close

Choose Your Site

Global

Social Media

Author: Site Editor Publish Time: 2025-07-04 Origin: Site

Hastelloy material delivers unmatched corrosion resistance in some of the world’s harshest environments. Engineers often select hastelloy because its unique blend of nickel, chromium, and molybdenum gives it an edge over other alloys. For example, hastelloy C-22 can withstand elemental sulfur at 205°C and highly saline conditions at 288°C. The table below shows how hastelloy C-22 outperforms C-276 in critical pitting and crevice corrosion temperatures, making it ideal for high corrosion resistance in corrosive environments.

| Alloy | Critical Pitting Temperature (°C) | Critical Crevice Corrosion Temperature (°C) |

|---|---|---|

| Hastelloy C-22 | > 150 | 102 |

| Hastelloy C-276 | 150 | 80 |

Hastelloy’s unique mix of nickel, chromium, and molybdenum creates a strong barrier against many types of corrosion.

The protective chromium oxide layer on Hastelloy’s surface blocks corrosive agents and prevents damage.

Hastelloy resists uniform, localized, and stress corrosion cracking better than many other alloys.

Compared to stainless steel, Inconel, Monel, and titanium, Hastelloy offers superior corrosion resistance in harsh chemical and high-temperature environments.

Different Hastelloy grades, like C-22 and C-276, provide specialized protection for various industrial needs.

Hastelloy is widely used in chemical processing, oil and gas, power generation, pharmaceuticals, and food industries due to its durability and reliability.

While Hastelloy costs more and requires careful machining, its long service life and resistance to corrosion reduce maintenance and downtime.

Ongoing innovations and sustainable manufacturing methods are improving Hastelloy’s performance and environmental impact for future applications.

Hastelloy stands out among high-performance nickel-based alloys because of its unique blend of elements. Nickel forms the base of these alloys and gives them excellent resistance to corrosion in both reducing acids and caustic solutions. Nickel also allows for higher chromium content, which increases corrosion resistance even further. Chromium in hastelloy creates a stable, passive chromium oxide layer on the surface. This layer acts as a shield, protecting the metal from corrosive agents and preventing further attack. Molybdenum plays a critical role by boosting resistance to non-oxidizing acids like hydrochloric and sulfuric acids. Together, chromium and molybdenum protect against localized corrosion, such as pitting and crevice corrosion, especially in chloride-rich environments.

The synergy between these elements is clear in the composition of popular hastelloy grades. For example, hastelloy C-22 contains about 22% chromium, 56% nickel, and 13% molybdenum. Hastelloy C-276 has around 16% chromium, 57% nickel, and 16% molybdenum. This combination results in superior corrosion resistance, even in harsh chemical environments. Scientific studies show that the crevice pitting resistance of hastelloy increases with higher molybdenum content. Molybdenum helps control corrosion propagation, especially when exposed to aggressive chloride solutions. This makes hastelloy a top choice for industries that demand high corrosion resistance.

The protective oxide layer is a key reason why hastelloy offers excellent resistance to corrosion. When chromium in the alloy reacts with oxygen, it forms a thin but stable chromium oxide (Cr2O3) film on the surface. This layer acts as a barrier, blocking corrosive agents from reaching the underlying metal. Experimental studies on hastelloy C-22 show that pre-oxidation treatment can greatly enhance corrosion resistance. In one study, samples exposed to molten alkali salts at 700°C for 100 hours developed a strong oxide layer. The pre-oxidized samples showed delayed penetration by corrosive agents compared to untreated ones. This result highlights the importance of the oxide layer in reducing corrosion damage and improving oxidation resistance.

Note: The stability and solubility of chromium oxide play a major role in the protective performance of hastelloy. The oxide layer not only resists uniform corrosion but also helps prevent localized attacks in aggressive environments.

Hastelloy provides protection against several types of corrosion, making it a highly resistant corrosion-resistant alloy. The main types include:

Uniform Corrosion: This occurs evenly across the surface. Hastelloy’s alloy composition ensures low corrosion rates, even in strong acids.

Localized Corrosion: This includes pitting and crevice corrosion, which can cause rapid failure in small areas. The high molybdenum and chromium content in hastelloy gives it superior resistance to these forms, especially in chloride-rich environments.

Stress Corrosion Cracking: This type happens when tensile stress and corrosive agents act together. Nickel in hastelloy provides increased corrosion resistance to stress corrosion cracking, making it reliable for critical applications.

