close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-12 Origin: Site

When you buy a 2 stainless steel pipe, you need to focus on how well it matches your project’s needs. The right pipe grade, wall thickness, and corrosion resistance all play a role in how long your pipes last. For example, thicker walls increase strength and help the pipe handle higher pressure. Pipes with high corrosion resistance work better in tough environments. Reliable suppliers give you pipes that meet safety standards, such as ASTM A312, so you get consistent quality.

Choosing the correct pipe means you avoid early failures and costly repairs.

Choose the right stainless steel grade to match your project’s environment and needs for strength and corrosion resistance.

Select pipe wall thickness and schedule based on pressure requirements; thicker walls handle higher pressure but reduce flow.

Decide between seamless and welded pipes by balancing cost, strength, and application demands.

Check that pipes meet recognized standards and certifications to ensure quality and safety.

Consider surface finish carefully, as smoother finishes improve corrosion resistance and ease of cleaning.

Buy from reputable suppliers who provide full documentation and quality assurance to avoid counterfeit or poor-quality pipes.

Balance initial cost with long-term value; investing in quality pipes reduces maintenance and replacement expenses over time.

You will find that a 2 stainless steel pipe serves many industries because of its strength and reliability. The table below shows where you might use these pipes and why they work so well in each setting:

Industry | Common Applications and Reasons for Using 2-inch Stainless Steel Pipes |

|---|---|

Chemical Processing | Transporting hazardous chemicals; corrosion resistance and chemical stability |

Oil and Gas | Pipelines and equipment for high pressures and temperatures; corrosion resistance |

Food and Beverage | Hygienic transport of liquids; resistance to bacteria; easy cleaning |

Water and Wastewater | Moving clean and wastewater; resistance to chlorine and chemicals; durability |

Construction and Architecture | Structural support, building frames, handrails; corrosion and weather resistance |

Automotive and Transportation | Exhaust systems, fuel and brake lines; withstands high temperatures and pressures |

Shipbuilding | Space and weight considerations; corrosion resistance in marine environments |

Power and Utilities | Reliable materials for uninterrupted service; durability and corrosion resistance |

Pharmaceutical | Hygiene, corrosion resistance, and compliance with strict standards |

You can see that these pipes play a vital role in moving fluids, supporting structures, and meeting hygiene standards. In each industry, the pipe must handle specific challenges, such as high pressure, harsh chemicals, or strict cleanliness.

When you choose a 2 stainless steel pipe, you gain several important advantages over other materials:

You get superior corrosion resistance. The chromium oxide layer on the pipe surface repairs itself, so the pipe lasts longer in tough environments.

You save money over time. Even though the initial cost may be higher, you spend less on maintenance, repairs, and replacements.

You benefit from high thermal conductivity. The pipe helps regulate temperature in industrial systems, making it ideal for heat transfer.

You enjoy versatility. You can use these pipes in oil and gas, food processing, construction, and even residential plumbing.

You install pipes with ease. The smooth surface and consistent quality reduce downtime and speed up installation.

You rely on strength and durability. The pipe stands up to high pressure, extreme temperatures, and heavy use.

You meet hygiene needs. The smooth surface resists bacteria and cleans easily, which is essential for food, beverage, and pharmaceutical uses.

You support the environment. Stainless steel pipes are 100% recyclable and non-toxic.

Tip: Always match the pipe’s benefits to your project’s needs. This ensures you get the best performance and value from your investment.

When you start selecting the right pipe material, you need to match the grade to your environment and use. The right choice ensures your pipe stands up to the demands of your project, whether you handle high-pressure fluids, need clean drinking water, or require pipes for fluid handling operations in harsh conditions. You have several pipe material options, each with unique properties that affect strength, corrosion resistance, and durability.

Austenitic stainless steel is the most common group used for 2-inch pipes. You find these grades in many industries because they combine strength, corrosion resistance, and easy fabrication. Austenitic grades contain high levels of chromium and nickel, which help the pipe resist rust and chemical attack. These grades work well for water supply, food processing, and high-pressure fluids.

