close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2026-01-29 Origin: Site

Stainless steel has no single “size.” It depends on what you buy, and how you use it. That is why stainless steel sizes can feel confusing at first.

In this guide, we break down stainless steel sizes by form, like sheet, plate, tube, pipe, and bar. You will learn the right size format, plus a simple RFQ method to avoid misorders.

Stainless steel sizes change by product form, not just by alloy grade. Sheets and plates use length, width, and thickness, while tubing uses outside diameter, wall, and length. Pipe may use nominal size and schedule, and bars use profile size plus length for machining. If you mix these languages, orders go wrong fast, so we always start by naming the form we need. Then we use the correct size format for that form, and we keep it consistent across the RFQ.

To simplify team communication, use this quick map of common size formats. It helps buyers and suppliers speak one language, and it also helps QA plan the right inspection method for each form.

Product form | Common size format | Typical buying goal |

Sheet | L × W × T | Flat parts, enclosures, panels |

Plate | L × W × T | Heavy bases, brackets, wear areas |

Tube | OD × WT × L | Equipment lines, frames, hygienic runs |

Pipe | NPS × Schedule × L | Plant piping, utility runs |

Bar | Dia or W × T × L | Machined shafts, blocks, pins |

Thickness often drives both cost and performance, and it may be written in mm or inches. Some buyers also see gauge for sheet products, which looks simple but can mislead new teams. Lower gauge usually means thicker metal, so “14 gauge” is thicker than “18 gauge,” and charts can vary by region and standard. That is why we restate gauge as real thickness every time, because it reduces quote disputes and shop errors.

Thickness also links directly to forming and welding behavior. Thin sheet bends easily and welds quickly, while thick plate needs higher heat, more time, and heavier handling equipment. So thickness is never just a number, it is a design and production decision that influences lead time, labor, and risk.

Most suppliers stock standard stainless steel sizes, including common sheets, plates, bars, tubes, and pipe dimensions. These stock sizes support shorter lead times and more stable pricing. If your drawing needs a unique size, suppliers usually cut it from stock using slitting, shearing, sawing, or laser cutting. This is why “stock first” thinking saves time and keeps scrap under control, since custom sizes often start from standard stock formats.

Your first word should be the product form, such as sheet, plate, tube, pipe, or bar. Each form uses different size rules, and if you skip this step suppliers must guess, which slows quotes and increases errors. Making the form explicit also helps QA choose the right inspection plan and helps fabrication choose the right tools for cutting, forming, or machining.

Each form has a standard dimension order that prevents misreads. Sheets and plates use length × width × thickness, tubes use OD × wall thickness × length, bars use profile size × length, and pipe often uses NPS × schedule × length. Using the right order reduces clarification emails and helps suppliers quote the correct item the first time. Keep units consistent per line item, and if you need conversions, do them yourself instead of forcing suppliers to guess.

If your drawing uses gauge, restate thickness as a numeric value using a known chart for your region. This protects you from chart differences and helps the supplier pick the correct coil or sheet faster. For plate, thickness is usually numeric only, while for tube and pipe wall thickness may appear as numeric or schedule-based language. Even when schedule appears, numeric thickness still improves clarity for inspection and acceptance. If thickness is critical, add a tolerance band so the supplier knows what “pass” means.

Stainless steel sizes do not stand alone, because grade and finish can change fit, appearance, and lead time. A polished finish can remove a small amount of material and can also tighten surface requirements for sealing. Some grades stock in fewer size combinations, which can affect availability even when the size looks common. If you want rapid supply, use common grades and sizes, and if you need special corrosion resistance plan for longer sourcing cycles. Always state finish when it matters to the end use, because it reduces rework and avoids wrong assumptions.

Many stainless steel sizes are nominal values, and nominal works for rough fabrication but fails in tight assemblies and automation. If fit, sealing, or repeatability matters, add tolerance for OD, thickness, and length. This is critical for sanitary clamps, orbital welding, press brakes, and laser-cut nests. If you do not state tolerance, suppliers follow defaults, and those defaults may not match your assembly needs. Treat tolerance as part of the size, because it is cheap to write and expensive to omit.