The table below compares the performance of hastelloy and other alloys in hydrochloric acid environments:

| Alloy | Molybdenum Content (%) | Corrosion Rate in HCl (mm/y) | Preferred Use Case |

|---|---|---|---|

| Inconel 625 | ~9 | Higher at high HCl/Temp | Moderate acid, lower temperature |

| Hastelloy C-276 | ~16 | Lower, even at high HCl/Temp | Aggressive acid, high temperature/pressure |

Hastelloy C-276 shows excellent resistance to localized corrosion due to its higher molybdenum and tungsten content. Field data confirm that hastelloy outperforms other alloys in severe environments, making it the preferred choice for components exposed to aggressive corrosive agents. Case studies also show that the Mo/Cr ratio and the presence of secondary phases can influence corrosion behavior. For example, hastelloy X, with a lower Mo/Cr ratio, experienced more severe localized corrosion and chromium depletion when exposed to molten salts. This highlights the importance of alloy composition and microstructure in achieving high corrosion resistance.

Stainless steel is one of the most common corrosion-resistant alloys used in industry. It contains iron, chromium, and sometimes nickel. The chromium in stainless steel forms a thin oxide layer that protects the metal from rust and corrosion. However, this protection has limits in aggressive environments. Stainless steel often struggles in highly acidic or chloride-rich settings, where pitting and crevice corrosion can occur quickly.

Hastelloy material offers better corrosion resistance than stainless steel, especially in harsh chemical and high-temperature conditions. While stainless steel relies mainly on chromium for its protective layer, hastelloy uses a combination of nickel, chromium, and molybdenum. This blend gives hastelloy superior resistance to acids, saltwater, and strong chemicals. In many industrial tests, hastelloy outperforms stainless steel in both uniform and localized corrosion.

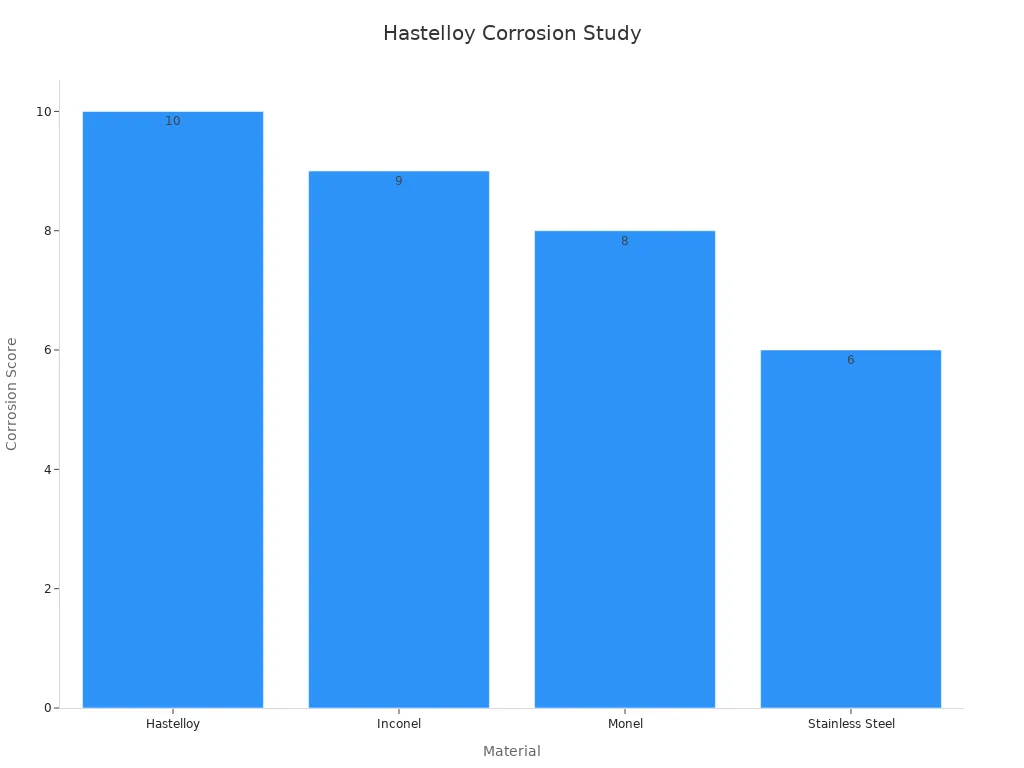

The following table shows the corrosion resistance scores for several common alloys:

| Material | Corrosion Resistance Score |

|---|---|

| Hastelloy | 10 |

| Inconel | 9 |

| Monel | 8 |

| Stainless Steel | 6 |

Stainless steel works well for general use, but industries facing aggressive environments often choose hastelloy for its higher corrosion resistance and longer service life.