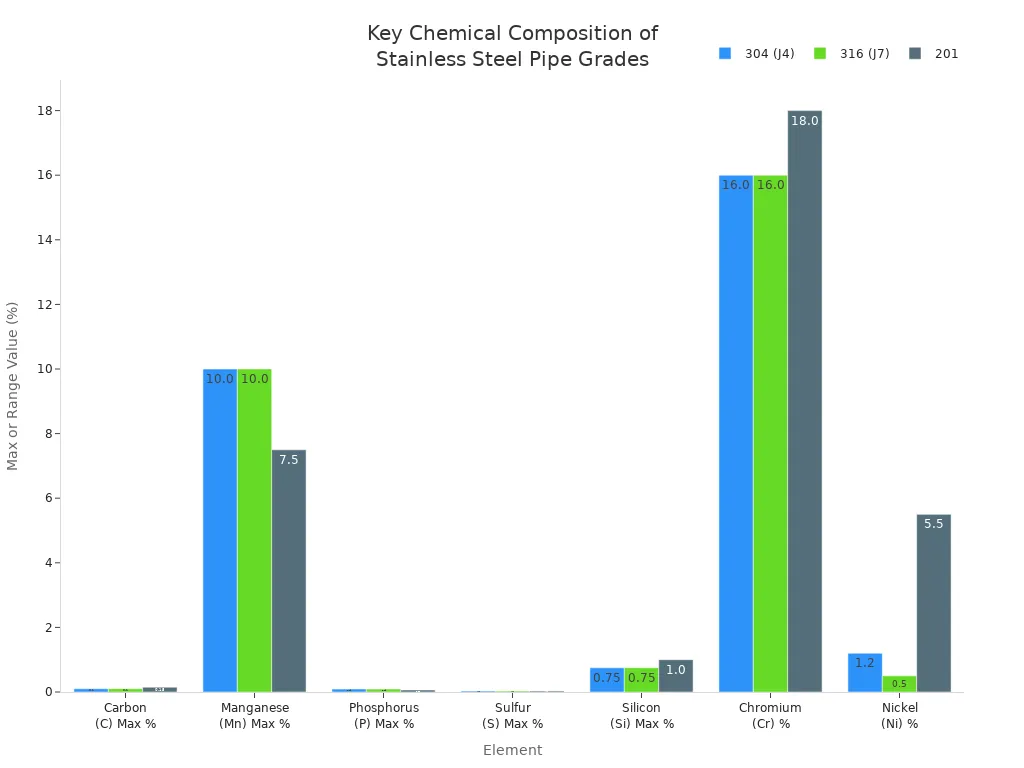

You often choose between 304 and 316 stainless steel for your pipe. Both grades belong to the austenitic family, but they have different chemical compositions and uses. The table below shows the main elements in each grade:

Stainless Steel Grade | Carbon (C) Max % | Manganese (Mn) Max % | Phosphorus (P) Max % | Sulfur (S) Max % | Silicon (Si) Max % | Chromium (Cr) % | Nickel (Ni) % | Molybdenum (Mo) % | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

304 (J4) | 0.1 | 8.5 - 10.0 | 0.09 | 0.03 | 0.75 | 15.0 - 16.0 | 0.8 - 1.2 | - | - |

316 (J7) | 0.1 | 8.5 - 10.0 | 0.09 | 0.03 | 0.75 | 15.0 - 16.0 | 0.25 - 0.5 | - | - |

201 | 0.15 | 5.5 - 7.5 | 0.06 | 0.03 | 1.0 | 16.0 - 18.0 | 3.5 - 5.5 | - | Nitrogen 0.25 |

304 stainless steel works well for most general uses. It resists corrosion from water, air, and many chemicals. You can use it for clean drinking water, food processing, and indoor fluid handling operations. 316 stainless steel contains more nickel and adds molybdenum, which boosts resistance to chlorides and harsh chemicals. You should select 316 for marine environments, chemical plants, or any place where the pipe faces saltwater or aggressive fluids. Both grades offer good strength and handle high-pressure fluids, but 316 gives you extra protection in tough settings.

201 stainless steel gives you a lower-cost option. It contains less nickel and more manganese and nitrogen. This grade works for light-duty applications where corrosion risk is low. You might use 201 for decorative pipes, handrails, or indoor structures. However, it does not match the corrosion resistance or strength of 304 or 316. If your project involves high-pressure fluids or harsh chemicals, you should avoid 201 and choose a higher grade.

Selecting the right pipe material means you must consider where and how you will use the pipe. Each environment places different demands on the pipe, so you need to match the grade to the job.

For marine environments, 316L stainless steel is the minimum grade you should use. It resists chloride-induced corrosion from seawater and salt spray. Super austenitic and super duplex stainless steels provide even higher resistance for submerged or splash zone applications.

In food processing, 304 and 316 stainless steels are ideal. They offer smooth, easy-to-clean surfaces and resist acids, alkalis, and frequent washings. These grades keep your pipes safe for food and water supply.

For industrial settings, you may need pipes that handle high-pressure fluids, steam, or chemicals. 316 and duplex grades resist cracking and corrosion in aggressive environments.

Tip: Always check the chemical compatibility of your pipe with the fluids or gases you plan to transport. Some chemicals or high temperatures can damage certain grades.

