where strength and durability are crucial. Components like engine blocks, turbochargers, and exhaust systems require pipes that can handle high pressures and temperatures. Seamless pipes, with their superior strength, are ideal for these parts, ensuring long-lasting performance under extreme operating conditions.

The automotive industry also relies on seamless pipes in exhaust systems. These pipes must endure high temperatures and exposure to corrosive gases, such as carbon monoxide and nitrogen oxide. Seamless pipes are more resistant to corrosion and wear, making them the ideal choice for exhaust systems, where longevity and safety are critical.

In automotive braking and fuel systems, seamless pipes provide the strength and reliability necessary for safe operation. These systems must withstand high-pressure fluids, and any weakness or defect could lead to catastrophic failure. Seamless pipes offer the uniformity and strength needed for critical automotive systems, ensuring safety and performance.

For automotive applications, seamless pipes are recommended for their superior strength, durability, and resistance to harsh chemicals and temperatures.

In the construction industry, seamless pipes are used for high-strength structural components. These pipes provide the necessary strength for building frameworks and support structures, ensuring the safety and stability of buildings, bridges, and other infrastructure. Their ability to withstand high loads makes them ideal for load-bearing applications.

Seamless pipes are commonly used in water and sewer systems, where durability and corrosion resistance are essential. These pipes are resistant to the chemicals found in water and sewage, ensuring they last longer and require less maintenance than other types of pipes. Seamless pipes are used in both residential and commercial construction for plumbing, drainage, and sewage systems.

Heating, ventilation, and air conditioning (HVAC) systems rely on seamless pipes for their durability and strength. These systems require pipes that can handle varying temperatures and pressures. Seamless pipes are ideal for HVAC systems due to their ability to withstand mechanical stress and resist corrosion, ensuring long-term reliability and performance.

Tip: Seamless pipes are a great choice for construction and infrastructure applications, as they provide the necessary strength and resistance to wear and corrosion.

Feature | Seamless Pipe | Welded Pipe |

Manufacturing | Single billet, no welds | Steel plate rolled and welded |

Strength | Higher, more resistant to pressure | Lower, but still strong |

Cost | Higher cost | Lower cost |

Applications | Oil & gas, aerospace, power generation | Construction, water systems, HVAC |

Seamless pipes offer superior strength compared to welded pipes due to the absence of seams. This results in a pipe that can withstand higher pressures and stresses, making it suitable for demanding applications in industries like oil and gas, aerospace, and power generation.

The uniformity of seamless pipes, with consistent wall thickness, ensures better structural integrity. This is particularly important in applications where precise fluid flow and pressure resistance are critical, such as in oil pipelines and hydraulic systems.

Seamless pipes, especially those made from corrosion-resistant alloys, perform well in harsh environments. Their resistance to rust and degradation makes them ideal for use in marine, chemical, and power generation industries, where exposure to corrosive elements is common.

Choose seamless pipes for projects that demand strength, uniformity, and corrosion resistance, ensuring long-term reliability and performance.

Seamless pipes are essential in a wide range of industries, from oil and gas to aerospace and construction. Their strength, durability, and resistance to harsh environments make them the preferred choice for high-performance applications. Whether it’s for high-pressure pipelines, engine components, or power generation systems, seamless pipes provide the reliability and safety needed for critical operations. Companies like Zhejiang Xintongda Special Steel Manufacturing Co., Ltd. offer high-quality seamless pipes, ensuring optimal performance in industries where reliability is key.

A: Seamless pipes are used in industries like oil and gas, aerospace, and power generation, where high strength, pressure resistance, and durability are crucial.

A: Seamless pipe is preferred for high-pressure applications due to its stronger structure, as it lacks seams that could be potential weak points.

A: Seamless pipes are made by heating and piercing a solid billet to form a hollow tube, without welding, ensuring higher strength and uniformity.

A: Yes, seamless pipes are generally more expensive than welded pipes due to their complex manufacturing process and superior strength.

A: Seamless pipes are commonly used in oil and gas, aerospace, power plants, automotive, and construction industries for applications requiring high performance.