close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-06-06 Origin: Site

C22 Hastelloy is a nickel-based alloy renowned for its exceptional corrosion resistance and versatility in challenging environments. This superalloy has become a material of choice for many industries that operate under extreme conditions, including chemical processing, aerospace, and marine engineering. Its unique combination of chemical composition and mechanical properties offers unparalleled performance where traditional materials fail. Hastelloy alloys have significantly contributed to advancements in technology and industry by providing reliable solutions to corrosion-related challenges.

The C22 Hastelloy alloy is primarily composed of nickel, chromium, molybdenum, and tungsten. The specific percentages of these elements are meticulously controlled to achieve the desired properties. Nickel serves as the base element, providing the alloy's overall corrosion resistance and structural integrity. Chromium adds resistance to oxidizing environments, while molybdenum and tungsten enhance resistance to pitting and crevice corrosion.

The microstructure of C22 Hastelloy is characterized by a face-centered cubic lattice, which contributes to its excellent mechanical properties and workability. The addition of elements like cobalt, iron, and vanadium, even in trace amounts, fine-tunes the alloy's performance. These elements improve thermal stability and prevent the formation of undesirable phases during heat treatment and welding processes.

C22 Hastelloy exhibits outstanding mechanical properties that make it suitable for high-stress applications. Its tensile strength exceeds 1100 N/mm² (159 ksi) in annealed conditions, ensuring it can withstand substantial mechanical loads without deformation. The alloy maintains its mechanical integrity across a wide temperature range, from cryogenic temperatures up to 400°C (750°F), making it ideal for both low and high-temperature applications.

The alloy's thermal stability is another noteworthy attribute. It resists grain boundary precipitation in the weld heat-affected zone, a common issue that can lead to intergranular corrosion. This resistance is critical in maintaining the alloy's corrosion-resistant properties post-welding, ensuring long-term durability and reliability in service.

One of the most significant benefits of C22 Hastelloy is its superior corrosion resistance in a variety of aggressive media. The alloy performs exceptionally well in both oxidizing and reducing environments. Its high chromium content enhances resistance to oxidizing agents, while the molybdenum and tungsten components provide defense against reducing agents.

C22 Hastelloy is highly resistant to localized forms of corrosion such as pitting, crevice corrosion, and stress corrosion cracking. This resistance is particularly important in environments containing chlorides and other halides. The alloy's resilience to wet chlorine gas, hypochlorite, and chlorine dioxide solutions makes it indispensable in industries where exposure to these substances is unavoidable.

Pitting and crevice corrosion are localized forms of attack that can lead to catastrophic failure in metals. C22 Hastelloy's formulation specifically combats these types of corrosion. The synergistic effect of chromium, molybdenum, and tungsten elevates the alloy's pitting resistance equivalent number (PREN), a quantitative measurement of pitting resistance. With a PREN value of approximately 46, C22 Hastelloy outperforms many other nickel-based alloys and stainless steels in resisting localized corrosion.

Stress corrosion cracking (SCC) can occur in alloys exposed to tensile stress and a corrosive environment. C22 Hastelloy demonstrates excellent resistance to SCC, even in chloride-rich environments. This resistance is crucial for maintaining structural integrity in components subjected to both mechanical stress and corrosive agents, such as in marine and chemical processing equipment.

The extensive benefits of C22 Hastelloy make it suitable for a myriad of industrial applications. Its ability to withstand highly corrosive environments and maintain mechanical integrity under extreme conditions has led to its adoption across various industries.