You also need to think about temperature. 316 and 316L grades work well in high-temperature pipe materials, handling temperatures from -425°F to 1,200°F. Above 800°F, some stainless steels may suffer from intergranular corrosion, so you must select stabilized grades like 321 or 347 for very hot systems. The pipe schedule, or wall thickness, affects how much pressure the pipe can handle. Thicker pipes (like Schedule 80) work better for high-pressure fluids and corrosive media.

When you select fittings, always use stainless steel fittings with stainless steel pipes. This prevents leaks and keeps your system strong. If you handle gases, make sure you avoid damage to the pipe ends, as this can affect sealing and safety.

Note: The right combination of grade, wall thickness, and fittings ensures your pipes deliver durability, strength, and safety for any application.

When you select a 2-inch stainless steel pipe, you need to know the exact measurements. The nominal size refers to the pipe’s name, but the actual outside diameter is slightly larger. For a 2-inch pipe, the outside diameter measures 2.375 inches. Wall thickness varies based on the pipe schedule. The schedule tells you how thick the pipe wall is, which affects both strength and pressure rating.

Here is a table showing the standard outside diameter and wall thickness for 2-inch stainless steel pipes:

Nominal Pipe Size (inches) | Outside Diameter (inches) | Wall Thickness (inches) |

|---|---|---|

2 | 2.375 | 0.065 (Schedule 40) |

2 | 2.375 | 0.109 (Schedule 40S) |

You will see that the wall thickness changes with the schedule. This difference impacts how much pressure the pipe can handle and how well it performs in fluid handling operations.

You often choose between Schedule 40 and Schedule 80 pipes. Schedule 40 pipes have a wall thickness of about 0.109 inches for a 2-inch size. Schedule 80 pipes have a thicker wall, around 0.154 inches. This extra thickness gives Schedule 80 pipes more strength and makes them better for high-pressure fluids. The thicker wall also means the inner diameter is smaller, which can affect flow rates in your system.

Schedule 40 pipes work well for general fluid handling operations and lower pressure needs. You might use them in residential plumbing or light industrial settings. Schedule 80 pipes are the right choice when you need to move high-pressure fluids or when your system faces heavy loads. The added strength helps prevent leaks and failures in demanding environments.

Tip: Always match the pipe schedule to your application. If you expect high pressure or heavy use, choose Schedule 80 for extra safety.

You should always check that your pipe meets recognized standards and certifications. These standards ensure your pipes have the right strength, pressure rating, and quality for your project. Many organizations set these standards, and you will find several important ones for 2-inch stainless steel pipes:

ASTM International (American Society for Testing and Materials)

ASME (American Society of Mechanical Engineers)

ANSI (American National Standards Institute)

ISO (International Organization for Standardization)

NSF (Public Health and Safety Organization)

DVGW Certification (European requirements for press fittings and pipes)

TÜV Certification (Independent safety and quality testing)

NACE International (Corrosion Engineering)

API (American Petroleum Institute)

AISI (American Iron and Steel Institute)

Some pipes also carry certifications like ISO 9001 for quality management, ISO 14001 for environmental management, and CE/PED for European market compliance. These certifications show that your pipe meets strict requirements for safety, performance, and reliability.

Note: Always ask your supplier for documentation on standards and certifications. This step protects your investment and ensures your pipe will perform as expected.

When you choose seamless pipes, you get a product made from a solid round billet. Manufacturers use processes like perforation, cold rolling, cold drawing, or hot extrusion to form the pipe. This method creates pipes without any weld seams. The result is a pipe with a smooth interior and exterior surface. You often see seamless pipes used in high-pressure or high-reliability applications. The absence of a weld seam means there are fewer weak points, so the pipe can handle more stress and pressure.

Seamless pipes usually cost more because the manufacturing process is complex. You may also notice that seamless pipes come in a more limited size range, especially for larger diameters. However, if your project requires high strength and durability, seamless pipes offer a reliable choice.

