close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-08-01 Origin: Site

DIN seamless pipes play a crucial role in industrial systems where performance, safety, and reliability matter. The differences in seamless steel pipe models and materials often determine how pipes, fittings, and pressure systems perform under demanding conditions. DIN standards guide the selection of seamless steel, ensuring that pipes and fittings meet strict requirements for pressure, temperature, and corrosion resistance. Manufacturers design seamless pipes and fittings to handle specific pressure applications and match exact DIN standards. Choosing the right seamless steel pipe, fittings, and steel grade protects equipment and maintains system integrity. The right DIN seamless pipes, fittings, and seamless steel pipe models support safe operation in high-pressure environments.

DIN seamless pipes follow strict standards that ensure high performance in demanding environments. DIN, or Deutsches Institut für Normung, sets the specifications for seamless steel pipe and fittings used in industries that require precision and durability. Standards such as DIN 2448 and DIN 17175 define the requirements for seamless steel pipes, including mechanical strength, dimensional accuracy, and chemical composition. These standards use metric units and focus on pressure resistance and corrosion resistance, making them ideal for high-pressure and high-temperature applications. Unlike ASTM, which uses imperial units and targets extreme environments, or JIS, which emphasizes welding and corrosion resistance for Asian markets, DIN standards prioritize rigorous control over every aspect of seamless steel pipe production. This approach ensures that seamless pipes and fittings meet the needs of industries like automotive manufacturing, boiler pipelines, and petrochemical plants.

Note: DIN seamless pipes are recognized for their precision, durability, and ability to maintain integrity under high pressure and temperature.

Manufacturers produce several models of DIN seamless pipes to meet diverse industrial requirements. The most common models include those specified by DIN 2448, DIN 17175, and DIN 1630. Each model offers unique features and specifications. For example, DIN 2448 pipes come in a range of outer diameters and wall thicknesses, using materials like 20# steel, Q345B alloy steel, and stainless steel 316L. These pipes serve petrochemical, natural gas, and boiler manufacturing sectors. DIN 17175 covers seamless alloy and carbon steel boiler tubes, known for precise dimensional tolerances and excellent mechanical properties. Pipe models can be circular or irregular in shape, with specifications tailored to fit specific fittings and system requirements.

| Model (DIN 2448 example) | Outer Diameter (mm) | Wall Thickness (mm) | Typical Materials | Application Areas |

|---|---|---|---|---|

| DIN 2448 (159 pipe) | 159 (±0.75) | 6-25 | 20# steel, Q345B, SS 316L | Petrochemical, natural gas, boiler manufacturing |

DIN seamless pipes and fittings play a vital role in many industries. Oil and gas companies use seamless steel pipe for transporting crude oil, natural gas, and refined products under high pressure and temperature. The petrochemical industry relies on seamless pipes and fittings to handle aggressive chemicals and maintain structural integrity. Power generation plants use seamless steel pipes in steam pipelines, boiler tubes, and heat exchangers. Automotive manufacturers use seamless pipes in hydraulic braking systems and exhaust components, benefiting from the strength and corrosion resistance of seamless steel. Construction and infrastructure projects depend on seamless steel pipes and fittings for structural support, water supply, and sewage systems. The food and beverage industry uses seamless pipes and fittings for hygienic processing equipment, breweries, and dairy operations.

Oil and Gas: Casing, tubing, and transfer lines

Engineering and Construction: Hydraulic presses, cylinders, pumps, and measurement technology

Automotive: Hydraulic braking systems and exhaust components

Power Generation: Boilers, heat exchangers, and turbine piping

Chemical and Petrochemical: High-pressure piping and heat exchanging systems

Food and Beverage: Hygienic piping for processing and production

DIN seamless pipes and fittings provide the reliability and performance needed for these critical applications, meeting strict standards and specifications for every industry.

| DIN Material Number | Equivalent International Grades (Approximate) | Key Chemical Composition (Typical Values, %) | Mechanical Properties (Typical Values) | Corrosion Resistance | Typical Application Scenarios |

|---|---|---|---|---|---|

| 1.4301 | AISI 304 / S30400 | C≤0.07, Cr18-20, Ni8-11, Mn≤2.0, Si≤1.0 | Tensile Strength: 520-720MPa, Yield Strength≥205MPa, Elongation≥40% | Good; resistant to atmosphere, fresh water, weak corrosive media | Food industry, medical equipment, decorative pipes |

| 1.4307 | AISI 304L / S30403 | C≤0.03, Cr18-20, Ni8-11, Mn≤2.0, Si≤1.0 | Tensile Strength: 480-680MPa, Yield Strength≥170MPa, Elongation≥40% | Better than 1.4301; resistant to intergranular corrosion | Chemical equipment, low-temperature pipelines, welded structures |

| 1.4828 | AISI 309S / S30908 | C≤0.08, Cr22-24, Ni12-15, Mn≤2.0, Si≤1.0 | Tensile Strength: 520-750MPa, Yield Strength≥205MPa, Elongation≥40% | Excellent high-temperature oxidation resistance, sulfur corrosion resistance | Furnace components, high-temperature flues, heat exchangers |

| 1.4841 | AISI 310S / S31008 | C≤0.08, Cr24-26, Ni19-22, Mn≤2.0, Si≤1.5 | Tensile Strength: 520-750MPa, Yield Strength≥205MPa, Elongation≥40% | Resistant to high-concentration oxidizing media; high high-temperature strength | High-temperature furnace tubes, incinerators, petrochemical cracking equipment |

