close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-23 Origin: Site

When you need a rust-free metal, you should choose the right types of stainless steel. The top types include 304, 316, 316L, duplex 2205, and super duplex. These types resist rust because they have high chromium and, in some cases, molybdenum. This combination creates a strong passive layer on the surface. In marine or chemical settings, 316 and super duplex types of stainless steel handle harsh conditions well. You should always match the types to your environment, as this helps answer the question: will stainless steel rust?

You might wonder why stainless steel can stay shiny and strong even in tough environments. The answer starts with chromium. When you choose stainless steel, you get a metal that contains at least 10.5% chromium. This chromium reacts with oxygen in the air to form a thin, invisible layer of chromium oxide on the surface.

Chromium oxide acts as a shield, blocking oxygen and moisture from reaching the iron inside the steel.

This passive layer is stable and self-healing. If you scratch the surface, the chromium in the steel quickly forms a new oxide layer.

The layer is non-crystalline, which means it does not have easy paths for rust to travel through.

When you use stainless steel with higher chromium content, such as above 24%, you get even better protection. Scientific tests show that these steels do not corrode, even after harsh testing.

Researchers have found that this passive oxide layer is only a few nanometers thick, but it is very effective. In fact, studies using advanced imaging and corrosion tests show that stainless steel with a well-formed passive layer can resist corrosion in seawater and other harsh environments. Special coatings on this layer can boost protection even more, sometimes stopping over 90% of corrosion.

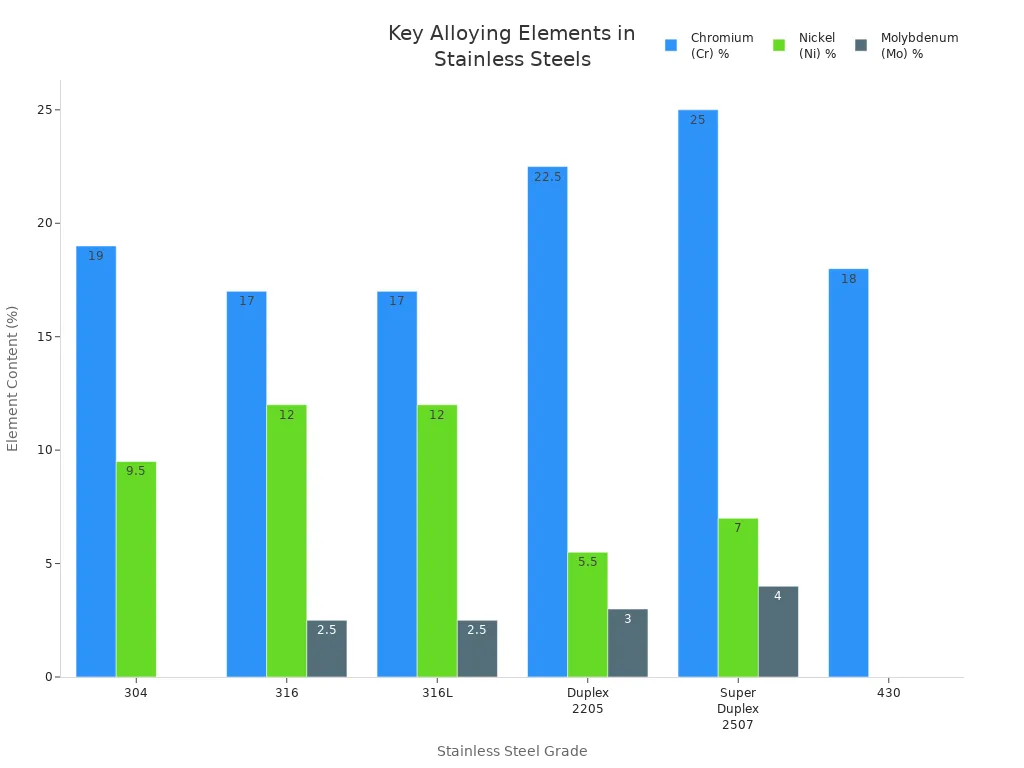

Chromium gives stainless steel its basic corrosion resistance, but other elements make it even better. You will see the best results when you pick a grade with the right mix of elements.

Molybdenum helps stainless steel resist corrosion in places where chloride, like salt, is present. It makes the passive layer stronger and stops pitting, which is a type of localized rust that can ruin metal quickly.

Nickel improves the structure of stainless steel. It helps the passive layer stay stable and durable, even when the steel faces acids or high temperatures. Nickel also lowers the risk of cracks and keeps the steel tough during welding.

Nitrogen boosts the strength of stainless steel and helps it resist corrosion, especially in tough environments. It works with molybdenum to stop pitting and crevice corrosion, which are common problems in marine or chemical settings.