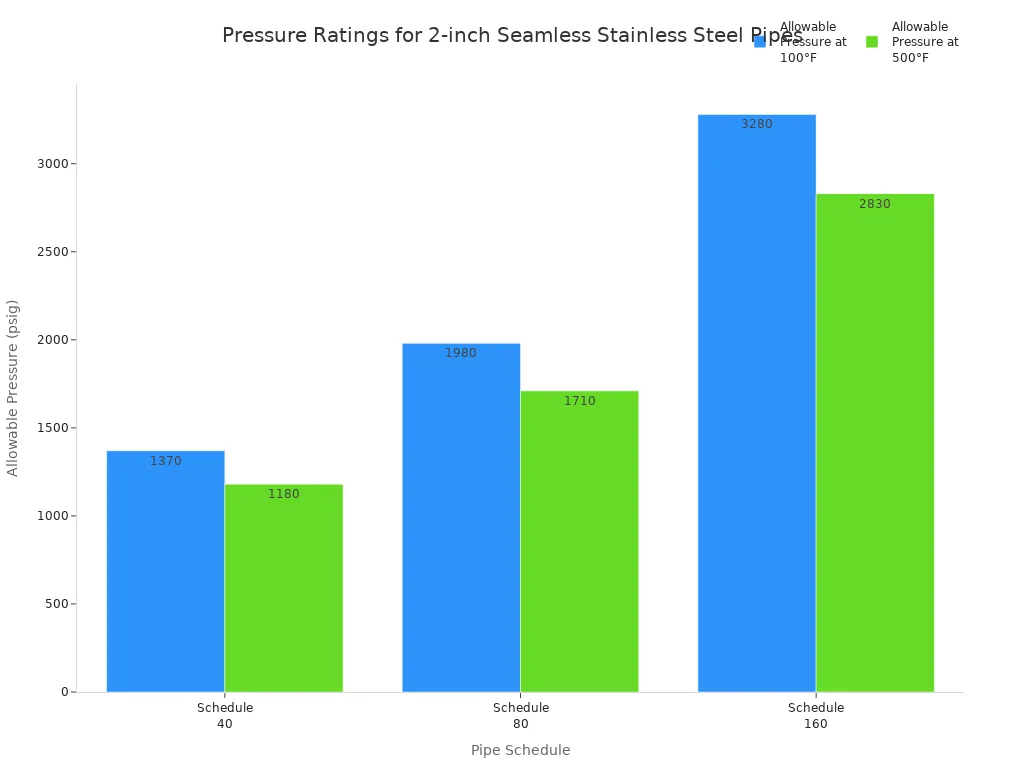

The pressure ratings for seamless 2-inch stainless steel pipes are impressive. The table below shows typical allowable pressure ratings at different wall thicknesses and temperatures:

Pipe Schedule | Wall Thickness (in) | Allowable Pressure (psig) at 100°F | Allowable Pressure (psig) at 500°F |

|---|---|---|---|

40 | 0.154 | ~1370 | ~1180 |

80 | 0.218 | ~1980 | ~1710 |

160 | 0.344 | ~3280 | ~2830 |

Welded pipes are made by curling flat steel plates or strips into a round shape and then welding the edges together. This process leaves a visible weld seam, usually on the inside of the pipe. Welded pipes are easier and faster to produce than seamless pipes. You can find welded pipes in a wide range of sizes, including larger diameters and thinner walls.

You often select welded pipes for projects where cost and availability matter most. The manufacturing process is less expensive, so welded pipes usually cost less than seamless pipes. These pipes work well for many general applications, but the weld seam can be a weak point. Over time, the seam may become a spot where stress or corrosion starts.

Welded pipes are a good choice for low to medium pressure systems, structural uses, or when you need a large quantity of pipe quickly.

You should compare seamless and welded pipes carefully before making your decision. Each type has its own strengths and weaknesses.

Feature | Seamless Pipes | Welded Pipes |

|---|---|---|

Cost | Higher due to complex manufacturing | More affordable and cost-efficient |

Strength | Superior strength, no weak seams | Adequate strength, seams are weak points |

Size Availability | Limited to smaller diameters, thicker walls | Wide range including larger diameters, thinner walls |

Seamless Pipes Advantages:

Higher strength and durability because there are no weld seams.

Smoother interior surface helps reduce contamination risk.

No welding defects, so you get better reliability for critical uses.

Seamless Pipes Disadvantages:

Higher cost due to complex manufacturing.

Limited size range, especially for larger diameters.

Longer lead times for delivery.

Welded Pipes Advantages:

Lower cost, which helps you stay within budget.

Available in many sizes, including large diameters.

Faster manufacturing and delivery times.

Welded Pipes Disadvantages:

Weld seams can weaken the pipe over time.

Seams may become stress points.

Rougher interior surface can increase contamination risk.

Tip: If your project involves high pressure, critical fluids, or harsh environments, seamless pipes offer better safety and performance. For general construction or low-pressure systems, welded pipes provide a cost-effective and flexible solution.