Inconel is another nickel-based alloy known for its strength and resistance to oxidation at high temperatures. Like hastelloy, inconel contains nickel and chromium, but it usually has less molybdenum. This difference affects its performance in certain corrosive environments.

Hastelloy provides stronger resistance to acids and chloride-induced corrosion than inconel. Inconel performs well in oxidizing environments and maintains its strength at high temperatures, but it can be more vulnerable to pitting and crevice corrosion in the presence of chlorides. Hastelloy’s higher molybdenum content helps prevent these problems, making it a better choice for chemical processing and other industries that deal with aggressive chemicals.

The chart below compares the corrosion resistance of hastelloy, inconel, monel, and stainless steel:

Hastelloy also maintains its mechanical strength at high temperatures. For example, hastelloy C-22 can operate safely up to 815°C (1,500°F), while hastelloy C-276 can reach 1037°C. Both alloys keep their yield and tensile strengths even in aggressive environments, which is important for equipment exposed to both heat and corrosive chemicals.

Monel is a nickel-copper alloy valued for its resistance to seawater and some acids. It performs well in marine environments and resists corrosion from saltwater better than many other alloys. However, monel does not match hastelloy’s performance in highly acidic or high-temperature settings.

Hastelloy’s combination of nickel, chromium, and molybdenum gives it a broader range of corrosion resistance. Monel works best in neutral or mildly acidic environments, but it can suffer from rapid corrosion in strong acids or oxidizing agents. In contrast, hastelloy resists both reducing and oxidizing acids, making it suitable for chemical plants, refineries, and other facilities that face aggressive environments.

The following points highlight the differences:

Monel resists corrosion in seawater and mild acids.

Hastelloy withstands strong acids, high temperatures, and aggressive chemicals.

Industries choose hastelloy when they need a corrosion-resistant alloy for the harshest conditions.

In summary, while stainless steel, inconel, and monel each have their strengths, hastelloy stands out for its better corrosion resistance and high temperature resistance in the most demanding applications.

Titanium stands out as a lightweight metal with impressive corrosion resistance. Many industries use titanium because it forms a strong, stable oxide layer on its surface. This layer protects the metal from many corrosive agents, including seawater, chlorine, and some acids. Titanium’s resistance to corrosion makes it popular in aerospace, marine, and medical applications.

Titanium alloys show excellent performance in environments with saltwater and oxidizing acids. They resist pitting and crevice corrosion better than most stainless steels. However, titanium can suffer from corrosion in reducing acids, such as hydrochloric acid, especially at high temperatures. In these situations, hastelloy material often performs better.

Hastelloy and titanium both offer high resistance to corrosion, but they excel in different environments. Titanium works best in oxidizing conditions and where weight matters. Hastelloy provides broader protection, especially in aggressive environments with strong acids and high temperatures.

Note: Titanium’s lightweight nature gives it an advantage in applications where reducing weight is critical. However, hastelloy’s superior resistance to a wider range of chemicals makes it the preferred choice for chemical processing and oil and gas industries.

The table below compares key properties of titanium and hastelloy:

| Property | Titanium | Hastelloy |

|---|---|---|

| Density (g/cm³) | 4.5 | 8.7 |

| Corrosion Resistance | Excellent (oxidizing) | Excellent (broad range) |

| Strength at High Temp | Good | Excellent |

| Weight | Low | Moderate |

| Cost | High | High |

Engineers often compare several alloys before choosing the right material for aggressive environments. Each alloy has strengths and weaknesses in terms of corrosion resistance, mechanical strength, and cost.

Key points of comparison:

Corrosion Resistance:

Hastelloy offers the best overall resistance, especially in strong acids and high temperatures.

Titanium resists corrosion well in oxidizing environments but struggles with reducing acids.

Inconel performs well at high temperatures but is less resistant to chlorides.

Monel excels in seawater but not in strong acids.

Stainless steel provides basic protection but fails in aggressive chemical settings.

Mechanical Strength:

Hastelloy maintains strength at high temperatures and under stress.

Titanium is strong and lightweight but loses strength above 600°C.