Processing changes the final usable size, so include cut method and edge condition when they matter. Shearing can leave a rolled edge and bow, laser cutting can leave heat tint, and waterjet can leave a clean edge but may take longer. If you need clean edges, tight flatness, or protective film, state it in the RFQ line. These notes prevent fit issues on the shop floor and help suppliers plan the best process route.

Tip: Write form + dimensions + thickness + grade + tolerance in one line.

Sheet products often start from standard footprints, and many markets use sizes like 4×8, 4×10, and 5×10 in feet or metric equivalents. Suppliers stock these sizes for quick turnaround, and they also match common fabrication tables and nesting layouts. If your part fits the stock footprint, both cost and scrap drop since nesting improves. When you need custom length, cut-from-stock remains common, but you should expect added time for cutting, deburring, and packaging.

Sheet usually covers thinner flat products, while plate covers thicker flat products, and the exact boundary can vary by supplier and region. A common rule uses about 6 mm as a shift point (needs verification), since thicker products behave like plate in handling and cutting. Thick products often require heavier lifting, stronger fixtures, and slower forming operations. This label change can also affect pricing and shipping methods, so it helps to confirm how your supplier defines sheet versus plate early.

Plate often comes in larger and heavier formats, and some suppliers offer large footprints such as up to 48×120 inches (needs verification). Many buyers order plate as cut blanks from larger stock, then machine it to final size in-house. This approach lowers cost for thick parts and protects critical surfaces until final machining. When ordering plate, state flatness needs clearly, because warp can break assembly alignment and can cause expensive rework.

Custom stainless steel sizes often start from stock, then suppliers cut to your required length and width. They may deburr edges, keep protective film, or add it depending on your notes. For complex shapes, provide a DXF file, and for simple rectangles a cut list can be enough. Either way, include tolerance for length and width, because it prevents short parts and costly remakes. Clear cut notes also support repeatable batch production and reduce disputes during receiving inspection.

Note: Always restate gauge as thickness in your purchase line.

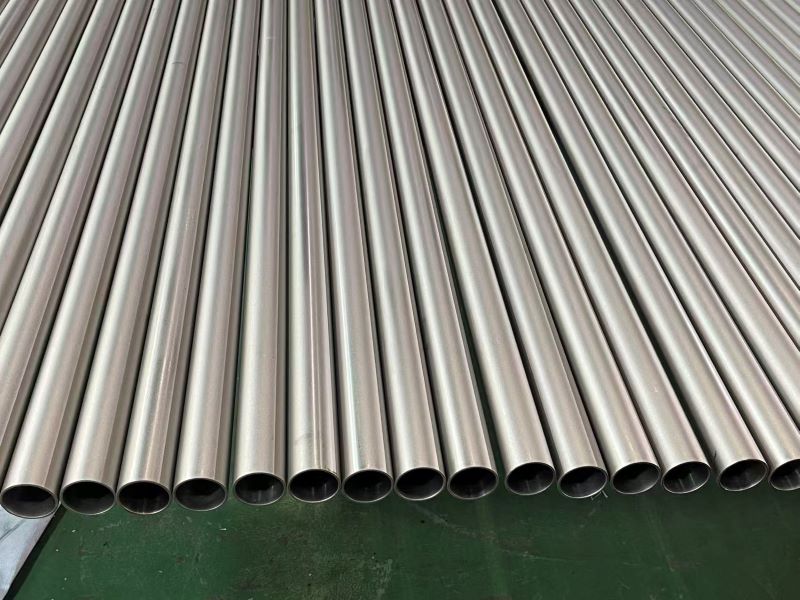

Tubing sizes usually use true outside diameter, then wall thickness, then length, so you often see OD × WT × L on drawings. You may also see square and rectangular tube sizes written as width × height × wall × length. Tubing supports equipment lines, frames, and hygienic systems, and its true OD supports precise fit for clamps and ferrules. Because of this, tubing sizing often feels simpler than pipe sizing, especially when assemblies demand tight repeatability.

Pipe sizing can look similar to tubing, yet it often uses NPS and schedule instead of true OD. NPS is a naming system, not a measured diameter, so a “one inch pipe” is not one inch OD, which surprises new buyers and causes fit failures. If your system uses tube fittings, buy tubing, and if it uses pipe fittings, buy pipe, unless you have a clear adapter plan. When you inspect incoming material, confirm fitting style first, because it is the fastest way to prevent a wrong order.