When you combine these elements, you get stainless steels like super duplex grades. These grades show excellent corrosion resistance and can handle the most demanding jobs.

Many things can affect how well your stainless steel resists corrosion:

Saltwater and chlorides can break down the passive layer, especially if you use the wrong grade.

Moisture, pollution, and chemicals speed up corrosion.

Extreme temperatures can damage the protective layer.

Scratches or contact with other metals may start rust spots.

Good maintenance, proper cleaning, and choosing the right grade for your environment are key to keeping your stainless steel rust-free.

If you work near the ocean or in a factory with chemicals, you need to pick a grade that can resist corrosion in those conditions. Always match your stainless steel to the environment for the best results.

You may ask yourself, will stainless steel rust? The answer depends on where and how you use it. Stainless steel resists rust much better than regular steel, but it is not completely immune. If you expose stainless steel to harsh environments or do not maintain it properly, rust can still form. Understanding the main causes of rust helps you make better choices and keep your stainless steel looking new.

You might notice rust on stainless steel in places like factories, kitchens, or outdoor spaces. Several factors can damage the protective layer and cause rust to appear. If you wonder, will stainless steel rust in these settings, consider the following common causes:

| Cause of Rust Formation | Explanation |

|---|---|

| Exposure to Strong Chlorides | Saltwater or pool water contains chlorides that attack the passive layer, especially on grades like 304. |

| Bimetallic/Galvanic Corrosion from Welding | When you weld stainless steel to other metals, electrical currents can speed up corrosion. |

| Contamination from Plain Iron or Steel | Using steel wool or tools made from regular steel can leave particles behind, breaking the protective layer. |

| Exposure to Temperature Extremes | High or changing temperatures can weaken the metal and its protective layer. |

| Environmental Factors | Long-term exposure to pollution, moisture, or chemicals can wear down even the best stainless steel. |

You may also see rust if you do not clean your stainless steel regularly. For example, in industrial or marine environments, chemicals like chlorine can break down the protective oxide layer. Even though grades like 316 stainless steel have molybdenum for extra protection, you still need to care for them. If you ask, will stainless steel rust in these tough conditions, the answer is yes—unless you take steps to prevent it.

You can take several steps to keep your stainless steel rust-free. If you want to avoid asking, will stainless steel rust after a few years, follow these proven methods:

Choose the Right Grade

Select stainless steel grades like 316 for marine or food processing environments. This grade resists corrosion from salt and cleaning chemicals, making it ideal for kitchens and factories.

Apply Protective Coatings

Use coatings such as epoxy or polyurethane to create a barrier against moisture and chemicals. In marine settings, these coatings last longer and stop rust from forming.

Keep Surfaces Clean

Regularly clean your stainless steel with mild soap and water. Avoid using steel wool or brushes made from regular steel, as they can leave behind particles that cause rust.

Avoid Contact with Other Metals

Prevent bimetallic corrosion by not welding stainless steel to dissimilar metals. If you must join different metals, use proper techniques and barriers.

Use Antibacterial and Alloyed Stainless Steels

Some stainless steels contain copper or silver, which help stop bacteria and rust. These are useful in food processing and medical settings.

Tip: Always inspect your stainless steel for scratches or damage. If you see any, repair them quickly to keep the protective layer strong.

If you follow these steps, you will not need to worry as much about the question, will stainless steel rust. Good maintenance and the right materials make a big difference. Remember, even the best stainless steel can rust if you ignore it, so regular care is key.

When you choose stainless steel for rust resistance, you need to understand the main types and their unique properties. The most common types include austenitic, ferritic, and martensitic stainless steel. Each type offers different levels of corrosion resistance, strength, and best-use scenarios. In this section, you will learn about the top rust-resistant grades: 304, 316, and 316L. These austenitic types stand out for their ability to resist rust in many environments.

Note: The austenitic types, such as 304 and 316, contain high levels of chromium and nickel. This combination gives them excellent corrosion resistance and makes them non-magnetic. Ferritic and martensitic types have different structures and uses, which you will see in later sections.

304 stainless steel belongs to the austenitic family. You will find it contains about 18-20% chromium and 8-11% nickel. This high chromium content forms a strong passive oxide layer on the surface, which protects the metal from rust. Nickel adds toughness and improves corrosion resistance. Unlike ferritic stainless steel, 304 does not contain much carbon or molybdenum. This makes it less likely to crack or become brittle.

Here is a quick look at the composition of 304 compared to other types:

| Stainless Steel Grade | Chromium (Cr) % | Nickel (Ni) % | Molybdenum (Mo) % | Nitrogen (N) % | Carbon (C) % | Key Rust Resistance Impact |

|---|---|---|---|---|---|---|

| 304 | 18-20 | 8-11 | 0 | N/A | ≤0.08 | Good corrosion resistance; no Mo reduces chloride resistance |

304 stainless steel is non-magnetic in most conditions. It has good formability and weldability, which means you can shape and join it easily.