You need to understand what affects the corrosion resistance of your 2-inch stainless steel pipe. Many environmental factors can change how well your pipe stands up to corrosion. The table below shows the most important factors and their effects:

Environmental Factor | Effect on Corrosion Resistance of 2-inch Stainless Steel Pipes |

|---|---|

Chloride Concentration | High chloride levels, especially near marine environments, cause pitting and crevice corrosion. Stainless steels with molybdenum show better resistance. |

pH and Oxygen in Fresh Water | Corrosion depends on pH and oxygen content; soft water is more corrosive than hard water. Increasing pH or reducing oxygen reduces corrosion. |

Acidic Water | Acidic water (containing sulfuric acid and ferric sulfate) accelerates corrosion, but austenitic stainless steels show high resistance. |

Salt Water | Salt water causes pitting by breaking down passive films; flow rate and design (reducing crevices) influence corrosion severity. |

Soil Conditions | Soil moisture and composition affect corrosion; austenitic stainless steels resist soil corrosion better than some martensitic grades. |

Temperature and Humidity | Higher temperature and humidity accelerate corrosion processes. |

Corrosive Gases/Chemicals | Exposure to acidic or dusty gases increases corrosion rates. |

Surface Condition | Matte surfaces are more sensitive to corrosion; surface finish and manufacturing processes impact susceptibility, especially in chloride environments. |

Mechanical and Electrochemical Factors | Mechanical damage and contact with dissimilar metals can degrade corrosion resistance by damaging protective films or causing galvanic corrosion. |

You will see that dry, ventilated, and non-corrosive gas environments help reduce corrosion. Humid, high-temperature, and dusty areas increase corrosion risk. Marine environments with high chloride ions can cause rapid damage. Chemical exposure and mechanical scratches also make your pipe more vulnerable. Localized corrosion, like pitting and crevice corrosion, often happens in areas with high chloride ions, low pH, or limited oxygen. You can improve corrosion protection by choosing a corrosion-resistant pipe material and by avoiding crevices in your system design.

The surface finish of your pipe affects both its corrosion resistance and its appearance. You can choose from several finishes, each with different properties. The table below highlights the most common finishes for 2-inch stainless steel pipes:

Finish Type | Processing Method | Surface Characteristics | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

No. 2B | Cold rolling, light skin pass | Smooth, semi-reflective, semi-bright | Good corrosion resistance; smooth surface suitable for many industrial and commercial uses | Deep drawing, cookware, kitchen equipment, pharmaceutical tools |

No. 2D | Cold rolled, annealed, pickled | Dull, matte, low reflectivity | Moderate corrosion resistance; retains lubricant for deep drawing | Pressure vessels, heat exchangers, furnaces |

No. 2BA (Bright Annealed) | Cold rolling, bright annealing in controlled atmosphere | Highly reflective, mirror-like, very smooth | Excellent corrosion resistance due to lack of oxidation and scaling | Automotive trim, appliance components, commercial refrigeration, surgical instruments |

No. 3 | Grinding with 80-100 grit abrasive | Coarse, unidirectional grain, dull | Moderate corrosion resistance; requires further finishing for enhanced protection | Food processing equipment, industrial surfaces |

No. 4 | Grinding with 150 grit abrasive | Satin finish, fine linear grain, not highly reflective | Good corrosion resistance; durable for rough handling | Restaurant equipment, architectural panels |

No. 6 | Polishing with abrasive paste on cloth mops | Non-directional satin blend texture | Good corrosion resistance; smoother than No. 4 | Architectural applications, kitchen surfaces |

No. 7 | Polishing with finer abrasives and buffing | High gloss, near mirror, some polishing lines visible | High corrosion resistance | Interior design, luxury furniture |

No. 8 | Multi-stage polishing and buffing with very fine compounds | True mirror finish, blemish free, highly reflective | Very high corrosion resistance | Luxury interiors, automotive trim, signage |

You will find that the No. 2B finish is the most common for industrial and commercial pipes. It gives you a smooth, semi-reflective surface with good corrosion resistance. The No. 2BA finish offers a mirror-like look and excellent protection, making it ideal for high-purity or decorative uses. Coarser finishes like No. 3 and No. 4 are durable and work well for equipment that faces rough handling. Finer finishes, such as No. 7 and No. 8, provide a high-gloss appearance and the best corrosion resistance. The smoother the finish, the easier it is to clean and maintain, which helps extend the durability of your pipe.

Tip: Select a finish that matches your environment and cleaning needs. Smoother finishes help prevent buildup and make cleaning easier.

If you use pipes in the food and beverage industry, you must meet strict sanitary standards. You need polished surfaces to stop bacteria from growing and to make cleaning simple. Grades 304 and 316 are the most common choices, with 316 preferred for salty or aggressive environments. You should look for pipes with a surface roughness between 0.4 and 0.8 Ra, often achieved through electrochemical polishing. This smooth surface reduces contamination risk and supports food safety.

Pipes must comply with FDA and industry certifications.

Both seamless and welded pipes are used, but seamless pipes offer higher strength for high-pressure systems.

Manufacturing steps like annealing and inside bead removal improve hygiene and mechanical properties.