Wall thickness drives strength and service margin, and in tubing it also drives stiffness in frames. In pipe, schedule often represents wall thickness families, but thicker walls still increase weight, cost, and welding time. Thicker walls also reduce inside diameter, which can raise pressure drop in flow systems, so you should confirm hydraulics after wall selection. In most cases, the best approach is to use the thinnest wall that meets duty and risk requirements, because it keeps stainless steel sizes efficient and practical.

Tip: For fit issues, check OD first, then wall, then unit system.

Bars come in many forms and size formats, such as round bar (diameter × length), flat bar (width × thickness × length), and square bar (width × length plus corner notes). These stainless steel sizes support machining and fabrication, and machinists often order oversize stock so they can machine down to final tolerance. This reduces risk from surface defects and scale, and it also protects final dimensions. If you need tight final dimensions, plan machining allowance and state it clearly to avoid undersize stock.

Bars often ship in standard mill lengths, which reduces price and improves availability. Cut blanks reduce waste, handling time, and sawing labor in your shop, so they often win for high-volume machining. For low-volume work, mill lengths can be fine and simpler to manage. If you order blanks, add length tolerance and specify square, deburred ends to prevent setup delays at the machine. These small notes protect throughput and reduce scrap piles.

Fabrication steps shape the best bar size choice, since sawing needs kerf allowance, facing needs cleanup allowance, and grinding needs extra thickness for removal. Bending also needs extra length due to bend radius effects, and skipping these allowances can make parts end short. That is why we choose bar sizes based on process plans, not only final dimensions. We also align surface finish to end use, since bright drawn bar can reduce polishing time while rough bar can save cost for hidden parts.

Function should guide your stainless steel sizes, because different jobs prioritize different outcomes. Decorative parts prioritize surface and flatness, general fabrication prioritizes availability and cost, and structural parts prioritize thickness and strength. Fluid systems add ID, pressure drop, and sealing fit into the decision. Define function first, then choose the form that matches it, then choose size and tolerance. This order reduces redesign cycles, reduces supplier churn, and improves first-pass build success.

Thickness bands help teams move faster, since thin sheet often suits covers and light brackets, mid thickness suits enclosures and supports, and thick plate suits bases and heavy wear areas. Exact bands vary by industry and code, so treat them as a starting guide only. Then confirm choices against loads, corrosion needs, and fabrication methods. If weight matters, consider ribs instead of more thickness, and if cost matters prefer stock thickness values. These shortcuts keep stainless steel sizes practical for buyers and shop teams.

A clean checklist prevents most ordering mistakes and speeds up quoting. Pick one unit system and stay consistent, state product form first, and write dimensions in the correct order for that form. State thickness as a numeric value, not gauge alone, then add grade and finish since they affect lead time. Add tolerance when fit or sealing matters, and add processing notes like cut method and edge finish. Ask suppliers to restate the size back in the quote, because that single step catches many errors early.

Note: If any field is missing, suppliers will guess, and risk rises.

Stainless steel sizes depend on the product form. Sheet and plate use L × W × thickness. Tube uses OD × wall × length. Pipe may use NPS and schedule. Bar uses profile size and length. Clear specs reduce errors and speed quotes.

For reliable supply, Zhejiang Xintongda Special Steel Manufacturing Co., Ltd. supports a wide range of stainless products. They offer seamless tubes and special alloy options. They also support custom lengths and strict standards. It helps buyers match fit, cost, and performance needs.

A: It depends on the form, so stainless steel sizes can mean sheet L×W×T, tube OD×wall×L, pipe NPS×schedule, or bar profile×length.

A: Stainless steel sizes for tubing use true OD and wall, while pipe often uses nominal NPS and schedule for compatibility.

A: State the form first, then dimensions in the right order, then thickness, grade, finish, tolerances, and any cutting notes.

A: Yes, thickness often drives material cost, cutting time, welding effort, and handling needs across many stainless steel sizes.

A: Confirm the unit system, recheck key dimensions, verify tolerances, and make sure tube was not ordered as pipe.