You get reliable rust resistance in most indoor and outdoor settings.

The austenitic structure gives you high ductility and toughness.

304 resists oxidation and many common chemicals.

You can clean and maintain it with little effort.

It costs less than many other types with similar corrosion resistance.

Tip: 304 stainless steel works well for most environments, but it may rust if exposed to high levels of salt or chlorides. For those situations, you should consider other types.

You will see 304 stainless steel in many industries because of its balance of cost and performance. Here are some common uses:

| Sector | Common Applications |

|---|---|

| Food & Beverage | Kitchen sinks, cookware, processing equipment, storage tanks |

| Medical & Pharmaceutical | Surgical instruments, implants, sterilization equipment |

| Architecture & Construction | Building facades, roofing, railings, structural components |

| Automotive | Exhaust systems, trim, structural components |

| Chemical Processing | Tanks, pipes, reaction vessels |

| Household Appliances | Refrigerators, washing machines, dishwashers |

| Industrial Equipment | Machinery components, pumps, valves |

You can also find 304 in hardware, screws, and bolts. Its versatility makes it one of the most popular types of stainless steel.

316 stainless steel is another austenitic type, but it contains 2-3% molybdenum. This addition makes a big difference in rust resistance, especially in chloride-rich environments. The chromium content is slightly lower than 304, at 16-18%, but the nickel content is higher, at 10-14%. This combination gives you better protection against pitting and crevice corrosion.

| Stainless Steel Grade | Chromium (Cr) % | Nickel (Ni) % | Molybdenum (Mo) % | Nitrogen (N) % | Carbon (C) % | Key Rust Resistance Impact |

|---|---|---|---|---|---|---|

| 316 | 16-18 | 10-14 | 2-3 | N/A | ≤0.08 | Mo improves chloride and rust resistance |

316 stainless steel is non-magnetic and keeps its strength at high temperatures. The austenitic structure also helps prevent cracking and makes it easy to weld.

You get superior resistance to rust in saltwater and chemical environments.

The molybdenum content protects against pitting and crevice corrosion.

316 maintains its strength and appearance even after long exposure to harsh conditions.

You can use it in both hot and cold environments without losing performance.

It is more durable than ferritic or martensitic stainless steel in aggressive settings.

Note: If you work near the ocean or with chemicals, 316 is one of the best types you can choose.

Many industries prefer 316 stainless steel for its superior rust resistance. You will find it in:

Marine components: Boat fittings, marine hardware, underwater piping

Chemical processing: Tanks, valves, and containers for corrosive chemicals

Medical devices: Surgical instruments, implants, dental equipment

Pharmaceutical manufacturing: Equipment that must meet strict hygiene standards

Food processing: Seafood equipment, dairy machinery, and food-grade surfaces

Outdoor electrical enclosures: Weather-resistant boxes and panels

Architectural and industrial equipment: Structural supports, exterior cladding

You can also use 316 in heat exchangers, furnaces, and other industrial machines that face tough conditions.

316L stainless steel is a low-carbon version of 316. The "L" stands for "low carbon," which means it contains a maximum of 0.03% carbon. This small change makes a big impact on rust resistance, especially after welding. Like 316, it has 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

| Property | 316 Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Carbon Content | Higher (up to 0.08%) | Lower (maximum 0.03%) |

| Corrosion Resistance | Good, but more prone to intergranular corrosion after welding | Better corrosion resistance, especially in welded areas due to reduced chromium carbide precipitation |

| Weldability | Good, but may require post-weld annealing to prevent sensitization | Excellent, typically no post-weld annealing needed due to low carbon content |

The austenitic structure remains, so you still get high toughness and ductility. 316L is non-magnetic and easy to form or weld.

You get enhanced rust resistance in welded structures.

The low carbon content prevents chromium carbide formation, which can cause rust at welds.

316L allows you to weld and repair parts without extra heat treatment.

It lasts longer in environments with frequent cleaning or chemical exposure.

You can use it in more demanding settings than standard 316.

Tip: If you need to weld stainless steel for marine, pharmaceutical, or laboratory use, 316L is one of the best types to pick.

316L stainless steel is the top choice for industries that demand the highest rust resistance and cleanliness. You will see it in:

Pharmaceutical manufacturing: Electropolished piping and tanks

Semiconductor manufacturing: Gas and chemical piping for purity

Marine equipment: Welded boat parts, underwater structures

Food and beverage: Processing equipment that needs frequent cleaning

Laboratory and medical devices: Surgical tools, sterilization trays

You can also use 316L in cosmetics, chemical processing, and any application where you need to avoid rust after welding.

Callout: Austenitic types like 304, 316, and 316L offer the best combination of rust resistance, strength, and versatility. Ferritic and martensitic stainless steel types have their own uses, but they do not match the corrosion resistance of these grades in most environments.