Inconel keeps its strength at very high temperatures.

Stainless steel and monel have moderate strength.

Performance in Aggressive Environments:

Hastelloy material remains stable in the harshest chemical and thermal conditions.

Titanium is ideal for marine and aerospace uses where weight and oxidizing corrosion are concerns.

Inconel suits high-temperature, less corrosive settings.

Monel is best for marine applications.

The following table summarizes the comparison:

| Alloy | Corrosion Resistance | Mechanical Strength | High Temp Performance | Typical Use Case |

|---|---|---|---|---|

| Hastelloy | Excellent | Excellent | Excellent | Chemical processing, oil & gas |

| Titanium | Excellent (oxidizing) | Good | Good | Aerospace, marine, medical |

| Inconel | Very Good | Excellent | Excellent | Power generation, aerospace |

| Monel | Good (seawater) | Good | Moderate | Marine, chemical |

| Stainless Steel | Moderate | Good | Moderate | General industry, food |

Engineers should match the alloy to the specific environment. Hastelloy provides the most reliable solution for aggressive environments with strong acids and high temperatures.

Hastelloy c-276 stands out as one of the most versatile corrosion-resistant alloys. Engineers often choose this grade for its ability to handle both oxidizing and reducing environments. The alloy contains high levels of nickel, chromium, and molybdenum. These elements work together to protect against pitting, crevice corrosion, and stress corrosion cracking. Many chemical processing plants use hastelloy c-276 in reactors, heat exchangers, and piping systems. The alloy performs well in harsh acids like hydrochloric and sulfuric acid. It also resists corrosion in wet chlorine gas and strong chloride solutions.

A key advantage of hastelloy c-276 is its resistance to the formation of grain boundary precipitates. This property allows the alloy to maintain its corrosion resistance even after welding. Fabricators can weld components without worrying about loss of protection at the joints. The alloy also keeps its strength at high temperatures, making it suitable for demanding industrial applications.

Tip: When selecting materials for equipment exposed to aggressive chemicals, hastelloy c-276 offers a reliable solution with proven performance in the field.

Hastelloy c-22 provides even greater resistance to corrosion than many other grades. This alloy contains more chromium than hastelloy c-276, which helps it form a stronger protective oxide layer. The increased chromium content gives hastelloy c-22 excellent resistance to both oxidizing and reducing acids. It also protects against pitting, crevice corrosion, and stress corrosion cracking in chloride-rich environments.

Many industries use hastelloy c-22 in applications where maximum corrosion resistance is critical. These include chemical reactors, scrubbers, and waste treatment systems. The alloy performs well in mixed acid environments and resists attack from ferric and cupric chlorides. Engineers often select hastelloy c-22 when they need a material that can handle unpredictable or changing chemical conditions.

The table below compares the main alloying elements in hastelloy c-276 and hastelloy c-22:

| Alloy | Nickel (%) | Chromium (%) | Molybdenum (%) | Iron (%) |

|---|---|---|---|---|

| Hastelloy C-276 | 57 | 16 | 16 | 5 |

| Hastelloy C-22 | 56 | 22 | 13 | 3 |

Hastelloy B-2 and B-3 belong to a family of nickel-molybdenum alloys. These grades excel in environments with strong reducing acids, such as hydrochloric acid. Hastelloy B-2 offers excellent resistance to pure hydrochloric, hydrobromic, and sulfuric acids. The alloy resists pitting and stress corrosion cracking, especially in non-oxidizing conditions. However, it does not perform as well in oxidizing environments.

Hastelloy B-3 improves on B-2 by offering better thermal stability and resistance to knife-line and heat-affected zone attack. This makes B-3 a good choice for processes that involve frequent temperature changes. Both B-2 and B-3 find use in chemical processing, pickling operations, and pharmaceutical manufacturing. They provide reliable protection where other alloys might fail.

Note: When choosing between hastelloy grades, engineers should match the alloy to the specific chemicals and temperatures in their process.

Engineers often need materials that can handle very specific challenges. Specialty grades of hastelloy meet these needs. These alloys have unique compositions that target certain types of corrosion or extreme environments. Manufacturers design these grades for industries like aerospace, nuclear power, and pollution control.

Some specialty grades include:

Hastelloy G-30: This grade resists phosphoric acid and strong oxidizing acids. It contains high chromium and added copper. Chemical plants use it for fertilizer production and acid manufacturing.