Packaging uses protective poly sleeves and airtight end caps to keep pipes clean.

Pipes should meet ASTM A270 S2 and 3-A sanitary specifications.

Surface roughness should not exceed 0.5 μm (20 μ-in Ra) inside and 0.8 μm (30 μ-in Ra) outside, measured by ASME/ANSI B46.1.

Mechanical and chemical testing ensures quality and traceability.

You can trust that a corrosion-resistant pipe material with the right finish will help you meet food safety rules and keep your system clean. Always check for certifications like PED, ISO, and AEO to confirm quality. Proper corrosion protection and finish selection keep your pipe safe, clean, and long-lasting in any sanitary application.

You need to make sure your 2-inch stainless steel pipe meets strict quality standards before you use it in any project. Reliable manufacturers follow a series of checks to guarantee the quality of materials and the finished product. These checks help you avoid costly failures and ensure your pipes perform as expected.

Here are the main quality control tests performed on pipes before shipment:

Raw materials checking: Inspectors check all incoming materials to confirm they meet the required standards for chemical composition and mechanical properties.

Production quality checking: During manufacturing, workers monitor the process closely. They look for defects and remove any pipe that does not meet the standards.

Pre-shipment inspection: Before the pipes leave the factory, a final inspection takes place. Sometimes, third-party agencies like SGS or TUV, or even your own appointed inspectors, verify that each pipe meets your quality requirements.

Tip: Always ask for test reports and inspection records. These documents prove that your pipe has passed all necessary checks.

Choosing the right supplier is just as important as selecting the right pipe. A reputable supplier gives you confidence in the quality of materials and the reliability of your supply. You can use several criteria to evaluate a supplier’s reputation:

Check for certifications and compliance with standards such as ISO 9001, ASTM A312, and PED. These show the supplier values quality and reliability.

Review the supplier’s manufacturing capabilities. Look for advanced technology, the ability to customize pipe sizes, and a wide range of grades.

Examine quality assurance processes. Reliable suppliers use non-destructive testing, corrosion resistance tests, and keep records for traceability.

Read client testimonials and case studies. A long track record and positive feedback show the supplier delivers on promises.

Ask about delivery timelines and logistics support. Timely delivery keeps your project on schedule.

Compare pricing, but focus on value. Avoid suppliers with prices that seem too low, as this may signal poor quality.

Request product samples or visit the factory. Seeing the production process helps you judge the quality of materials firsthand.

Review post-sale support and warranty policies. Good suppliers stand behind their pipes and offer help if problems arise.

Consider sustainability practices. Suppliers who use eco-friendly methods and recycling show responsibility and modern standards.

Note: A strong reputation means you can trust the supplier to deliver high-quality pipe every time.

You must protect your project from counterfeit or substandard pipes. Fake or low-quality pipes can cause leaks, failures, and safety risks. You can spot many signs of counterfeit or poor-quality pipe if you know what to look for.

Look out for these warning signs:

Used or worn appearance, even though the pipe is supposed to be new

Unusual or poor packaging, such as wrapping in foreign newspapers

Scratches, dents, or other physical damage on the pipe’s surface

Evidence of tampering or hand-made repairs

Missing, inconsistent, or meaningless markings and labels

Signs of corrosion, pitting, or weld repairs

Ground off or altered casting marks and logos

Threads that show wear or have been reworked

Inconsistent or missing manufacturer’s markings, size, pressure rating, or specification numbers

Pipes that are thinner than expected

Multiple certification logos combined in strange ways

Painted stainless steel or excessive wire brushing

Identification that only lists the country, with no manufacturer details

You should always request proper documentation from your supplier. Important certifications and documents include:

ISO 9001:2015 for quality management

ASTM and ASME standards for mechanical and chemical properties

EN and PED certifications for European compliance

NACE certification for corrosion resistance

CE marking for health, safety, and environmental standards

Mill Test Reports (MTRs) that verify the pipe’s properties

Hydrostatic and non-destructive testing reports

Traceability markings on each pipe

Import/export documents for international orders

Always check the markings and paperwork before accepting any pipe. Authentic pipes come with clear, consistent labels and full documentation.