You will find that duplex 2205 stainless steel stands out because of its unique dual-phase structure. This grade contains about 21-23% chromium, 4.5-6.5% nickel, 2.5-3.5% molybdenum, and 0.08-0.20% nitrogen. The balance of austenite and ferrite phases gives duplex 2205 its name and its special properties. The high chromium content forms a strong passive oxide layer, which protects the steel from rust. Molybdenum and nitrogen boost resistance to pitting and crevice corrosion, especially in environments with lots of chlorides.

The dual-phase microstructure of duplex 2205 stainless steel improves both strength and corrosion resistance. The ferrite phase makes the steel strong and helps prevent stress corrosion cracking. The austenite phase adds ductility and toughness. This combination means you get a material that resists rust and mechanical fatigue, even in harsh or changing environments.

You gain several benefits when you choose duplex 2205 stainless steel for your project:

Excellent resistance to general corrosion, pitting, and crevice corrosion, especially in chloride-rich environments

High strength, which allows you to use thinner sections and save weight

Superior resistance to stress corrosion cracking compared to austenitic grades like 304 and 316

Good fatigue resistance, making it suitable for cyclically loaded structures

Lower nickel content than many austenitic grades, which can reduce material costs

Tip: Duplex 2205 stainless steel works well in aggressive environments where standard stainless steels might fail. You can rely on it for both strength and rust resistance.

You will see duplex 2205 stainless steel in many demanding industries. Its combination of strength and corrosion resistance makes it a top choice for:

Chemical processing: tanks, reactors, piping, and heat exchangers for corrosive substances

Oil and gas: pressure vessels, pipelines, and offshore platforms

Marine engineering: boat fittings, cargo tanks, and seawater handling systems

Pulp and paper: digesters, bleaching equipment, and storage tanks

Food and beverage: equipment exposed to chlorides and acidic conditions

Desalination plants and biofuels facilities

You can use duplex stainless steel in any setting where you need both high strength and excellent rust resistance.

Super duplex stainless steel takes the benefits of duplex grades even further. You get a higher chromium content, usually around 25%, and increased molybdenum and nitrogen. This composition creates a microstructure with roughly equal parts austenite and ferrite, just like standard duplex, but with even better corrosion resistance.

Super duplex stainless steel offers outstanding protection against pitting, crevice corrosion, and stress corrosion cracking. The higher alloy content means you can use it in the most aggressive environments, such as offshore oil and gas or desalination plants. The steel remains strong and tough, even at large thicknesses or under high pressure.

| Feature | Duplex Stainless Steel | Super Duplex Stainless Steel |

|---|---|---|

| Chromium Content | ~22% | ~25% |

| Molybdenum Content | 3-4% | 5-6% |

| Corrosion Resistance | Good resistance to pitting and SCC | Excellent resistance to pitting, SCC, crevice corrosion |

| Stress Corrosion Cracking | Resistant, but less than super duplex | Superior resistance to SCC |

| Applications | Chemical, petrochemical, marine, oil and gas | Offshore, subsea, highly corrosive chemical environments, desalination |

When you select super duplex stainless steel, you benefit from:

Superior resistance to localized corrosion, including pitting and crevice corrosion, even in seawater and high-chloride environments

Exceptional strength, which allows for lighter and more compact designs

Outstanding resistance to stress corrosion cracking, making it ideal for aggressive chemical and marine settings

Long service life, even in the harshest environments

Note: Super duplex stainless steel is the best choice when you need the highest level of rust resistance and mechanical strength.

You will find super duplex stainless steel in the most demanding applications, such as:

Offshore oil and gas: pipework systems, manifolds, risers, pumps, and valves

Chemical engineering: pressure vessels, heat exchangers, condensers, and distillation columns

Water treatment: desalination plants, large water storage tanks, and wastewater treatment

Pulp and paper: digesters, pressure vessels, and liquor tanks

Petrochemical industry: pipelines and pressure vessels

Marine engineering: subsea equipment and marine chemical tankers

You should use super duplex stainless steel when you need maximum rust resistance and durability in extreme environments.

430 stainless steel belongs to the ferritic family. It contains about 16-18% chromium and very little nickel (less than 0.5%). This grade forms a passive oxide layer that gives it moderate corrosion resistance. However, it does not resist rust as well as austenitic or duplex grades, especially in moist or acidic environments.

430 stainless steel is magnetic and has good formability. You can shape it into many products, but it does not have the same toughness or weldability as austenitic or duplex stainless steel.

You might choose 430 stainless steel for several reasons:

Lower cost compared to austenitic and duplex grades

Good resistance to oxidation and mild corrosion in dry indoor environments

Easy to form and polish for decorative uses

Magnetic properties, which can be useful in some applications

Alert: 430 stainless steel is not the best choice for wet, salty, or acidic environments. You should use it where only moderate rust resistance is needed.