Hastelloy X: This alloy works well at high temperatures. It resists oxidation and maintains strength up to 1200°C (2190°F). Gas turbine engines and furnace parts often use hastelloy X.

Hastelloy C-2000: This grade combines high chromium with added copper. It offers broad resistance to both oxidizing and reducing acids. It also protects against pitting and crevice corrosion. Many chemical processing plants choose this alloy for its versatility.

Hastelloy G-35: This alloy was developed for strong resistance to wet process phosphoric acid. It also performs well in other aggressive acids. Fertilizer and chemical industries rely on hastelloy G-35 for critical equipment.

Note: Specialty grades often cost more than standard grades. However, they can save money in the long run by reducing equipment failure and downtime.

The table below highlights some specialty grades and their main features:

| Grade | Key Elements | Main Strengths | Typical Use Case |

|---|---|---|---|

| G-30 | High Cr, Cu | Phosphoric acid resistance | Fertilizer, acid production |

| X | High Ni, Cr, Fe | High temp strength, oxidation | Gas turbines, furnaces |

| C-2000 | Cr, Mo, Cu | Broad acid resistance, pitting | Chemical processing |

| G-35 | High Cr, Mo | Wet phosphoric acid, other acids | Fertilizer, chemical industry |

Specialty grades of hastelloy help solve problems that standard alloys cannot. They protect equipment in environments where failure could be dangerous or costly. Engineers should review the chemical and temperature conditions before choosing a grade. Specialty grades offer targeted solutions for unique industrial challenges.

Chemical processing plants face some of the harshest corrosive environments in industry. Many processes use strong acid solutions, such as hydrochloric acid and sulfuric acid, which can quickly damage ordinary metals. Engineers often select hastelloy alloys like C-22 and B-3 for these settings. These alloys resist both oxidizing and reducing acids, even at high temperatures. For example, hastelloy C-22 contains extra chromium, molybdenum, and tungsten. This blend protects reactors and piping from aggressive chemical environments, including those with chlorides and mixed acids.

Hastelloy B-3 stands out for its unique ability to resist hydrochloric acid at any concentration or temperature. This property allows equipment to maintain structural integrity during high heat and exposure to corrosive agents. As a result, plants experience fewer shutdowns and lower maintenance costs. Reliable operation of piping systems and reactors ensures consistent production and safety.

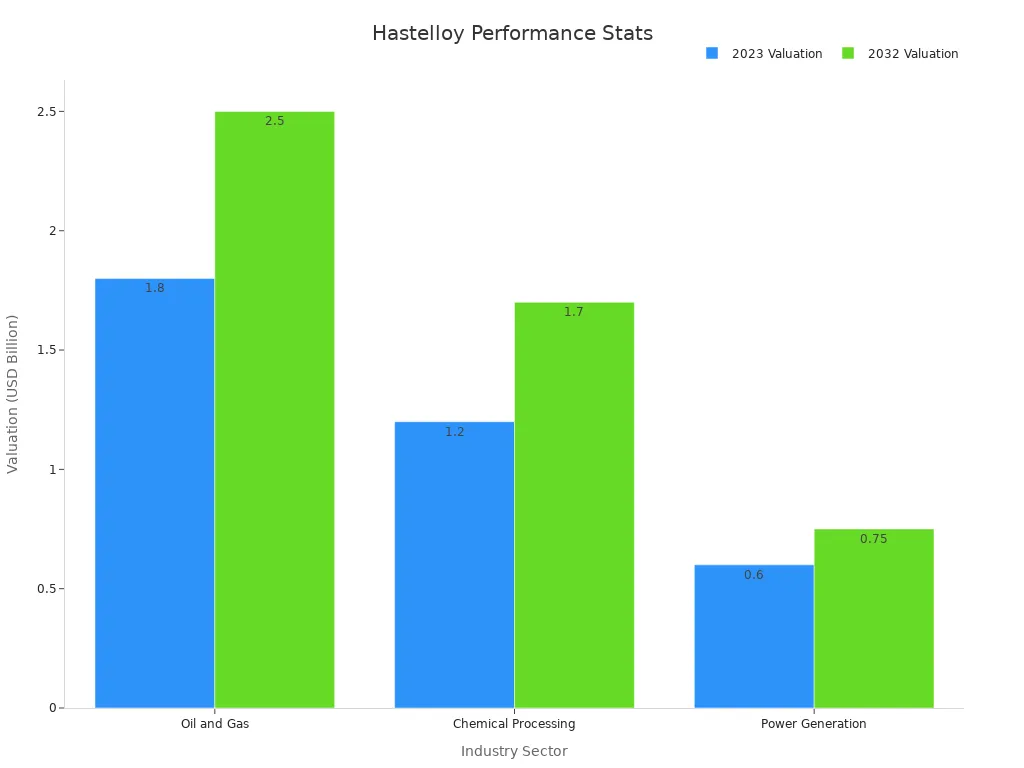

| Industry Sector | Market Valuation 2023 (USD Billion) | Projected Valuation 2032 (USD Billion) | Key Performance Attributes Supporting Hastelloy Use |

