close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-01 Origin: Site

Seamless, welded, and ERW represent the three main types of hastelloy c276 pipe. Each type offers a broad selection of sizes and shapes, ranging from small diameters to large custom dimensions. Seamless pipes deliver higher strength and better load-bearing capacity because manufacturers extrude them from hot billets, while welded pipes, produced from welded sheets or strips, provide cost savings for larger diameters. ERW pipes feature a smooth finish and consistent wall thickness. Users can select from various specifications to match the demands of high-pressure, moderate, or general applications.

Hastelloy C276 pipes come in three main types: seamless, welded, and ERW, each suited for different needs and applications.

Seamless pipes have no weld seam, offering the highest strength and reliability for high-pressure and critical systems.

Welded pipes are cost-effective for large diameters and moderate pressures, making them ideal for budget-conscious projects.

ERW pipes provide a smooth finish and consistent wall thickness, balancing strength and affordability for medium-sized systems.

Seamless pipes handle extreme conditions with excellent corrosion resistance and durability, perfect for harsh environments.

Welded and ERW pipes suit moderate pressure and general industry uses, offering good corrosion resistance and flexibility.

Choosing the right pipe depends on application, pressure, size, shape, and budget; proper sizing and certification ensure safety.

Manufacturers offer custom sizes, shapes, and end types to fit unique project requirements and improve installation ease.

Seamless hastelloy c276 pipe stands out because of its unique manufacturing process. Manufacturers create these pipes by extruding a solid billet through a die, which forms a continuous, uniform tube without any welded seam. This method results in pipes with high strength and excellent uniformity. The absence of a weld seam eliminates weak points, making seamless pipes ideal for high-pressure and critical applications.

The material properties of seamless hastelloy c276 pipe support its reputation for strength and durability. The table below highlights key mechanical properties:

| Property | Value | Significance |

|---|---|---|

| Tensile Strength | Minimum 690 MPa | High material strength |

| Yield Strength (0.2%) | Minimum 310 MPa | Resistance to permanent deformation |

| Elongation | Minimum 40% | Ductility and toughness |

| Modulus of Elasticity | Minimum 206 GPa | Stiffness of the material |

| Dimensional Tolerances | ASTM B444 | Uniform pipe dimensions |

Researchers have found that seamless pipes made from Hastelloy C-276 show increased microhardness and nano-hardness, which means better wear resistance and surface strength. The uniform structure also improves corrosion resistance, making these pipes reliable in harsh environments.

Seamless hastelloy c276 pipe comes in a wide range of sizes and shapes. Manufacturers offer pipes with diameters from as small as 1/8 inch up to 150 inches nominal bore (NB). The outside diameter (OD) typically ranges from 6.00 mm to 1219.2 mm, and wall thickness can vary from 0.5 mm to 30 mm. The following table summarizes common size ranges for different shapes:

| Product Type | Wall Thickness (mm) | Diameter (mm) Range |

|---|---|---|

| Seamless Round Pipe | 0.05 to 30 | 6 to 630 |

| Seamless Square Pipe | 0.05 to 30 | 12.7 x 12.7 to 300 x 300 |

| Seamless Rectangular Pipe | 0.05 to 30 | 10 x 20 to 100 x 200 |

| Seamless Ornamental Pipe | 0.05 to 2.0 | 12.7 to 76.2 |

| Seamless Electropolished Pipe | 0.05 to 30 | 12.7 to 250 |

Seamless pipes meet standards such as ASTM B622 and are available in various schedules, including SCH5, SCH10, SCH40, STD, SCH80, and SCH160. End types include plain, beveled, and threaded. Shapes can be round, square, rectangular, coiled, straight, or custom-designed for special applications.

Many industries rely on seamless hastelloy c276 pipe for demanding applications. Chemical processing plants use these pipes to handle corrosive fluids and gases. The oil and gas industry values their strength and resistance to sour gas environments. Power generation facilities choose seamless pipes for high-pressure steam and heat exchanger systems. Other common uses include pharmaceuticals, marine engineering, and pollution control equipment.

Tip: Seamless pipes provide the best choice for projects that require maximum reliability and resistance to leaks or failures.