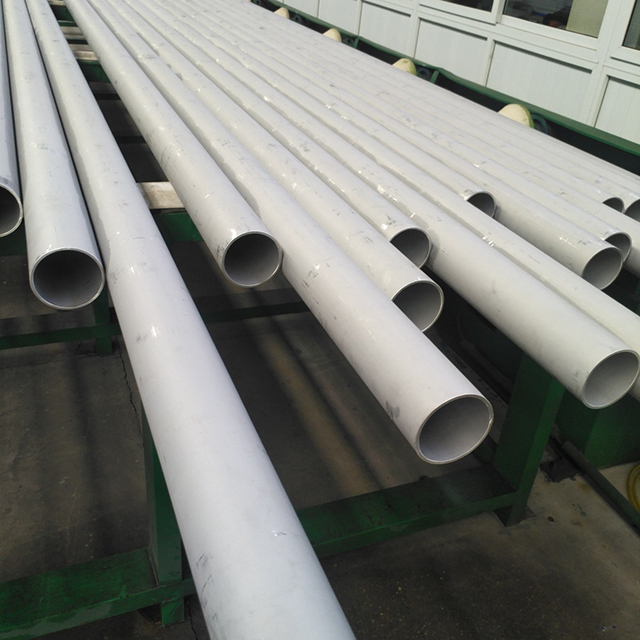

In the chemical processing industry, equipment is often exposed to aggressive chemicals at elevated temperatures. C22 Hastelloy is used to manufacture reactors, heat exchangers, and piping systems that handle substances like sulfuric acid, hydrochloric acid, and chlorine compounds. Its resistance to intergranular corrosion after welding makes it ideal for fabricating complex chemical processing equipment that requires reliable performance over extended periods.

The pharmaceutical industry requires materials that can withstand corrosive environments while maintaining high levels of purity. C22 Hastelloy is employed in the production of Active Pharmaceutical Ingredients (API), buffer solutions, and other processes where contamination must be minimized. The alloy's resistance to pitting and crevice corrosion ensures that equipment surfaces remain intact, preventing microbial contamination and ensuring product integrity.

In the oil and gas sector, equipment must endure harsh environments, including exposure to hydrogen sulfide, carbon dioxide, and high chloride concentrations. C22 Hastelloy's exceptional corrosion resistance extends the service life of downhole and topside components such as valves, pumps, and tubing. Its mechanical strength under high-pressure conditions makes it a reliable material for these critical applications.

C22 Hastelloy is used in aerospace engineering for components that require high strength and corrosion resistance at elevated temperatures. Its thermal stability and resistance to oxidizing atmospheres make it suitable for manufacturing combustion chambers, exhaust ducts, and other engine components. The alloy's ability to maintain structural integrity under thermal cycling enhances the safety and efficiency of aerospace systems.

C22 Hastelloy exhibits excellent fabrication characteristics. It can be hot or cold worked using conventional methods. The alloy's ductility allows it to be formed into complex shapes without cracking, which is essential for manufacturing intricate components. Heat treatment processes, such as solution annealing at 1122°C (2050°F) followed by rapid quenching, are employed to restore the alloy's mechanical properties after fabrication.

Welding C22 Hastelloy requires careful attention to prevent contamination and preserve its corrosion resistance. The alloy can be welded using methods like Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW). It's crucial to ensure cleanliness and use low heat input to avoid the formation of detrimental phases that could compromise corrosion resistance. The use of matching filler materials is recommended to maintain the integrity of the weld joints.

When compared to other high-performance alloys like Hastelloy C-276, Inconel 625, and stainless steels like 904L and 254 SMO, C22 Hastelloy often exhibits superior overall corrosion resistance. Its enhanced resistance to localized corrosion makes it a preferred choice in environments where pitting and crevice corrosion are significant concerns.

While alloys like Inconel 625 offer good corrosion resistance, they may not perform as well as C22 Hastelloy in highly aggressive media. Similarly, superaustenitic stainless steels may reach their performance threshold under extreme conditions where C22 Hastelloy continues to provide reliable protection.

Although C22 Hastelloy is more expensive than standard stainless steels, its cost is justified by the extended service life and reduced maintenance it provides. The alloy reduces the likelihood of equipment failure due to corrosion, minimizing downtime and replacement costs. Its availability in various forms—including plates, sheets, bars, tubes, and fittings—facilitates its use in custom fabrication and large-scale production.