|---|---|---|---|

| Chemical Processing | 1.2 | 1.7 | Resistance to harsh chemicals, corrosion resistance |

The oil and gas sector demands materials that can withstand extreme conditions. Wells and refineries often encounter acid gases, high pressures, and temperatures. Corrosive environments with hydrochloric acid and sulfuric acid are common, especially during acidizing treatments and refining. Hastelloy alloys provide the durability needed for these challenges. Their resistance to acid attack and stress corrosion cracking makes them ideal for piping, valves, and downhole tools.

Hastelloy C-22 and C-276 maintain performance in aggressive chemical environments, even when exposed to high concentrations of hydrochloric acid. This reliability reduces the risk of leaks and failures in critical systems. The market for hastelloy in oil and gas continues to grow as companies seek longer-lasting solutions.

| Industry Sector | Market Valuation 2023 (USD Billion) | Projected Valuation 2032 (USD Billion) | Key Performance Attributes Supporting Hastelloy Use |

|---|---|---|---|

| Oil and Gas | 1.8 | 2.5 | Durability in extreme conditions, corrosion resistance |

Power generation facilities, such as nuclear and fossil fuel plants, operate under high temperatures and corrosive environments. Boilers, turbines, and heat exchangers often face acid exposure, especially from sulfuric acid and hydrochloric acid. Hastelloy alloys deliver high-temperature strength and corrosion resistance, making them suitable for these demanding systems.

A case study of hastelloy C-276 welded to stainless steel 316L shows strong mechanical properties. The joint region reached a tensile strength of 425 MPa and an elongation of 14%. Microhardness measured 290 HV, and the weld zone contained Fe-Ni intermetallic phases and carbides of molybdenum, chromium, and tungsten. These features help maintain the integrity of piping systems and critical components in power plants.

| Parameter | Value | Description/Context |

|---|---|---|

| Electric Field Intensity | 5.86 × 10^4 V/m | Concentrated electric field at the joint region during microwave hybrid heating |

| Resistive Losses | 3.07 × 10^7 W/m³ | Heat generation facilitating rapid local heating at the joint |

| Microhardness | 290 HV | Average hardness of the welded joint region |

| Tensile Strength | 425 ± 10 MPa | Mechanical strength of the Hastelloy C-276 and SS-316L joint |

| Elongation | 14% | Ductility measure of the welded joint |

| Microstructural Features | Fe-Ni intermetallic phases, Mo, Cr, W-carbides | Observed grain boundary phases contributing to joint properties |

Power plants benefit from the longevity and reliability of hastelloy. These alloys help reduce downtime and ensure safe, efficient operation in systems exposed to acid and other corrosive agents.

Pharmaceutical and food industries require materials that can handle very harsh and corrosive environments. Many cleaning and sterilization processes use strong acid solutions. These processes often involve hydrochloric acid and sulfuric acid. Equipment must resist attack from these chemicals to keep products safe and pure.

Pharmaceutical plants use acids to clean reactors, tanks, and piping. Hydrochloric acid removes mineral deposits and organic residues. Sulfuric acid helps break down tough contaminants. Both acids can damage ordinary metals. Corrosion can lead to leaks or contamination. Engineers select materials that can resist these acids and keep systems running safely.

Food processing also uses acids for cleaning and processing. Hydrochloric acid helps remove scale and bacteria from surfaces. Sulfuric acid can treat water or adjust pH levels. Acid exposure happens in piping systems, tanks, and valves. These areas must stay free from corrosion to protect food quality.

A table below shows common acids used in these industries and their main uses:

| Acid | Main Use in Industry |

|---|---|

| Hydrochloric acid | Cleaning, scale removal |

| Sulfuric acid | Water treatment, pH control |

| Nitric acid | Sterilization, passivation |

| Acetic acid | Food preservation, flavoring |

Note: Corrosive environments in pharmaceutical and food plants demand careful material selection. Acid-resistant alloys help prevent failures and protect public health.