You will see 430 stainless steel in many everyday products where moderate rust resistance is enough:

Household appliances: oven doors, dishwashers, refrigerators, and washing machines

Automotive components: exhaust systems, trim, and decorative elements

Architectural uses: railings, building facades, and wall cladding

Kitchenware: cutlery, sinks, and range hoods

Industrial equipment: storage tanks and equipment for mildly corrosive fluids

Fasteners and hardware: screws, bolts, nuts, hinges, and brackets

You can use 430 stainless steel for indoor or decorative applications, but you should avoid it in harsh or wet environments.

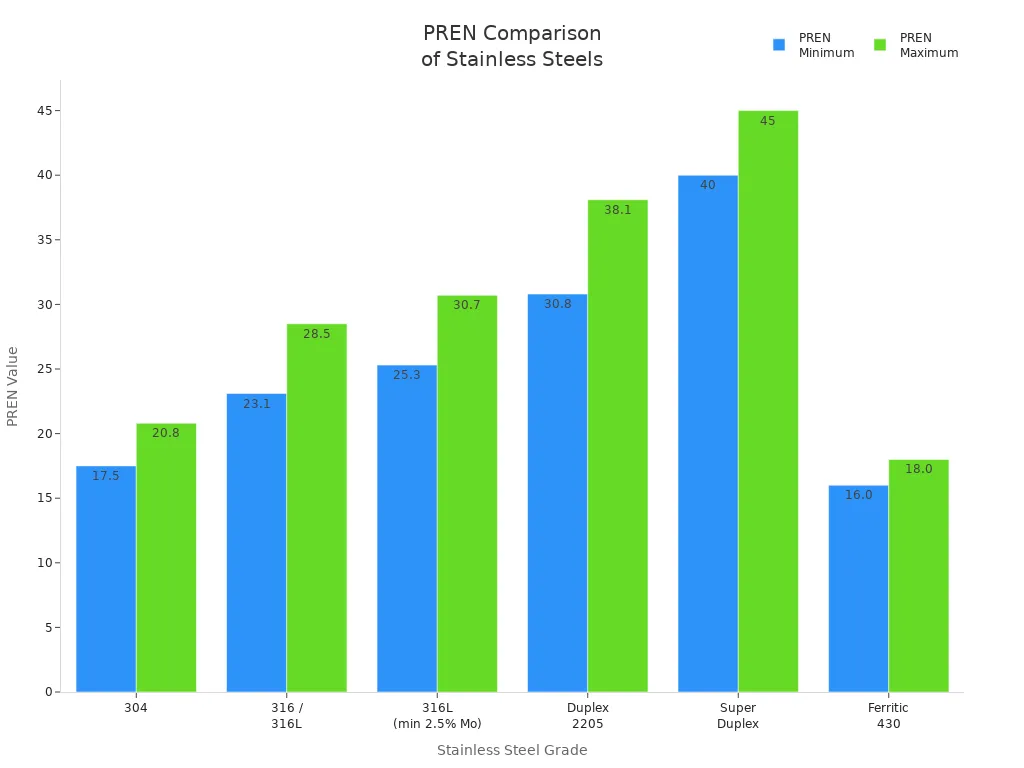

When you compare stainless steel grades, you need to look at how well each one stands up to rust. The Pitting Resistance Equivalent Number (PREN) helps you see which grades offer the best corrosion resistance, especially in tough environments. PREN takes into account the amounts of chromium, molybdenum, and nitrogen in the steel. Higher PREN means better protection against pitting, which is a dangerous form of rust.

Here is a table that shows the PREN ranges for the most common stainless steel grades:

| Stainless Steel Grade | Chromium (%) | Molybdenum (%) | Nitrogen (%) | PREN Range |

|---|---|---|---|---|

| 304 (austenitic) | 17.5 - 19.5 | Not Specified | Max 0.11 | 17.5 - 20.8 |

| 316 / 316L (austenitic) | 16.5 - 19.0 | 2.0 - 3.2 | Max 0.11 | 23.1 - 30.7 |

| Duplex 2205 | 21.0 - 23.0 | 2.5 - 3.5 | 0.10 - 0.22 | 30.8 - 38.1 |

| Super Duplex | 24.0 - 26.0 | 3.0 - 4.0 | 0.24 - 0.35 | > 40 |

| 430 (ferritic) | 16.0 - 18.0 | Not Specified | Not Specified | 16.0 - 18.0 |

You can see that austenitic grades like 316 and 316L have higher PREN values than 304. Duplex and super duplex grades have the highest PREN, which means they offer the best corrosion resistance. Ferritic grades like 430 have the lowest PREN, so they work best in dry or mild conditions.