| 1.4845 | — | C≤0.08, Cr23-26, Ni19-22, Si≤1.5, Nb+Ta≥10×C | Tensile Strength: 520-750MPa, Yield Strength≥205MPa, Elongation≥40% | Resistant to high-temperature creep and intergranular corrosion | Power plant boilers, high-temperature pressure vessels |

| 1.4466 | Duplex 2205 / S31803 | C≤0.03, Cr21-23, Ni4.5-6.5, Mo2.5-3.5, N0.14-0.20 | Tensile Strength: 690-895MPa, Yield Strength≥450MPa, Elongation≥25% | Excellent resistance to pitting, crevice corrosion, and stress corrosion | Seawater treatment, oil and gas extraction, chemical pipelines |

| 1.4401 | AISI 316 / S31600 | C≤0.08, Cr16-18.5, Ni10-14, Mo2-3, Mn≤2.0 | Tensile Strength: 520-720MPa, Yield Strength≥205MPa, Elongation≥40% | Resistant to acids, alkalis, salt spray; better than 304 series | Marine engineering, pharmaceutical equipment, printing and dyeing industry |

| 1.4404 | AISI 316L / S31603 | C≤0.03, Cr16-18.5, Ni10-14, Mo2-3, Mn≤2.0 | Tensile Strength: 480-680MPa, Yield Strength≥170MPa, Elongation≥40% | Resistant to intergranular corrosion; suitable for post-weld non-heat-treated scenarios | Chemical pipelines, seawater desalination, nuclear energy equipment |

| 1.4429 | — | C≤0.03, Cr19-21, Ni12-15, Mo4-5, N0.1-0.2 | Tensile Strength: 650-850MPa, Yield Strength≥280MPa, Elongation≥35% | High corrosion resistance; better pitting resistance than 316 | High-concentration chloride environments, sulfuric acid recovery equipment |

| 1.4571 | AISI 316Ti / S31635 | C≤0.08, Cr16-18.5, Ni10-14, Mo2-3, Ti≥5×C | Tensile Strength: 520-720MPa, Yield Strength≥205MPa, Elongation≥40% | Resistant to intergranular corrosion; good high-temperature stability | Heat exchangers, high-temperature chlorine-containing medium pipelines |

| 1.4449 | Duplex 2507 / S32750 | C≤0.03, Cr24-26, Ni6-8, Mo3-4, N0.24-0.32 | Tensile Strength: 800-1000MPa, Yield Strength≥550MPa, Elongation≥25% | Extremely high pitting resistance; resistant to stress corrosion cracking | Severe marine environments, high-concentration brine pipelines |

| 1.4438 | AISI 317L / S31703 | C≤0.03, Cr18-20, Ni11-15, Mo3-4, Mn≤2.0 | Tensile Strength: 480-680MPa, Yield Strength≥170MPa, Elongation≥40% | Resistant to high-concentration organic acids and salt solutions | Pharmaceutical fermentation equipment, printing and dyeing wastewater treatment |

| 1.4541 | AISI 321 / S32100 | C≤0.08, Cr17-19, Ni9-12, Ti≥5×C | Tensile Strength: 520-720MPa, Yield Strength≥205MPa, Elongation≥40% | Resistant to intergranular corrosion at high temperatures; oxidation resistance | Aerospace pipelines, high-temperature steam pipelines |

| 1.4878 | — | C≤0.10, Cr19-21, Ni30-35, Si≤1.5, Al1.0-1.5 | Tensile Strength: 550-750MPa, Yield Strength≥205MPa, Elongation≥40% | High-temperature oxidation resistance (up to 1100℃) | Furnace components, gas turbine parts |

| 1.4550 | — | C≤0.08, Cr16-18, Ni10-13, Ti5×C-0.7, Nb+Ta≤0.1 | Tensile Strength: 520-720MPa, Yield Strength≥205MPa, Elongation≥40% | Resistant to nitric acid corrosion; good high-temperature stability | Nitric acid production equipment, denitration system pipelines |

Selecting the right seamless steel pipe depends on understanding the differences between carbon steel, alloy steel, and stainless steel. Each type offers unique properties, making them suitable for specific DIN applications and environments. The chemical composition, mechanical strength, and corrosion resistance vary across these materials, directly impacting performance and longevity.

Carbon steel DIN seamless pipes remain the backbone of many industrial systems. Manufacturers rely on these pipes for their strength, affordability, and versatility.