Welded hastelloy c276 pipe is made by rolling flat strips or plates of Hastelloy C276 into a cylindrical shape and then joining the edges with a weld. This process creates a visible seam along the length of the pipe. Welded pipes offer several advantages, especially for larger diameters. Manufacturers can produce these pipes in custom lengths and shapes, making them flexible for many projects.

One of the main benefits of welded pipes is cost-effectiveness. For large diameters, welded pipes are less expensive than seamless pipes. The table below compares key features of welded and seamless pipes:

| Feature | Welded Hastelloy C276 Pipes | Seamless Hastelloy C276 Pipes |

|---|---|---|

| Price per ton (USD) | $62,000 - $63,500 | $63,000 - $64,500 |

| Maximum Diameter | Up to 1219.2 mm (48 inches) | Up to 203.2 mm (8 inches) |

| Wall Thickness Range | 1 mm to 15 mm | 1 mm to 15 mm |

| Mechanical Strength | Lower than seamless; suitable where extreme strength is not critical | Higher mechanical strength; preferred for high-pressure applications |

| Corrosion Resistance | Excellent, but slightly less than seamless due to weld seams | Slightly superior due to absence of weld seams |

| Cost-Effectiveness | More cost-effective, especially for large diameters and custom shapes | More expensive due to manufacturing process |

| Application Suitability | Large diameter, budget-conscious, and flexible size requirements | High-pressure, high-temperature, and extreme corrosion conditions |

Welded pipes are best for moderate pressure applications. They have pressure ratings from about 2200 psig to over 4600 psig, depending on wall thickness and size. These pipes pass strict quality tests, including hardness, flattening, and corrosion resistance checks. They meet standards such as ASTM B619 and ASTM B622.

Welded hastelloy c276 pipe comes in a wide range of sizes. Manufacturers can produce diameters from 5.0 mm up to 1219.2 mm (about 48 inches). Wall thicknesses range from 1.0 mm to 15.0 mm. This flexibility allows for both standard and custom sizes. The pipes are available in many schedules, such as Sch 5, Sch 10, Sch 40, STD, Sch 80, and Sch 160.