Tip: If you need stainless steel for salty or chemical-rich environments, choose a grade with a higher PREN.

Each stainless steel grade has its own strengths and weaknesses. You should match the grade to your needs, whether you want the best corrosion resistance, the lowest cost, or the easiest material to work with.

Austenitic stainless steels (like 304, 316, and 316L) give you excellent corrosion resistance and are easy to form and weld. They do not attract magnets. You will find them in kitchens, hospitals, and marine settings.

Ferritic stainless steels (like 430) cost less and resist oxidation in dry air. They are magnetic and work well for appliances and indoor uses, but they do not handle salty or wet conditions as well.

Martensitic stainless steels offer high strength and hardness. You will see them in knives, tools, and some machine parts. They do not match the corrosion resistance of austenitic or duplex grades, but they are tough and can be heat-treated.

Here is a quick comparison of key attributes:

| Attribute | Austenitic (304, 316, 316L) | Ferritic (430) | Martensitic (410, 420, 440C) |

|---|---|---|---|

| Corrosion Resistance | Excellent | Moderate | Fair to moderate |

| Strength | Good | Moderate | High |

| Hardness | Moderate | Moderate | High (after heat treatment) |

| Magnetic? | No | Yes | Yes |

| Weldability | Excellent | Fair | Poor to fair |

| Cost | Higher | Lower | Moderate |

| Typical Uses | Food, marine, medical | Appliances, trim | Knives, tools, valves |

Note: Martensitic stainless steels give you strength and hardness, but you should not use them where corrosion resistance is the top priority.

If you want the best all-around corrosion resistance, pick an austenitic or duplex grade. For high strength and cutting edges, martensitic grades work best. Ferritic grades help you save money for indoor or decorative uses.

When you choose stainless steel for food contact, you want materials that keep food safe and resist rust. Food grade stainless steel must meet strict standards. The FDA requires that stainless steel food grade materials are durable, non-porous, corrosion resistant, and do not contaminate food. You will find several grades that meet these requirements.

304, 316, and 430 are the most common food grade stainless steel types.

304 stainless steel food grade has high chromium and nickel. It resists most acids found in foods and works well for vats, bowls, and dairy equipment.

316 stainless steel food grade contains molybdenum. This element gives it extra protection against salt and strong acids. You will see it in seafood processing and pickling equipment.

430 stainless steel food grade is a ferritic alloy. It costs less and resists mild acids, so you can use it for utensils and surfaces that touch mildly acidic foods.

Other options include 420 for knives, 1.4539 for salty foods, and 1.4462 duplex for high strength and stress corrosion resistance.

Electropolishing can make the surface even smoother and more hygienic.

You should always look for food grade stainless steel that is easy to clean and does not absorb food particles. The best food grade stainless steel for your needs depends on the food you process and the cleaning chemicals you use. If you work with salty or acidic foods, 316 is often the best food grade stainless steel. For general use, 304 is a reliable choice.

Tip: Always check that your stainless steel food grade equipment meets FDA standards for safety and hygiene.

You will see food grade stainless steel in almost every part of the food industry. Each grade has its own strengths, so you should match the material to your process. Here is a table that shows how 304 and 316 stainless steel food grade types are used:

| Stainless Steel Grade | Common Food Industry Applications | Rust Resistance and Suitability |

|---|---|---|

| 304 | Containers, countertops, sinks, kitchen utensils, general food handling where little or no salt or aggressive chemicals are present | Good corrosion resistance in moderate conditions; cost-effective; suitable for normal food processing environments |

| 316 | Food processing equipment exposed to salty water, pickles, fruits, acidic foods; seafood industries; marine-related food environments | Superior corrosion resistance due to molybdenum; ideal for chloride-rich, acidic, or salty environments; preferred for harsher conditions despite higher cost |

You will find 304 stainless steel food grade in kitchen sinks, mixing bowls, and dairy tanks. It works well for most foods that do not have high salt or acid. If you process seafood, pickles, or fruit juices, you should use 316 stainless steel food grade. This grade stands up to salt and acids, so your equipment lasts longer.

You may also see 430 stainless steel food grade in utensils, trays, and surfaces that touch food for short periods. This grade is magnetic and less expensive, but it does not resist rust as well as 304 or 316.

Food grade stainless steel helps you keep your equipment clean and safe. You can wash it easily, and it does not hold bacteria. The different types of food grade stainless steel let you choose the right material for every job in the food industry. When you select the best food grade stainless steel, you protect your products and your customers.