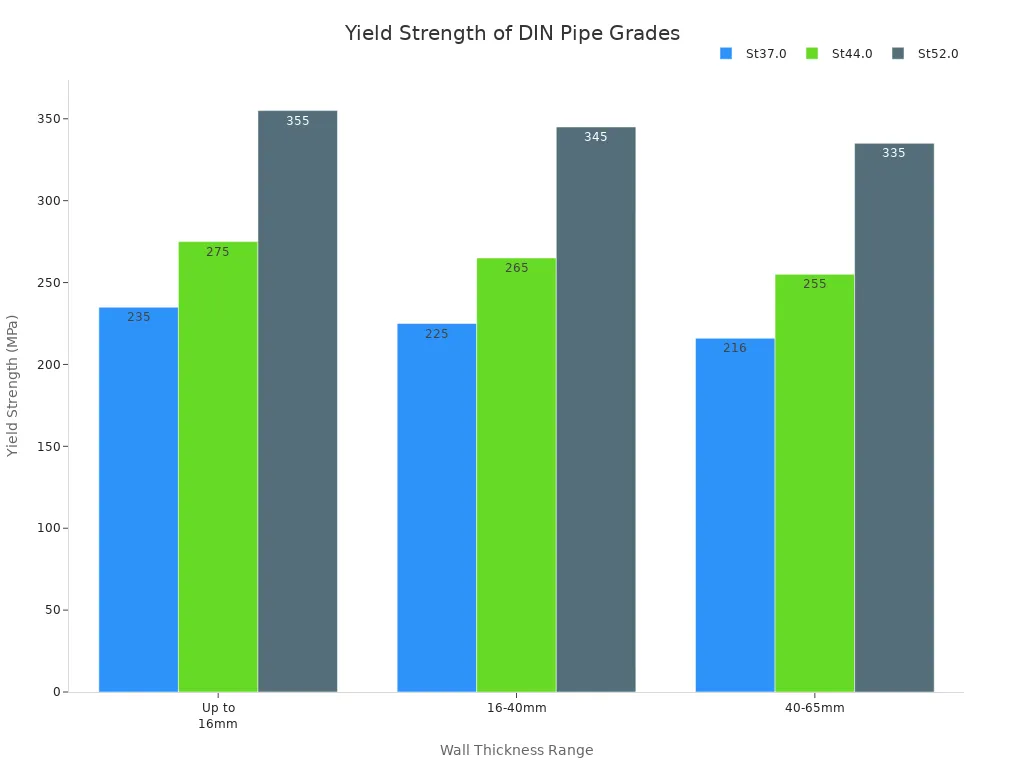

DIN standards specify several carbon steel grades for seamless pipes. The most common grades include ST37.0, ST44.0, ST52.0, and ST35. Each grade features distinct mechanical properties and carbon content, influencing its suitability for different applications.

| Grade | Carbon Content (%) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| ST37.0 | 0.17 | 235 | 350 to 480 | 25 |

| ST44.0 | 0.21 | 275 | 420 to 550 | 21 |

| ST52.0 | 0.22 | 355 | 500 to 650 | 21 |

| ST35 | ≤ 0.17 | 235 to 315 | 340 to 480 | 6 to 25 |

| ST52.4 | 0.12-0.20 | ≥320 | 490-670 | ≥21 |

Carbon steel pipes contain iron and carbon, with silicon and manganese in small amounts. Sulfur and phosphorus levels stay below 0.035% to ensure quality. The carbon content determines if the steel is low, medium, or high carbon, which affects strength and ductility.

DIN seamless carbon steel pipes serve a wide range of industries. Chemical plants, vessels, and mechanical engineering projects use these pipes for their mechanical strength and pressure resistance. Oil, water, and gas pipelines depend on carbon steel for reliable transport. Shipbuilding, aviation, and construction sectors also use these pipes for structural support and fluid conveyance. In high-temperature and high-pressure environments, such as boilers and heat exchangers, grades like 15Mo3 provide resistance up to 500°C. Seamless steel pipe for structure applications benefit from the balance of strength and ductility found in these grades.

Alloy steel DIN seamless pipes offer enhanced performance by incorporating additional alloying elements. These elements improve strength, toughness, and resistance to wear and corrosion.

DIN specifications cover several alloy steel grades, each designed for demanding environments. Common grades include P235GH, P265GH, and P355N. These grades meet strict requirements for mechanical properties, weldability, and suitability for high temperature and pressure.

| Steel Grade | Standard (Old/New) | Typical Application | Key Properties and Reasons for Specification |

|---|---|---|---|

| P235GH | DIN 17175 / EN 10216-2 | Boilers, pressure vessels, heat exchangers | Non-alloy, low carbon steel with good weldability and high mechanical properties; suitable for elevated temperature and pressure |

| P265GH | EN 10028 / EN 10216-2 | Pressure vessels, boilers, petrochemical industry | Weldable pressure vessel steel, designed for elevated temperature service, good mechanical strength |

| P355N | DIN 1629 / EN 10216-3 | High strength applications, pipelines | Alloy fine grain steel, normalized for strength and toughness, suitable for pressure applications |

Alloy steel pipes contain elements such as chromium, nickel, molybdenum, vanadium, and titanium. These elements enhance specific properties:

| Alloying Element | Effect on Performance |

|---|---|

| Chromium | Increases hardness, toughness, wear, and corrosion resistance |

| Nickel | Improves strength, toughness, and corrosion resistance |

| Molybdenum | Boosts high temperature strength and wear resistance |

| Manganese | Raises hardenability and shock resistance |

| Vanadium | Enhances strength and fatigue resistance |

| Silicon | Improves toughness and hardness |

| Titanium | Prevents chromium carbide precipitation |

Alloy steel DIN seamless pipes excel in high-temperature and high-pressure environments. Industries such as chemical, petrochemical, and power generation use these pipes for steam boilers, pressure vessels, and heater tubes. Grades like St35.8 and St45.8 perform well in boilers up to 500°C, while 13CrMo44 and 10CrMo910 handle ultra-high pressure and temperatures up to 650°C. These pipes transport gases and liquids where carbon steel has limitations. Seamless steel pipe for structure applications in extreme conditions benefit from the enhanced mechanical properties of alloy steel.

Used in high-temperature services such as heater tubes

Suitable for very high pressure services such as steam headers

Ideal for chemical, petrochemical, power generation, and oil refinery industries

Alloy composition (chrome-molybdenum) enhances corrosion resistance and oxidation resistance at elevated temperatures

Used where carbon steel has limitations, especially for transporting gases and liquids under extreme conditions

Stainless steel DIN seamless pipes stand out for their superior corrosion resistance and durability. These pipes contain significant amounts of chromium and nickel, which protect against oxidation and chemical attack.