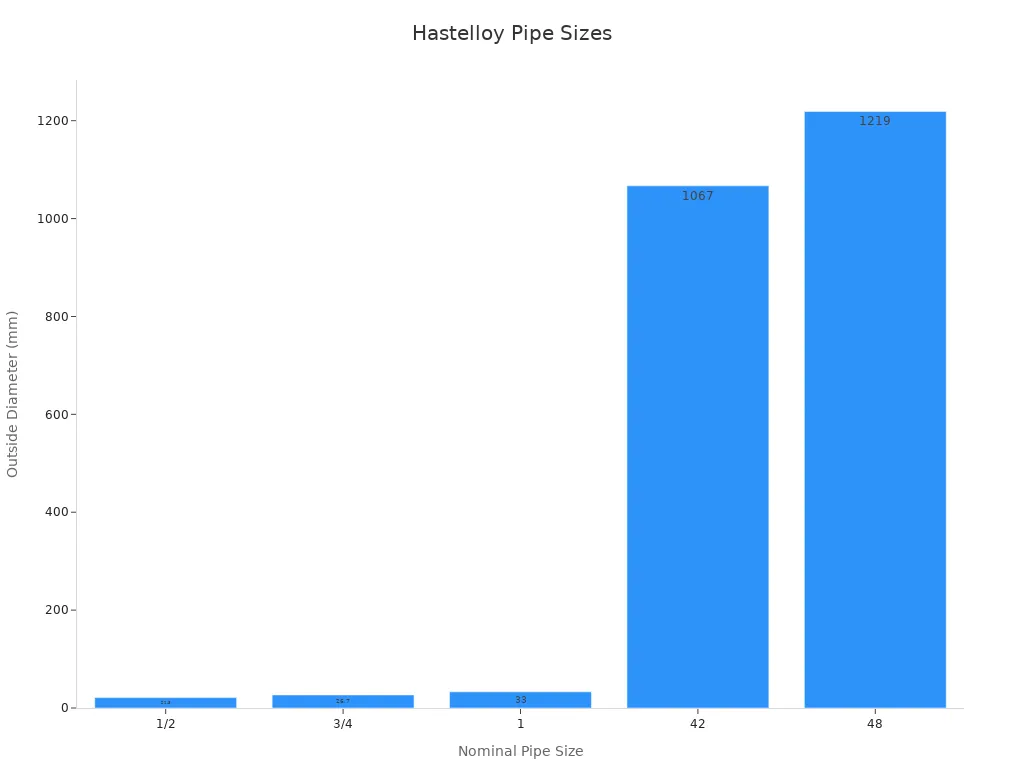

The following chart shows the relationship between nominal pipe sizes and outside diameters:

Welded pipe fittings, such as elbows, tees, and reducers, also come in large sizes. For example, elbows can reach up to 42 inches, and reducers up to 48 inches. Wall thickness tolerances are tight, ensuring reliable performance.

| Fitting Type | Maximum Size (Welded) | Thickness Range / Schedules |

|---|---|---|

| Elbows | Up to 42" | Sch 5, 5s, 10, 10s, 20, 30, 40s, 40, STD, 60, 80s, 100, 120, XS, XXS, 160, up to 50mm thickness |

| Tees | Up to 36" | Same as elbows |

| Reducers | Up to 48" | Same as elbows |

Manufacturers can supply welded pipes with plain, beveled, or threaded ends. Shapes include round, square, rectangular, and custom profiles.

Many industries choose welded hastelloy c276 pipe for moderate pressure and corrosive environments. These pipes are common in water treatment plants, exhaust systems, and structural applications. Chemical processing and aerospace industries also use welded pipes where moderate pressure and corrosion resistance are important. Welded pipes offer a reliable and cost-effective solution for large-scale projects that do not require the extreme strength of seamless pipes.

Note: Welded pipes provide excellent value for large diameter and custom-shaped piping systems, especially when budget and flexibility are key factors.

ERW stands for Electric Resistance Welded. Manufacturers create ERW pipes by forming flat strips of Hastelloy C276 into a round shape and then welding the edges together using electric resistance. This process produces a pipe with a smooth surface and a consistent wall thickness. ERW pipes work well for medium diameter applications. They offer efficient production and reliable quality. The weld seam is usually very small and smooth, making these pipes suitable for many industrial uses.

Key features of ERW Hastelloy C276 pipes include:

Efficient manufacturing for medium diameters

Consistent wall thickness throughout the pipe

Smooth internal and external surfaces

Good mechanical strength for general and process piping

Cost-effective for standard sizes

Tip: ERW pipes provide a balance between strength and affordability, especially for medium-sized piping systems.