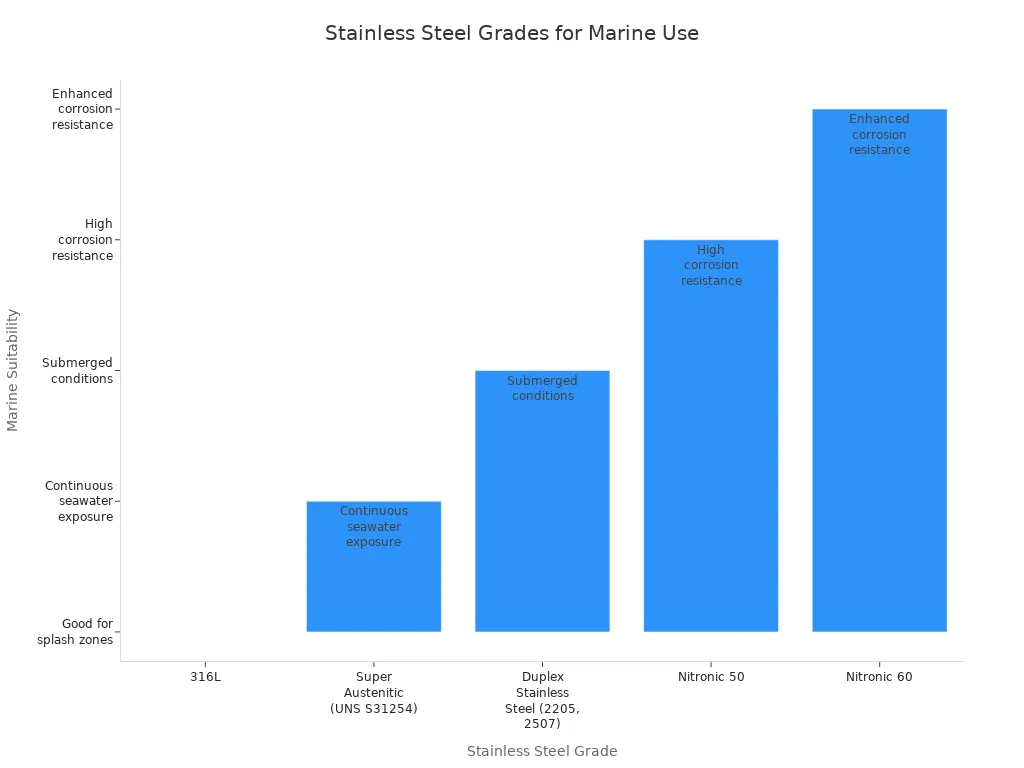

If you work near the ocean or need materials for boats, docks, or coastal buildings, you must choose stainless steel that stands up to saltwater. Salt and moisture in the air cause rust quickly. Not all stainless steel grades can handle these harsh conditions. You should look for grades with high chromium and molybdenum content. These elements help form a strong passive layer that blocks rust.

Here is a table that compares the best stainless steel grades for marine environments:

| Stainless Steel Grade | Key Features | Corrosion Resistance | Marine Suitability |

|---|---|---|---|

| 316L | Low carbon, molybdenum | Good pitting and crevice corrosion resistance | Best for splash zones, not for full submersion |

| Super Austenitic (UNS S31254) | High alloy, extra molybdenum and nitrogen | Excellent, PREN > 40 | Suitable for continuous seawater exposure |

| Duplex (2205, 2507) | Dual-phase, high strength | Superior resistance to localized corrosion | Used in offshore and submerged structures |

| Nitronic 50/60 | High silicon and nitrogen | High resistance in seawater | Good for marine applications needing extra durability |

You should avoid using 304 stainless steel for marine use if the metal will touch saltwater often. 316L is the minimum recommended grade for areas near the sea. For parts that stay underwater, super austenitic or duplex stainless steels work best. These grades resist pitting and crevice corrosion, which are common in corrosive environments like the ocean. Nitronic grades also offer strong performance for marine applications.

Tip: Even the best stainless steel can rust if you do not clean it or if it stays wet for long periods. Rinse surfaces with fresh water and inspect them often.

When you select stainless steel for kitchens or food factories, you must focus on hygiene and rust resistance. Food grade stainless steel is the standard for these settings. You should choose grades that resist acids, salt, and cleaning chemicals. The most common food grade stainless steel types are 304, 316, and 430.

304 food grade stainless steel works well for sinks, counters, and general kitchen tools. It resists most food acids and is easy to clean.

316 food grade stainless steel contains molybdenum, so it stands up to salty foods, pickles, and seafood processing.

430 food grade stainless steel costs less and is good for utensils and surfaces that do not touch strong acids or salt.

Always check that your food grade stainless steel meets FDA standards for safety and hygiene.

Choose a smooth finish or electropolished surface for easier cleaning and better acid resistance.

Avoid using steel wool or harsh brushes, as they can scratch the surface and cause rust.

Set up a cleaning plan to keep your food grade stainless steel in top shape.

Note: Food grade stainless steel is not just for factories. You can use it at home for cookware, sinks, and even water bottles.