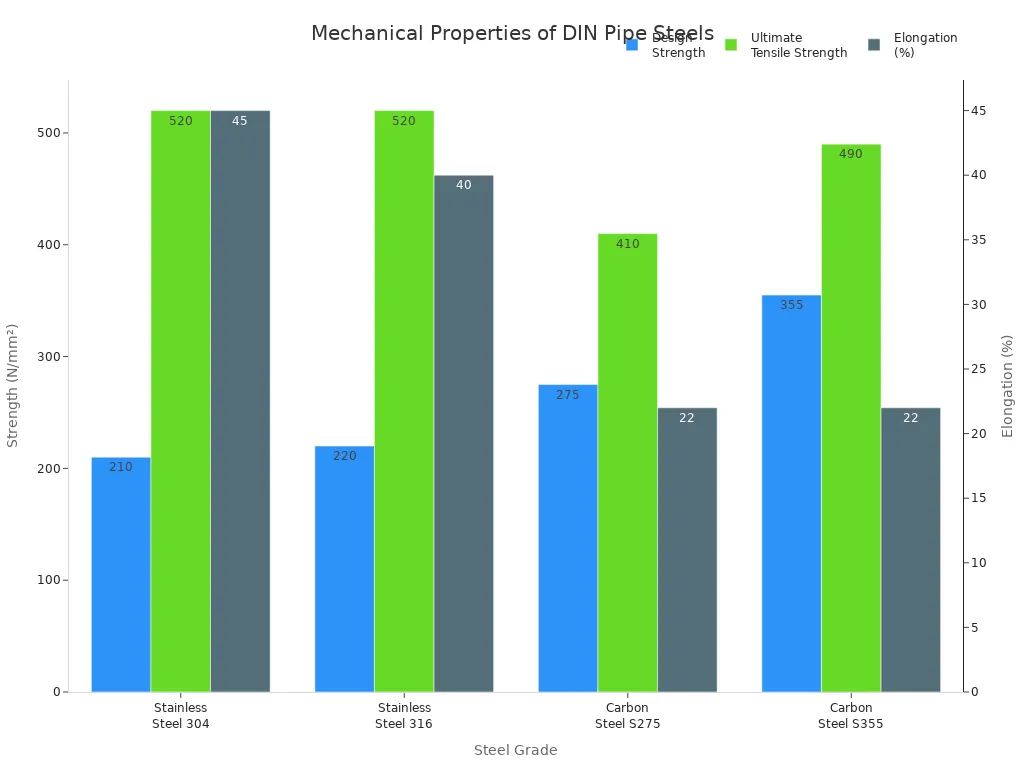

DIN seamless stainless steel pipes include austenitic, ferritic, and martensitic grades. Austenitic grades, such as 304 and 316, dominate industrial applications due to their ductility and corrosion resistance. Ferritic grades contain high chromium and little or no nickel, making them magnetic and suitable for less demanding environments. Martensitic grades, like 410 and 420, offer higher hardness but lower corrosion resistance.

| Steel Grade | Design Strength (N/mm²) | Ultimate Tensile Strength (N/mm²) | Young's Modulus (N/mm²) | Elongation (%) |

|---|---|---|---|---|

| Stainless Steel 304 | 210 | 520 | 200,000 | 45 |

| Stainless Steel 316 | 220 | 520 | 200,000 | 40 |

Note: Austenitic stainless steels have a face-centered cubic structure stabilized by nickel, manganese, and nitrogen. Ferritic grades have a body-centered cubic structure with high chromium content. Martensitic grades can be hardened by heat treatment and are magnetic.

Stainless steel DIN seamless pipes serve industries that demand high corrosion resistance and hygiene. Chemical and petrochemical plants use these pipes for handling acids, solvents, and process chemicals. The food and beverage sector relies on sanitary-grade pipes for transporting milk, juice, and water. Pharmaceutical and biotechnology companies require ultra-clean, sterile piping for sensitive fluids. Construction, water treatment, oil and gas, and power generation also depend on stainless steel pipes for their durability and resistance to harsh environments.

| Industry / Sector | Common Uses of Stainless Steel DIN Seamless Pipes |

|---|---|

| Chemical and Petrochemical | Handling highly corrosive fluids such as acids, solvents, and process chemicals; grades like 316L and 904L preferred for resistance |

| Food and Beverage | Transporting liquids (milk, juice, wine, water) with sanitary-grade pipes (304, 316 stainless steel) meeting FDA and 3-A standards |

| Pharmaceutical and Biotechnology | Ultra-clean, sterile piping for water for injection, clean steam, and sensitive fluids under strict sanitary conditions |

| Construction and Infrastructure | HVAC systems, fire sprinkler systems, plumbing, structural supports with corrosion resistance and long lifespan |

| Water Treatment and Desalination | Piping exposed to saltwater, chemicals, and high flow rates in municipal water treatment and desalination plants |

| Oil and Gas | Oil casing, tubing for offshore/onshore production, exploration, and processing; withstands corrosive environments and high pressure |

| Power Generation and Environment | Heat exchangers, reheaters, superheaters in power plants and waste incineration plants |

| Fertilizer Industry | High-pressure tubes and piping systems in melamine plants, urea synthesis, ethylene plants |

| Shipbuilding | Tubes for ship construction, e.g., stainless steel 304 pipes |

| Mechanical and Plant Engineering | Food manufacturing, automobile technology, measurement and control technology, pumps, hydraulic cylinders |

| Automotive Industry | Hydraulic braking systems and other automotive applications |

DIN seamless stainless steel pipes meet strict specifications for mechanical strength, corrosion resistance, and hygiene. These pipes ensure safe operation in critical applications where failure is not an option.