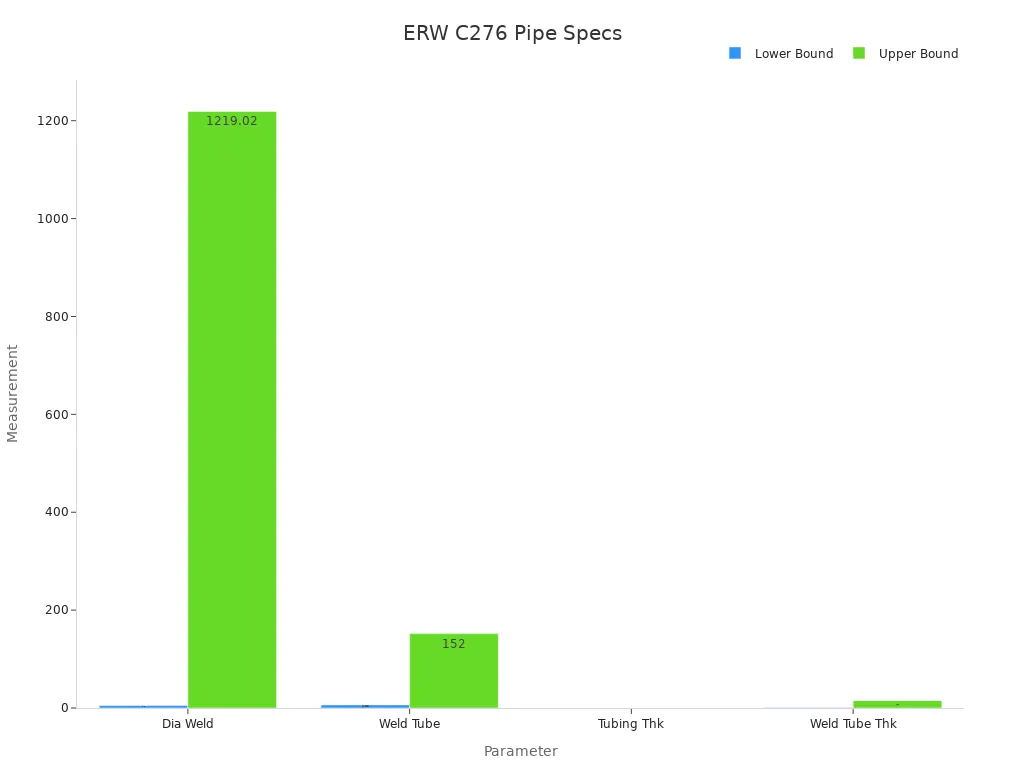

ERW Hastelloy C276 pipes come in a wide range of diameters and wall thicknesses. Manufacturers can produce pipes with diameters from as small as 5.0 mm up to 1219.02 mm. Welded tube sizes range from 6.35 mm to 152 mm in outside diameter. Wall thicknesses start at 0.020 inches for tubing and go up to 15.00 mm for welded tubes. This variety allows users to select the right pipe for their specific needs.

The following table shows the typical size ranges for ERW pipes:

| Parameter | Range / Values |

|---|---|

| Diameter Range (Welded Pipe) | 5.0 mm to 1219.02 mm |

| Welded Tube Size | 6.35 mm to 152 mm OD |

| Tubing Wall Thickness | 0.020" to 0.220" (custom thicknesses available) |

| Welded Tube Wall Thickness | 1.00 mm to 15.00 mm |

| Pipe Schedules Available | SCH80, XXS, SCH10S, SCH5, XS, SCH120, SCH160, SCH140, SCH30, STD, SCH40S, SCH40, SCH10, SCH60, SCH20 |

Manufacturers also follow strict standards for ERW pipes, such as ASTM B619 and ASTM B626. Pipes are available in many schedules, including SCH5, SCH10, SCH40, SCH80, and more. End types include plain, beveled, and threaded ends.

The chart below shows the lower and upper limits of pipe diameters and wall thicknesses for ERW Hastelloy C276 pipes:

For common pipe sizes, the table below provides more details:

| Nominal Pipe Size (NPS) | Wall Thickness (inch) | Wall Thickness (mm) | Outside Diameter (inch) | Outside Diameter (mm) |

|---|---|---|---|---|

| 1/2" | 0.0109 - 0.0147 | 2.0769 - 3.0734 | 0.84 | 21 |

| 3/4" | 0.0113 - 0.0154 | 2.0870 - 3.0912 | 1.005 | 27 |

| 1" | 0.0133 - 0.0179 | 3.0378 - 4.0547 | 1.0315 | 33 |

| 1 1/4" | 0.0140 - 0.0191 | 3.0556 - 4.0851 | 1.066 | 42 |

| 1 1/2" | 0.0145 | 3.0683 | 1.090 | 48 |

Many industries use ERW pipes for general and process piping. These pipes work well in chemical plants, food processing, and water treatment systems. Manufacturers often choose ERW pipes for their consistent quality and smooth finish. ERW pipes also appear in HVAC systems, fire protection lines, and light structural applications.

Some common uses include:

General industry piping

Process piping for fluids and gases

Water distribution systems

Structural supports in buildings

Heat exchanger tubes

Note: ERW pipes offer a reliable and cost-effective solution for many standard industrial applications.