Engineers often choose special alloys for piping and equipment in these industries. These alloys resist attack from hydrochloric acid and sulfuric acid. They keep piping systems safe and extend equipment life. Stainless steel works for mild acid exposure, but stronger acids need better protection. Some plants use nickel-based alloys for the most aggressive acids.

Corrosion can cause big problems in pharmaceutical and food production. Acid leaks can stop production and cause safety risks. Regular inspection and maintenance help spot early signs of corrosion. Many companies use sensors to monitor acid levels and detect leaks.

Key benefits of using acid-resistant materials in these industries include:

Longer equipment life in corrosive environments

Fewer leaks and less contamination

Safer products for consumers

Lower maintenance costs

Engineers must match the material to the acid and the process. Hydrochloric acid and sulfuric acid each attack metals in different ways. The right choice keeps systems safe and reliable.

Hastelloy alloys offer several important benefits for industries that need reliable corrosion resistance. These materials perform well in environments where acids, chlorides, and high temperatures can quickly damage ordinary metals. The unique blend of nickel, chromium, and molybdenum in hastelloy creates a strong barrier against many types of corrosion. This makes hastelloy a top choice for chemical processing, oil and gas, and power generation.

Key benefits include:

High-temperature stability: Hastelloy maintains its strength and oxidation resistance at temperatures up to 2200°F (1200°C) or even higher in some grades. This allows equipment to operate safely in extreme heat.

Protection against multiple corrosion types: The alloy resists pitting, crevice corrosion, and stress corrosion cracking. These forms of attack can cause sudden failure in other metals.

Versatility: Different grades of hastelloy provide specialized resistance profiles. For example, C-276 and C-22 handle both oxidizing and reducing acids, while B-3 excels in strong hydrochloric acid.

Long service life: Equipment made from hastelloy often lasts longer, reducing downtime and maintenance costs.

Note: The high nickel and molybdenum content in hastelloy forms a protective barrier that blocks corrosive agents, even in aggressive chemical environments.

The table below highlights important performance metrics:

| Metric / Property | Numerical Value / Description | Relevance to Corrosion Resistance and Limitations |

|---|---|---|

| Maximum Temperature Tolerance | Up to ~2200°F (1200°C) to 2470°F (1355°C) | High-temperature stability enhances corrosion resistance in extreme environments |

| Key Alloying Elements | High Nickel, Molybdenum, Chromium content | These elements form protective barriers against pitting, crevice corrosion, and stress corrosion cracking |

While hastelloy provides excellent resistance, it does have some drawbacks. These limitations can affect material selection for certain projects.

Hastelloy costs much more than common alloys like stainless steel or monel. The price comes from the high content of nickel, molybdenum, and chromium, as well as the complex manufacturing process. Many companies use hastelloy only when other materials cannot provide enough corrosion resistance. The higher cost limits its use to specialized applications where failure would be very expensive or dangerous.

| Metric / Property | Numerical Value / Description | Relevance to Corrosion Resistance and Limitations |

|---|---|---|

| Cost | Significantly higher than stainless steel or Monel | Limits use to specialized applications due to expense |

Machining hastelloy presents challenges. The alloy’s toughness and work-hardening properties require specialized cutting tools and slower speeds. This can cause rapid tool wear and increase fabrication time. Stress corrosion cracking may occur if the material experiences high stress during machining or welding. Fabricators must use careful techniques to avoid premature failure.

Specialized tools and slower speeds needed

Increased tool wear and higher production costs

Careful processing required to prevent stress corrosion cracking

Tip: Engineers should plan for extra time and cost when fabricating hastelloy components.

Some environments also restrict the use of hastelloy. The alloy is incompatible with lead and zinc, which limits its use in systems containing these materials.

Researchers continue to push the boundaries of corrosion-resistant materials. Recent advancements in processing technology have improved both manufacturing efficiency and product quality. Enhanced casting methods and additive manufacturing now allow for more precise and complex shapes. These methods also reduce waste and support custom designs for demanding industries.

New products, such as Hastelloy X, feature improved compositions and heat treatments. These changes help the material perform better in extreme environments, especially at temperatures up to 1200°C. Strategic partnerships between manufacturers and aerospace companies have led to faster innovation and wider market reach. Many companies now invest in research and development to create new processing techniques and advanced coatings. These include nanocoatings and smart coatings that boost durability and corrosion resistance. Digital tools and Industry 4.0 technologies enable real-time monitoring and predictive maintenance, making corrosion management more efficient.