Hot rolling stands as the primary method for producing DIN seamless steel pipe with larger diameters and thicker walls. Manufacturers heat billets above the recrystallization temperature, often exceeding 1200°C. The billet then passes through a series of rollers, which shape and elongate the material into seamless pipes. This process destroys the original casting microstructure, refines the grain, and eliminates many microstructural defects. As a result, the steel gains improved mechanical properties, especially along the rolling direction.

| Aspect | Hot Rolling |

|---|---|

| Microstructure | Refined grain, denser steel, anisotropic |

| Dimensional Accuracy | Lower, less precise thickness and edge control |

| Surface Finish | Rougher, oxidized skin, more surface defects |

| Mechanical Behavior | High torsional stiffness, better torsion resistance |

| Applications | Fluid transport, mechanical structures |

Hot-rolled seamless steel pipe often contains residual stresses due to uneven cooling. These stresses can affect deformation, stability, and fatigue resistance. Despite these factors, hot-rolled pipes remain cost-effective for applications where dimensional precision is less critical. DIN standards ensure that these pipes meet strict requirements for strength and durability.

Cold drawn manufacturing produces DIN seamless pipes with smaller diameters and thinner walls. The process begins with a hot-rolled seamless steel pipe billet. After annealing and surface cleaning, the billet passes through a die at room temperature. This method enhances dimensional accuracy and surface finish, resulting in seamless pipes with uniform wall thickness and tight tolerances.

| Feature | Cold Drawing |

|---|---|

| Surface Finish | Smoother, brighter, high-quality |

| Dimensional Range | Smaller diameters, thinner walls |

| Dimensional Accuracy | High, with uniform wall thickness |

| Mechanical Properties | Improved by grain refinement |

| Applications | Precision instruments, hydraulics, pneumatics |

Cold drawn seamless pipes exhibit smaller residual stresses and better surface quality than hot-rolled pipes. These pipes suit applications that demand high accuracy, such as hydraulic systems and precision instruments. The process, however, increases production costs due to additional steps.

DIN seamless steel pipe often receives specialized coatings to enhance performance and extend service life. Coatings protect pipes from corrosion, abrasion, and chemical attack, especially in harsh environments.

| Coating Type | Description | Performance Benefits |

|---|---|---|

| Epoxy Coatings | Powder-applied, forms hard, durable layer | Excellent corrosion and chemical resistance; smooths interior surface for improved fluid flow |

| Polyethylene (PE) Coatings | Flexible, impact-resistant barrier | Shields against moisture, oxygen, and mechanical damage; UV resistant; ideal for buried pipelines |

| Fusion Bonded Epoxy (FBE) | Epoxy fused at high temperature | Strong bond, resists cracking and peeling; suitable for offshore and abrasive environments |

| Zinc Coatings | Hot-dip galvanizing forms metallurgical bond | Sacrificial corrosion protection; cost-effective; long-term durability |

| Ceramic Coatings | Ceramic materials provide hardness and wear resistance | Exceptional abrasion and erosion resistance; thermal stability for high-velocity flows |

Manufacturers select coatings based on the intended application of the seamless steel pipe. For underground or offshore DIN pipes, fusion bonded epoxy or three-layer polyethylene coatings offer superior protection. Zinc coatings remain popular in construction for their cost-effectiveness and sacrificial protection. Ceramic coatings serve mining and power generation, where abrasion resistance is critical.

Tip: Choosing the right coating for DIN seamless pipes ensures long-term performance and reduces maintenance costs in demanding environments.

DIN seamless pipes deliver consistent mechanical strength, meeting strict requirements for industrial applications. Manufacturers design each seamless steel pipe to withstand high pressure and mechanical loads. The mechanical properties depend on the steel grade and the manufacturing process. For example, seamless steel pipe for fluid transportation must meet specific quality requirements for yield strength, tensile strength, and elongation. The table below compares typical values for common DIN grades:

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| St35.8 | ≥235 | 360 - 480 | ≥25 |

| St45.8 | ≥255 | 410 - 530 | ≥21 |

| 15Mo3 | ≥270 | 450 - 600 | ≥20 |

| 13CrMo44 | ≥290 | 440 - 590 | ≥20 |

| 10CrMo910 | ≥280 | 450 - 600 | ≥18 |

Testing ensures that each seamless steel pipe meets the mechanical requirements for its intended use. Quality requirements include strict dimensional tolerances and surface finish. The grouped bar chart below illustrates how yield strength varies by grade and thickness for DIN pipes:

Seamless steel pipe for petroleum cracking and other high-pressure applications must pass rigorous testing to confirm mechanical strength and durability.

