close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-12-26 Origin: Site

Seamless pipes and welded pipes are both widely used, but which is better? Understanding their differences can help you make the right choice for your project. In this article, we'll explore the key differences between seamless and welded pipes, highlighting their strengths and ideal uses. By the end, you'll know which pipe type is best for your needs.

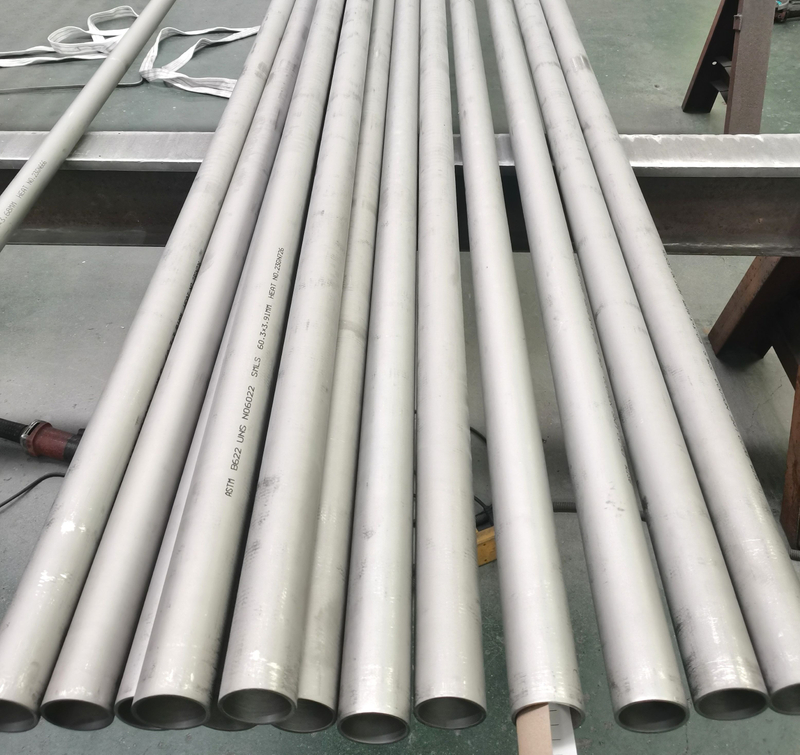

A seamless pipe is a type of pipe that is formed without any joints or seams. Unlike welded pipes, seamless pipes are created from a single billet of steel, which is heated and then pierced to form a hollow tube. The tube is then stretched and elongated to the desired length. This manufacturing process results in a pipe with no welds, making it stronger and more durable than welded alternatives.

Seamless pipes offer several advantages, including:

● High Strength: One of the primary benefits of seamless pipes is their exceptional strength. Since they are manufactured from a solid billet and do not have welded seams, they are less susceptible to weak points that may develop in welded pipes. This absence of a seam makes seamless pipes inherently stronger, allowing them to withstand higher levels of pressure and stress without risk of failure. As a result, they are ideal for use in high-pressure systems such as oil and gas pipelines and power plants.

● Uniformity: The production of seamless pipes ensures a uniform wall thickness, as there are no welds to create inconsistencies. This consistency in wall thickness enhances the structural integrity of the pipe, ensuring that it can handle the internal and external pressures of its intended application. This uniformity also helps with material flow, which is important in processes that require precise measurements, such as in the aerospace and chemical industries.

● Corrosion Resistance: Seamless pipes are more resistant to corrosion, especially when made from high-quality alloys such as stainless steel or other corrosion-resistant materials. This makes them highly suitable for applications in harsh environments where exposure to chemicals, moisture, or high temperatures is common. For instance, seamless pipes are often used in the marine, chemical, and petroleum industries, where they are exposed to corrosive substances that could degrade the performance of other types of pipes.

Seamless pipes are commonly used in industries that require high-performance materials, such as:

● Oil and Gas: Seamless pipes are particularly well-suited for high-pressure applications in the oil and gas industry. They are used in pipelines that transport oil and natural gas, as well as in offshore rigs where the pipes are subjected to harsh environmental conditions and significant pressure. The strength and integrity of seamless pipes make them the ideal choice for ensuring safe and reliable transportation of these critical resources.

● Aerospace: These pipes are used in aerospace for parts that require extreme strength and lightweight properties.

● Power Generation: Seamless pipes are used in power plants for applications involving high-temperature steam.