Note: The market for corrosion-resistant materials is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2025 to 2033, reaching a projected value of $4.5 billion by 2033.

Corrosion-resistant materials find new uses as industries evolve. The aerospace sector demands lightweight, high-strength components that can withstand harsh conditions. Energy companies use these materials in boilers, heat exchangers, and pipelines exposed to aggressive chemicals. The pharmaceutical industry relies on clean, corrosion-resistant equipment to ensure product safety.

A growing number of applications benefit from advanced manufacturing processes. Additive manufacturing, also known as 3D printing, allows for the creation of complex parts with improved corrosion resistance. This technology supports the production of custom components for medical devices, power generation, and oil and gas systems. The Asia Pacific region leads in market growth due to rapid industrialization and infrastructure development.

| Industry | Key Application | Benefit |

|---|---|---|

| Aerospace | Engine parts, exhaust systems | High strength, heat resistance |

| Oil & Gas | Downhole tools, pipelines | Corrosion resistance |

| Power Generation | Boilers, heat exchangers | Durability at high temperatures |

| Pharmaceutical | Reactors, piping | Clean, safe processing |

Sustainability shapes the future of corrosion-resistant materials. Manufacturers focus on eco-friendly operations, recycling, and the use of sustainable resources. Additive manufacturing reduces waste by building parts layer by layer, using only the material needed. This process also lowers energy consumption and carbon emissions.

Technological advancements in protective coatings further extend the life of equipment, reducing the need for replacements. Companies measure sustainability using indicators such as energy use, cutting forces, and carbon emissions. For example, minimum quantity lubrication (MQL) during machining can lower energy use and emissions by up to 27%. These improvements help industries meet environmental regulations and reduce their impact on the planet.

Tip: Companies that invest in sustainable manufacturing and innovative technologies will lead the way in the next generation of corrosion-resistant solutions.

Hastelloy material stands out as a top performer in harsh industrial settings. Its unique blend of nickel, molybdenum, and chromium gives it unmatched resistance to corrosion, even where stainless steel and other alloys fail. Case studies show that hastelloy maintains strength and stability in chemical plants and power generation. While higher costs and fabrication challenges exist, the long-term reliability and ongoing innovations make it a smart choice for critical equipment in aggressive environments.

Hastelloy contains more nickel and molybdenum than stainless steel. This blend gives Hastelloy better resistance to strong acids and high temperatures. Stainless steel works well for mild environments, but Hastelloy protects equipment in much harsher conditions.

Engineers can weld most Hastelloy grades with standard techniques. The alloy resists grain boundary precipitation, so welded joints keep their corrosion resistance. Proper welding methods help prevent cracking and maintain strength.

Industries use Hastelloy in chemical processing, oil and gas, power generation, and pharmaceuticals. The alloy protects reactors, piping, valves, and heat exchangers from aggressive chemicals and high heat.

Yes. Hastelloy resists corrosion from cleaning acids and sterilization chemicals. This property helps keep food and medicine safe from contamination. Many plants choose Hastelloy for critical equipment.

Hastelloy maintains its strength and corrosion resistance at temperatures up to 1200°C (2200°F). This feature makes it ideal for power plants, refineries, and other high-heat environments.

Hastelloy needs less maintenance than many other alloys. Its strong resistance to corrosion means equipment lasts longer and needs fewer repairs. Regular inspection still helps ensure safety and performance.

Hastelloy costs more than common alloys. Machining and fabrication can be challenging because of its toughness. Engineers often use Hastelloy only when other materials cannot provide enough protection.

Yes. Hastelloy resists many acids, such as hydrochloric and sulfuric acid, and also stands up to caustic solutions. This versatility makes it useful in a wide range of industrial processes.

China Petrochemical Equipment Procurement Summit & Exhibition-CSSOPE 2025

Top 10 Most Common Austenitic Stainless Steel Grades And Their Everyday Uses

Exploring The Benefits And Applications of Austenitic Stainless Steel

How To Choose The Right Austenitic Stainless Steel Bar Grade for Industrial Use

Austenitic Stainless Steel Alloys Pros And Cons Explained Simply

Top 7 Ways Stainless Steel Tubing Is Used in Modern Industry