Corrosion resistance is a critical factor in selecting DIN seamless pipes, especially for water, gas, and chemical transport. Stainless steel DIN pipes offer the highest corrosion resistance due to their chromium content, which forms a protective oxide layer. This feature makes them ideal for seamless steel pipe for fluid transportation in aggressive environments. Alloy steel pipes provide better corrosion resistance than carbon steel pipes, but they do not match the performance of stainless steel. Carbon steel pipes have the lowest corrosion resistance and require coatings or linings to meet quality requirements in harsh conditions.

| Pipe Type | Key Alloying Elements | Corrosion Resistance Characteristics |

|---|---|---|

| Stainless Steel | Chromium (≥10.5%-13%), Nickel, Molybdenum | Forms a protective oxide layer; excellent corrosion resistance; varies by stainless steel type; generally superior corrosion resistance |

| Alloy Steel | Chromium, Nickel (less than stainless steel) | Better corrosion resistance than carbon steel due to alloying elements; does not match stainless steel corrosion resistance |

| Carbon Steel | Mainly Iron and Carbon, minimal alloying elements | Lowest corrosion resistance; prone to rust and corrosion in harsh environments |

Testing for corrosion resistance forms part of the quality requirements for DIN seamless pipes. Water and gas pipelines, as well as chemical processing systems, depend on the right material choice to prevent leaks and maintain system integrity.

Pressure ratings define the maximum pressure that DIN seamless pipes can safely handle. Manufacturers determine these ratings through testing and by following DIN requirements for wall thickness, diameter, and material grade. Seamless pipes excel in high-pressure environments because they lack weld seams, which are common failure points. Each seamless steel pipe undergoes hydrostatic testing to verify its pressure resistance. Quality requirements specify the minimum burst pressure and safety factors for each application.

Water supply systems require pipes with high pressure ratings to prevent leaks and bursts.

Gas transmission lines use seamless pipes that meet strict pressure and quality requirements.

Industrial steam and process lines rely on seamless steel pipe for fluid transportation, where pressure and temperature fluctuate.

Tip: Always match the pressure rating of the DIN seamless pipe to the system’s maximum operating pressure. Consult manufacturer data sheets and testing results to ensure compliance with all requirements.

DIN seamless pipes provide reliable performance in water, gas, and industrial systems by meeting mechanical strength, corrosion resistance, and pressure requirements. Testing and strict quality requirements guarantee that each pipe delivers safe and long-lasting service.

Selecting the right DIN seamless pipes and fittings requires a systematic approach. Engineers and buyers must evaluate several factors to ensure the chosen pipes and fittings meet all operational, mechanical, and environmental requirements. The following checklist outlines the essential criteria:

Material Grade: Choose the appropriate steel grade based on the application. For example, ASTM A106 Grade B suits high-pressure and high-temperature systems. Stainless steel grades like 304 or 316 are ideal for corrosive environments.

Pipe Size and Wall Thickness: Match the pipe diameter and wall thickness to the system’s pressure and flow requirements. Thicker walls handle higher pressure and provide added durability.

Corrosion Allowance: Assess the environment for corrosive elements such as chemicals or saltwater. Select pipes and fittings with suitable coatings or materials to ensure long-term performance.

Temperature and Pressure Ratings: Confirm that the pipes and fittings meet the maximum operating temperature and pressure of the system. Hot-rolled seamless pipes (EN 10210) are recommended for harsh, high-pressure environments.

Compliance with Standards: Verify that all pipes and fittings comply with DIN 2448, ISO, ASTM, API, and other relevant standards. This ensures compatibility and safety.

Mechanical Properties: Evaluate strength, ductility, and toughness. Different steel grades, such as St 37.4, St 44.4, and St 52.4, offer varying tensile strength and elongation.

Fluid Characteristics: Consider the type of fluid—whether it is water, gas, oil, or a corrosive chemical. The fluid’s properties influence material selection and pressure requirements.

End Connections: Select the appropriate connection type, such as welded, flanged, or threaded, to match the system’s fittings and installation needs.

Cost-Effectiveness: Balance performance, durability, and cost. Welded pipes may suffice for less demanding applications, while seamless pipes offer superior strength for high-pressure systems.

Testing and Certification: Ensure the pipes and fittings have passed all required inspections, including dimensional checks, tensile and impact tests, hardness tests, and hydrostatic pressure tests.

Tip: Always consult with manufacturers to confirm that the selected pipes and fittings meet all project-specific requirements and testing protocols.

DIN seamless pipes and fittings serve a wide range of industries, each with unique requirements and specifications. The table below summarizes how different materials and models fit various application scenarios:

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Carbon Steel (ASTM) | Oil/gas pipelines, boiler systems |

| Certification | RoHS Certified | Compliance-driven manufacturing projects |

| Finish | Galvanized | Corrosion-prone marine or chemical sites |

| Grade Range | Q195-Q345 | Structural supports, high-pressure lines |

| Tolerance | ±1% | Precision-fitting industrial assemblies |

| Standards | DIN 2448, ASTM, JIS, GB | Global infrastructure projects |

| Surface Treatment | Cold Rolled & Galvanized | Smooth-surface applications (e.g., HVAC) |

Stainless steel seamless pipes and fittings, such as grades 304, 316, and 321, excel in industries that demand superior corrosion and heat resistance. These pipes and fittings are common in petroleum, oil and gas transport, and chemical processing plants. Their resistance to chemical corrosion ensures system integrity and safety. Power generation facilities use these pipes and fittings for high-temperature steam lines and feed water systems. The food and beverage industry values their sanitary properties, while pharmaceutical manufacturing relies on their purity and corrosion resistance. Automotive manufacturers use these pipes and fittings in exhaust, fuel, and hydraulic systems.

Hot-rolled seamless pipes and fittings, produced by advanced mills, offer high precision and uniform wall thickness. These pipes and fittings are versatile, serving low and medium pressure boiler systems, high-pressure boiler applications, petroleum cracking, and structural support. Their adaptability makes them suitable for demanding environments such as oil and gas pipelines, chemical plants, and power stations.