Hastelloy C276 pipes come in three main types: seamless, welded, and ERW. Each type serves different needs in industry. Seamless pipes have no weld seam, which gives them high strength and reliability. Welded pipes are made by joining flat strips or plates, making them cost-effective for large diameters. ERW pipes use electric resistance to join the edges, creating a smooth finish and consistent wall thickness.

The table below summarizes the main features of each type:

| Type | Manufacturing Process | Key Features | Typical Uses | Standards |

|---|---|---|---|---|

| Seamless | Extruded from solid billet | No weld seam, high strength | High-pressure, critical systems | ASTM B622 |

| Welded | Rolled and welded plate/strip | Cost-effective, visible seam | Large diameter, moderate pressure | ASTM B619, B622 |

| ERW | Electric resistance welding | Smooth finish, consistent thickness | Medium diameter, general industry | ASTM B619, B626 |

Note: Each type offers unique benefits for specific applications.

Manufacturers produce these pipes in a wide range of sizes. Seamless pipes typically range from 1/8 inch to 150 inches nominal bore, with outside diameters from 6.00 mm to 1219.2 mm. Welded and ERW pipes can reach similar maximum diameters, especially for large projects. Wall thickness varies from 0.5 mm to 30 mm, depending on the type and application.

Seamless: 1/8" to 150" NB, 6.00 mm to 1219.2 mm OD, 0.5 mm to 30 mm wall thickness

Welded: 5.0 mm to 1219.2 mm OD, 1.0 mm to 15.0 mm wall thickness

ERW: 5.0 mm to 1219.02 mm OD, 1.00 mm to 15.00 mm wall thickness

Shapes include round, square, and rectangular, with custom options available for special projects.

Seamless, welded, and ERW pipes differ in strength, cost, and application suitability. Seamless pipes offer the highest strength and pressure resistance. Pressure ratings for seamless pipes can reach over 10,000 psig, making them ideal for critical chemical processing and high-stress environments. Welded and ERW pipes, while strong, are better suited for moderate or lower-pressure systems such as water supply or fire protection. These types provide excellent corrosion resistance and thermal stability.

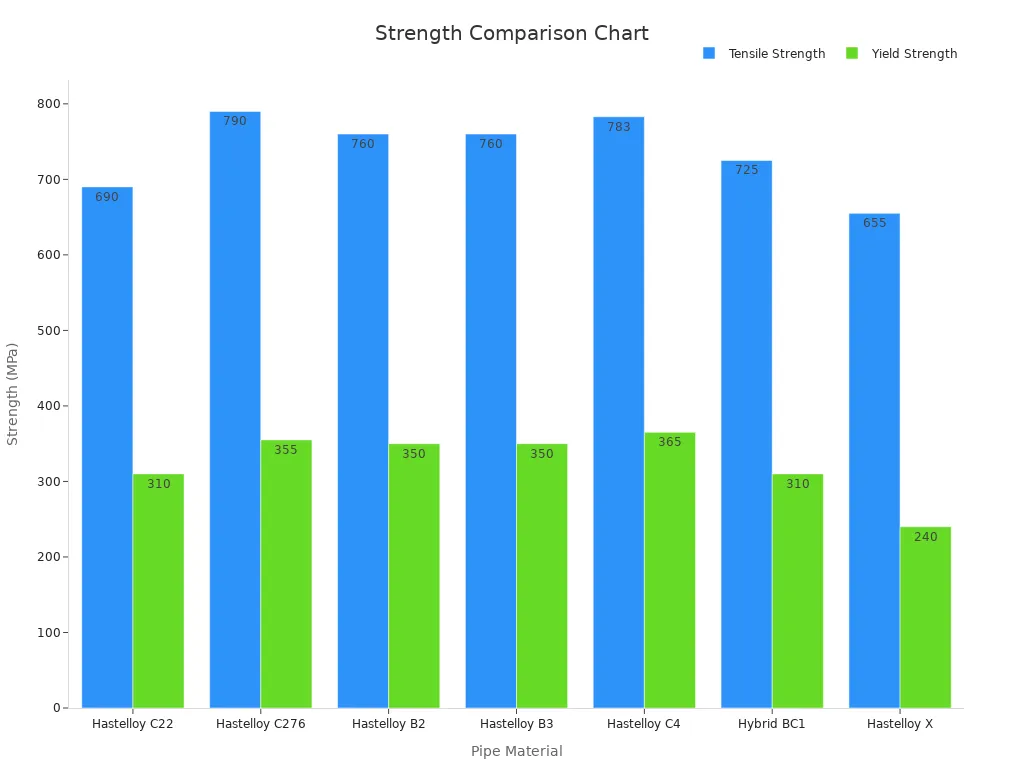

The chart below compares tensile and yield strengths across different pipe materials, including Hastelloy C276:

Cost also plays a role in selection. Seamless pipes usually cost more due to their complex manufacturing process. Welded and ERW pipes offer better value for large or standard-sized systems where extreme strength is not required.

Seamless: Best for high-pressure, high-temperature, and critical applications.

Welded: Suitable for large diameters and moderate pressures, offering cost savings.

ERW: Ideal for medium diameters, general industry, and automation systems.

Tip: Choose the type of hastelloy c276 pipe based on the pressure, environment, and budget of your project.

Selecting the right pipe starts with understanding the application. Different industries require specific properties from their piping systems. For example, chemical processing plants often face aggressive environments with acids and chlorides. In these cases, engineers choose pipes that resist corrosion and maintain strength under stress. Hastelloy C276 pipe stands out because it handles both oxidizing and reducing conditions. Its nickel-molybdenum-chromium composition, with added tungsten, protects against pitting and crevice corrosion. Industries such as oil and gas, pharmaceuticals, and pollution control rely on this alloy for its proven performance in harsh settings. Certification from organizations like ASTM and ASME ensures the pipe meets strict standards for safety and reliability.

Typical applications include:

Oil and gas wells with corrosive gases

Acid production plants

Geothermal and nuclear power components

Paper and pulp processing

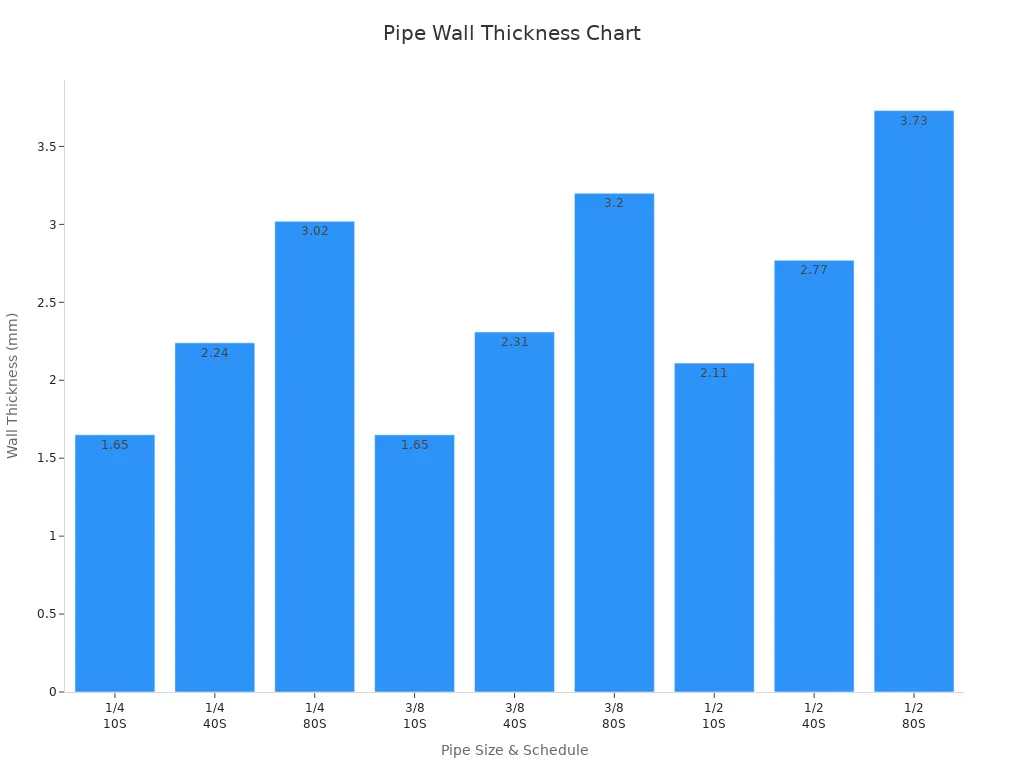

Proper sizing ensures the pipe will handle the required pressure and flow. Engineers look at nominal pipe size, wall thickness, and schedule to match system needs. For example, a small-diameter pipe with a thicker wall can withstand higher pressure. The table below shows how size and schedule affect wall thickness and weight for common pipe sizes:

| Nominal Pipe Size (inch) | Outer Diameter (mm) | Wall Thickness (mm) | Schedule | Weight (kg/m) |

|---|---|---|---|---|

| 1/4 | 13.72 | 1.65 | 10S | 0.50 |

| 1/4 | 13.72 | 2.24 | 40S | 0.64 |

| 1/2 | 21.34 | 2.11 | 10S | 1.02 |

| 1/2 | 21.34 | 2.77 | 40S | 1.29 |

| 1/2 | 21.34 | 3.73 | 80S | 1.65 |

Engineers also consider the end type—plain, beveled, or threaded—to ensure proper connection with other system parts. The following chart shows how wall thickness changes with pipe size and schedule:

Choosing the right hastelloy c276 pipe involves more than just size and application. Engineers should:

Match the pipe schedule to the system’s pressure and temperature requirements.

Select the correct end type for easy installation and maintenance.

Choose the shape—round, square, or rectangular—based on the layout and support needs.

Request certifications like ASTM B622 or ASME SB622 to confirm quality.

Consult with industry experts for unique or challenging environments.

Tip: Custom and fabricated options are available for projects with special requirements. Manufacturers can produce pipes in non-standard sizes, shapes, or lengths to fit complex systems.

A careful selection process ensures the piping system will perform safely and efficiently for years.

Selecting the right type and size of hastelloy c276 pipe ensures safe and efficient operation in demanding environments. Seamless, welded, and ERW pipes each offer unique benefits and size ranges. Performance data highlights the importance of matching pipe properties to application needs:

| Metric | Hastelloy C-276 |

|---|---|

| PRE Number | 45 |

| ASTM G28B Corrosion Rate | <0.5 mm/year |

| Maximum Service Temperature | Up to 1037°C |

| Yield Strength | ~283 MPa |

| Weldability | Excellent |

Careful comparison and selection help users achieve long-term reliability and safety.

Hastelloy C276 pipe resists corrosion better than most stainless steel pipes. It handles harsh chemicals and high temperatures. Many industries choose it for tough environments where stainless steel may fail.

Yes, users can weld Hastelloy C276 pipes on-site. The alloy has excellent weldability. Welders should use matching filler materials and follow proper procedures to maintain corrosion resistance.

Industries such as chemical processing, oil and gas, power generation, and pharmaceuticals use Hastelloy C276 pipes. These industries need pipes that resist corrosion and handle high pressure.

Users select the pipe schedule based on pressure and temperature needs. Higher schedules mean thicker walls and higher pressure ratings. Engineers check system requirements before choosing the schedule.

Yes! Manufacturers offer custom sizes, shapes, and lengths. Users can request round, square, or rectangular pipes to fit unique project needs.

| Pipe Type | Common Standards |

|---|---|

| Seamless | ASTM B622 |

| Welded | ASTM B619, B622 |

| ERW | ASTM B619, B626 |

These standards ensure quality and performance.

Store pipes in a dry, clean area. Use padded supports to prevent scratches. Avoid contact with carbon steel to prevent contamination. Proper handling keeps the pipes in top condition.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Stainless Steel Tube Dimensions Chart Explained for Industrial And Residential Uses

Top 10 Applications for Stainless Steel Tube Schedule 10 in 2025

Top 10 Stainless Steel Tube Fittings for Marine And Industrial Applications

Comparing Stainless Steel Tube Suppliers for Your Next Project

A Comprehensive Guide To Stainless Steel Tube Schedule 40 Dimensions And Charts