When you look at things to consider when buying pipes, cost often comes first. The price of a 2-inch stainless steel pipe depends on grade, supplier, and region. You will see big differences between budget, mid-tier, and premium brands. The table below shows typical price ranges per foot for common grades:

Grade | Budget Brands (USD/ft) | Mid-Tier Brands (USD/ft) | Premium Brands (USD/ft) |

|---|---|---|---|

304 (1" Sch40) | $3.50 - $8.00 | $5.00 - $8.00 | $8.00 - $12.00 |

316 (2" Sch80) | $7.00 - $10.00 | $10.00 - $14.00 | $14.00 - $20.00 |

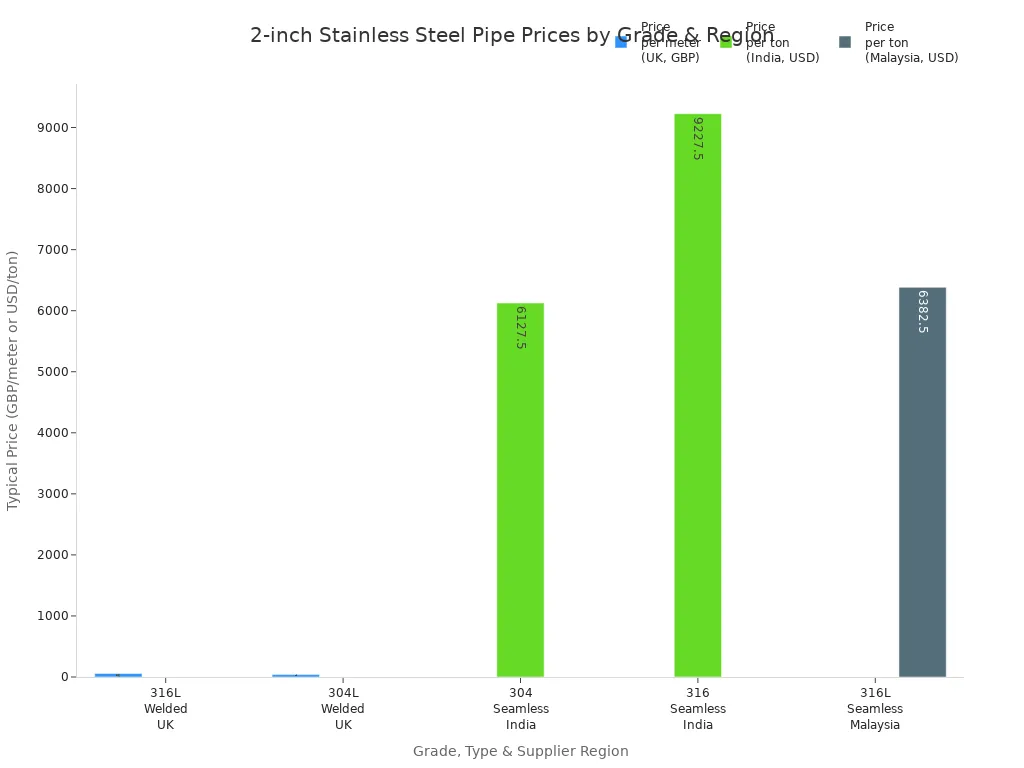

You can also compare prices by region and supplier. For example, UK suppliers list 316L welded pipe at about £56 per meter, while Indian suppliers offer 304 seamless pipe between $4,630 and $7,625 per ton. The chart below compares prices for 2-inch stainless steel pipes by grade and supplier region:

You should not focus only on the cost of the material. Stainless steel pipes have a higher upfront cost than plastic or galvanized steel, but they last much longer—up to 100 years. Over a 10-year period, you will likely spend less on repairs and replacements. This long lifespan means you get better value and lower total ownership costs, even if you pay more at the start.

Tip: Always balance initial cost with long-term value. A higher-quality pipe may save you money over time.

Welding and installation are important things to consider when buying pipes. You want a pipe that is easy to install and welds well. TIG welding works best for 2-inch stainless steel pipes, especially for thin walls. This method gives you clean, strong welds with good corrosion resistance. You should use low-carbon filler metals like 304L or 316L to prevent corrosion at the welds.

Here are some steps for a successful weld:

Clean the pipe surface and align the joints.

Use the right shielding gas, such as argon, to protect the weld.

Control heat input to avoid cracks or distortion.

After welding, treat the weld area by pickling or passivation to improve quality.

Common challenges include cracks, porosity, and distortion. You can avoid these by following best practices and using the right materials. Good welding and installation help your pipe system last longer and perform better.

The weight of your pipe affects how you install and support it. A 2-inch stainless steel pipe gets heavier as the wall thickness increases. For example, Schedule 80 pipes weigh more than Schedule 40 pipes. Heavier pipes need stronger supports and careful handling during installation. You must plan for this in your building design.

Flexibility is lower in stainless steel pipes compared to plastic, so you need to use fittings for bends and turns. Stainless steel pipes also reduce noise better than plastic pipes, which helps in buildings where quiet operation matters.

Note: Always check the weight and support needs before you buy. This ensures safe installation and long-lasting performance.