Several industries have documented the benefits of using C22 Hastelloy in their operations. For instance, chemical plants handling acetic anhydride and other aggressive chemicals have reported significantly reduced corrosion rates after switching to C22 Hastelloy equipment. In the pharmaceutical industry, manufacturers have observed improved product purity and reduced contamination risks by utilizing C22 Hastelloy in their processing equipment.

In oil refineries, C22 Hastelloy has been employed in components exposed to sour gas environments, where its resistance to sulfide stress cracking has enhanced operational safety and longevity. These real-world applications underscore the alloy's value in critical environments.

Ongoing research aims to further enhance the performance of nickel-based alloys like C22 Hastelloy. Advanced manufacturing techniques, such as additive manufacturing, are being explored to produce complex components with optimized properties. Research into surface treatments and coatings may also extend the alloy's service life and open up new application areas.

The development of variants with altered compositions could tailor C22 Hastelloy for specific environments. For example, adjusting the tungsten or cobalt content may improve certain properties without compromising overall performance. Collaboration between material scientists and industry professionals will continue to drive innovation in the use of C22 Hastelloy.

C22 Hastelloy stands as a pinnacle of material engineering, offering unmatched corrosion resistance, mechanical strength, and thermal stability. Its unique properties address the critical needs of industries operating in harsh environments, providing solutions where conventional materials fall short. The alloy's versatility and reliability make it an indispensable resource in advancing industrial processes and technologies. Investing in Hastelloy components not only enhances performance but also contributes to long-term economic benefits through reduced maintenance and increased equipment lifespan.

1. What makes C22 Hastelloy superior to other nickel-based alloys?

C22 Hastelloy offers a unique combination of high chromium, molybdenum, and tungsten content, providing exceptional resistance to both oxidizing and reducing environments. This makes it superior in resisting localized corrosion like pitting and crevice corrosion compared to other nickel-based alloys.

2. Can C22 Hastelloy be used in high-temperature applications?

Yes, C22 Hastelloy maintains excellent mechanical properties and corrosion resistance up to 400°C (750°F), making it suitable for various high-temperature applications across multiple industries.

3. How does C22 Hastelloy perform in welding processes?

C22 Hastelloy exhibits good weldability with conventional techniques like GTAW and GMAW. It's important to maintain cleanliness and control heat input to prevent the formation of detrimental phases that could affect corrosion resistance.

4. Is C22 Hastelloy cost-effective despite its higher price compared to stainless steel?

While the initial cost is higher, C22 Hastelloy's durability and superior corrosion resistance lead to reduced maintenance, fewer replacements, and less downtime, providing long-term cost savings and improved operational efficiency.

5. What industries benefit the most from using C22 Hastelloy?

Industries that operate in highly corrosive environments benefit significantly, including chemical processing, pharmaceutical production, oil and gas exploration, and aerospace engineering, due to the alloy's exceptional resistance to aggressive media.

6. Are there any limitations to using C22 Hastelloy?

C22 Hastelloy should not be used in environments exceeding 1250°F (677°C), as it may form detrimental phases that affect its properties. Proper selection based on operating conditions is essential to maximize performance.

7. How does C22 Hastelloy contribute to environmental sustainability?

By providing extended equipment life and reducing the need for frequent replacements, C22 Hastelloy minimizes waste and resource consumption. Its durability leads to fewer disruptions and energy usage associated with manufacturing new components.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Top 10 Most Common Austenitic Stainless Steel Grades And Their Everyday Uses

Exploring The Benefits And Applications of Austenitic Stainless Steel

How To Choose The Right Austenitic Stainless Steel Bar Grade for Industrial Use

Austenitic Stainless Steel Alloys Pros And Cons Explained Simply

Top 7 Ways Stainless Steel Tubing Is Used in Modern Industry