Note: Always match the pipe and fittings material and model to the specific requirements of the application, considering pressure, temperature, and environmental exposure.

Leading manufacturers provide valuable guidance for selecting DIN seamless pipes and fittings. Their advice focuses on matching the steel type and grade to the project’s demands, balancing performance, durability, corrosion resistance, and cost. The table below summarizes manufacturer recommendations:

| Steel Type | Key Properties | Typical Applications | Manufacturer Advice Summary |

|---|---|---|---|

| Carbon Steel | Strong, durable, cost-effective | Oil & gas transmission, water pipelines, structural | Recommended for high-pressure and industrial uses where strength and cost-efficiency are priorities. |

| Alloy Steel | Enhanced with chromium, molybdenum, nickel; high strength, heat and corrosion resistance | Power plants, refineries, chemical processing | Preferred for demanding environments requiring high strength, temperature resistance, and corrosion resistance. |

| Stainless Steel | Superior corrosion resistance, hygienic, durable | Food & beverage, pharmaceuticals, water treatment, marine | Advised for applications needing corrosion resistance and hygiene; also durable in harsh environments. |

| Seamless Pipes | Uniform structure, superior strength | High-pressure and extreme condition applications | Favored for high-pressure scenarios due to strength and reliability. |

Manufacturers recommend the following steps for optimal product selection:

Research potential suppliers through official websites, industry forums, trade shows, and referrals.

Evaluate manufacturers based on quality assurance, technical expertise, reputation, pricing, and customer service.

Consider environmental and application-specific factors to ensure the pipes and fittings meet operational and longevity requirements.

Communicate clearly with manufacturers to obtain customized solutions tailored to project needs.

Select suppliers who provide comprehensive product information, timely delivery, and reliable after-sales support.

Compare shortlisted manufacturers for long-term partnership potential.

Buyers should assess environmental considerations such as exposure to corrosive elements, temperature extremes, and abrasive conditions. Verifying compliance with industry standards, obtaining certifications, and consulting industry experts are essential steps. Manufacturers with advanced technology, a comprehensive product range, and value-added services such as pipe threading, coating, and supply chain management offer significant advantages.

For reliable DIN seamless pipes and fittings, reputable suppliers like xtd-stainless.com provide technical consulting, rigorous quality assurance, and tailored solutions. Their expertise ensures that all requirements and specifications are met for water, gas, and high-pressure applications.

Manufacturers of DIN seamless pipes and fittings maintain strict quality control at every stage of production. They start by sourcing high-quality raw materials from approved suppliers. Skilled professionals use modern technology to shape and finish the pipes and fittings. Each batch undergoes comprehensive material testing, including chemical analysis, mechanical strength checks, hardness evaluation, and corrosion resistance assessment.

Dimensional testing ensures that outside diameter, wall thickness, and length meet DIN requirements.

Surface inspections use visual checks and non-destructive methods like liquid penetrant and magnetic particle testing.

Mechanical testing, such as tensile and Charpy impact tests, confirms that pipes and fittings meet strength and ductility standards.

Hydrostatic testing and ultrasonic or radiographic testing detect leaks or internal flaws.

Multi-stage inspections cover material intake, in-process checks, and final product review.

Manufacturers provide detailed documentation, including mill test certificates, traceability reports, and inspection records.

Clear marking and identification of pipes and fittings support traceability and auditing.

Note: Effective packaging protects pipes and fittings during shipment, ensuring they arrive in perfect condition.

Many buyers overlook key factors when selecting DIN seamless pipes and fittings. These mistakes can lead to system failures or costly replacements.

Ignoring the importance of matching material grade to application requirements often results in premature corrosion or mechanical failure.

Failing to verify compliance with DIN standards and quality requirements can cause compatibility issues with existing systems.

Skipping thorough testing or relying on incomplete documentation increases the risk of undetected defects.

Overlooking the need for proper coatings or surface treatments exposes pipes and fittings to environmental damage.

Neglecting to consult manufacturers about specific requirements may result in selecting fittings that do not meet pressure or temperature demands.

Manufacturers recommend that buyers always review documentation, confirm testing results, and ensure all pipes and fittings meet the necessary requirements for their intended use.

XTD Stainless stands out among DIN seamless pipe and fittings suppliers. The company offers a wide range of products, including austenitic, duplex stainless steel, and nickel alloy pipes and fittings. Duplex fittings provide up to double the strength of standard grades, making them ideal for high-pressure and extreme temperature applications.

XTD Stainless uses rigorous quality assurance processes, such as certified weld inspections, ultrasonic and radiographic testing, and surface finish checks. The company complies with international standards like ASTM, ASME, and ISO, providing mill test certificates and detailed inspection reports for every order.

Customers benefit from responsive technical support, customization options, reliable delivery, and after-sales service. XTD Stainless holds ISO 9001 certification and employs an experienced engineering team. Positive feedback highlights consistent product quality, dependable delivery, and expert guidance during product selection. The company balances price, quality, and service, making it a trusted partner for critical projects in oil and gas, petrochemical, marine, and nuclear power industries.

Tip: Choosing a supplier with strong quality control, comprehensive documentation, and technical expertise ensures that DIN seamless pipes and fittings meet all requirements for safety and performance.