A welded pipe is produced by rolling a flat steel plate into a tubular shape and then welding the seam. The welding process can either be longitudinal or spiral, and the seam is reinforced for added strength. The pipe can be manufactured in various sizes and thicknesses, making it a versatile option for many industries.

Welded pipes are often more cost-effective compared to seamless pipes. They offer several benefits:

● Lower Cost: The manufacturing process for welded pipes is more cost-efficient, making them more affordable for large-scale projects.

● Versatility: Welded pipes can be made in different sizes and wall thicknesses, making them adaptable for various applications.

● Faster Production: The process of producing welded pipes is faster, making them suitable for projects with tight deadlines.

Welded pipes are commonly used in:

● Construction: Welded pipes are used in the construction of buildings, highways, and infrastructure projects.

● Water and Sewage Systems: They are often employed in municipal water and sewage pipelines.

● HVAC: Welded pipes are used in heating, ventilation, and air conditioning systems for their flexibility and affordability.

The most notable difference between seamless and welded pipes lies in their strength and durability. Seamless pipes, due to their lack of welded seams, are generally stronger and more resistant to pressure. They are preferred in high-stress applications where safety is paramount, such as in oil and gas pipelines.

On the other hand, welded pipes, although strong, are not as resilient as seamless pipes when exposed to extreme conditions. However, they are more than adequate for applications like water transportation and construction.

Welded pipes tend to be more affordable than seamless pipes due to their simpler manufacturing process. The production of seamless pipes requires more raw material and a more complex process, making them more expensive. Therefore, welded pipes are often the go-to choice for projects that need to balance cost and performance.

Seamless pipes are ideal for high-pressure, high-temperature, and corrosive environments due to their superior strength. Welded pipes, however, are versatile and suitable for less demanding applications such as plumbing and HVAC systems.

Feature | Seamless Pipe | Welded Pipe |

Manufacturing | Single billet, no welds | Steel plate rolled and welded |

Strength | Higher, more resistant to pressure | Lower, but still strong |

Cost | Higher cost | Lower cost |

Applications | Oil & gas, aerospace, power generation | Construction, water systems, HVAC |

Application Area | Seamless Pipe | Welded Pipe |

Oil and Gas | Preferred for high-pressure pipelines | Suitable for medium-pressure systems |

Aerospace | Used for components requiring high strength | Less common for aerospace uses |

Construction | Less common, used for critical structural components | Commonly used for general construction |

HVAC | Not typically used | Ideal for HVAC systems |

Water and Sewage Systems | Rarely used due to cost | Commonly used in municipal systems |

For systems that operate under high pressure, such as oil and gas pipelines, seamless pipes are the preferred choice. Their structural integrity, free from weld seams, ensures they can withstand the extreme forces exerted by pressurized fluids.

Welded pipes, while strong, are not ideal for applications where failure could result in significant damage or safety hazards. For lower pressure applications, however, welded pipes perform just as well.

When cost is a major consideration, welded pipes are the more economical option. They are ideal for large-scale projects such as water distribution systems and construction. However, it’s important to assess the required pressure ratings and environmental conditions before making a choice.

Seamless pipes are widely used in industries that operate under extreme conditions. In high-temperature environments, such as those found in power plants, seamless pipes ensure better performance due to their ability to handle high pressure and resist fatigue.

Seamless pipes also offer an excellent strength-to-weight ratio, making them suitable for applications where both strength and weight are crucial, such as in aerospace and high-end manufacturing.

This article explores the key differences between seamless and welded pipes, focusing on their manufacturing processes, strengths, and ideal applications. Seamless pipes offer higher strength and durability, making them suitable for high-pressure environments. Welded pipes are more cost-effective and versatile for less demanding uses. Zhejiang Xintongda Special Steel Manufacturing Co., Ltd. provides high-quality seamless pipes, ensuring reliability and performance for industries requiring superior pipe materials.

A: The main difference is that seamless pipes are made without joints or seams, offering higher strength and durability compared to welded pipes, which are formed by welding steel plates together.

A: Seamless pipes are preferred in high-pressure and high-temperature applications because they provide better structural integrity and resistance to stress.

A: Seamless pipes are manufactured by heating a solid billet and forming it into a tube without welding, ensuring no seams or joints.

A: Seamless pipes are generally more expensive due to their complex manufacturing process, while welded pipes are more affordable and faster to produce.