Stainless steel is a smart choice for outdoor buildings, sculptures, and roofs. You get a material that resists rust, lasts for years, and needs little care. For outdoor use, you should pick a grade and finish that match your climate.

Stainless steel cladding protects buildings from rain, sun, and snow.

Roofing made from stainless steel keeps its shine and blocks rust, even after years of weather.

You can choose from polished, matte, or brushed finishes to match your style and boost corrosion resistance.

Stainless steel is hard and durable, so it works for both homes and large buildings.

The reflective surface helps lower cooling costs by bouncing sunlight away.

Stainless steel is recyclable, making it a green choice for new projects.

Pick the right grade for your area. In coastal cities, use 316 or duplex stainless steel for the best results.

Callout: Minimal maintenance keeps your outdoor stainless steel looking new. Just wash it with mild soap and water when needed.

When you choose stainless steel for industrial or chemical settings, you face tough demands. Factories, chemical plants, and water treatment facilities expose metal to harsh chemicals, high temperatures, and constant moisture. You need a grade that stands up to these challenges and keeps your equipment running safely.

Corrosion resistance is the most important factor in these environments. If you pick the wrong grade, you may see rust, leaks, or even equipment failure. Grades like 316, 316L, 904L, and duplex 2205 offer strong protection against chlorides, acids, and other aggressive chemicals. These grades help you avoid costly repairs and downtime.

You should also think about the cost and maintenance needs of each grade. Some grades cost more at first but save you money over time because they last longer and need less upkeep. Here is a table that compares popular stainless steel grades for industrial use:

| Stainless Steel Grade | Cost Characteristics | Corrosion Resistance & Maintenance Implications | Typical Applications |

|---|---|---|---|

| 304 | Most affordable due to wide availability and lower production costs | Moderate corrosion resistance; may require more maintenance in harsh environments | General industrial equipment, kitchen appliances |

| 316 | Pricier because of molybdenum addition enhancing corrosion resistance | Superior resistance to chlorides; lower maintenance in aggressive environments | Marine hardware, chemical processing |

| 303 | Slightly more expensive than 304 due to improved machinability | Less corrosion resistant than 316; maintenance depends on environment | Machined parts like fittings, fasteners, gears |

| 17-4 PH | Among the most expensive due to complex alloy and heat treatment | Exceptional strength and corrosion resistance; potentially lower maintenance but higher upfront cost | Aerospace, medical industries |

| Duplex grades (e.g., 2205) | Higher initial cost | Enhanced corrosion resistance and strength; reduced maintenance frequency | Industrial environments with harsh conditions |

You can see that grades like 316 and 2205 cost more at first. They pay off in the long run because they resist rust and need fewer repairs. Lower-cost grades like 430 or 3CR12 work for less demanding indoor jobs, but you may need to replace them sooner if the environment is harsh.

When you weld stainless steel in industrial settings, you should look for low-carbon grades like 304L or 316L. These grades reduce the risk of rust at welds and make repairs easier. Hardenable grades such as 17-4 PH give you high strength and corrosion resistance, but they need special heat treatment.

Tip: Always match the stainless steel grade to the chemicals, temperature, and cleaning methods in your facility. This choice helps you avoid unexpected failures and keeps your operation safe.

You now know the best stainless steel grades for rust resistance. Choose 304 for general use, 316 or 316L for salty or chemical-rich areas, and duplex or super duplex for the harshest environments. Always match the grade to your setting.

Review your needs before you buy.

Ask suppliers or experts if you feel unsure.

Tip: The right stainless steel saves you money and trouble in the long run.

You get rust resistance from the chromium in stainless steel. Chromium forms a thin, invisible oxide layer on the surface. This layer blocks moisture and oxygen, which stops rust from forming.

Yes, stainless steel can rust if you expose it to harsh chemicals, saltwater, or poor maintenance. You can prevent rust by choosing the right grade and cleaning it regularly.

You should use 316 or duplex 2205 for outdoor projects. These grades resist rust from rain, pollution, and salt in the air. 304 works for mild climates, but it may rust near the ocean.

You should clean stainless steel with mild soap and water. Avoid steel wool or harsh cleaners. Dry the surface after washing. Regular cleaning keeps the protective layer strong.

Yes, 430 stainless steel is safe for food contact. You can use it for utensils and kitchen appliances. It resists mild acids but does not handle salty or acidic foods as well as 304 or 316.

You may see brown stains from surface contamination or exposure to chlorides. These stains are not always rust. You can remove them with a stainless steel cleaner or a paste of baking soda and water.

Yes, you can weld stainless steel. For best results, use low-carbon grades like 316L or 304L. These grades prevent rust at welds and keep the protective layer intact.

PREN stands for Pitting Resistance Equivalent Number. It measures how well stainless steel resists pitting corrosion. Higher PREN means better protection, especially in salty or chemical-rich environments.