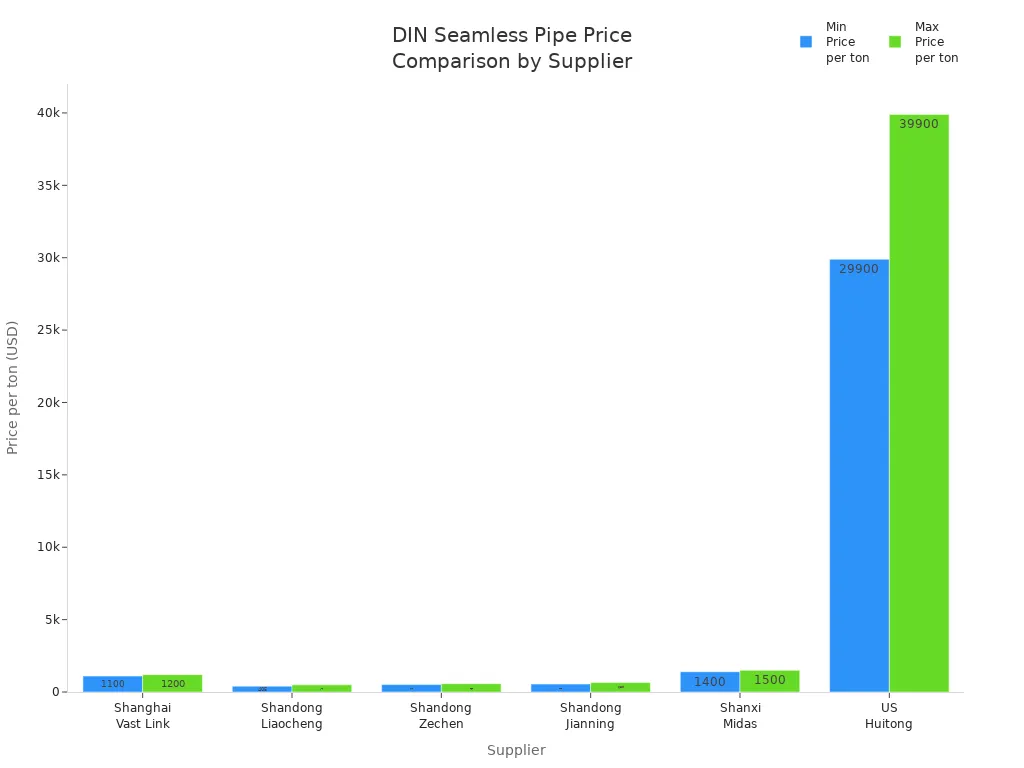

Selecting the right DIN seamless pipes requires careful comparison of models, materials, and supplier reliability. The table below highlights key supplier differences, including product focus and price range:

| Supplier | Product Focus | Price Range (per ton) | MOQ | Key Attributes |

|---|---|---|---|---|

| Shanghai Vast Link Industrial | ASTM A106 Gr.B seamless pipe for high-temp service | $1,100 - $1,200 | 10 tons | Established supplier, high reliability, standard compliance |

| Shandong Liaocheng Jiuyang | General high-strength seamless steel pipe | $405 - $495 | 25 tons | Very competitive pricing, high buyer satisfaction |

| Shandong Zechen Xinghua | Pre-insulated API 5L Gr.B seamless pipe | $512 - $568 | 5 tons | Most competitive price at volume, PU foam insulation |

| Shandong Jianning Metals | Alloy steel seamless pipes (15CrMoG, 12Cr1MoVG) | $550 - $650 | 10 tons | High-temp, high-pressure boiler and heat exchanger pipes |

| Shanxi Midas Industrial | High-temp seamless pipes for solar thermal power | $1,400 - $1,500 | 100 tons | Specialized for solar thermal power applications |

| US Huitong Pipeline | Thermally expanded seamless pipes | ~$29,900 - $39,900 per ton equivalent | 100 kg | Small MOQ, suitable for prototyping, higher cost |

Matching DIN pipe selection to application needs ensures long-term safety and performance. Buyers should always verify specifications, inspect surfaces, and request proper documentation. Consulting trusted suppliers like https://www.xtd-stainless.com/ helps guarantee that DIN pipes meet all project requirements.

DIN seamless pipes offer higher strength and better pressure resistance. Manufacturers produce these pipes without weld seams, which reduces the risk of leaks or failures. Many industries choose seamless pipes for critical applications that demand reliability and safety.

Manufacturers use hydrostatic, ultrasonic, and radiographic tests to check pipes for defects. They also perform dimensional checks and mechanical property tests. These steps ensure that pipes meet strict DIN standards and deliver consistent performance in demanding environments.

Industries such as oil and gas, power generation, chemical processing, and construction rely on DIN seamless pipes. These pipes handle high pressure, temperature, and corrosive fluids. Many manufacturers supply pipes for both industrial and infrastructure projects.

Yes, DIN seamless pipes suit both gas and water transport. Their strength and corrosion resistance make them ideal for pipelines carrying fluids under pressure. Proper material selection ensures long service life and system safety.

Manufacturers offer epoxy, polyethylene, fusion bonded epoxy, zinc, and ceramic coatings for DIN seamless pipes. Each coating type protects pipes from corrosion, abrasion, or chemical attack. The choice depends on the application and environmental conditions.

Buyers should consider material grade, pipe size, pressure rating, and application environment. Consulting with manufacturers helps match pipes to specific project needs. Reviewing certifications and test reports ensures compliance with industry standards.

Yes, manufacturers can produce DIN seamless pipes in custom diameters and wall thicknesses. Customization allows pipes to fit unique system requirements. Buyers should provide detailed specifications when requesting custom pipes.