When you select a 2-inch stainless steel pipe, appearance can be just as important as strength or durability. You often see these pipes in places where people notice them, such as building entrances, stair railings, or commercial kitchens. In these settings, the look of the pipe helps define the overall style and feel of the space.

You should prioritize aesthetics in projects where the pipe is visible or serves as a design element. These include:

Architectural structures and decorative features where visual impact matters most.

Luxury interiors, such as hotels, offices, and high-end homes, where polished finishes add elegance.

Commercial kitchens and food service areas, where a clean, shiny surface signals hygiene and quality.

Medical facilities and fitness centers, where a sleek, modern look supports both function and style.

Outdoor or marine projects, where corrosion resistance keeps pipes looking good over time.

You can choose from many surface finishes and treatments to match your design goals. Each finish changes the way light reflects off the pipe and can make it stand out or blend in. The table below shows common finishes and how they affect the appearance of 2-inch stainless steel pipes:

Surface Finish / Treatment | Description | Effect on Appearance | Suitability for 2-inch Architectural Stainless Steel Pipes |

|---|---|---|---|

Polishing | Mechanical finishing that produces a mirror-like shine | Creates a highly reflective, decorative surface | Ideal for enhancing visual appeal in architectural applications |

Electroplating | Application of thin metal layers such as nickel or chrome | Adds metallic luster and improves hardness | Suitable for decorative pipes requiring enhanced aesthetics |

PVD Coating | Ultra-thin, wear-resistant physical vapor deposition layer | Provides durable, colored or metallic finishes without altering metal properties | Excellent for durable, high-performance architectural pipes |

Brushing | Mechanical finish producing a matte, textured surface | Creates a subtle, non-reflective finish | Commonly used for aesthetic matte effects in architecture |

Sandblasting | Mechanical texturing to roughen surface | Adds texture for better paint adhesion and unique appearance | Useful when painting or coating architectural pipes |

You can use mirror-polished pipes for a bold, modern look. Brushed or matte finishes give a softer, understated effect. PVD coatings let you add color or extra durability without changing the metal’s properties. Sandblasted pipes work well if you plan to paint or want a unique texture.

Tip: Always match the pipe’s finish to your project’s style and cleaning needs. Smoother finishes are easier to keep clean, while textured finishes can hide fingerprints and scratches.

When you think about things to consider when buying pipes, remember that appearance often goes hand-in-hand with function. In many projects, you need a pipe that looks good and stands up to daily use. Stainless steel gives you both. You can choose from round, square, or rectangular shapes to fit your design. Custom finishes and treatments help you create the exact look you want.

If you work on projects where both performance and appearance matter, stainless steel pipes offer the flexibility you need. You can achieve a balance between style, durability, and ease of maintenance. This makes them a top choice for architects, designers, and builders who want to make a strong visual statement.

When you buy a 2 stainless steel pipe, focus on the right grade, corrosion resistance, and strength for your project. Always check standards, pipe type, and fittings compatibility. Avoid common mistakes like choosing the wrong grade or ignoring environmental factors. Use this checklist before you decide:

Confirm the pipe type and intended use.

Check steel grade and standards.

Choose seamless or welded construction.

Verify quantity and sizing.

Match fittings for your 2 stainless steel pipe.

Make informed choices to ensure your 2 stainless steel pipe lasts and performs safely.

Schedule 40 pipes have thinner walls than Schedule 80 pipes. You get higher pressure resistance with Schedule 80. For most home or light industrial uses, Schedule 40 works well. Choose Schedule 80 for high-pressure or heavy-duty systems.

Yes, you can use 304 stainless steel pipes outdoors. They resist rust and corrosion in most environments. In coastal or salty areas, you should choose 316 stainless steel for better protection against corrosion.

You measure the outside diameter, not the inside. A 2-inch pipe has an outside diameter of about 2.375 inches. Always check the wall thickness to confirm the exact size for your project.

Seamless pipes offer higher strength and no weld seam. You should use them for high-pressure or critical systems. Welded pipes cost less and work well for general or low-pressure uses. Choose based on your project’s needs.

Look for certifications like ASTM, ASME, ISO 9001, and PED. These show the pipe meets quality and safety standards. Always ask your supplier for documentation and test reports.

You should choose the right grade for your environment. Keep the surface clean and dry. Avoid contact with harsh chemicals or dissimilar metals. Regular inspections help you spot early signs of corrosion.

Yes, you can weld stainless steel pipes if you have the right tools and skills. TIG welding works best for clean, strong joints. Use proper filler metals and shielding gas for the best results.

Surface finish affects both appearance and corrosion resistance. Smoother finishes resist bacteria and are easier to clean. For food, medical, or decorative uses, you should choose a polished or mirror finish.